Improvement Design of Packaged Juice Production Process using Business Process Reengineering

Published at : 24 Dec 2024

Volume : IJtech

Vol 15, No 6 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i6.5630

Pratama, N.R., Agustin, P.A. 2022. Improvement Design of Packaged Juice Production Process using Business Process Reengineering. International Journal of Technology. Volume 15(6), pp. 1851-1861

| Novandra Rhezza Pratama | Department of Industrial Engineering, Faculty of Engineering, Universitas Indonesia, 16424, West Java, Indonesia |

| Putri Amaliyah Agustin | Department of Industrial Engineering, Faculty of Engineering, Universitas Indonesia, 16424, West Java, Indonesia |

Process efficiency is required in

packaged juice production to meet the greater demand for its product. The

manual production process causes time loss, poses a bottleneck, and results in

waste due to the time-consuming process. This study aims to design an

improvement in the production process of packaged juice by eliminating the

waste that occurs to increase the productivity and efficiency of processing.

Process Activity Mapping and Waste Assessment are used to map the activities

and identify waste. The improvement design is executed using a Business Process

Reengineering (BPR) through implementing a combination of BPR best practices

and simulation using iGrafx software. Process improvement involves the entire

production process that consists of three stages, namely the puree-making

stage, production stage, and packaging stage. This research resulted in designs

of improvement solutions. The models of the improvement solutions are then

simulated and produce an improved production process time. This solution resulted

in a 34.9% reduction in distance traveled and a 50.54% reduction in total

processing time.

Business process reengineering; Packaged juice production; Process activity mapping; Waste; Waste assessment

In 2020, Indonesia continued the trend of

increasing fruit production by recording an increase of 10.46% from production

in 2019 (BPS, 2020). However, the

abundance of fruit production in Indonesia is not in line with the level of

fruit consumption of the Indonesian population. Until 2020, the reality of the

average consumption of fruits and vegetables in Indonesia was only

89gr/Cap/Day, far below the WHO's recommended RDA of 150gr/Cap/Day (BPS,

2021). Currently, packaged juice as one of the

processed products derived from the fruit is often an alternative and a good

approach to increase fruit consumption (Mushtaq,

2018). The continuous increase in consumer demand for packaged

fruit juice presents opportunities for players in the Indonesian food and

beverage industry to meet consumer needs, improve food security, and achieve

Sustainable Development Goals (SDGs) (Berawi, 2019).

PT API is a food and beverage industry company specializing in packaged fruit juice drinks. One of PT API's production lines, namely packaged juice with the "Signature" label, has continued to increase in demand every month since the beginning of 2021. Given this projection, the current daily production capacity for "Signature" products may not be sufficient due to several constraints. These include the manual nature of the production process, which is time-consuming, lacks accuracy, and requires a significant number of workers. Due to these production problems, corrective steps needed to be taken by the company in the "Signature" production process to improve the business process and assess the waste problems.

Business processes can be stated as the

formality of operations and process behavior of activities in an organization (Saragih, Dachyar, and

Zagloel, 2021). The fundamental rethinking and radical redesign of business processes to

achieve dramatic improvements in critical, contemporary measures of

performance, such as cost, quality, service, and speed (Kyfyak and Lopatynskyi, 2018;

Dumas et al., 2018; Gunasekaran, and Kobu, 2002).

Business Process Reengineering (BPR) is a philosophy of improvement (Towill, 2001) that aims

to improve process performance (Mansar, Reijers, and Ounnar, 2009) by

redesigning the processes an organization operates (Al-Shammari, M., 2009),

maximizing value-added activities, and minimizing other activities (Martonová, 2013). There

are 5 BPR steps (Mudiraj,

2014; Guimaraes and Paranjape, 2013): Prepare for BPR, Map &

Analyze As-Is Process, Design To-Be Processes, Implement Reengineered Process,

and Improve continuously. There are 10 best practices that can be applied in

BPR (Kumar

and Bhatia 2012; Mansar and Reijers, 2007), that is

task elimination, task composition, integral technology, empower, order

assignment, resequencing, specialist generalist, integration, parallelism, dan

numerical involvement.

