Effect of Drying Pretreatment Methods on Amla (Emblica officinalis) Extracts Obtained Through Maceration Using Ethanol as Solvent

Corresponding email: m.dani.supardan@unsyiah.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.5669

Raaf, A., Mulana, F., Syamsuddin, Y., Suriaini, N., Supardan, M.D., 2024. Effect of Drying Pretreatment Methods on Amla (Emblica officinalis) Extracts Obtained Through Maceration Using Ethanol as Solvent. International Journal of Technology. Volume 15(4), pp. 917-926

| Auliyaa Raaf | Doctoral Program, School of Engineering, Post Graduate Program, Universitas Syiah Kuala, Banda Aceh 23111, Indonesia |

| Farid Mulana | Department of Chemical Engineering, Universitas Syiah Kuala, Banda Aceh 23111, Indonesia |

| Yanna Syamsuddin | 1 Department of Chemical Engineering, Universitas Syiah Kuala, Darussalam, Banda Aceh, 23111, Indonesia 2 Halal Research Center, Universitas Syiah Kuala, Banda Aceh, 23111, Indonesia |

| Nanda Suriaini | Department of Chemical Engineering, Universitas Syiah Kuala, Banda Aceh, Indonesia 23111 |

| Muhammad Dani Supardan | 1 Department of Chemical Engineering, Universitas Syiah Kuala, Darussalam, Banda Aceh, 23111, Indonesia 2 Halal Research Center, Universitas Syiah Kuala, Banda Aceh, 23111, Indonesia |

