Instability of Detonation Wave at Downstream of Aluminum Crimped Ribbon

Corresponding email: jayan@ugm.ac.id

Published at : 17 May 2024

Volume : IJtech

Vol 15, No 3 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i3.5616

Sentanuhady, J., Prasidha, W., Majid, A.I., Muflikhun, M.A., 2024. Instability of Detonation Wave at Downstream of Aluminum Crimped Ribbon. International Journal of Technology. Volume 15(3), pp. 492-504

| Jayan Sentanuhady | Departement of Mechanical and Industrial Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jl. Grafika No.2, Sinduadi, Mlati, Sleman, D.I. Yogyakarta, 55281 Indonesia |

| Willie Prasidha | Departement of Mechanical and Industrial Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jl. Grafika No.2, Sinduadi, Mlati, Sleman, D.I. Yogyakarta, 55281 Indonesia |

| Akmal Irfan Majid | Departement of Mechanical and Industrial Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jl. Grafika No.2, Sinduadi, Mlati, Sleman, D.I. Yogyakarta, 55281 Indonesia |

| Muhammad Akhsin Muflikhun | Departement of Mechanical and Industrial Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jl. Grafika No.2, Sinduadi, Mlati, Sleman, D.I. Yogyakarta, 55281 Indonesia |

Natural gas is a very

reactive fuel that easily causes a detonation wave, especially when the

oxidizer is enriched with oxygen or pure oxygen. If the combustion wave is not

controlled, a detonation wave can occur, which is dangerous for the safety of

workers and industrial facilities. This study was conducted to develop a

prototype of a detonation arrester to control detonation waves by using a

detonation test tube with a total length of 3000 mm. The characteristics of the

combustion wave were evaluated in the present study using a pressure sensor, an

ion probe sensor, and a soot track record plate. Results showed that the

propagation velocity of the combustion wave and the shock wave pressure

increased, whereas the detonation cell size and the reinitiation distance

decreased. The experiments performed were able to produce a shock wave pressure

that was close to the Chapman–Jouguet pressure. The use of a detonation

arrester model could reduce the shock wave pressure and the velocity of the

combustion wave. At the initial pressure of the gas mixture of natural

gas–oxygen of 10 kPa, the observed combustion phenomenon was deflagration. By

contrast, when the initial pressure of the gas mixture of natural gas–oxygen

was increased to 20 kPa, the observed combustion phenomenon was detonation

quenching. Furthermore, increasing the

initial pressure of the natural gas-oxygen mixture to 30 kPa or higher led to

detonation wave propagation as the observed combustion phenomenon.

Arrester model; Detonation quenching; Detonation reinitiation; Detonation wave

Natural gas, which mainly consists of methane gas, is a fuel that is often used in industrial processes (Faramawy, Zaki, and Sakr, 2016). The use of natural gas as a fuel is also considered to fulfill energy needs in various applications, including transportation sectors, industries, and households (Supriyanto et al. 2022; Farizal, Dachyar, and Prasetya 2021; Rosyidi et al. 2020). Natural gas plays a crucial role as a transition fuel for sustainable energy systems toward a cleaner environment (Ediger and Berk, 2023; Bugaje et al., 2022; Mohammad et al., 2021; Safari et al., 2019). Meanwhile, to meet the safety standard, the design of an industrial system should consider any hazardous aspects, for example, a spontaneous fire (Thabari et al. 2023), and high propagation flame which may cause severe accidents (Hou et al., 2022; Zardasti et al., 2017; Sovacool, 2008). Interestingly, natural gas easily reacts and causes a detonation wave, particularly when the oxidizer is enriched with oxygen or pure oxygen, such as in glass-forming industries. worse conditions, the natural gas mixture may induce detonation during transport and storage (Sun and Lu, 2020b).