Lean Manufacturing (LM) is a method

that helps companies identify and eliminate waste (Gupta and Jain, 2013; Wahab, Mukhtar,

and Sulaiman, 2013) to increase value (Driouach, Zarbane, and Beidouri, 2019), improve

quality (Anvari,

Ismail, and Hojjati, 2011), increase production output (Singh, Singh, and Singh,

2018), and reduce lead time and production costs (Ahmad et al., 2019; Satao,

2012). There are eight types of manufacturing waste (Liker, 2004):

Overproduction, Excessive Inventory, Defect, Unnecessary Motion,

Transportation, Overprocessing, Waiting, and Non-Utilized Resources. Waste can

be divided into two categories (Gaspersz, 2007), namely non-value-added activities (NVA) and necessary but non-value-added

activities (NNVA).

To describe the production process in

detail from each activity, Process Activity Mapping (PAM) can be used (Amrina and Andryan, 2019; Zuting

et al., 2014; Pude, Naik, and Naik, 2012). PAM

involves simple steps, first, analyzing the production process which is carried

out sequentially from the beginning, followed by a detailed recording of all

items needed in each process and conducting waste assessment (Mikkelsen, Lydekaityte, and

Tambo, 2021; de Bucourt et al., 2012; Teichgräber and De Bucourt, 2012). The

waste assessment is used to identify critical waste that occurs throughout the

manufacturing process (Singh, Ramakrishna, and Gupta, 2017; Rybicka et al., 2015; Moinuddin,

Collins, and Bansal, 2007) by distributing questionnaires to expert

practitioners (Ekanayake

and Ofori, 2004). The questionnaire was conditioned based on the Borda Count Method (BCM) (Emerson, 2013). BCM is

one of the methods used to determine an alternative with the highest preference

from several alternatives to be selected (Orouskhani, Teshnehlab, and

Nekoui, 2019; Albanna and Karningsih, 2018; Van Erp and Schomaker, 2000).

This study discusses how we overcame technical problems,

such as manual processing, bottlenecks, and long production times, as well as

waste problems, including identifying the waste generated and how we overcame

it. We improved our company efficiency and productivity by using the methods

mentioned above. Through this research, we were able to determine the required

production process tools, identify and eliminate waste, and design process

improvements. We aspired that this research would contribute to enhancing the

science of BPR and LM application in manufacturing processes.