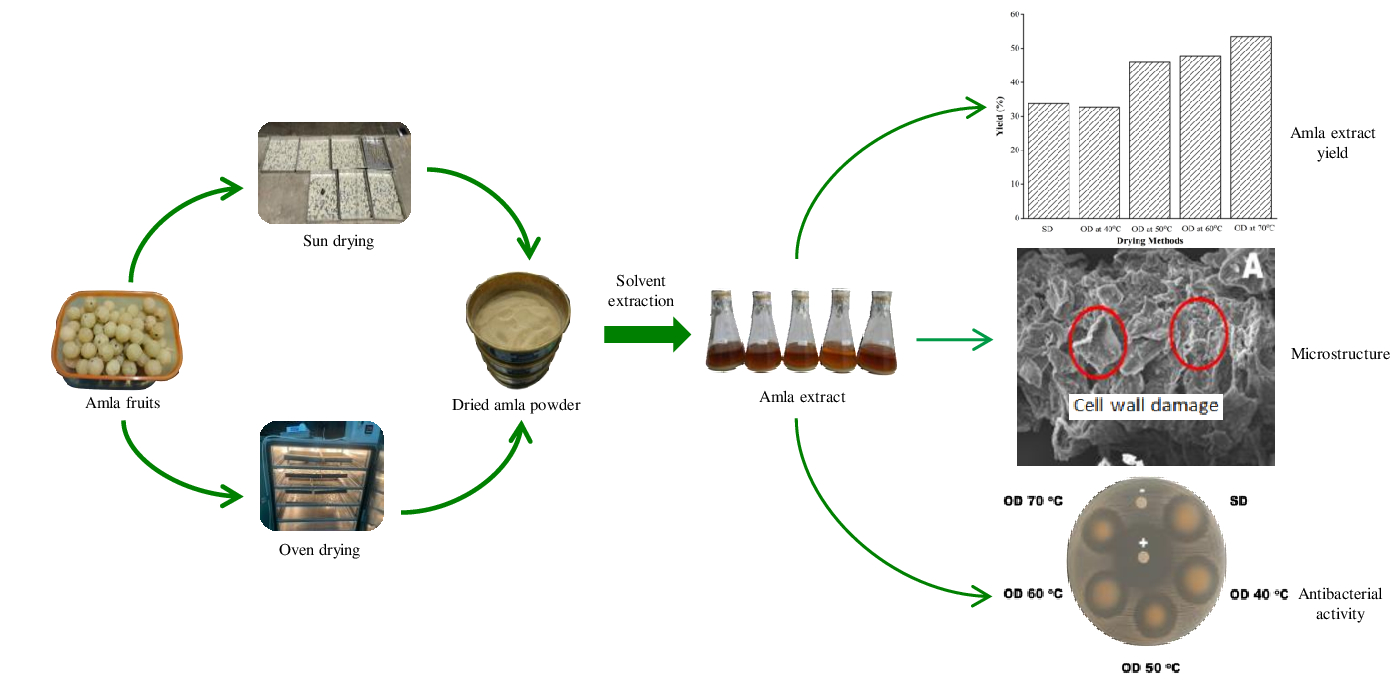

This study investigated the effects of drying methods on the yield, bioactive compounds, and antibacterial activity of amla extract. Fresh amla was oven-dried and sun-dried at different temperatures and ground into powder. Bioactive compounds were extracted from amla using maceration with ethanol as a solvent. The amla extract was used for the antibacterial susceptibility test using the agar disc diffusion method. The yield of amla extract increased with increasing drying temperature. The highest yield (53.47%) was obtained at a drying temperature of 70o C. Fourier Transform Infrared (FTIR) analysis confirmed that sun-drying and oven-drying exhibited no qualitative effect on the bioactive compound in amla extract. FTIR analysis also indicated that amla extract contains bioactive compounds, validated by phytochemical analysis. The antibacterial activity of oven-dried samples at 40 oC produced the largest inhibition zone (24.57 mm) compared to sun-drying and oven-drying at other temperatures. It can be concluded that drying temperature, especially higher temperatures, had a significant impact on the antibacterial activity of amla as its active components degraded.

Amla extract; Antibacterial activity; Bioactive compound; Drying methods

Amla (Emblica officinalis) has

long been recognized for its health benefits and has been used as a medicinal

plant and in food preparation. It is currently distributed in India, Sri Lanka,

South-East Asia, China, and Indonesia (Khan, Qais, and Ahmad,

2019)

and is available in

large quantities for food and pharmaceutical purposes. Amla has been

extensively used as a medicinal plant to treat inflammation, as an

antibacterial, and to treat cancer (Pareek and Kitinoja, 2011). A previous study has reported

that amla has high pharmaceutical activity, sparking interest due to its

potential as an antibacterial source (Jahan and Akter, 2015).

The

potential of amla as a medicinal plant is mostly due to the bioactive compounds

contained in the plant, which can treat various diseases in the human body. The

bioactive compounds include flavonoids, tannins, alkaloids, saponins, and

phenolic compounds (Arina and Harisun, 2019). Hussein, Mamman, and Mansur (2015) reported that the

Bioactive compounds,

mainly phytochemical content from amla, are extremely important for many

purposes. The phytochemical content of amla extract is heavily influenced by

how the extract is produced. Maceration is an extraction method commonly

used to extract bioactive compounds from plant materials through the use of

solvents (solid–liquid extraction) (Safdar et al.,

2017).

Ethanol is one of the most widely used solvents for the extraction of plant

bioactive compounds, such as alkaloids and

flavonoids (Pratiwi,

Utami, and Arbianti, 2020). Ethanol is also considered a food-grade solvent (Dianursanti et al.,

2020).

The

extraction of bioactive compounds from a plant begins with the drying of the

plant. Plant drying aims to produce raw

materials in simplicia, facilitating the extraction of phytochemicals with a

high yield, and facilitating plant storage for future use (Amir et al., 2021; Hasmita

et al., 2015). Additionally, drying significantly reduces volume, thereby saving on

packaging, storage, and transportation costs (Sonkar et al., 2020). Gudapaty et al.

(2010)

reported that drying affects the quality attributes of amla. The drying

pretreatment method can affect the input energy, increase the extraction yield,

and increase the quality of the extracted bioactive compounds. Thus, drying

methods must be evaluated to determine their effect on extracted bioactive

compounds.

For

continuous production of amla extract, drying techniques must be determined for

recommendation to producers. Raaf et al. (2022) reported the impact of temperature and drying methods on amla's drying

kinetics and microstructure. However, little information has been reported

regarding the effect of the drying method on bioactive compounds. Thus, this

research evaluates the effects of oven-drying (at different temperatures) and

sun-drying on the phytochemical content and antibacterial activity of amla.

