Power Requirement and Cost Analysis of Electric Bus using Simulation Method with RCAVe-EV1 Software and GPS Data; A Case Study of Greater Jakarta

Corresponding email: ghany.heryana81@ui.ac.id

Published at : 07 Oct 2022

Volume : IJtech

Vol 13, No 4 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i4.5688

Budiono, H.D.S., Heryana, G., Adhitya, M., Sumarsono, D.A., Nazaruddin, Siregar, R., Rijanto, E., Aprianto, B.D., 2022. Power Requirement and Cost Analysis of Electric Bus using Simulation Method with RCAVe-EV1 Software and GPS Data; A Case Study of Greater Jakarta. International Journal of Technology. Volume 13(4), pp. 793-802

| Hendri D S Budiono | Research Center for Advanced Vehicles (RCAVe), Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Jawa Barat 16424, Indonesia |

| Ghany Heryana | 1. Research Center for Advanced Vehicles (RCAVe), Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Jawa Barat 16424, Indonesia 2. Mechanical Engineering Department, Sekolah Tinggi Tekn |

| Mohammad Adhitya | Research Center for Advanced Vehicles (RCAVe), Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Jawa Barat 16424, Indonesia |

| Danardono Agus Sumarsono | Research Center for Advanced Vehicles (RCAVe), Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Jawa Barat 16424, Indonesia |

| Nazaruddin | Research Center for Advanced Vehicles (RCAVe), Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Jawa Barat 16424, Indonesia |

| Rolan Siregar | 3Research Center for Smart Mechatronics, National Reseacrh and Innovation Agency, Bandung, Jawa Barat, Indonesia |

| Estiko Rijanto | Research Center for Smart Mechatronics, National Reseacrh and Innovation Agency, Bandung, Jawa Barat, Indonesia |

| Bayu D Aprianto | Research Center for Advanced Vehicles (RCAVe), Faculty of Engineering, Universitas Indonesia, Kampus UI Depok, Jawa Barat 16424, Indonesia |

Electric

vehicles’ power requirement and cost analysis require consideration in terms of

their usage load and mileage. It is due to the

unique character of the charging energy compared to internal combustion

vehicles. The motor capacity and mileage will affect the vehicle's weight,

especially the battery. If the battery is excessively big, it will affect

passenger space. In comparison, buses with diesel engines are generally

designed for long distances and rough roads. If used in the city, with

relatively gentle road types, the engine will tend to be over-specification.

This research aims to design the bus power requirements according to road

conditions. The method is theoretical and simulated with specific GPS data. In

this case, the bus power is designed for the city's needs, with a case study of

battery electric buses (BEBs) for the route of the city of Jakarta and its

surroundings, namely Bogor, Depok, Tangerang, and Bekasi. In addition, an

economic study will also be a part of this research. Bus companies need this

study to decide on the procurement and use of an electric bus fleet. The

simulation results show that the power and battery capacity of inner-city buses

need not be as large as inter-city buses. A bus with a motor power rating of

100 kW and batteries with a total of 200 kWh is very appropriate to carry 85

passengers over a distance of 200 km on one charge. Moreover, with proper

incentives from the government, the price of electric inner-city buses is very

competitive. It has the advantage of having a service life of more than ten

years.

BEBs; Cost analysis; Electric bus fleet; EV; Power requirement

Because

decision-makers depend on the findings, bus fleet design is fascinating for

researchers. Inner buses have become one of the targets to be used as electric

buses because the population in the city is expected to replace many private

vehicles. Inner buses can achieve the target of clean air in the city and town

to become comfortable to live in or become a place for healthy activities (Adheesh et al., 2016). However, the transition

from the diesel bus era to the electric bus was not free from problems. It has

been discussed and described in research conducted in Italy (Pelletier et al., 2019).

The

discussion of this bus design is generally to overcome the time required for

charging the battery. The fast-charging strategy is one option, but a short

stop time is not enough for the fast charger to charge the battery adequately.