Figure 1 Methodology of this Research using combination of BPR and PAM

3.1. Overview of

“Signature” Production Process

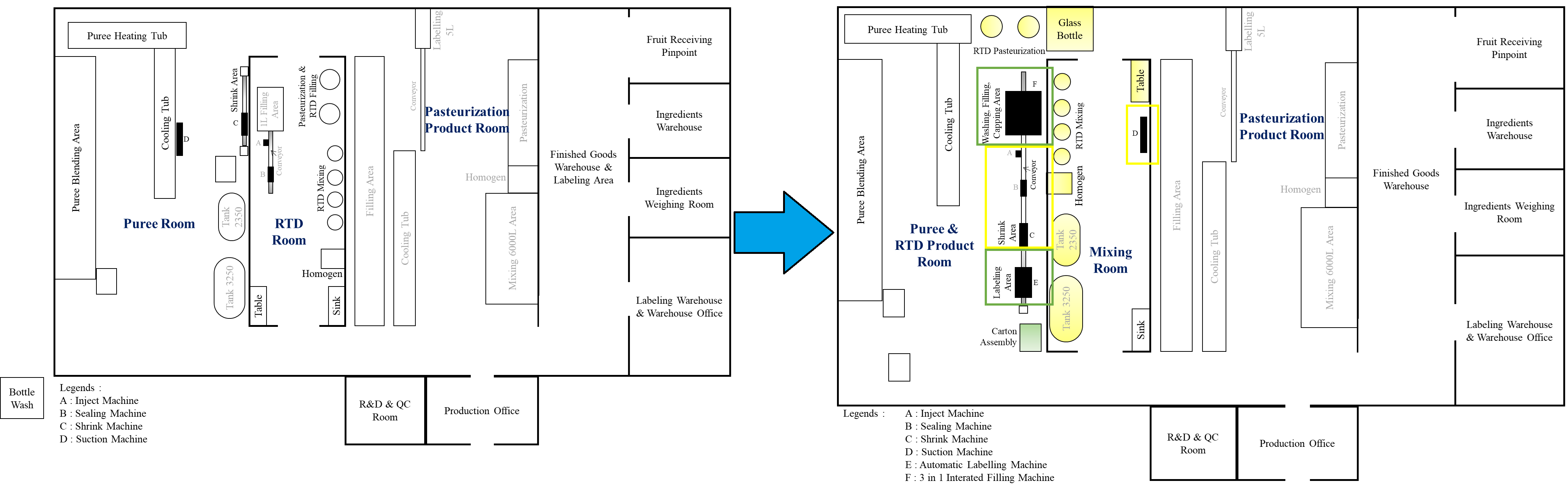

Figure 2 As-is Production Floor Layout

3.2. Current Process

Activity Mapping

The identified activities

are mapped into PAM with the following Table 1 and Table 2. Overall we can see

that the production process consists of 76 processes, a total distance traveled

of 195 m, and a total number of workers of 19 workers, with a total production

time of 24 hours 51 minutes 5 seconds.

Table 1 Number of processes, the distance of movement,

and the number of workers in the current PAM

|

Process |

Puree Making |

Production |

Packaging |

Total Process |

|

Operation |

9 |

18 |

18 |

45 |

|

Transportation |

3 |

11 |

4 |

18 |

|

Inspection |

0 |

4 |

2 |

6 |

|

Delay |

1 |

4 |

1 |

6 |

|

Storage |

1 |

0 |

0 |

1 |

|

Total Process |

14 |

37 |

25 |

76 |

|

Distance Traveled (m) |

45 |

96.6 |

54.14 |

195 |

|

Total Number of Workers |

5 |

6 |

8 |

19 |

3.3. Critical Waste

Identification

Questionnaires were distributed to

experts to rank the types of waste that occur in the production process.

Experts were asked to rate the types of waste with a rank of 1 to 8, then

processed using BCM. Table 3 shows the

result of the waste score.

Table

2 Overall Production

Process based on Current PAM

|

Value

Category |

Total |

Percentage |

Time (hh:mm: ss) |

Time Contribution |

|

VA |

34 |

44.7% |

14:10:23 |

57.00% |

|

NVA |

7 |

9.20% |

01:02:33 |

4.20% |

|

NNVA |

35 |

46.10% |

09:38:09 |

38.80% |

|

Total |

76 |

100.00% |

100.00% |

Table

3 Result of Waste

Score with Borda Count Method (BCM)

|

Waste |

Total |

Percentage |

Rank |

|

Waiting |

37 |

25.34% |

1 |

|

Transportation |

27 |

18.49% |

2 |

|

Unnecessary Motion |

22 |

15.07% |

3 |

|

Defect |

19 |

13.01% |

4 |

|

Overprocessing |

13 |

8.90% |

5 |

|

Excessive Inventory |

10 |

6.85% |

6 |

|

Non-Utilized Resource |

9 |

6.16% |

7 |

|

Overproduction |

9 |

6.16% |

8 |

From this score, it can be concluded that along the

production line, the three largest contributing wastes are: waiting,

transportation, and unnecessary motion. Waiting time between processes is

mostly caused by machine set-up processes and separate processes between

workstations. According to PAM, transportation is the second highest number of

processes after an operation. This was deemed too frequent and a cause for

concern with current production floor layout arrangements, requiring workers to

carry out more transporting activities. Unnecessary Motion occurs due to the

unnecessary movement of workers during the production process, which can be

caused by transportation and over-processing. The authors focused on solving

these problems in the next steps, as these already covered more than half of

the total score.

