Application of a Polypyrrole Sensor Array Integrated into a Smart Electronic Tongue for the Discrimination of Milk Adulterated with Sucrose

Published at : 18 Jan 2023

Volume : IJtech

Vol 14, No 1 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i1.5613

Arrieta, A., Barrera, I., Mendoza, J., 2023. Application of a Polypyrrole Sensor Array Integrated into a Smart Electronic Tongue for the Discrimination of Milk Adulterated with Sucrose. International Journal of Technology. Volume 14(1), pp. 90-99

| Alvaro Arrieta | Department of Biology and Chemistry, University of Sucre (Universidad de Sucre), Road 28 No. 5-267 Red Door neighborhood, Sincelejo, postal code 700001, Colombia |

| Isora Barrera | Mercedes Abrego Educational Institution, Diag. 6-119, Tv. 1 #6-1, Monteria, postal code 230004, Colombia |

| Jorge Mendoza | Department of Mechanical Engineering, University of Córdoba, Montería, postal code 230002, Colombia |

This work presents the use of a smart electronic tongue for

discriminating adulterated milk samples with various concentrations of sucrose.

The smart electronic tongue was integrated by a voltammetric sensor array from

polypyrrole doped with various doping agents, a portable multi-potentiostat

controlled by a smartphone with an Android application. Sucrose concentrations

ranging from 1% to 20% were used to adulterate the tested samples. The sensor

array was optimized to perform measurements on milk while maintaining good

performance in terms of stability and signal quality. The sensor array was

prepared by chronoamperometric electropolymerization of pyrrole with different

doping agents, varying polymerization time (from 50 to 300 s), and

concentration of monomer (from 0.10 to 0.40 M) and doping agent (from 0.05 to

0.30 M). The optimization process results demonstrated that the parameters

polymerization time, monomer concentration, and doping agent concentration

affect the stability of the signals in the sensors, allowing for the

establishment of adequate conditions to guarantee maximum stability through an

experimental design. Thus, values of 0.10 M for monomer concentration, 0.05 to

0.10 M for doping agent concentration, and 50 to 70 s for polymerization time

were established. The measurements taken with the smart electronic tongue on

the milk samples allowed a principal component analysis to classify the samples

in the plane of the first two principal components. Principal components 1 and

2 registered a variance of 93.39% (78.68% and 14.71%, respectively), indicating

a high degree of information registered by the sensor array. It could be

concluded that the array of optimized polypyrrole sensors allows sufficient

information to be recorded through measurements made with the smart electronic

tongue to discriminate adulterated milk samples with different sucrose

concentrations.

Adulteration; Milk; Polypyrrole; Smart electronic tongue; Sucrose

Milk is one of the most important natural foods for humans due to its high nutritional value. The United Nations Food and Agriculture Organization (FAO) considers it a complete and irreplaceable food for humans due to its nutritional composition (Guetouache et al., 2014). Due to this, its consumption worldwide has increased significantly as it is considered a staple first need product in the daily diet, either as milk or any of its derivatives (Wang et al., 2020). Being a product of high consumption, it is necessary to monitor its quality and safety in order to avoid serious health problems.

An alternative to control the quality of milk

relies on four very substantial guidelines: constituents of milk, bacterial

content, its appearance, and contains adulterants. The adulteration of milk is

undoubtedly one of the most serious issues in the industry. One of the most

common practices on producer farms is the addition of water and chemicals such

as sucrose to increase profits (Yang et al., 2020). The development of new markets as a consequence of free

trade agreements between different milk-producing countries obligates

governments and the dairy industry to provide excellent quality products; as a

result, it is critical to identify foreign or rare substances in the standard

composition of milk. The main tools used for the detection of adulterants are

traditional chemical methods such as volumetric methods, infrared spectroscopy,

atomic absorption spectroscopy, liquid chromatography-mass spectrometry, and

nuclear magnetic resonance, among others (Dos-Santos et al.,

2012; Azad & Ahmed,

2016; Song et al., 2020). All these

techniques have been demonstrated to be effective in milk analysis. However,

these techniques are typically performed with expensive equipment, highly

qualified personnel, require sample pre-treatment, and lengthy analysis times.

