Physical, Chemical and Electrical Conductivity Properties of Bismuth Oxide/ Rice Husk-Based Activated Carbon/Graphite Composite Prepared by the Hydrothermal Method

Corresponding email: yayuk.astuti@live.undip.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.5624

Astuti, Y., Annisa, L., Widodo, D.S., Darmawan, A., 2024. Physical, Chemical and Electrical Conductivity Properties of Bismuth Oxide/ Rice Husk-Based Activated Carbon/Graphite Composite Prepared by the Hydrothermal Method. International Journal of Technology. Volume 15(4), pp. 987-998

| Yayuk Astuti | Department of Chemistry, Faculty of Natural Sciences and Mathematics, Universitas Diponegoro, Jl. Prof. Jacob Rais, Tembalang, Semarang, Central Java 50275, Indonesia |

| Lifiany Annisa | Department of Chemistry, Faculty of Natural Sciences and Mathematics, Universitas Diponegoro, Jl. Prof. Jacob Rais, Tembalang, Semarang, Central Java 50275, Indonesia |

| Didik Setiyo Widodo | Department of Chemistry, Faculty of Natural Sciences and Mathematics, Universitas Diponegoro, Jl. Prof. Jacob Rais, Tembalang, Semarang, Central Java 50275, Indonesia |

| Adi Darmawan | Department of Chemistry, Faculty of Natural Sciences and Mathematics, Universitas Diponegoro, Jl. Prof. Jacob Rais, Tembalang, Semarang, Central Java 50275, Indonesia |

The synthesis of Bismuth

Oxide/Rice Husk-based

Activated Carbon/Graphite

(BO/RH-AC/G) composites using the hydrothermal method with varying

concentrations of bismuth nitrate pentahydrate has been conducted. The

composites are synthesized from bismuth nitrate pentahydrate, sodium sulfate,

and sodium hydroxide precursors added with activated carbon from rice husks and

graphite using the hydrothermal method at 110oC

for 5 hours. The characterization results show that the concentration of the

added bismuth nitrate pentahydrate precursor affects the physical, chemical,

and electrical properties of the resulting composites such as crystallinity,

presence of functional groups, pore and surface properties, morphology, element

distribution, thermal stability, and electrical conductivity. In the use of

smaller bismuth nitrate pentahydrate, composite has the highest crystallinity

containing mostly Bi2O3 having monoclinic crystal

structure, small pore size and high surface area. Each composite showed

different pattern of thermal decomposition. Moreover, most products have the

same rod-like morphology even though the highest precursor used resulted in

lumpy surface shape. The electrical conductivity of composites is higher than

that of pure bismuth oxide and rice husk-activated carbon.

Bismuth Oxide (BO); Composite; Graphite (G); Hydrothermal; Rice Husk-activated Carbon (RH-AC)

The battery is a source of energy supply that works by converting the

chemical energy contained in the active ingredients of the battery components

into electrical energy through electrochemical reactions of reduction and

oxidation (Reddy, 2011). Batteries have

important components that enable generate chemical reactions to create

electricity. These components include electrodes, electrolytes, and separators.

The electrode is the conductor in which the redox reaction takes place.

The battery electrode is divided into cathode and anode, which are the positive

and negative electrodes, respectively. The anode is a negative electrode, with

reference to the half-cell oxidation reaction, that releases electrons into the

external circuit (Subhan, 2011). Materials

that are able to be used as anodes must have properties that include good

charge/ion conductivity (>103 Sm-1), large energy capacity (Li

metal: 3850 mAh.g-1 (Goriparti et

al., 2014), and long life cycle, and they

also need to be easy to process, safe in use (non-toxic) and low in price.

Metal oxides (Li et al., 2021; Kim et al., 2019) have been studied intensively as somethe most promising candidates for

battery anodes due to their high theoretical capacities and low costs. One of

the metal oxides that have the potential to be used as an electrode is bismuth

oxide (Xu et al., 2022;

Nandi and Das, 2020). Expediently, bismuth oxide has high theoretical

capacity value (690 mAh.g-1), volumetric capacity value of 3765

mAh.cm-1, a potential difference of 2.8 V, is non-toxic, abundant,

and relatively cheap (Fang et al., 2017; Li et al.,

2013).

However, the problem with using bismuth oxide as a battery anode is that it

possesses low conductivity value which has a tendency to give a result of the

slow charge/ion conductivity of the battery anode. This low conductivity value,

however, is able to overcome by adding other materials that have the ability to

increase the conductivity value, namely activated carbon and graphite.