3.4. Determination of

Process Improvement Solutions

Based on as-is process analysis, we proposed

solutions based on BPR Best Practices. The Business Process Improvement Plan is

shown in Table 4. A solution was designed based on the proposed

implementation of two technologies, namely an automatic labeling machine and 3

in 1 integrated filling machine, to assist the production and packaging stages.

The implementation of this machine is proposed because, based on the As-Is

model, the packaging stage is the process that takes the longest time because

the labeling on the product packaging is done manually. With the implementation

of this machine, more precise labeling can be achieved in less time. The

automatic labeling machine can reduce the possibility of defects caused by

damaged labels due to worker errors. This, in turn, ensures that the use of

resources in the form of sticker labels is in line with the production plan and

does not require additional goods requests. Figure 3 shows the proposed To-be

production floor layout.

With the addition of a 3 in 1 machine,

the process of bottle washing, filling, and bottle closing can be carried out

in one machine, thus speeding up processing time and shortening process stages.

This machine is needed to balance the speed of the automatic labeling machine

so that starving does not occur. With the implementation of the 3 in 1

Integrated Filling Machine, there is no need for a bottle-washing workstation

because the bottle-washing phase is carried out directly on the proposed 3 in 1

machine. Using these solutions, we can reduce the total processes in the future

PAM (Tables 5 and 6). Comparing Table 5 with Table 1, we can see that the total

process is reduced from 76 to 48, the total distance traveled is reduced from

195 m to 127 m, and the total number of workers is reduced from 19 workers to 8

workers. Comparing Table 6 with Table 2, we can also see that total production

time is reduced from 24 hours 51 minutes 5 seconds to 12 hours 17 minutes 29

seconds, amounting 50.54% decrease in total time.

Table

4 Business Process

Improvement Plan.

Figure 3 Production Floor Layout for To-be Process. Yellow marked are layout

changes, and green marked are additional areas

The To-be model is mapped with BPMN based on the As-is

model. Figure 4 shows the To-be model of Puree Making stage, Figure 5 shows the

Production stage, and Figure 6 shows the Packaging stage of the “Signature”

Production Process. Processes marked in red are eliminated, yellow indicates a

change in processing time, green indicates a change in the sequence of

processes, and purple represents new processes that were added. There were no

changes in the Puree-making stage.

Table 5 Number of processes, the distance of movement,

and the number of workers of future PAM.

|

Waste |

Problem |

Solution |

BPR

Best Practices |

|

Process

Efficiency and Accuracy |

The

production process is done manually, and there are no accurate measuring

tools in the process, so the process takes a long time and produces a lot of

waste |

Automate

processes by implementing automated machines to reduce process work time,

increase the accuracy of resource use, and eliminate waste that occurs along

the production line |

Integral

Technology, Task Elimination, Parallelism |

|

Integration |

The

implementation of each phase in a process often changes places so that the

flow between processes is stagnant and intermittent |

Re-layout

on the production floor, which also requires process resequencing |

Resequencing,

Task Elimination |

|

Process |

Puree Making |

Production |

Packaging |

Total Process |

|

Operation |

9 |

14 |

6 |

29 |

|

Transportation |

3 |

6 |

1 |

10 |

|

Inspection |

0 |

4 |

1 |

5 |

|

Delay |

1 |

2 |

0 |

3 |

|

Storage |

1 |

0 |

0 |

1 |

|

Total Process |

14 |

26 |

8 |

48 |

|

Distance Traveled (m) |

44.71 |

69.54 |

13.24 |

127 |

|

Total Number of Workers |

4 |

2 |

2 |

8 |

Table

6 Overall Production

Process of Future PAM.