Detonation is a combustion wave that propagates

at supersonic velocity and increases when the pressure reaches 20 to 30 times

the initial pressure (Zhang et al., 2020). In more detail, it is also defined as a

reactive shockwave that propagates at a nearly ideal Chapman-Jouguet (CJ)

velocity, trailed by chemical reactions (Lee, 2008). Consequently, the compression and ignition of the

air-fuel mixture by the shockwave lead to an energy release, supports the shockwave propagation (Pan et al., 2017). The detonation wave

created in a combustible gas mixture can be very dangerous if it interacts with human bodies or artificial

structures due to the high pressure and temperature behind the wave. The

detonation behavior can be the detonation wave was quenched, and the detonation

wave was initially quenched behind the block but then re-initiated again due to

the focusing mechanisms of a reflected shock wave on a central axis (Obara et al. 2006a; 2006b). Detonation

control can be applied by converting the detonation wave into the deflagration

wave, which has less energy, to prevent damage caused by the detonation wave (Sun et al., 2022; Ciccarelli, Johansen, and

Parravani, 2011). A simple method to reduce the detonation wave is to

reduce the channel diameter. The study was conducted by Gholamisheeri, Wichman, and Toulson (2017) using

experiments and simulations where the detonation propagation can also be

controlled in tube and obstacle geometries.

Furthermore, one of the methods that can be used to convert

detonation into deflagration is to absorb the wave energy, which can be

absorbed by installing the orifice or arrester in the detonation track. This

method is supported by experiments using the channel geometry that can affect

the flame acceleration and deflagration to detonation transition (DDT) in a

detonable mixture (Azadboni et al., 2017;

Ettner, Vollmer, and Sattelmayer, 2014) and can be adapted

without disturbing the gaseous fuel flow.

Several researchers have conducted studies of detonation propagation and control using a plate with an orifice for the hydrogen-oxygen gas mixture. Their results showed that the orifice with small holes caused the detonation quenching phenomenon. Otherwise, the presence of an obstacle in the pipeline ensured the easy and rapid development of flame acceleration from the deflagration wave to the detonation wave (Sun and Lu, 2020a; Wang et al., 2018a; Rainsford, Aulakh, and Ciccarelli, 2018; Cross and Ciccarelli, 2015; Teodorczyk, Drobniak, and Dabkowski, 2009). The reinitiation of detonation is influenced by the detonation instability, which is affected by the size of the orifice or obstruction and flow velocity. Examples in this field include the reinitiation process of detonation waves behind slit-plates (Obara et al., 2008), notably influenced by initial test gas pressure (Obara et al., 2006b) and slit-plate configuration (Sentanuhady et al., 2007). Visualization of re-initiation and quenching processes of detonation wave behind slit-plate was conducted by Obara et al., (2007).

Meanwhile, metal is the best material to absorb the detonation energy since it has a high thermal conductivity. Increasing the detonation energy absorption area and thermal conductivity of the arrester can affect the effectivity of detonation quenching. These parameters can increase the heat transfer in the arrester because one of the factors that can influence detonation quenching is heat transfer (Thomas, Oakley, and Bambrey, 2020). A study using a crimped ribbon flame arrester was conducted by several scientists, and they varied the length of the arrester (see a brief review from Wang et al., 2018b). Sun et al. (2018) numerically investigated detonation wave propagation and quenching in an in-line crimped-ribbon flame arrester, offering key insights into initiation, quenching rules, and the impact of structural parameters on propagation. Moreover, the parameters used to assess the flame arrester's effectiveness are the propagation velocity of the combustion wave, shock wave pressure, reinitiation distance, and detonation cell size.

This study aimed to observe and analyze the characteristics and combustion phenomena of natural gas–oxygen mixture with an equivalence ratio of unity through a detonation arrester model with various initial pressures (i.e., between 10 kPa and 100 kPa). The arrester was made from an aluminum sheet with a crimped ribbon configuration. Furthermore, insights obtained from this study are expected to improve the current understanding of detonation quenching and the development of flame arrester devices.