Other strategies, such as swapping, are also possible alternatives, although

later infrastructure will be needed, especially for buses' battery withdrawal

mechanism and installation. In the end of it is the costs of charging station

infrastructure. The

results suggest:

·

The service frequency, circulation

length, and operating speed of a transit system;

·

Charging lanes enabled by currently

available inductive wireless charging technology;

·

Swapping stations;

·

Charging stations are cost-competitive

only for transit systems with shallow service frequency and short circulation;

and

·

Reduce their unit-length construction

cost or enhance their charging power (Chen et al., 2018).

Fast charging

is a good solution, but it requires charging station infrastructure and good

battery life (Ding et al., 2015). The wireless charging

method has also been developed to reduce the plug-in and plug-out time of the

charger cable. This induction charging requires environmental conditions and

the precision of the bus position when at the bus stop or charging station (Bi et al., 2015). Uncertainty in demand

and bus utility must be addressed. It is much more complex than handling buses

with diesel engines, where these buses do not have much problem with the

distance and the presence of a gas station. However, bus lanes must be appropriately

designed on electric buses, and drivers must be disciplined to pass through

predetermined routes. Otherwise, the risk of running out of energy and not

finding a charging station and a long queue of charging stations will be a big

problem (Teoh et al., 2018). Again, the battery must

be considered in the design of the charging station infrastructure. The deployment of charging

infrastructures and the number of standby buses available significantly affect

the operational efficiency of electric bus systems. This work has developed a

stochastic integer program to jointly optimize charging station locations and

bus fleet size under random bus charging demand, considering time-of-use

electricity tariffs (An, 2020).

The mileage concern was also overcome by the design of the

hybrid bus. Thus, there are two types of propulsion on the bus. It is not much

different from creating a small hybrid vehicle or sedan. With this design, the

mileage becomes more flexible. However, the targets for obtaining energy and a

cleaner environment have not been achieved. Thus, the hybrid bus is not the

best solution in this case. This research was

carried out at the beginning of the era of electric vehicles being

touted (Xiong et al., 2009). For particular needs,

hybrid buses may be needed. Therefore, research on this matter also remains

strategic. Optimizing energy use on hybrid buses is done by creating a dynamic

power management program (Peng et al., 2017).

Research with a case study in Penghu seeks to reduce the

construction costs of plug-in electric buses. In this study, extensive analysis

has been done on every facet of expenses deemed significant. Vehicle scheduling

and vehicle route planning are options for solving cost problems. The optimized parameters involved the

hourly residual battery capacity and battery charging times during the daytime

operating hours. The results showed that although daytime charging involved

electricity uses during peak hours and thus incurred additional costs, it

contributed to the use of e-buses and an overall reduction in construction

costs.

In

summary, the proposed optimization method would successfully reduce the

construction cost of the Penghu e-bus transportation system (Ke et

al., 2016). The studies mentioned above were

conducted when buses were already available. The results of these studies are

needed to complete the bus design to be made.

In this

study, a bus will be planned according to the route taken, namely the inner

city of Jakarta. The data or conclusions from this research are expected to be

the basis for making an appropriate electric bus. In general, on electric

buses, the powers for power steering and compressed air are generated from a

separate electric motor. These powers are obtained from the crankshaft rotation

on buses with diesel engines. Research to electrify bus brakes is also carried

out to simplify control and reduce losses (Budiono

et al., 2020; Nugraha et al., 2021; Nazaruddin et al., 2020). The type and number of transmission

acceleration levels are also necessary because, without a gearbox, the power

and torque losses will be very significant (Rahman

et al., 2022). Meanwhile, small electric car

planning with the help of GPS and software is carried out to minimize trial and

error in determining the main motor and the number of batteries (Sumarsono

et al., 2021).

The

challenge of this research are:

·

The low population of electric buses in

Jakarta or Indonesia. So, data collection requires a unique strategy;

·

the absence of regulations regarding

electric buses makes the problem boundaries must be processed so that they are

not too broad;

·

the procurement of buses must be based on

planning according to the needs and conditions in the field.