|

Value Category |

Total |

Percentage |

Time (hh:mm:ss) |

Time Contribution |

|

VA |

37 |

77.10% |

10:36:56 |

86.40% |

|

NVA |

0 |

0.00% |

0:00:00 |

0.00% |

|

NNVA |

11 |

22.90% |

1:40:33 |

13.60% |

|

Total |

48 |

100.00% |

12:17:29 |

100.00% |

Figure 4 To-be model of Puree Making Stage, include Process No. 1-14

3.5. Discussions

The implementation time of this solution takes around 3-5 days. Comparing Tables 1-2 and Tables 5-6, this solution is able to solve the NVA problem, reducing the total time from around 24 hours to just around 12 hours, reducing labor use from 19 workers to 8 workers, reducing the distance traveled from 195 m to 127 m amounting to 34.9% decrease of distance traveled, and reduce total production time from 24 hours 51 minutes 5 seconds to 12 hours 17 minutes 29 seconds amounting 50.54% decrease of total time. The automatic labeling machine has approximately 2.8 × 1.6 × 1.5 meters, and the 3 in 1 integrated filling machine has dimensions of 2.1 × 1.7 × 2.35 meters (Zhang and Li, 2015). The cost of procuring these machines may vary, depending on the capacity. In this case, with the production speed of 2,000 bottles per hour, the additional cost will be around $4,000 for the automatic labeling machine and $3,500 for 3 in 1 integrated filling machine.

Figure 5 To-be model of Production Stage, include Process No. 15-39

Figure 6 To-be model of Packaging Stage, include Process No. 40-63

In this research, we improved the business

process of the "Signature" production process and assess the waste

problems. Based on the discussion of the analysis that has been carried out

previously, the proposed process improvement results in the following

conclusions: Improvement solutions to improve process efficiency are designed

by combining the implementation of BPR best practices, namely integral

technology, task elimination, parallelism, and resequencing. To implement the

solutions, we changed the production floor layout, eliminated, parallelized,

and resequenced the production process, automated the bottle labeling process

by installing an automatic labeling machine, and combined and automated the

bottle washing, filling, and capping processes by installing a 3-in-1

integrated filling machine; These solutions resulted in a 34.9% reduction in

distance traveled and a 50.54% reduction in total processing time. This

research only provides the potential solutions for the improvement that needs

to be tested and selected. Further research can be done by selecting a solution

through a feasibility analysis. Research on problems and improvements in other

production lines also needs to be done, considering that PT API is not a

company that produces a single product but a multi-product. Future research can

also combines more detailed aspects of facilities planning, such as facilities

location and systematic layout planning.

Ahmad, A.N.A., Ahmad, M.F., Hamid, N.A., Ngadiman, Y., Pakir, M.I., Manawir, G., Bakri, A., Rahim, M., 2019. Process Time Improvements Through the Application of Value Stream Mapping Support Lean System. International Journal of Advanced Trends in Computer Science and Engineering, Volume 8, pp. 310–317 DOI: 10.30534/ijatcse/2019/4681.62019

https://doi.org/10.1093/rpd/ncy248

Al-Shammari, M., 2009. Redesigning

Processes. In Customer Knowledge Management: People, Processes, and

Technology, pp. 136–167 DOI:

10.4018/978-1-60566-258-9.ch005

Albanna, R.A., Karningsih, P.D.,

2018. Reduction of Waste on Freight Services of QWZ Company with Lean Service

Application. International Journal of Innovative Science and Research

Technology, Volume 3(1), pp. 689–697

Amrina, E., Andryan, R., 2019.

Assessing Wastes in Rubber Production using Lean Manufacturing: A Case Study. In: 2019

IEEE 6th International Conference on Industrial Engineering and

Applications (ICIEA), pp. 328–332 DOI: 10.1109/iea.2019.8714925

Anvari, A., Ismail, Y., Hojjati,

S.M.H., 2011. A Study on Total Quality Management and Lean Manufacturing:

Through Lean Thinking Approach. World Applied Sciences Journal, Volume

12(9), pp. 1585–1596

Badan Pusat Statistik (BPS), 2020.

Pengeluaran untuk Konsumsi Penduduk Indonesia (Spending for Consumption of

Indonesian Population). 1st Edition. Jakarta: Badan Pusat

Statistik

Badan Pusat Statistik (BPS), 2021.