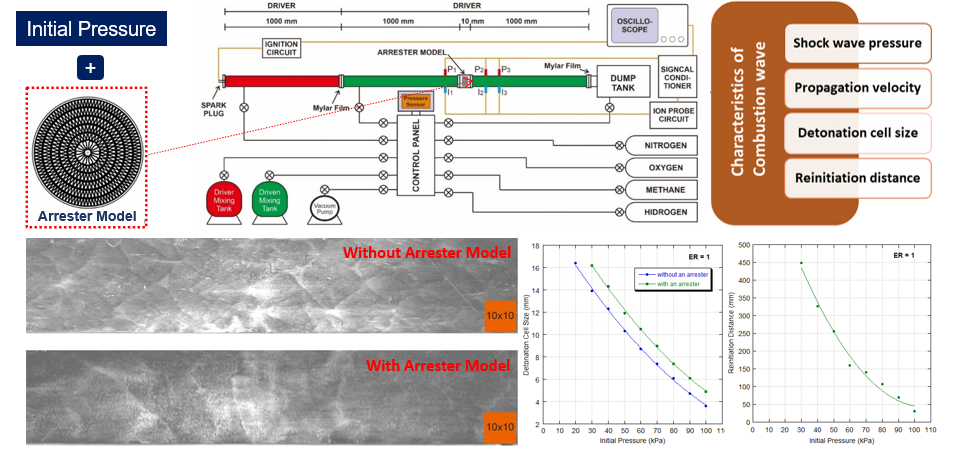

This study used a detonation test tube

with an inner diameter of 50 mm and a total length of 3,000 mm. The detonation

test tube consisted of three parts, namely, the driver section tube, driven

upstream tube, and driven downstream tube where each section has a length of

1,000 mm, respectively. The details of experimental facility can be found in

our previous paper (Sentanuhady et al., 2021)

and only the main features are presented here. Figure 1 illustrates the

schematic diagram of the detonation test equipment.

The combustion process in the driver section tube was initiated by a spark plug installed in the upstream part of the driver section. One pressure sensor (P1; PCB Piezotronics S111A26 series) was mounted on the driven upstream tube 1,900 mm from the spark plug, and two pressure sensors (P2 and P3) were mounted on the driven downstream tube 2,100 and 2,200 mm from the spark plug. The pressure sensor mounted on the driven upstream tube was used to measure the amount of shock wave pressure, whereas the ion probe sensor mounted opposite the pressure sensor was used to detect the arrival time of the combustion wave.

Detonation waves can be visualized as a detonation cell structure placed along the driven downstream tube and recorded using the soot track record plate. The soot track record plate was made of 0.3 mm-thick aluminum, whose surface had a layer of film from kerosene-burning soot. Mylar film with a thickness of 0.03 mm was inserted between the driver section tube and the driven upstream tube and between the driven downstream tube and the dump tank. The arrester model was installed in a housing that was placed between the driven upstream tube and the driven downstream tube. The housing of this arrester model was 100 mm long with an inner diameter of 50 mm. In this study, a crimped ribbon flame arrester model with a length of 25.4 mm was used. The arrester model used in this study is made of aluminum with a thickness of 0.2 mm and BR = 34.6%. Here, BR (blockage ratio) is defined as the ratio of the covered metal area to the cross-sectional area of the tube used. Figure 2 shows the photograph of arrester model used in the present study.

Figure 1 Schematic of the detonation test equipment

Figure 2 Arrester model (a) design and (b) postproduction

The experimental conditions applied in this study are shown in Table 1.

The fuel used in the driver section tube was a

stoichiometric mixture of hydrogen-oxygen at a pressure of 100 kPa, whereas the

fuel used in the tube was

a gas mixture of natural gas–oxygen with an equivalence ratio of unity and

various initial pressures. The gas

pressure used for the mixing process of both hydrogen–oxygen and natural

gas–oxygen in the mixing tank, as well as the injection of the gas mixtures

into the detonation test tube, is regulated and controlled using a

high-precision pressure sensor. The natural gas used in this experiment is

natural gas sourced from Indonesian wells that have a methane number of 96.7. In

the present study, we ensure that the equipment and tools used are calibrated

by the manufacturer. Thus, all the parameter testing is in the range of the

equipment specification of the tools.