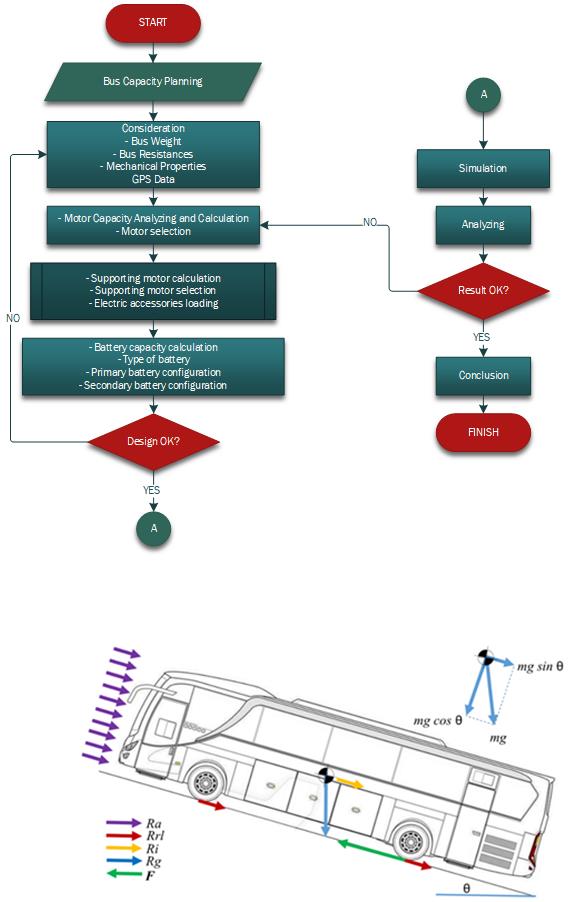

With

this fact, this research offers a solution for designing motor and battery

power needs with a combination strategy of theoretical examination and

simulation with GPS data and mechanical properties. The target is to develop a

bus that fits the needs of the route with a little trial and error. It also

proves the usefulness and importance of the RCAVe-EV1 software designed by the

University of Indonesia.

Strava

GPS data, RCAVe-EV1 software, and additional data from the interviews were

beneficial and provided data and conclusions about the required electric bus

specifications. Motor and battery power capacity is adjusted to the needs and

bus routes. The power and torque can be minor for the inner bus with a

relatively low speed. Besides, the battery capacity does not need to be too

large with the correct charging strategy. It is so that the space for passengers

remains wide. The use of design software and route data taken with GPS greatly

helps the accuracy of the design. Bus operating costs are relatively

competitive compared to conventional buses. In addition, even though the study

results have not included an incentive factor from the government. The service

life of electric buses can be longer than ten years because the motor's

efficiency is relatively more stable than an internal combustion engine. For Transjakarta bus with the route of Blok M

– Raden Inten, it can be considered that the bus transmission in the city can

be simplified. It is also advantageous in terms of vehicle weight and

maintenance costs. The 100 kW rated electric motor (200 kW max.) can provide a

maximum torque of about 700 Nm. Then, with a bus operating time of 19

hours per day, there is a stop time of 5 hours. This time can be used for

maintenance and charging the battery. Thus, the ideal time for charging is

around 4 hours or less than 5 hours.

This

research was supported by Lembaga Pengelola Dana Pendidikan –the Ministry of

Finance Republic of Indonesia, with the contract number PRJ-86/LPDP/2020.

Adheesh. S.R.. . Vasisht. M.S.. Ramasesha. S.K..

2016. Air-Pollution and Economics: Diesel Bus Versus Electric Bus. Current Science. Volume 110(5). pp. 858–862

Al-Ogaili. A.S.. Ramasamy. A.. Hashim. T.J.T.. Al-Masri.

A.N.. Hoon. Y.. Jebur. M.N.. Verayia. R.. Marsadek. M.. 2020. Estimation of the

Energy Consumption of Battery Driven Electric Buses by Integrating Digital

Elevation and Longitudinal Dynamic Models: Malaysia as a Case Study. Applied Energy. Volume 280. p. 115873

An. K.. 2020. Battery Electric Bus Infrastructure

Planning under Demand Uncertainty. Transportation

Research Part C: Emerging Technologies. Volume 111. pp. 572–587

Bi. Z.. Song. L.. De Kleine. R.. Mi. C.C.. Keoleian.