Activated carbon is an amorphous carbon consisting of a flat plate with

carbon atoms arranged and covalently bonded in a hexagonal lattice (Gilles and Loehr, 1994). Activated carbon has a

conductivity value of 6.04 S.m-1 and a large surface area between

300 m2.g-1 to 3500 m2.g-1 (Kim et al., 2016). A large surface area is

one of the advantageous factors that comprise an electrode material (Ariyanto,

Prasetyo, and Rochmadi, 2012), whereby the larger the

surface area, the greater the capacitance value (Ciszewski

et al., 2015). In addition to the surface area, the volumetric

capacity of 1770 mAh.cm-1 and a potential difference of 0.2 V (Kim et al., 2016) of activated carbon are

highly sought-after in an electrode-making material (Bijesh, Selvaraj, and Andal, 2022).

Graphite is one of the carbon core materials that act as an electrical

conductor and able to be used as an electrode material (Sari,

2015). Graphite has the characteristics of being soft, light, and

capable of conducting electricity, though graphite has a low theoretical

capacity (372 mAh.g-1) (Fang et al.,

2017).

2.1. Materials

The materials used in this study are Bi(NO3)3.5H2O

(sigma aldrich), H3PO4 (Merck), Na2SO4

(Merck), NaOH (Merck) bought from Darmstadt-Germany, rice husks, and distilled

water.

2.2. Research Procedure

2.2.1.

Rice Husk-Based Activated

Carbon Production

The production of rice

husk-based activated carbon followed the procedure reported by Arnelli, Santoso, and Astuti (2021). Clean rice husks were charred by pyrolysis at 300oC

for 10 minutes. A total of 5 grams of the carbon produced were activated by the

addition of 125 mL 60% H3PO4 and processing in the

microwave with a power of 400 W for 5 minutes. The activated carbon was then

washed with distilled water until the pH was constant. The activated carbon

that had been washed was then dried using an oven at 105oC for 5

minutes. The resulting activated carbon was destructed and sieved to a size of

100 mesh.