Table 1 Experimental conditions

The experimental results on the propagation of

the gas mixture are presented. Without an arrester model, the natural

gas-oxygen combustion wave showed two observable characteristics: deflagration

waves and detonation waves. During testing with an initial pressure of 10 kPa,

a deflagration wave was observed. Increasing the starting pressure to 20 kPa

accelerated the combustion process, resulting in the formation of a detonation

wave. Similarly, a detonation wave was formed at initial pressures above 20

kPa. The detonation waves produced within the range of 20-100 kPa can be

classified into two types: unstable and stable.

An unstable detonation wave was observed at

initial pressures ranging from 20 to 50 kPa, while a stable detonation wave was

detected at pressures higher than 50 kPa. This is attributed to the rapid

combustion reaction caused by the high initial pressure of the gas mixture (Song et al. 2018; Miao et al. 2008).

Furthermore, a substantial quantity of heat energy was created, resulting in a

rapid DDT formation process. The response velocity fluctuated with an unstable

detonation wave, causing the detonation wave's propagation velocity to vary or

be unstable. This phenomenon can be attributed to the

formation of a detonation cell structure on the surface of the soot track

record plate, with the instability of the detonation cell size occurring under

unstable detonation wave conditions. The combustion wave propagation mechanisms

of both deflagration and detonation waves at various initial pressures are

shown in Table 2.

Table 2 The propagation mechanism of combustion wave

without an arrester model

|

Propagation

mechanism |

Initial

pressure (kPa) |

|

Deflagration |

10 |

|

Detonation (Unstable) |

20, 30,

40, 50 |

|

Detonation (Stable) |

60, 70,

80, 90, 100 |

The installation of the detonation arrester model between the driven

upstream tube and the driven downstream tube resulted in different

characteristics and combustion at the downstream tube of the arrester model

compared with the conditions without an arrester model. The combustion

experiments using a detonation arrester model resulted in three characteristics

of the combustion wave, namely, deflagration, detonation quenching, and

detonation reinitiation, as listed in Table 3.

The classification of combustion wave

propagation is based on the changes in the combustion wave propagation pattern

that can be observed on the soot track record plate both without and with an

arrester model. The detonation quenching phenomenon, which only occurred under

the conditions with the arrester model, was formed because of the quenching

process of the detonation waves due to heat loss through the arrester model.

Thus, the combustion wave that occurred downstream of the arrester model was a

deflagration wave. Along the driven downstream section of the tube, no DDT

phenomenon occurred. The DDT phenomenon is the transition of the combustion

wave from subsonic velocity to supersonic velocity. Furthermore, when the

velocity of the detonation wave at the driven upstream tube was sufficiently

high, as generally occurs at high initial pressures of the gas mixture, the

combustion wave that emerges from the arrester model was a deflagration wave.

This deflagration wave immediately propagated and interacted with the inner

wall of the tube, converting into a detonation wave. This phenomenon is known

as detonation reinitiation.

Table 2 and Table 3 indicate

different propagation mechanisms because by using arrester, combustion energy

will be absorbed by the arrester material. Thus, the propagation velocity of

the flame is reduced. For the cases when the arrester was used, stable and

non-stable detonations were not be observed. The deflagration phenomena can

only be observed in the detonation quenching and detonation reinitiation in the

initial pressure.

Table 3 Mechanism of the propagation of combustion wave

with an arrester model

|

Mechanism |

Initial pressure (kPa) |

|

Deflagration |

10 |

|

Detonation quenching |

20 |

|

Detonation reinitiation |

30, 40, 50, 60, 70, 80, 90, 100 |

Deflagration wave propagation without the arrester model occurred at low

initial pressures. This phenomenon was observed in the experiment at a pressure

of 10 kPa, as shown in Figure 3a. Notably, the combustion wave propagation

occurred at all observation points (i.e., P1, P2, and P3) under the

deflagration wave condition. This is characterized by the propagation of the

combustion wave several microseconds after the shock wave. In experiments

conducted under this condition, the shock wave pressure increased approximately

23 times from the initial pressure. Meanwhile, the velocity in positions P2

and P3 was 1,786 m/s, which was smaller than the Chapman–Jouguet

(CJ) theoretical velocity of 2,361 m/s.