G.A.. 2015. Plug-In vs Wireless Charging: Life Cycle Energy and Greenhouse Gas

Emissions for an Electric Bus System. Applied

Energy. Volume 146. pp. 11–19

Budiono. H.D.. Sumarsono. D.A.. Adhitya. M..

Baskoro. A.S.. Saragih. A.S.. Prasetya. S.. Zainuri. F.. Nazaruddin. Heryana.

G.. Siregar. R.. 2020. Development of Smart Magnetic Braking Actuator Control

for a Heavy Electric Vehicle. International

Journal of Technology. Volume 11(7).

pp. 1337–1347

Chen. Z.. Yin. Y.. Song. Z.. 2018. A Cost-Competitiveness

Analysis of Charging Infrastructure for Electric Bus Operations. Transportation Research Part C: Emerging

Technologies. Volume 93. pp. 351–366

Ding. H.. Hu. Z.. Song. Y.. 2015. Value of the

Energy Storage System in an Electric Bus Fast Charging Station. Applied Energy. 157. 630–639

Jun-Qiang. X.. Guang-Ming. X.. Yan. Z.. 2008.

Application of Automatic Manual Transmission Technology in Pure Electric Bus. In: IEEE Vehicle Power and Propulsion

Conference (VPPC). September 3-5. 2008. Harbin. China

Ke. B.-R.. Chung. C-Y.. Chen. Y.-C.. 2016.

Minimizing the Costs of Constructing an All Plug-In Electric Bus Transportation

System: A Case Study in Penghu. Applied

Energy. Volume 177. pp. 649–660

Nazaruddin. Adhitya. M.. Sumarsono. D.A.. Siregar.

R.. Heryana. G.. 2020. Review of Electric Power Steering Type Column Steering

with Booster Motor and Future Research for EV-Bus. In: AIP Conference Proceedings. p. 020016. AIP Publishing LLC

Nugraha. A.A.. Sumarsono. D.A.Adhitya. M..

Prasetya. S.. 2021. Development of Brake Booster Design for Electric City Cars. International Journal of Technology.

Volume 12(4). pp. 802-812

Pelletier. S.. Jabali. O.. Mendoza. J.E.. Laporte.

G.. 2019. The Electric Bus Fleet Transition Problem. Transportation Research Part C: Emerging Technologies. Volume 109. pp. 174–193

Peng. J.. He. H.. Xiong. R.. 2017. Rule Based

Energy Management Strategy for a Series–Parallel Plug-In Hybrid Electric Bus

Optimized by Dynamic Programming. Applied

Energy. Volume 185. pp. 1633–1643

Rahman. A.. Hassan. N.. Ihsan. S.I.. 2022. Fuzzy

Logic Controlled Two Speed Electromagnetic Gearbox for Electric Vehicle . International Journal of Technology.

Volume 13(2). pp. 297–309

Sumarsono. D.A.. Heryana. G.. Adhitya. M..

Siregar. R.. 2021. Performance Analysis of a Main Drive Motor—Initial Study of

an EV Modeling Software Design. World

Electric Vehicle Journal. Volume 12(4).

p. 1–14

Teoh. L.E.. Khoo. H.L.. Goh. S.Y.. Chong. L.M..

2018. Scenario-Based Electric Bus Operation: A Case Study of Putrajaya.

Malaysia. International Journal of

Transportation Science and Technology. Volume 7(1). pp. 10–25

Xiong. W.. Zhang. Y.. Yin. C.. 2009. Optimal Energy

Management for a Series–Parallel Hybrid Electric Bus. Energy Conversion and Management. Volume 50(7). pp. 1730–1738

Zhou. B.. Wu. Y..

Zhou. B.. Wang. R.. Ke. W.. Zhang. S.. Hao. J.. 2016. Real-World Performance of

Battery Electric Buses and Their Life-Cycle Benefits with Respect to Energy

Consumption and Carbon Dioxide Emissions. Energy.

Volume 96. pp. 603–613