They cannot be performed in situ due to the equipment's large volume and

weight.

The

electronic tongue can be defined as an analytical instrument, which has proved

its analytical capacity in various fields of the food industry and has been

used to analyze wines, beers, coffee, tea, honey, and milk, which have grown in

popularity in recent years. This type of device operates on systems comprised

of three major components: a sensor array with cross selectivity, an electronic

multichannel measurement device, and a data analysis unit utilizing

multivariate or pattern recognition techniques (Vlasov et al.,

2005). The electronic tongue devices

developed were based on different analytical principles, and various sensor

arrays have been used (Facure et al., 2020; Zabadaj

et al., 2018; Lipkowitz et al., 2018; Arrieta et al., 2020). However, electronic tongues based on electrochemical

measurements have received widespread acceptance from the scientific community

and the industry, particularly those based on potentiometric and voltammetric

sensor arrays (Lipkowitz et al., 2018; Arrieta et al., 2020;

Oroian & Ropciuc, 2019).

The

main systems of potentiometric electronic tongues reported the use of selective

ion or non-selective electrodes elaborated with various types of materials and

have been used in many applications and have shown to be effective in the

analysis of food products (Oroian & Ropciuc, 2019; Borges et al., 2018; Witkowska

& Kubota, 2016). However, these electronic

tongues are limited to the detection of charged chemical species (of ionic

nature); they are also highly sensitive to electronic noise and require a high

cost in terms of electronic instrumentation and data acquisition.

On

the other hand, voltammetric electronic tongues work with electrodes o sensors

made of noble metals (platinum, gold, iridium, rhodium, and palladium) or

modified electrodes (Arrieta et al., 2020; Alcañiz et al., 2012; Wei et al., 2013). In contrast to potentiometric sensors, they are not

limited to detecting charged species and possess desirable properties such as

versatility, robustness, and simplicity (Hayat et al.,

2019; Khalil et al., 2018).

Nevertheless, systems based on metallic electrodes offer poorly resolved

voltammetric signals with little information because the curves do not

represent defined electrochemical processes by the concept (Winquist

et al., 2005). For this reason, several

research groups have focused on improving and perfecting those voltammetric

systems by applying various sensor modification strategies whose signals

include better-defined electrochemical processes in order to obtain more

information from the analyzed medium. Sensors have been modified using

phthalocyanines, perylene derivatives, polypyrrole, and other substances (Arrieta

et al., 2020; Medina-Plaza et al., 2015).

The

miniaturization and modification of voltammetric sensors are common practices

in analytical chemistry (Katseli et al., 2020). However,

very few works that focus on the modification and miniaturization of sensor

arrays for electronic tongues in such a way that they allow portability and

extend their field of application to in situ analysis. This work has presented

the application of an array of miniaturized and modified polypyrrole

voltammetric sensors in analyzing milk adulterated by sucrose. The study of

milk in situ is crucial in the dairy industry because it prevents harmful or

adulterated milk from being carried to the plant. Currently, there is no

technology of this type. Hence, this research investigates the possibility of

implementing the technology to detect milk adulteration using a smart

electronic tongue in our laboratory, which is equipped with a miniaturized

sensor array coupled to a portable electronic device based on PSoC microchip

technology and controlled by a Smartphone.

2.1. Reagents and Materials

The following reagents were used: pyrrole, sodium dodecylbenzene

sulfonate, sodium sulfate, ammonium persulphate, potassium ferrocyanide,

p-toluenesulfonic acid, anthraquinone-2,6-disulfonic acid disodium salt,

lithium perchlorate, and sucrose. All the reagents used were of analytical

quality and were purchased from Sigma-Aldrich (St. Louis, Missouri, USA). The

solutions were prepared using ultrapure water of milli-Q quality (18 M? cm-1).

The samples analyzed were produced from the same sample of raw milk from Zebu

cows (Bos taurus indicus). For this, an unadulterated sample (0%) and

sucrose-adulterated samples (1%, 2%, 3%, 4%, 5%, 10%, and 20%) were taken for

this purpose. There were five replicates for each sample, for a total of 40

samples (8 concentrations x 5 replicates each).