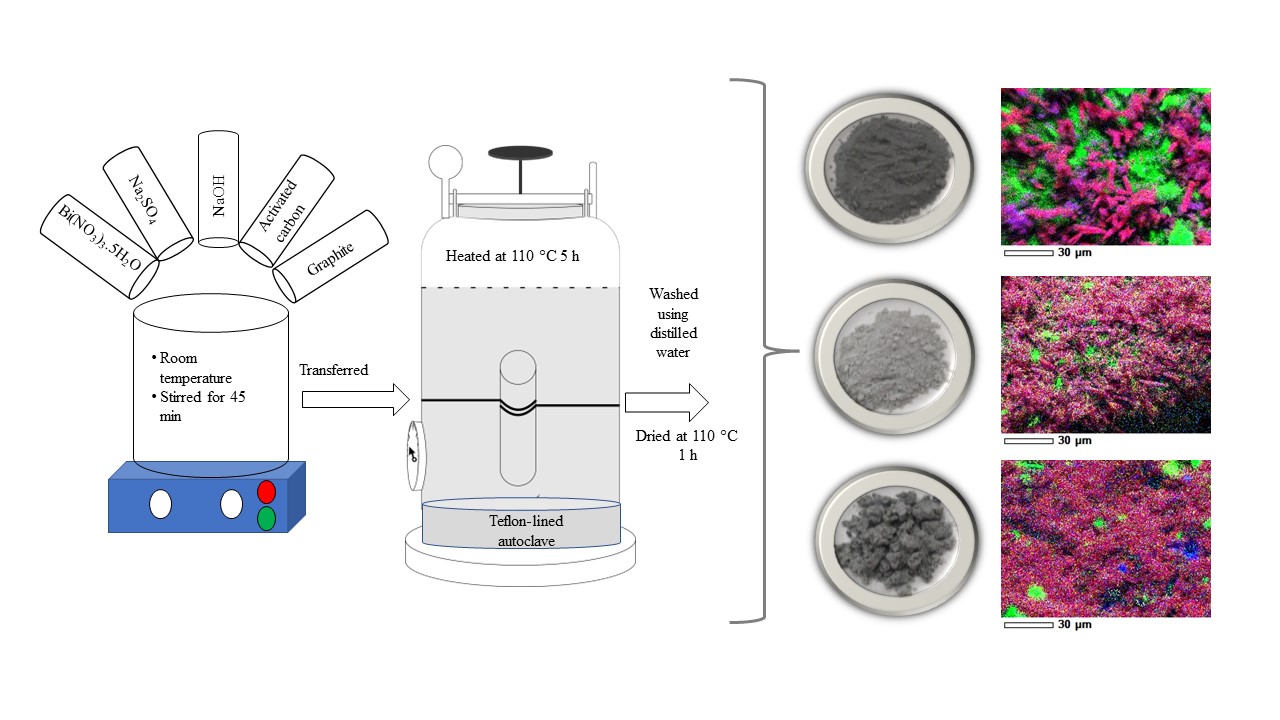

2.2.2.

Synthesis of Bismuth

Oxide/Rice Husk-Activated Carbon/Graphite Composite

The synthesis of BO/RH-AC/G composites

was carried out using the hydrothermal method with variations in Bi(NO3)3.5H2O

of 8, 24, and 32 mmol. For the 8 mmol BO/RH-AC/G variation, initially 8 mmol of

bismuth nitrate pentahydrate was added with 12 mmol of Na2SO4.

They were dissolved in 40 mL of distilled water and then stirred using a

magnetic stirrer for 45 minutes. Later, 40 mL of 72 mmol of NaOH was added to

the solution mixture followed by 0.5 grams of rice husk-activated carbon and

0.1 grams of graphite and the mixture was stirred. The mixture was then poured

into a stainless-steel tube and into a hydrothermal reactor, heated at 110oC

for 5 hours. At the final stage, the product was filtered and dried using an

oven at a temperature of 110oC for 1 hour, then sieved to a size of

100 mesh. The same procedure was used to synthesize the 24 mmol and 32 mmol

BO/RH-AC/G composites. The three composite products were labeled[BO/RH-AC/G]1,

[BO/RH-AC/G]2 and [BO/RH-AC/G]3 for the composites that

were synthesized with variations of 8 mmol, 24 mmol, and 32 mmol, respectively.

2.2.3.

Characterization of the Bismuth Composite Material

The characterizations of the three

composites were carried out using Fourier

Transform Infrared Spectroscopy (FTIR), X-ray Diffraction (XRD),

Scanning Electron

Microscopy (SEM), Thermo Gravimetric Analyzer-Derivative Thermogravimetri

(TGA-DTG), Inductance,

Capacitance, and

Resistance (LCR), and Gas Sorption Analyzer (GSA) instruments. The characterization of the composite

products by FTIR (Shimadzu IRAffinity-1) was carried out in the wave number

range of 400 cm-1 - 4000 cm-1 to determine the presence

of functional groups in the resulting composite products. Analysis of composite

products using XRD (Shimadzu 7000) was done with 2theta ()= 0 to 90, to

identify the crystal structure of bismuth oxide in the synthesized composites.

Furthermore, the Scanning Electron Microscope-Energy Dispersive X-Ray (SEM-EDX)

instrument (Jeol JED 6510LA) was used to identify the surface morphology of the

sample and the compositions of the composites. A mapping test was also carried

out to determine the distribution of the elements that make up the composite

materials. The characterization of the composite products using TGA (Mettler

Toledo TGA/DSC 3+) was used to determine the thermal stability of the

composites. Meanwhile, the electrical conductivities of the composite products

were determined using an LCR meter (HIOKI 3532-50). Composite characterization

with GSA (Tristar II 3020) was carried out with N2 gas adsorbate to

determine the surface area, pore volume, and pore size of the composites.

3.1

BO/RH-AC/G Composite

The synthesis of BO/RH-AC/G composites

was initiated by reacting the precursor materials consisting of Bi(NO3)3.5H2O,

Na2SO4, and NaOH according to the procedure reported by Wu et al. (2011). Subsequently, the

solution was added with rice husk-activated carbon and graphite, homogenized,

and heated in a hydrothermal reactor.

Figure

1 Synthesized (a)

[BO/RH-AC/G]1 (b) [BO/RH-AC/G]2 and (c) [BO/RH-AC/G]3

composites

3.2 BO/RH-AC/G Composite Material

Characteristics

3.2.1. Composites Functional Groups Structures

Figure 2 FTIR spectra

of composite products, graphite, activated carbon, bismuth oxide pentahydrate

The

composite products also contain activated carbon, indicated by the presence of

the absorption of the C-O group at the wave numbers of 1118 cm-1,

1103.10 cm-1, and 1112.16 cm-1 for the [BO/RH-AC/G]1,

[BO/RH-AC/G]2, and [BO/RH-AC/G]3 products, respectively.