The representation of the conditions of this

phenomenon is shown in Figure 4a, i.e., the pressure profile of the combustion

wave along the detonation test tube without an arrester model with an initial

pressure of 20 kPa. These findings show that, at position P1, which was 1,900

mm from the spark plug, the combustion wave that could be observed was the

detonation wave. Furthermore, this wave would propagate downstream toward

positions P2 and P3. Figure 4a shows the combustion waves at positions P2 and P3

were detonation waves.

Figure 5 Visualization of the combustion wave at an initial pressure of 20 kPa:

(a) without and (detonation cells appear) (b) with an arrester model (no detonation cell)

In the experiment using an arrester model, detonation reinitiation

downstream of the arrester model could be observed with an initial pressure of

more than 30 to 100 kPa. This phenomenon involved reinitiating the combustion

wave into a detonation wave after the quenching process occurred in the

downstream area of the arrester model. Figure 6a represents the detonation

reinitiation phenomenon at an initial pressure of 60 kPa. Figure 6a also shows

that the combustion wave at position P1, which was upstream of the

arrester model, was a detonation wave. Furthermore, after passing through the

arrester model, the detonation wave was quenched and became a deflagration

wave. Then, this wave propagated downstream, and at position P3, the

combustion wave was a detonation wave. This was indicated by the increasing

time of the shock wave pressure and the arrival time of the combustion wave at

the same time. These conditions indicate that between positions P2

and P3, the reinitiation process occurred, resulting in the

conversion of the deflagration wave into a detonation wave that was detected at

position P3. This phenomenon was confirmed by the visualization of

the soot track record on aluminum foil under the same pressure conditions in

Figure 6b, where detonation reinitiation (R1) occurred approximately 30 mm before position P3. The shock

wave pressure downstream of the observed arrester model was the maximum

pressure measured on the P2 or P3 sensor.

The shock wave pressure increased with the

increase in the initial pressure applied. In the experiment of the gas mixture

of natural gas–oxygen with an initial pressure of 20 to 100 kPa without an

arrester model, the shock wave pressure was approximately close to or greater

than the CJ theoretical pressure. After installing the arrester model, the

shock wave pressure was smaller than the CJ theoretical pressure at all initial

pressures applied, as shown in Figure 7a. Thus, using the arrester model can significantly

reduce the shock wave pressure, with an average decrease

of 41.5%.

Increasing the initial pressure of the gas mixture of natural gas–oxygen accelerated the molecular reactions in the gas mixture, thereby inducing a fast combustion reaction. This condition increased the momentum in the reaction process and the pressure of the shock wave, which was driven by the combustion wave. The pressure wave decreased as it passed through the arrester model, which was mostly under CJ conditions. This suggests that the arrester model effectively absorbed heat from the propagation of the detonation wave, resulting in a decrease in the combustion reaction velocity and momentum, consequently reducing the shock wave pressure far below the CJ theoretical pressure.

Figure 6 Characteristics of the combustion wave at an initial pressure of 60 kPa

with an arrester model: (a) pressure and ion profiles of the combustion wave,

(b) visualization of the combustion waves on the soot track record plate

In the combustion experiment of the gas

mixture of natural gas–oxygen with an initial pressure of 20 to 100 kPa using

an arrester model, the combustion wave underwent quenching into a deflagration

wave. This deflagration wave propagated downstream of the arrester model

following the pressure wave. The pressure wave hit the wall of the detonation

test tube and caused a hot spot on the inner surface of the wall of the

detonation test tube. When the temperature was high enough, this hot spot

initiated a detonation wave directly so that small detonation cells appeared

around the wall. The process of forming this detonation wave is called

detonation reinitiation. The distance between the location where the

reinitiation occurs and the surface of the arrester model is called the detonation

initiation distance. The detonation reinitiation distance is strongly

influenced by the initial pressure, with the reinitiation distance decreasing

with an increase in the initial pressure, as shown in Figure 8b. The increase

in the initial pressure, a large amount of energy was generated from the

combustion process, thereby increasing the reaction velocity and time that the

pressure wave reaches the wall surface, which in turn reduced the reinitiation

distance.