2.1. Materials

The

study used amla collected near Blang Bintang, Aceh Besar. The solvent used for

the extraction process was ethanol 96% (Merck, Germany). The antibacterial

assay used nutrient agar (Oxoid, UK) and amoxicillin (Mersi, Indonesia). The

bacterial species used were Staphylococcus

aureus ATCC 25923, obtained from stock cultures of Fundament Lab Sains,

Aceh Besar.

2.2. Drying Methods

Fresh amla was washed with clean water and thinly sliced and dried. Cutting was performed to ensure that the amla samples dried evenly. The amla was sun-dried (SD) in air temperatures of 37–45 OC. For oven-drying (OD), amla was placed on a tray and dried at four different temperatures (40 OC, 50 OC, 60OC, and 70 OC). All samples were ground into a fine powder using an electric blender and screened through a mesh sieve to obtain a uniform size.

2.3. Extraction Procedure

2.4. Analysis Method

Proximate

analysis of amla powder was conducted to analyze parameters such as fat

content, carbohydrates, protein, moisture, and ash using the standard method as

per Indonesian National Standard (SNI) 01-2891-1992 procedures.

The preliminary

phytochemical evaluation of each extract was qualitatively tested to determine

the presence of flavonoids, alkaloids, tannins, saponin, quinone, steroids, and

triterpenoids. The tests were performed according to the methods reported by Guluma et

al. (2020).

A

Fourier transform infrared spectrophotometer (FTIR Shimadzu Prestige 6400) was

used to identify the functional group of amla extract. The spectra were observed

in the wavenumber region of 4000–400 cm-1. A Carl Zeiss-Bruker EVO

MA10 scanning

electron microscope (SEM) was used to observe the morphological changes of the

dried amla powder after extraction. The analysis was presented using a 1000×

magnification.

Figure 1 Illustration of the amla

extraction process using maceration

2.5. Antibacterial Assay

The

antibacterial activity of the amla extract was tested using the Kirby–Bauer

agar disk diffusion method, as reported by Zullkiflee et al. (2022). S. aureus (ATCC 25923) was used in this study. The nutrient agar

(NA) was used as the media. The NA was

compacted in a Petri dish, and the bacterial culture was inoculated and diluted

with 0.5 McFarland standard. The amla extract-soaked paper disk was drained and impregnated on the

agar plate medium surface. The plates were incubated for 24 h at 37 OC. The clear zone around the paper

disk was measured to determine the antibacterial activity. All results were

compared to distilled water as a negative control and the standard antibiotic

(amoxicillin) as a positive control.

3.1. Proximate Analysis of Dried

Amla Powder

The

proximate composition of dried amla powder is presented in Table 1. The

proximate analysis results indicate that the carbohydrate and ash values are

similar to those reported by Mishra and Mahanta (2014) for amla fruit powder; the fat and protein

content was lower. This is a result of fruit from different geographical

locations, which affects the nutritional content of the fruit, including fat

and protein, as reported by Okeke et al. (2021). The

fat content of amla ranged from 0.36% to 0.48% (Parveen and Khatkar, 2015). The protein content in amla is used by the

body for growth and maintenance. Protein also plays a role in the formation of

blood cells and antibodies that protect the body from disease and infection (Hermann, 2019). The obtained moisture content was high

(10.08%). A less than 10% moisture content must be maintained to prevent

microbial growth in dry food products (Zambrano et al.,

2019).

Thus, proper pretreatment is required to limit the amount of moisture in dried

amla powder without reducing its nutritional value.

Table 1 Proximate analysis of

dried amla powder

|

Parameter |

Content (%) |

|

Moisture |

10.08 |

|

Ash |

3.57 |

|

Fat |

0.15 |

|

Protein |

4.43 |

|

Carbohydrates |

81.77 |

3.2. Effect of Drying Methods on

Amla Extract Yield

The effect of the drying method on the yield of amla extract is presented in Figure 2. Oven-drying at 50-70oC produced a higher amla extract yield than sun-drying. The amla extract yield was slightly higher with sun-drying than with oven-drying at 40oC as the drying temperature was 40–45 oC. This indicates that drying methods have a linear effect on the increase in amla extract yield. These results are consistent with those reported by Justine et al. (2019).