The absorption of the C=C group which indicates the presence of activated

carbon and graphite was also observed in the three composites at wave numbers

of 1631 cm-1, 1634.94 cm-1, and 1645.85 cm-1.

The existence of the two absorption areas is consistent with a conducted by (Sastrohamidjojo, 2018), stating that activated

carbon is characterized by a sharp absorption at wave number 1626.64 cm-1

indicating the presence of the C=C group and absorption at wave number 1039.87

cm-1 that denotes the C-O group. The absorption of the C=C group at

the wave number 1630 cm-1 also indicates the presence of graphite (Huang et al., 2017).

The identifications of the functional groups in the composite samples, pure Bi2O3,

rice husk-activated carbon, and graphite are summarized in Table 1.

3.2.2.

Crystal Structures

The XRD characterization results of the

composites are depicted in Figure 3. Composite [BO/RH-AC/G]3 has

sharp peaks at 2 theta () 21.720o; 28.896o; and 33.211o.

The peaks have similarities with the peaks in the pure Bi(NO3)3.5H2O

diffractogram, namely at 21.943o; 28.7854o, and 32.783o.

Meanwhile, the composite [BO/RH-AC/G]2 possesses no sharp and

specific peaks, meaning it is possible that the amounts of

-Bi2O3

crystals formed in this composite was small making the sample amorphous.

Figure 3

Diffractograms of the [BO/RH-AC/G]1, [BO/RH-AC/G]2, and

[BO/RH-AC/G]3 composites, rice husk-activated carbon, graphite, and

bismuth nitrate pentahydrate (BNP)

3.2.3. Morphology and Elemental

Distribution

Composite

analysis results using SEM presented in Figure 4a and b and shows that the

composite products [BO/RH-AC/G]1 and [BO/RH-AC/G]2 at

magnifications of 1000x and 5000x have almost the same rod-like morphology. The

[BO/RH-AC/G]1 composite has rod-like particles with a length of 2.72–20.9 and a width of 2.72–8.28

, while the [BO/RH-AC/G]2 is 3.63–18.18

long and 0.9–3.36

wide. The shape of the particle is distinct from the

shape of the Bi2O3 particles as reported by Yakout (2020). Meanwhile, in Figure 4c, the

composite [BO/RH-AC/G]3 has an irregular and a lumpy surface shape.

Bismuth oxide synthesized using the hydrothermal method generates rod-like

shape particles (Astuti et al., 2022b) meanwhile

other methods result in irregular shapes (Astuti et al., 2021; Astuti

et al., 2020a; 2020b). This morphology affects the value of the electrical conductivity of

bismuth oxide (Astuti et al., 2022b).

The particle shapes in one dimension including wires, rods, or tubes are the

most magnificent shape for developing the electrochemical behavior due to the

large surface areas and the shortened ion diffusion paths (Yousif et al., 2022).

Figure 5 Mapping of (a) [BO/RH-AC/G]1; (b)

[BO/RH-AC/G]2; (c) [BO/RH-AC/G]3

3.2.4. Composite Thermal Stability

The TGA-DTG curves of the [BO/RH-AC/G]1

composite (Figure 6a) shows five stages weight loss. The first and second

stages occurred at the temperatures between 200–380oC in which

around 0.2% and 13% of mass are lost and are attributed to the removal of NaOH,

NaNO3, and SO42- residues as well as the mass lost from the

transformation of the precursors into Bi2O3 (Zhang et al., 2011). In stage three, there was a further Bi2O3

formation process which occurred at temperatures between 400 – 450oC

with mass loss of around 2% (Ma et al., 2010; Christensen et al., 2003). In stage four, about 0.2% weight reduction was

observed 0.2% at 500oC, denoting the phase transition from -Bi2O3

to

-Bi2O3 (Shen et

al., 2012). The fifth stage at

640oC indicated by a weight loss of about 0.2% is identified as the

phase transition from

-Bi2O3 to

-Bi2O3

(Klinkova et al., 2007).