Produksi Tanaman Buah-buahan, 1997-2020 (Production of Fruit Plants,

1997-2020). Available online at:

https://www.bps.go.id/indicator/55/62/1/produksi-tanaman-buah-buahan.html,

Accessed on January 30, 2021

Berawi, M.A., 2019. The Role of

Industry 4.0 in Achieving Sustainable Development Goals. International

Journal of Technology, Volume 10(4), pp. 644–647 DOI: 10.14716/ijtech.v10i4.3341

de Bucourt, M., Busse, R.,

Güttler, F., Reinhold, T., Vollnberg, B., Kentenich, M., Hamm, B., Teichgräber,

U.K., 2012. Process Mapping of PTA and Stent Placement in a University Hospital

Interventional Radiology Department. Insights Into Imaging, Volume

3, pp. 329–336 DOI:

10.1007/s13244-012-0147-2

Driouach, L., Zarbane, K., Beidouri,

Z., 2019. Literature Review of Lean Manufacturing in Small and Medium-sized

Enterprises. International Journal of Technology, Volume 10(5), pp.

930–941 DOI:

10.14716/ijtech.v10i5.2718

Dumas, M., Rosa, L.M., Mendling,

J., Reijers, A.H., 2018. Fundamentals of business process management.

Springer-Verlag. DOI:

10.1007/978-3-662-56509-4

Ekanayake, L.L., Ofori, G., 2004.

Building Waste Assessment Score: Design-Based Tool. Building and Environment, Volume

39(7), pp. 851–861 DOI: 10.1016/j.buildenv.2004.01.007

Emerson, P., 2013. The Original Borda

Count and Partial Voting. Social Choice and Welfare, Volume 40(2),

pp. 353–358 DOI:

10.1007/s00355-011-0603-9

Gaspersz, V., 2007. Lean Six

Sigma for Manufacturing and Service Industries. Jakarta: Gramedia Pustaka

Utama

Gunasekaran, A., Kobu, B., 2002. Modelling

and Analysis of Business Process Reengineering. International Journal of

Production Research, Volume 40(11), pp. 2521–2546 DOI: 10.1080/00207540210132733

Gupta, S., Jain, S.K., 2013. A Literature

Review of Lean Manufacturing. International Journal of Management

Science and Engineering Management, 8(4), pp. 241–249 DOI:

10.1080/17509653.2013.825074

Kumar, D., Bhatia, A., 2012. BPR-Organization

Culture, Best Practices and Future Trends. International Journal of

Computer Applications, 44(23), pp. 1–5 DOI: 10.5120/6424-8653

Kyfyak, V., Lopatynskyi, Y., 2018.

Methodical Approaches to Business Processes Reengineering at Modern Enterprises. Baltic

Journal of Economic Studies, Volume 4(4), pp. 151–158 DOI:

10.30525/2256-0742/2018-4-4-151-158

Liker, J.K., 2004. The Toyota

Way: 14 Management Principles from the World’s Greatest Manufacturer. 1st

Edition. McGraw-Hill

Mansar, S.L., Reijers, H.A., 2007.

Best Practices in Business Process Redesign: Use and Impact. Business

Process Management Journal, Volume 13(2), pp. 193–213 DOI: 10.1108/14637150710740455

Mansar, S.L., Reijers, H.A.,

Ounnar, F., 2009. Development of a Decision-Making Strategy to Improve the

Efficiency of BPR. Expert Systems with Applications, Volume 36(2),

pp. 3248–3262 DOI:

10.1016/j.eswa.2008.01.008

Martonová, I., 2013. The Integration

of TQM and BPR. Quality Innovation Prosperity, Volume 17(2),

pp. 59–76 DOI:

10.12776/qip.v17i2.186

Mikkelsen, J.S., Lydekaityte, J.,

Tambo, T., 2021. June. Optimization of Packaging Processes for Special Orders

Using Process Activity Mapping. In: Global Congress on Manufacturing and

Management, pp. 1–14 DOI:

10.1007/978-3-030-90532-3_1

Moinuddin, K., Collins, T.,

Bansal, A., 2007. Process Activity Mapping-Activity-Based Costing for Semiconductor