The amla extract yield increased linearly with increasing drying temperature, related to the moisture content in the amla. Higher drying temperatures produced a lower moisture content in the amla (Raaf et al., 2022). Thermal drying causes cell wall damage, facilitating the release of phytochemical compounds and increasing amla extract yield (Justine et al., 2019). Cell wall damage caused by thermal drying is shown in Figure 3. Higher drying temperatures can increase cell wall damage (Figure 3B). Raaf et al. (2021) reported that the amount of water in the material at high temperatures was smaller, resulting in the stretching of the plant cell wall structure, which facilitated the rupture of the cell wall into small particles.

Figure 3 Effect of drying

temperature on the cell wall damage after extraction: A: 50 oC; B: 70 oC

Figure 4 Effect of extraction on cell wall damage: A:

before extraction (after oven-drying at 60 oC); B: after extraction

The effect of the drying method on cell wall damage after extraction is presented in Figure 5. Sun-drying (Figure 5A) and oven-drying at 40 oC (Figure 5B) have similar thermal temperatures, with a difference of 5 oC. Cell wall damage caused by thermal drying is difficult to determine. The amla extract yield was 1% greater with sun-drying than with oven-drying at 40 oC (Figure 2). Cell wall damage after extraction appeared to be greater with oven-drying at 40 oC than sun-drying. Oven-drying has a closed drying system; sun-drying has an open drying system. There is less heat loss in oven-drying than sun-drying (Babu et al. 2018). Thus, oven-drying at 40 oC (Figure 5B) observed greater cell wall damage than sun-drying (Figure 5A).

3.3. Effect of Drying Method on Phytochemical

Analysis of Amla Extract

Figure 5 Effect of drying method on cell wall damage after

extraction: A: sun-drying; B: oven-drying at 40 oC

Figure 6 FTIR spectrum of amla extract (sun-drying (SD) and oven

drying (OD) at 40–70oC)

The FTIR spectra of amla extract exhibited several main peaks. The peak

at 3652–3588 cm-1 indicates the presence of –OH (stretching)

vibration of the phenol group (Nandiyanto,

Oktiani, and Ragadhita, 2019). The C-H

vibration was found at 2964–2957 cm-1. It exhibits phenolic aromatic

compounds (Öztürk

et al., 2019). The peak at

1759–1754 cm-1 shows the ester group's C=O (stretching) vibration (Nandiyanto,

Oktiani, and Ragadhita, 2019). Peaks

at 1473–1470 cm-1, 1410–1409 cm-1, and 1257–1254 cm-1

indicate C=C-C (stretching) vibration of the aromatic ring, -OH (bending) of

the phenol group, and C-O (stretching) of the phenol aromatic ring,

respectively (Nandiyanto,

Oktiani, and Ragadhita, 2019).

Overall, the FTIR spectra exhibited good consistency with the results reported

by Firdous,

Ringø, and Elumalai (2020).

Polyphenol compounds are indicated by the functional groups of –OH, C=O, and

C-O (Raaf et

al., 2021). This ester group

indicates the presence of flavonoids (Noh, Azmin, and Amid, 2017),

saponins (Almutairi

and Ali, 2015), and tannins (Grasel,

Ferrão, and Wolf, 2016).

The results are also supported and confirmed by identification using the

reagents presented in Table 2. Flavonoids, saponins, and tannins were

qualitatively identified through FTIR and phytochemically by reagents in amla

extract under each drying condition. The results indicated that sun-drying and

oven-drying had no qualitative effect on the phytochemical compounds in amla

extract.