There are four stages of mass loss that occurred

in [BO/RH-AC/G]2 as shown in Figure 6.b. The first stage was able to

be observed at temperatures between 200–380oC where there was a

weight loss of about 9% which was able to be attributed to the removal of

residues such as NaOH, NaNO3, and SO42- and

the mass loss from the transformation from the precursors to Bi2O3

(Zhang et al., 2011). In the second stage, there was a reduction in

weight at temperatures between 400–450oC as much as 1.5%, representing the

process of further formation of Bi2O3 (Ma et al., 2010; Christensen et al., 2003). In the third stage, there was a reduction in weight of 0.5% at the

temperatures around 500oC denoting the phase transition from -Bi2O3

to

-Bi2O3 (Shen et

al., 2012). In the last stage,

at 640oC, mass loss of about 2% occurred, which is the phase

transition from

-Bi2O3 to

-Bi2O3 (Klinkova et al., 2007).

Figure 6 TGA and DTG curves

of (a) [BO/RH-AC/G]1; (b) [BO/RH-AC/G]2; (c) [BO/RH-AC/G]3

composites

The [BO/RH-AC/G]3 composites

underwent three stages of mass loss as shown in Figure 6.c. In the first stage,

there was a weight loss of 8% at temperatures between 200-275oC

which may be derived from the removal of functional groups (-COO-, -CO-, -OH-,

and hydrate) from graphite (Deng et al., 2017). The second stage was accentuated by a mass

reduction of 10% at the temperature of about 400oC which was

assigned to the transformation of the precursors to form Bi2O3

(Ma et al., 2010). In the third stage, a mass loss of 0.2% occurred at the temperature of

about 500oC which was attributed to the phase transition from (Shen et

al., 2012).

3.2.5

Composite Electrical Conductivity

The ionic and electrical conductivity of

a material is determined by its crystal structure. The electrical conductivity

values of the three composite products, pure bismuth oxide (Bi2O3),

activated carbon and graphite are presented in Table 2.

Table 2 shows that

the electrical conductivity value of pure Bi2O3 is very

low. So is the case of the rice husk-based activated carbon with its electrical

conductivity value. Meanwhile graphite as the dopant has a high conductivity

value. The three composites that have been formed have higher electrical

conductivity values than pure Bi2O3 and activated carbon

from rice husks. The rice husk-activated carbon added into the composite

functions as a matrix so that the distribution of bismuth oxide particles is

more even, which would make it easier for the electrons to flow, thus allowing

good electrical conductivity.

The [BO/RH-AC/G]3

composite product has the highest electrical conductivity value compared to the

[BO/RH-AC/G]1 and [BO/RH-AC/G]2 composites. This is

because there are more initial precursors contained, in which bismuth nitrate

pentahydrate has a high electrical conductivity value, causing the electrical

conductivity of the [BO/RH-AC/G]3 composites to be high.

The [BO/RH-AC/G]2

composite has the smallest electrical conductivity value. The value of the

electrical conductivity is influenced by the crystallinity of a material. The

more crystalline a material is, the higher its electrical conductivity it

becomes (Kim, Lee, and Jang, 2014). The XRD

data presented that the [BO/RH-AC/G]3 and [BO/RH-AC/G]1

are crystalline, while [BO/RH-AC/G]2 is amorphous. Therefore, the

electrical conductivity value [BO/RH-AC/G]2 is low.

The [BO/RH-AC/G]1 has an

electrical conductivity value in between the [BO/RH-AC/G]3 and

[BO/RH-AC/G]2. This is attributed to the successfully formed Bi2O3

confirmed through the XRD and FTIR data. The XRD data showed that the composite

[BO/RH-AC/G]1 contained Bi2O3 crystals and

the FTIR spectra confirmed the presence of the Bi-O group with the highest

intensity.

3.3.6 Pore and Surface Properties

Figure 7 Nitrogen adsorption-desorption isotherm

graphs of (a) [BO/RH-AC/G]1; (b) [BO/RH-AC/G]2; and (c)

[BO/RH-AC/G]3

Table 3

shows that the more the bismuth nitrate pentahydrate precursor is used, the

larger the pore size, the smaller the pore volume, and thus the smaller the

surface area. This is because a higher amount of Bi (NO3)3.5H2O in the composite

would mean that more activated carbon would be covered resulting in less number

of pores, as activated carbon has a large surface area of 18.83 m²/g. Based on

the resulting data, [BO/RH-AC/G]1 has the largest surface area and

[BO/RH-AC/G]3 has the smallest. The data is supported by the XRD

data (Figure 3), in which [BO/RH-AC/G]3 composite formed still

contained a lot of bismuth nitrate pentahydrate.