This study observed several characteristics and phenomena that occurred

without or with an arrester model at the initial pressure of the natural gas

mixture of 10 to 100 kPa, which can be utilized as design considerations for

detonation arresters. The initial pressure influenced the characteristics of

the combustion wave: the shock wave pressure, combustion wave propagation

velocity, detonation cell size, and reinitiation distance. Increasing the

initial pressure raised the shock wave pressure and combustion wave propagation

velocity. Otherwise, the detonation cell size and reinitiation distance were

decreased. Furthermore, the combustion process using the gas mixture of natural

gas–oxygen without an arrester model with an initial pressure of 20 to 100 kPa

produced a detonation wave at downstream of the arrester model. However, after

installing the arrester model in the detonation test tube, the detonation wave

phenomenon did not occur immediately after passing the arrester model. Instead,

the detonation wave was extinguished to be a deflagration wave and reinitiated

again to a detonation wave after interacting with the wall of the detonation

test tube when the initial pressure was higher than 20 kPa. Otherwise, the

detonation wave was quenched when the initial pressure was 20 kPa and below. The arrester also decreased the combustion wave

propagation velocity by about 20%. Experiments using the arrester model have

demonstrated that the arrester model affected the combustion wave propagation

process from high-risk to lower-risk propagation wave, where this method can be

adapted to gas transport processes to avoid accidents.

The

authors would like to thank the Energy Conversion Laboratory - Universitas

Gadjah Mada and the Innovation Center for Automotive (ICA) - Universitas Gadjah

Mada for their facilities and assistance.

Azadboni, R.K., Wen, J.X., Heidari, A., Wang, C.,

2017. Numerical Modeling of Deflagration to Detonation Transition in

Inhomogeneous Hydrogen/Air Mixtures. Journal of Loss Prevention in the

Process Industries, Volume 49, pp. 722–730

Bugaje, A.B., Dioha, M.O., Abraham-Dukuma, M.,

Wakil, M., 2022. Rethinking The Position Of Natural Gas In A Low-Carbon Energy

Transition. Energy Research & Social Science, Volume 90, p. 102604

Ciccarelli, G, Johansen,

C.T., Parravani, M., 2011. Transition in the Propagation Mechanism During

Flame Acceleration in Porous Media. In: Proceedings of the Combustion

Institute, Volume 33, pp. 2273–2278

Cross, M., Ciccarelli, G., 2015. DDT and

Detonation Propagation Limits in an Obstacle Filled Tube. Journal of Loss

Prevention in the Process Industries, Volume 36, pp. 380–386

Ediger, V.S., Berk, I., 2023.

Future Availability Of Natural Gas: Can It Support Sustainable Energy

Transition? Resources Policy, Volume 85, Part A, p. 103824

Ettner, F., Vollmer, K.G.,

Sattelmayer, T., 2014. Numerical Simulation of the

Deflagration-to-Detonation Transition in Inhomogeneous Mixtures. Journal of

Combustion, Volume 2014, p. 686347

Faramawy, S., Zaki, T., Sakr, A.A.-E., 2016.