Enterprises. Journal of Cost Management, Volume 21(2), pp. 29–33

Mudiraj, A.R., 2014. BPR: The

First Step for ERP Implementation. International Research Journal of

Commerce Business Social Sciences (IRJCBSS), Volume 2(13), pp. 1–4

Mushtaq, M., 2018. Extraction of

Fruit Juice: An Overview. In: Fruit Juices: Extraction, Composition, Quality

and Analysis, pp. 131–159 DOI: 10.1016/b978-0-12-802230-6.00008-4

Orouskhani,

M., Teshnehlab, M., Nekoui, M.A., 2019. Evolutionary Dynamic

Multi-Objective Optimization Algorithm Based on Borda Count Method. International

Journal of Machine Learning and Cybernetics, Volume 10, pp. 1931–1959 DOI: 10.1007/s13042-017-0695-3

Pude, G.C., Naik, G.R., Naik,

P.G., 2012. Application of Process Activity Mapping for Waste Reduction a Case

Study in Foundry Industry. International Journal of Modern Engineering

Research, Volume 2(5), pp. 3482–3496

Rybicka, J., Tiwari, A., Del

Campo, P.A., Howarth, J., 2015. Capturing Composites Manufacturing Waste Flows

Through Process Mapping. Journal of cleaner production, 91,

pp. 251–261 DOI:

10.1016/j.jclepro.2014.12.033

Saragih, L.R., Dachyar, M.,

Zagloel, T.Y.M., 2021. Business Process Reengineering at ICT Operations, In

Managing Smart Cities as New Customers (Non-Human). International Journal of

Technology, Volume 12(2), pp. 378–389 DOI: 10.14716/ijtech.v12i2.4418

Satao, S.M., 2012. Enhancing Waste

Reduction Through Lean Manufacturing Tools and Techniques, a Methodical. International

Journal of Research in Management & Technology (IJRMT), Volume 2(2),

pp. 253–257

Singh, J., Singh, H., Singh, G.,

2018. Productivity Improvement Using Lean Manufacturing in Manufacturing

Industry of Northern India: A Case Study. International Journal of

Productivity and Performance Management, Volume 67(8), pp. 1394–1415 DOI: 10.1108/ijppm-02-2017-0037

Singh, S., Ramakrishna, S., Gupta,

M.K., 2017. Towards Zero Waste Manufacturing: A Multidisciplinary Review. Journal

Of Cleaner Production, Volume 168, pp. 1230–1243 DOI:

10.1016/j.jclepro.2017.09.108

Teichgräber, U.K., De Bucourt, M.,

2012. Applying Value Stream Mapping Techniques to Eliminate Non-Value-Added

Waste for the Procurement of Endovascular Stents. European Journal of

Radiology, 81(1), pp. e47–e52 DOI: 10.1016/j.ejrad.2010.12.045

Towill, D.R., 2001. The Process of

Establishing a BPR Paradigm. Business Process Management Journal, Volume

7(1), pp. 8–23 DOI:

10.1108/14637150110383872

Van Erp, M., Schomaker, L., 2000.

Variants of the Borda Count Method for Combining Ranked Classifier Hypotheses. In: 7th

International Workshop on Frontiers in Handwriting Recognition, pp. 443–452

Wahab, A.N.A., Mukhtar, M.,

Sulaiman, R., 2013. A Conceptual Model of Lean Manufacturing Dimensions. Procedia

Technology, Volume 11, pp.1292–1298 DOI: 10.1016/j.protcy.2013.12.327

Zhang, D., Li, S., 2015. Design

and Realization of Liquid Filling Machine Intelligent Control System. In:

2015 IEEE International Conference on Mechatronics and Automation, pp. 1283–1288 DOI: 10.1109/icma.2015.7237670

Zuting, K.R., Mohapatra, P.,

Daultani, Y., Tiwari, M.K., 2014. A Synchronized Strategy to Minimize Vehicle

Dispatching Time: A Real Example of Steel Industry. Advances in

Manufacturing, Volume 2, pp. 333–343 DOI: 10.1007/s40436-014-0082-1