Larger pore size allows for faster ion transport (Hu et al., 2016). If the pore size is

large, the number of pores become less and thus generate lower resistance. This

allows more ions to flow more, resulting in a higher electrical conductivity

value. This is in accordance with the LCR data (Table 2) in which [BO/RH-AC/G]3

has the highest electrical conductivity.

The

physical, chemical, and electrical properties of BO/RH-AC/G composite prepared

by the hydrothermal method are influenced by the amount of bismuth nitrate

pentahydrate precursor added. A real difference is seen in the formation of

bismuth oxide (Bi2O3) in the resulting composite. In the

use of 8 mmol bismuth nitrate pentahydrate, the composite has the highest

crystallinity. The high amount of the precursor added also causes the composite

to tend to clump. Regarding the thermal stability as well as pore and surface

properties, each composite showed successively different patterns of thermal

decomposition and surface area and pore size. Meanwhile, the nature of the

electrical conductivity indicates that the high amount of precursor added

causes the electrical conductivity value to be higher, which may be promoted

from the precursor itself.

The authors fully acknowledged the

Institute for Research and Community Services (LPPM) of Diponegoro University

for the research funding through the World Class Research Universitas

Diponegoro (WCRU) 2021 scheme with the grant No.118-12/UN7.6.1/PP/2021.

Ariyanto, T., Prasetyo, I., Rochmadi,

R., 2012. The

Effect of Pore Structure on the Capacitance of Supercapacitor Electrodes Made

of Carbon Nanopores. Reaktor, Volume

14(1), pp. 25–32

Arnelli, Santoso, B., Astuti,

Y., 2021.

Modification of Activated Carbon of Rice Husk

using HDTMA-Br (SMAC) Surfactant

as Nitrite Ion (NO2?) Adsorbent. In: Journal

of Physics: Conference Series, IOP Publishing, Volume 1943(1), p. 012159

Astuti, Y., Amri, D., Widodo, D.S., Widiyandari, H., Balgis, R., Ogi, T., 2020a. Effect of Fuels on the Physicochemical

Properties and Photocatalytic Activity of Bismuth Oxide, Synthesized using

Solution Combustion Method. International Journal of Technology Volume 11(1), pp. 26–36

Astuti, Y., Aprialdi, F., Haryanto, I., 2019. Synthesis of Activated Carbon/Bismuth

Oxide Composite and its Characterization for Battery Electrode.

In: IOP Conference Series: Materials Science and

Engineering, IOP Publishing, Volume

509(1), p. 012153

Astuti, Y., Elesta, P.P., Widodo, D.S., Widiyandari, H., Balgis, R., 2020b. Hydrazine and Urea Fueled-solution

Combustion Method for Bi2O3 Synthesis: Characterization of Physicochemical Properties and Photocatalytic Activity. Bulletin of Chemical Reaction

Engineering and

Catalysis, Volume 15(1),

pp. 104–111

Astuti, Y., Fauziyah, A., Nurhayati, S., Wulansari, A.D., Andianingrum, R., Hakim, A.R., Bhaduri, G., 2016.

Synthesis of ?-Bismuth Oxide

using Solution Combustion Method and its Photocatalytic Properties. In: IOP

Conference Series: Materials Science and Engineering, IOP Publishing, Volume 107(1), p. 012006

Astuti, Y., Listyani, B.M., Suyati, L.,

Darmawan, A.,

2021. Bismuth Oxide Prepared by Sol-Gel Method: Variation of Physicochemical

Characteristics and Photocatalytic Activity Due to Difference in Calcination

Temperature. Indonesian Journal of Chemistry, Volume 21(1), pp. 108–117

Astuti, Y., Mei, R., Darmawan,

A., Arnelli, A., Widiyandari, H., 2022a. Enhancement of Electrical

Conductivity of Bismuth Oxide/Activated Carbon Composite. Scientia Iranica, Volume 29(6), pp. 3119–3131

Astuti, Y., Musthafa, F., Arnelli, A.,

Nurhasanah, I.,

2022b. French Fries-Like Bismuth Oxide: Physicochemical Properties, Electrical

Conductivity and Photocatalytic Activity. Bulletin of Chemical Reaction

Engineering and Catalysis,

Volume 17(1),

pp. 146–156

Bandyopadhyay, S., Dutta, A.,

2017. Thermal, Optical and Dielectric Properties of Phase Stabilized

?–Dy-Bi2O3 Ionic Conductors. Journal of Physics and

Chemistry of Solids, Volume 102,

pp. 12–20

Bartonickova, E., Cihlar, J.,

Castkova, K., 2007.