3.4. Antibacterial Activity

Figure 7 Inhibition of S. aureus growth by amla extract using sun-drying (SD) and oven drying (OD) at 40–70oC

The antibacterial activity of oven-dried samples (40 oC) was shown to be greater than that of other oven-dried (50 oC, 60 oC, 70 oC) and sun-dried samples. Compared with the other treatments, drying at 40 ? exhibited the greatest inhibitory activity, with an inhibition zone of 24.57 mm against gram-positive bacteria S. aureus. The results indicate that amla extract has reasonable antibacterial activity against the test microorganisms regardless of the drying method. The antibacterial activity of amla extract on S. aureus was greater than that previously reported by Kumari and Khatkar (2016).

The

inhibition zones indicated the test organisms' susceptibility to amla extract

and decreased as the amla drying temperature increased. This is reasonable; Hussein, Mamman, and Mansur (2015) reported

that M. oleifera leaf extract was

more effective at low temperatures. The presence of tannins (Khan, Qais, and Ahmad,

2019) and flavonoids (Abdullah et al., 2019) as

bioactive components is thought to be responsible for the antibacterial

activity of amla extract.

The drying method significantly affected the yield of amla extract, which was slightly greater with sun-drying than with oven-drying at 40oC and increased with increasing drying temperature. Sun-drying and oven-drying methods caused cell wall damage in dried amla powder before extraction. The extraction process also causes cell wall damage due to solvent activity, which releases phytochemical compounds from dried amla powder. FTIR and phytochemical analysis indicated that amla extract contains flavonoids, tannins, and saponins. The presence of an inhibition zone indicated that amla extract demonstrated antibacterial activity. The antibacterial activity of amla extract on S. aureus decreased with increasing amla drying temperature.

The authors are

thankful for the support of the Ministry of Education and Culture of the

Republic of Indonesia and Universitas Syiah Kuala through the PMDSU research

grant (No. 060/E5/PG.02.00.PT/2022).

Abdullah, N.A., Ja'afar, F., Yasin, H.M., Taha, H., Petalcorin, M.I.R.,

Mamit, M.H., Kusrini, E., Usman, A., 2019. Physicochemical Analyses,

Antioxidant, Antibacterial, and Toxicity of Propolis Particles Produced by

Stingless Bee Heterotrigona Itama Found in Brunei Darussalam. Heliyon, Volume

5(9), p. e02476

Ajak, S.N.F.H., Ja’afar, F., Yasin, H.M., Petalcorin, M.I.R., Usman, A.,

2020. Electrochemistry, Antioxidant Activity, and Toxicity of Unfermented Aidia borneensis Leaves Infusions. Chinese Traditional Medical Journal, Volume 3(1), pp. 1–11

Almutairi, M.S., Ali, M., 2015. Direct Detection of

Saponins in Crude Extracts of Soapnuts by FTIR. Natural Product Research, Volume 29(13), pp. 1271–1275

Amir, N., Efendy, M., Yoo, Y.J., Gozan,

M., 2021. Improved Salt Quality and Reduced Energy Consumption via Hot Air

Drying. International Journal of Technology. Volume 12(3),

pp. 592–601

Aneklaphakij,

C., Saigo, T., Watanabe, M., Naake, T., Fernie, A.R., Bunsupa, S.,

Satitpatipan, V., Tohge, T., 2021. Diversity of Chemical Structures and

Biosynthesis of Polyphenols in Nut-bearing Species. Frontiers in Plant Science, Volume 12, pp. 1–15

Arina, M.Z.I., Harisun, Y., 2019. Effect of Extraction

Temperatures on Tannin Content and Antioxidant Activity of Quercus Infectoria

(Manjakani). Biocatalysis and Agricultural Biotechnology, Volume 19, pp. 1–5

Babu, A.K., Kumaresan, G.,

Anthony-Aroul Raj, V., Velraj., R., 2018. Review of Leaf

Drying: Mechanism and Influencing Parameters,

Drying Methods, Nutrient Preservation, and Mathematical Models. Renewable and Sustainable

Energy Reviews, Volume 90, pp.