2.2. Smart Electronic Tongue Setup

The smart electronic tongue developed in our

laboratory consisted of a polypyrrole voltammetric sensors array and a portable

multi-potentiostat controlled by a smartphone. The sensor array was comprised

of seven electrodes or voltammetric sensors of polypyrrole (PPy) doped with

seven different doping agents (i.e., counterions): PPy/DBS (PPy doped with

sodium dodecylbenzene sulfonate), PPy/SO4 (PPy doped with sodium sulfate),

PPy/SF (PPy doped with ammonium persulphate), PPy/FCN (PPy doped with potassium

ferrocyanide), PPy/TSA (PPy doped with p-toluenesulfonic acid), PPy/AQDS (PPy

doped with anthraquinone-2,6-disulfonic acid disodium salt), and PPy/PC (PPy

doped with lithium perchlorate). The preparation of the sensor array was

conducted by chronoamperometric electropolymerization of pyrrole

at 0.8 V, using an EG&G 2273 PAR potentiostat/galvanostat, controlled by

the PowerSuite software. The PPy with each dopant was electrodeposited on

graphite substrates arranged in a circular shape using an AC9C card of BVT

Technologies.

The polymerization process was optimized by applying

an experimental design in which the variables of greatest significance were

evaluated to achieve the optimal parameters of polypyrrole synthesis in the

elaboration of each sensor in the array. The experimental process corresponds

to a 33-factorial design (three factors and three levels), totaling 27

treatments. The three factors were pyrrole concentration (0.10 M, 0.20 M, and

0.40 M), polymerization time (50 s, 100 s, and 300 s), and doping agent

concentration (0.05 M, 0.10 M, and 0.30 M). The portable multi potentiostat was

made on a FREESOC card using a PSoC 5LP microchip which was programmed with the

PSoC creator software. This electronic device was designed to record the

voltammetric signals of the seven sensors on the array simultaneously through

seven measurement channels. In addition, a Bluetooth card was also included for

data transmission to a Smartphone equipped with an Android application designed

for device control and data recording. Details on electrochemical

polymerization techniques and electronic device development have previously

been reported (Arrieta et al., 2015; Arrieta et al., 2018; Arrieta

& Fuentes, 2016).

2.3. Measurement

Milk samples were measured at room temperature on 10

mL samples. The voltammetric signals were recorded at a sweep speed of 100 mV s-1

in a potential range of -1.0 V to 0.5 V with an initial potential of 0.0 V.

Each sensor generated a voltammogram (i.e., voltammetric signal) of each

sample, which was made up of 100 current data, allowing for 700 data points

with the entire sensor array, each of which was a variable in the data matrix

in each sample. When all samples were analyzed, a matrix of 28 000 data (700

variables x 40 samples) was constructed. The obtained matrix was analyzed using

the principal components analysis method to determine the discrimination

ability of the smart electronic tongue on this type of sample.