Microwave-assisted Synthesis

of Bismuth Oxide. Processing and Application of

Ceramics, Volume 1(1-2),

pp. 29–33

Bijesh, P., Selvaraj, V., Andal, V., 2022. A Review on Synthesis and Applications of Nano Metal

Oxide/porous Carbon Composite. Materials Today: Proceedings,

Volume 55, pp.

212–219

Byrappa, K., Yoshimura,

M., 2000. Hydrothermal Growth of Some Selected

Crystals. In Handbook of

Hydrothermal Technology, Nowrwich: William Andrew Publishing, pp. 198–314

Christensen, A. N., Jensen,

T.R., Scarlett, N.V., Madsen, I.C., Hanson, J.C., Altomare, A., 2003. In-situ X-ray Powder Diffraction

Studies of Hydrothermal and Thermal Decomposition

Reactions of Basic Bismuth

(iii) Nitrates in the Temperature Range 20–650 C. Dalton Transactions, Volume 16,

pp. 3278–3282

Ciszewski, M., Mianowski, A., Szatkowski, P., Nawrat, G.,

Adamek, J., 2015.

Reduced Graphene Oxide–bismuth Oxide Composite

as Electrode Material for Supercapacitors. Ionics, Volume 21(2), pp. 557–563

Deng, Z., Liu, T., Chen, T., Jiang, J., Yang, W., Guo, J., Zhao, J., Wang, H.,

Gao, L.,

2017. Enhanced Electrochemical Performances of Bi2O3/rGO

Nanocomposite via Chemical Bonding as Anode Materials

for Lithium Ion Batteries.

American Chemical Society (ACS) Applied Materials and Interfaces,

Volume 9(14),

pp. 12469–12477

Fang, W., Fan, L., Zhang, L., Zhang, Q., Yin, Y., Zhang, N., Sun, K., 2017. Synthesis of Carbon Coated

Bi2O3 Nanocomposite

Anode for Sodium-ion Batteries. Ceramics International, Volume 43(12), pp. 8819–8823

Gilles, D.G., Loehr,

R.C., 1994. Waste Generation

and Minimization in Semiconductor Industry. Journal of Environmental

Engineering, Volume 120(1),

pp. 72–86

Goriparti, S., Miele, E., De

Angelis, F., Di

Fabrizio, E., Zaccaria, R.P., Capiglia, C., 2014. Review on Recent Progress

of Nanostructured Anode Materials

for Li-ion Batteries. Journal of

Power Sources, Volume 257,

pp. 421–443

Gupta, S., Aberg, B.,

Carrizosa, S.B.,

2016. Hydrothermal Synthesis of Vanadium Pentoxides–Reduced Graphene Oxide

Composite Electrodes for Enhanced Electrochemical Energy Storage. Materials Research Society (MRS) Advances,

Volume 1(45),

pp. 3049–3055

Hu, J., Sun,

C.-F., Gillette, E., Gui,

Z., Wang, Y., Lee, S.B., 2016. Dual-template Ordered Mesoporous

Carbon/Fe2O3

Nanowires as Lithium-ion Battery Anodes.

Nanoscale, Volume 8(26),

pp. 12958–12969

Huang,

Z., Li, Z., Zheng, L., Zhou, L., Chai, Z., Wang, X., Shi, W., 2017. Interaction

Mechanism of Uranium (VI) with Three-dimensional Graphene Oxide-chitosan Composite:

Insights from Batch Experiments, Infrared (IR), X-ray Photoelectron Spectroscopy

(XPS), and Extended X-ray Absorption Fine Structure Spectroscopy (EXAFS) Spectroscopy.

Chemical Engineering Journal, Volume 328, pp. 1066–1074

Kim,

M., Lee, C., Jang, J., 2014. Fabrication of Highly Flexible, Scalable, and High-performance

Supercapacitors using Polyaniline/Reduced Graphene Oxide Film with Enhanced Electrical

Conductivity and Crystallinity. Advanced Functional Materials, Volume 24(17),

pp. 2489–2499

Kim,

T., Jo, C., Lim, W.-G., Lee, J., Lee, J., Lee, K,-H., 2016. Facile Conversion

of Activated Carbon to Battery Anode Material using Microwave Graphitization. Carbon,