536–556

Bin Fazal, D., Ahmad, I., 2024. A Critical Analysis of

Extracts of Okra Seeds and Amla Offering Green Chemistry for Synthesis of Zinc

Oxide Nanoparticles and Their Promising Role in Reducing Crude Oil Viscosity. Materials

Today Communications, Volume 38, pp. 108172

Dianursanti, Siregar, A.R., Maeda, Y., Yoshino, T.,

Tanaka, T., 2020. The Effects of Solvents and Solid-to-Solvent Ratios on

Ultrasound-Assisted Extraction of Carotenoids from Chlorella vulgaris. International

Journal of Technology, Volume 11(5), pp. 941–950

Firdous, A., Ringø, E., Elumalai, P., 2021. Effects of

Green Tea- and Amla Extracts on Quality and Melanosis of Indian White Prawn (Fenneropenaeus indicus, Milne Edwards,

1837) During Chilled Storage. Aquaculture

and Fisheries, Volume 6, pp. 617–627

Grasel, F.S., Ferrão, M.F., Wolf, C.R., 2016. Development

of Methodology for Identification the Nature of the Polyphenolic Extract by

FTIR Associated with Multivariate Analysis. Spectrochimica

Acta Part A: Molecular and Biomolecular Spectroscopy, Volume 153, pp. 94–101

Gudapaty, P., Indavarapu, S., Korwar, G.R., Shankar, A.K.,

Adake, R.K.V., Bandi V., Kanche, S.R., 2010. Effect of Open Air Drying, LPG

Based Drier and Pretreatments on the Quality of Indian Gooseberry (aonla). Journal of Food Science and Technology, Volume 47(5), pp. 541–548

Guluma, T., Babu N.G., Teju, E., Dekebo, A., 2020.

Phytochemical Investigation and Evaluation of Antimicrobial Activities of

Brucea Antidysenterica Leaves. Chemical Data Collections, Volume 28, pp. 1–10

Hasmita, I., Adisalamun, Alam, P.N., Satriana, Mahlinda,

Supardan, M.D.,

2015. Effect of

Drying and Hydrodistillation Time on the Amount of Ginger Essential Oil. International Journal on Advanced

Science, Engineering and Information Technology, Volume 5, pp. 300–303

Hermann, J.R., 2019. Protein and the Body. Agricultural

Sciences and Natural Resources, pp. 1–4

Hussein, I.I., Mamman, M., Mansur, A., 2015. Effect of

Varying Drying Temperature on the Antibacterial Activity of Moringaoleifera

Leaf (Lam). IOSR Journal of Pharmacy and Biological Sciences, Volume 10(4), pp. 39–43

Jahan, N., Akter, S., 2015. Assessment of the Antimicrobial Activity of the

Ethanolic Extract of Phyllanthus Emblica in Combination with Different Classes

of Antibiotics against Single and Multi-Drug Resistant Strains. Journal of

Pharmacognosy and Phytochemistry, Volume 4(4), pp. 142–155

Justine,

V.T., Mustafa, M., Kankara, S.S., Go, R., 2019. Effect of Drying Methods and

Extraction Solvents on Phenolic Antioxidants and Antioxidant Activity of Scurrula ferruginea (Jack) Danser

(Loranthaceae) Leaf Extracts. Sains

Malaysiana, Volume 48 (7), pp. 1383–1393

Khan, M.S., Qais, F.A., Ahmad, I., 2019. Indian Berries

and Their Active Compounds. Elsevier Inc

Kumari, P.,

Khatkar, B.S., 2016. Assessment of Total Polyphenols, Antioxidants and

Antimicrobial Properties of Aonla Varieties. Journal of Food Science and Technology, Volume 53 (7), pp. 3093–3103

Mishra, P., Mahanta, C.L., 2014. Comparative Analysis of Functional and Nutritive

Values of Amla (Emblica Officinalis) Fruit, Seed and Seed Coat Powder. American

Journal of Food Technology, Volume 9 (3), pp. 151–161

Nandiyanto,

A.B.D., Oktiani, R., Ragadhita, R., 2019. How to Read and Interpret FTIR

Spectroscope of Organic Material. Indonesian

Journal of Science & Technology, Volume 4 (1), pp. 97–118

Noh,

C.H.C., Azmin, N.F.M., Amid, A., 2017. Principal Component Analysis Application

on Flavonoids Characterization. Advances

in Science, Technology and Engineering Systems Journal, Volume 2(3), pp.