Once the sensor array was

elaborated, it was integrated into the device to test its proper functioning

and the correct registration of the voltammetric signals through the seven

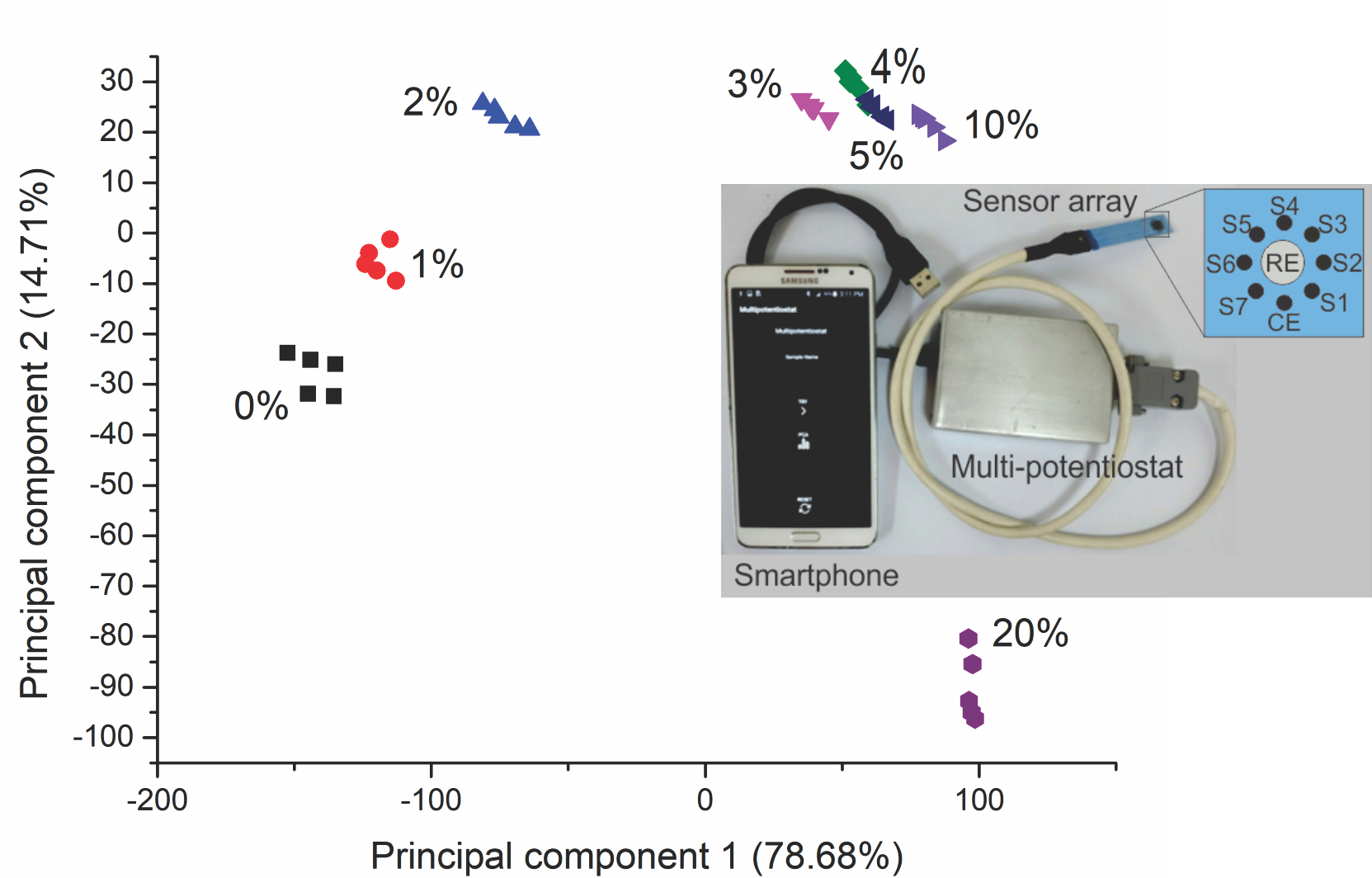

channels. Figure 1 depicts a smart electronic tongue. It can be seen the three

components that make it up as well as an expansion of the sensor array where

the reference electrode of Ag/AgCl of the array (RE), the counter electrode

(CE), and the array of seven sensors (S1…S7) can be observed.

Figure 1 Image of the smart electronic tongue formed by the

miniaturized sensor array, the portable electronic device, and a Smartphone

with an Android application for device control

To guarantee the proper functioning of

the sensors, their response to a raw milk sample was initially explored; all

the sensors were synthesized using a polymerization time of 70 s, with monomer

and doping agent concentrations of 0.20 M and 0.10 M, respectively.