Volume 104, pp. 106–111

Kim,

T., Song, W., Son, D.Y., Ono, L.K., Qi, Y., 2019. Lithium-ion Batteries: Outlook

on Present, Future, and Hybridized Technologies. Journal of Materials

Chemistry A, Volume 7(7), pp. 2942–2964

Klinkova,

L.A., Nikolaichik, V.I., Barkovskii, N.V., Fedotov, V.K., 2007. Thermal Stability

of Bi2O3. Russian Journal of Inorganic Chemistry, Volume

52(12), pp. 1822–1829

Li,

Q., Li, H., Xia, Q., Hu, Z., Zhu, Y., Yan, S., Ge, C., Zhang, Q., Wang, X., Shang,

X., Fan, S., Long, Y., Gu, L., Miao, G.-X., Yu, G., Moodera, J.S., 2021. Extra Storage

Capacity in Transition Metal Oxide Lithium-ion Batteries Revealed by in Situ Magnetometry.

Nature Materials, Volume 20(1), pp. 76–83

Li,

Y., Trujillo, M.A., Fu, E., Patterson, B., Fei, L., Xu, Y., Deng, S., Smirnov,

S., Luo, H., 2013. Bismuth Oxide: A New Lithium-ion Battery Anode. Journal

of Materials Chemistry A, Volume 1(39),

pp. 12123–12127

Ma,

M.-G., Zhu, J.-F., Sun, R.-C., Zhu, Y.-J., 2010. Microwave-assisted Synthesis

of Hierarchical Bi2O3 Spheres Assembled from Nanosheets with Pore Structure. Materials

Letters, Volume 64(13), pp. 1524–1527

Nandi,

S., Das, S.K., 2020. An Electrochemical Study on Bismuth Oxide (Bi2O3)

as an Electrode Material for Rechargeable Aqueous Aluminum-ion Battery. Solid

State Ionics, Volume 347, p. 115228

Reddy,

T.B., 2011. Linden's Handbook of Batteries. Mcgraw-hill Education, New

York

Sari,

K., 2015. Manufacturing Lithium Batteries Using Active Mesocarbon Microbead

(MCMB) As Anode With Variation in Weight Percentage of Solvent N, N-Dimethyl

Acetamide (DMAC). University of North Sumatra Institutional Repository

Sastrohamidjojo,

H., 2018. Dasar-Dasar Spektroskopi (Spectroscopy Basics). Gadjah Mada

University Press

Shen,

Y.D., Li, Y.W., Li, W.M., Zhang, J.Z., Hu, Z.G., Chu, J.H., 2012. Growth of Bi2O3

Ultrathin Films by Atomic Layer Deposition. The Journal of Physical

Chemistry C, Volume 116(5), pp. 3449–3456

Subhan,

A., 2011. Fabrication and Characterization of Li4Ti5O12

for Lithium Ceramic Battery Anode Material= Synthesis and Characterization of

Li4Ti5O12 as Anode Material for Lithium Ceramic

Battery. University of Indonesia Thesis, University of Indonesia Library

Wu,

C., Shen, L., Huang, Q., Zhang, Y.-C., 2011. Hydrothermal Synthesis and Characterization

of Bi2O3 Nanowires. Materials Letters, Volume 65(7),

pp. 1134–1136

Xu,

M., Niu, Y., Teng, X., Gong, S., Ji, L., Chen, Z., 2022. High-capacity Bi2O3

Anode for 2.4 V Neutral Aqueous Sodium-ion Battery-supercapacitor Hybrid Device

Through Phase Conversion Mechanism. Journal of Energy Chemistry, Volume 65,

pp. 605–615

Yakout,

S. M., 2020. ?-Bi2O3/?-Ni(OH)2 Composites: Effective

Solar Light Photocatalysts for Organic Pollutants Degradation. Ceramics

International, Volume 46(14), pp. 22504–22512

Yousif,

Q. A., Ranjeh, M., Ghiyasiyan-Arani, M., Al-Nayili, A., Monsef, R., Salavati-Niasari,

M., 2022. Morphology Engineering of LiFeO2 Nanostructures Through Synthesis

Controlling for Electrochemical Hydrogen Storage Inquiries. Fuel, Volume

313, p. 123025

Zhang,

L., Hashimoto, Y., Taishi, T., Nakamura, I., Ni, Q.-Q., 2011. Fabrication of Flower-shaped

Bi2O3 Superstructure by a Facile Template-free Process. Applied

surface science, Volume 257(15), pp. 6577–6582