435–440

Okeke,

H.C., Okeke, O., Nwanya, K.O., Offor, C.R., Aniobi, C.C., 2021. Comparative

Assessment of the Proximate and Mineral Composition of Cucumis sativus L. and Solanum aethiopicum L. Fruit Samples

Grown in South Eastern and North Central Regions of Nigeria Respectively. Natural Resources, Volume 12, pp. 237–249

Öztürk,

M., Bulduk, I., Korcan, S.E., Liman, R., Çoban, F.K., Karg?o?lu, M., Konuk, M.,

2018. Total Phenolics, Flavonoids Contents, Antioxidant Activity and DNA

Protective Effect of Lenten Rose (Helleborus

orientalis). Asian Journal of

Biochemistry, Genetics and Molecular Biology,

Volume 1 (4), pp. 1–12

Pareek, S., Kitinoja, L., 2011. Aonla ( Emblica Officinalis

Gaertn.). In Postharvest Biology and Technology of Tropical and Subtropical

Fruits, Woodhead Publishing, pp. 65–99

Parveen, K., Khatkar, B.S., 2015. Physico-Chemical

Properties and Nutritional Composition of Aonla (Emblica officinalis)

Varieties. International Food Research Journal, Volume 22(6), pp. 2358–2363

Pratiwi, F.A., Utami, T.S.,

Arbianti, R., 2020. Using Ultrasonic Assisted Extraction to Produce a

Bioinsecticide from Cigarette Butt Waste and Green Solvent to Control Armyworm

Infestation. International Journal of Technology, Volume 11(7),

pp. 1329–1336

Raaf, A., Putra,

T.W., Mulana, F., Syamsuddin, Y., Supardan, M.D., 2022. Investigation of

Kinetics of Amla (Emblica officinalis) Fruit Drying Process. South

African Journal of Chemical Engineering, Volume 41, pp. 10–16

Raaf,

A., Suriaini, N., Djafar, F., Syamsuddin, Y., Supardan, M.D., 2021. Effect of

Drying Temperature on the Moisture Loss, Acidity and Characteristics of Amla

Fruit. IOP

Conference Series: Earth and Environmental Science, Volume 667, pp. 1–6

Safdar, M.N., Kausar, T., Jabbar, S., Mumtaz, A., Ahad, K., Saddozai, A.A., 2017. Extraction and Quantification of Polyphenols from

Kinnow (Citrus Reticulate L.) Peel Using Ultrasound and Maceration

Techniques. Journal of Food and Drug Analysis, Volume 25(3), pp. 488–500

Sonkar, N., Rajoriya,

D., Chetana, R., Murthy K.V., 2020. Effect of Cultivars, Pretreatment and

Drying on Physicochemical Properties of Amla (Emblica officinalis)

Gratings. Journal of Food Science and Technology, Volume 57(3), pp. 980–992

Variya,

B.C., Bakrania, A.K., Patel, S.S., 2016. Emblica

officinalis (Amla): A Review for Its Phytochemistry, Ethnomedicinal Uses

and Medicinal Potentials with Respect to Moleculer Mechanisms. Pharmacological Research, Volume 111,

pp. 180–200

Zambrano, M.V., Dutta, B., Mercer, D.G., MacLean, H.L., Touchie, M.F., 2019. Assessment of Moisture Content

Measurement Methods of Dried Food Products in Small-Scale Operations in

Developing Countries: A Review. Trends in Food Science and Technology,

Volume 88, pp. 484–496

Zullkiflee, N., Taha, H., Abdullah, N.A., Hashim, F., Usman, A., 2022.

Antibacterial and Antioxidant Activities of Ethanolic and Water Extracts of

Stingless Bees Tetrigona Binghami, Heterotrigona Itama, and Geniotrigona

Thoracica Propolis Found in Brunei. Philippine Journal of Science, Volume

151(4), pp. 1455–1462