Natural Gas Origin, Composition, and Processing: A Review. Journal of

Natural Gas Science and Engineering, Volume 34, pp. 34-54

Farizal, F., Dachyar, M., Prasetya, Y., 2021. City

Gas Pipeline Routing Optimization Considering Cultural Heritage and

Catastrophic Risk. International Journal of Technology, Volume 12(5),

pp. 1009–1018

Gholamisheeri, M., Wichman, I.S., Toulson, E.,

2017. A Study of The Turbulent Jet Flow Field in a Methane Fueled Turbulent Jet

Ignition (TJI) System. Combustion and Flame, Volume 183, pp. 194–206

Hou, S., Liu, Y., Wang,

Z., Jing, M., Zhang, Y., Zhang., B., 2022. The Potential for Deflagration To

Detonation Transition (DDT) - Lessons From LPG Tanker Transportation Accident. Journal

of Loss Prevention in the Process Industries, Volume 80, p. 104902

Lee, J.H.S., 2008. The Detonation

Phenomenon. England: Cambridge University Press

Miao, H., Jiao, Q., Huang, Z., Jiang, D., 2008.

Effect of Initial Pressure on Laminar Combustion Characteristics of Hydrogen

Enriched Natural Gas. International Journal of Hydrogen Energy, Volume

33(14), pp. 3876–3885

Mohammad, N., Ishak, W.W.M., Mustapa, S.I.,

Ayodele, B.V., 2021. Natural Gas as a Key Alternative Energy Source in

Sustainable Renewable Energy Transition: A Mini Review.

Frontiers

in Energy Research, Volume 9, p. 625023

Obara, T., Sentanuhady,

J., Tsukada, Y., Ohyagi, S., 2006a. A Study on Behavior of Detonation Wave

Passing through Narrow Grooves. Nippon Kikai Gakkai Ronbunshu B Hen (Transactions

of the Japan Society of Mechanical Engineers Part B), Volume 18(6), pp.

1605–1612

Obara, T., Sentanuhady, J.,

Tsukada, Y., Ohyagi, S., 2006b. Re-Initiation Processes of Detonation Wave behind

Slit Plate (Influence of Initial Gas Pressure). Nihon Kikai Gakkai

Ronbunshu, B Hen/Transactions of the Japan Society of Mechanical Engineers,

Volume 72(12), pp. 3158–3165

Obara, T., Sentanuhady, J.,

Tsukada, Y., Ohyagi, S., 2008. Reinitiation Process Of Detonation Wave Behind A

Slit-Plate. Shock Waves, Volume 18, Issue 2, pp. 117–127

Obara, T., Tsukada, Y.,

Sentanuhady, J., Ohyagi, S., 2007. Re-Initiation Processes of Detonation Wave

behind Slit Plate (Visualization of Re-Initiation and Quenching Process of

Detonation Wave). Nihon Kikai Gakkai Ronbunshu, B Hen/Transactions of the

Japan Society of Mechanical Engineers, Volume 73(11), pp. 2354–2361

Pan, Z., Chen, K., Pan,

J., Zhang, P., Zhu, Y., Qi, J., 2017. An Experimental Study of The Propagation

Characteristics For A Detonation Wave Of Ethylene/Oxygen In Narrow Gaps. Experimental

Thermal and Fluid Science, Volume 88, pp. 354–360

Rainsford, G., Aulakh, D.J.S., Ciccarelli, G.,

2018. Visualization of Detonation Propagation in A Round Tube Equipped with

Repeating Orifice Plates. Combustion and Flame, Volume 198, pp. 205–221

Rosyidi, M.I., Widodo, E.M., Purnomo, T.A.,

Setiyo, M., Karmiadji, D.W., 2020. Converting ToD Vehicle from Gasoline to LPG

in Indonesia: Cost Identification and Investment Analysis. International

Journal of Technology, Volume 11(1), pp. 100–110

Safari, A., Das, N.,

Langhelle, O., Roy, J., Assadi, M., 2019. Natural Gas: A Transition Fuel for

Sustainable Energy System Transformation? Energy Science & Engineering,

Volume 7 (4), pp. 1075–1094

Sentanuhady, J., Obara,

T., Tsukada, Y., Ohyagi, S., 2007. Re-Inititaion Processes of Detonation Wave

behind Slit Plate (Influence of Slit-Plate Configuration). Nihon Kikai

Gakkai Ronbunshu, B Hen/Transactions of the Japan Society of Mechanical

Engineers, Volume 73, Issue 8, pp. 1737–1744

Sentanuhady, J., Tuasikal,

J.A., Prasidha, W.,, Majid, A.I., 2021. The Characteristics of LPG

Detonation Wave Propagation Behind Porous Media Model. IOP Conf. Ser: Mater.

Sci. Eng., Volume 1096, p. 012040

Song, Z., Zhang, X., Hou, X., Li, M., 2018. Effect

of Initial Pressure, Temperature and Equivalence Ratios on Laminar Combustion

Characteristics of Hydrogen Enriched Natural Gas. Journal of the Energy

Institute, Volume 91(6), pp. 887–893

Sovacool, B.K., 2008. The Costs of Failure: A

Preliminary Assessment of Major Energy Accidents, 1907–2007. Energy Policy,

Volume 36, pp. 1802–1820

Sun, S., Liu, G., Shu, Y.,

Ye, C., Deng, J., 2022. Effect Of Flame Speed And Explosion Pressure On Flame

Quenching Performance For In-Line Crimped-Ribbon Flame Arresters. Cogent

Engineering, Volume 9 (1), p. 2118651

Sun, S.C., Shu, Y., Feng,

Y., Sun, D.C., Long, H.T., Bi, M.S., 2018, Numerical Simulation Of Detonation

Wave Propagation And Quenching Process In In-Line Crimped-Ribbon Flame

Arrester. Cogent Engineering, Volume 5(1), p. 1469377

Sun, X., Lu, S., 2020a. Effect of

Obstacle Thickness on the Propagation Mechanisms of a Detonation Wave. Energy,

Volume 198, p. 117186

Sun, X., Lu, S., 2020b. Experimental Study of

Detonation Limits in CH4-2H2-3O2 Mixtures:

Effect of Different Geometric Constrictions. Process Safety and

Environmental Protection, Volume 142, pp. 56–62

Supriyanto, E., Sentanuhady, J., Hasan, W.H.,

Nugraha, A.D., Muflikhun, M.A., 2022. Policy and Strategies of Tariff

Incentives Related to Renewable Energy: Comparison between Indonesia and Other

Developing and Developed Countries. Sustainability, Volume 14(20), p.

13442

Teodorczyk, A., Drobniak, P., Dabkowski, A., 2009.

Fast Turbulent Deflagration and DDT of Hydrogen-Air Mixtures in Small

Obstructed Channel. International Journal of Hydrogen Energy, Volume

34(14), pp. 5887–5893

Thabari, J.A., Auzani, A.S., Nirbito, W., Muharam,

Y., Nugroho, Y.S., 2023. Modeling of Coal Spontaneous Fire in A Large-Scale

Stockpile. International Journal of Technology, Volume 14(2), pp.

257–266

Thomas, G., Oakley, G., Bambrey, R., 2020.

Fundamental studies of explosion arrester mitigation mechanisms. Process

Safety and Environmental Protection, Volume 137, pp. 15–33

Wang, L.Q., Ma, H.H., Shen, Z.W., Chen, D.G. 2018b. Flame

Quenching By Crimped Ribbon Flame Arrestor: A Brief Review. Process Safety

Progress, Volume 38(1), pp. 27–41

Wang, L.Q., Ma, H.H., Shen, Z.W., Lin, M.J., Li,

X.J., 2018a. Experimental Study of Detonation Propagation in A Square Tube

Filled with Orifice Plates. International Journal of Hydrogen Energy,

Volume 43(9), pp. 4645–4656

Zardasti, L., Yahaya, N., Valipour, A., Rashid, A.S.A., Noor, N.Md., 2017. Review On The Identification Of Reputation Loss Indicators In An Onshore Pipeline Explosion Event, Journal of Loss Prevention in the Process Industries, Volume 48, pp. 71–86

Zhang, B., Liu, H., Yan, B., Ng, H.D., 2020. Experimental Study of Detonation Limits in Methane-Oxygen Mixtures: Determining Tube Scale and Initial Pressure Effects. Fuel, Volume 259, p. 116220