Voltammetric signals were obtained without noise and with well-defined peaks

during the measurements. However, the sensors showed signals with some loss of

intensity, which could affect the measurements made with the smart electronic

tongue. As an example, Figure 2 demonstrates the response of the S7 sensor

(PPy/AQDS). It can be seen that the signal in the first recorded cycle had a

current intensity of 508.8 uA. After 50 consecutive cycles, the signal reached

a current intensity of 470.4 uA, representing a loss of intensity of 7.54%. For

the other sensors, the intensity losses recorded were 5.23%, 8.25%, 0.71%,

4.84%, 1.12%, 3.40% for PPy/SO4, PPy/DBS, PPy/SF, PPy/FCN, PPy/PC and PPy/TSA,

respectively. As previously described in other projects that

evaluated the response of polypyrrole sensors in various types of products, the

loss of intensity in the signals could be caused by the exit of the doping

agent from the polypyrrole matrix, which can be modulated by factors such as

the concentration of monomer and doping agent used in the synthesis solution

and the polymerization time (Arrieta et al., 2020; Foroughi et al., 2009).

Although the current losses do not

exceed 9%, which represents a low loss due to the sensors, in this case, no

more than 50 voltammetric cycles should be registered, and process optimization

of the sensor elaboration process was carried out to generate a more stable and

consistent signal over time. Therefore, monomer and doping agent concentration,

as well as polymerization time, were used to carry out the optimization process

by applying an experimental design in which the loss of intensity in the

signals, represented as a percentage of stability, was used as the output

variable.

Figure 2 Voltammetric signal of the PPy/AQDS sensor registered

in a raw milk sample

The results of the optimization

experiment design revealed that the analyzed factors influence the signals'

stability and the fact that there are interactions between them. Table 1

displays the results of the variance analysis performed with the PPy/TSA sensor.

The statistical significance of the factors and their interactions can be

appreciated, specifically polymerization time, the interaction between

polymerization time and concentration of the doping agent, and the interaction

between concentrations of monomer and doping agent used in the

electrodeposition process. In this case, it is possible to conclude that these

factors significantly impact the sensor signal's stability. These effects had P

values less than 0.05, indicating that they significantly differed from zero at

a 95 % confidence level. The most significant factor is the interaction between

the concentration of pyrrole and the concentration of the doping agent. It was

very important to determine an optimal value for these factors because they can

significantly interfere with the sensor array's performance when analyzing milk

samples.

The interactions and behavior of the

factors against stability were observed in the response surface graphs obtained

from the optimization study, as shown in Figure 3.

Response surface graphs and level curves were utilized to analyze the effects

of polymerization time, pyrrole concentration, and doping agent concentration

on signal stability (i.e., loss of signal intensity), which was used as the

response variable. This was done to obtain the optimal values of the levels for

each factor used in elaborating each sensor in the array.

It

was possible to determine that the dopant concentration presents optimum

stability at intermediate values close to 0.10 M. The concentration of pyrrole

for extreme values tends to increase the sensors' instability. In this sense,

the instability increases because of the rise in time and is offset by a high

or low dopant concentration. As for the time, the trend exhibits greater

instability using prolonged reaction times. It can also be seen that the lowest

areas of the response surface have the most suitable values to carry out the

elaboration of the sensors, which correspond to polymerization times of less

than 100 s, pyrrole concentration between 0.10 and 0.20 M, and a dopant

concentration between 0.05 and 0.10 M.

Table 1 Variance analysis of the

factors; polymerization time (t), the concentration of monomer [Py], and

concentration of doping agent [DA] obtained in the optimization process of the

PPy/TSA sensor

|

Source of variation |

Sum of Squares |

GI |

Mean Squares |

F |

P-Value |

|

A:Time

(t) |

169.341 |

1 |

169.341 |

6.24 |

0.0230 |

|

B:[Py] |

3.25976 |

1 |

3.25976 |

0.12 |

0.7331 |

|

C:[DA] |

5.95125 |

1 |

5.95125 |

0.22 |

0.6454 |

|

AA |

2.87042 |

1 |

2.87042 |

0.11 |

0.7489 |

|

AB |

52.0833 |

1 |

52.0833 |

1.92 |

0.1837 |

|

AC |

172.521 |

1 |

172.521 |

6.36 |

0.0219 |

|

BB |

4.335 |

1 |

4.335 |

0.16 |

0.6943 |

|

BC |

431.28 |

1 |

431.28 |

15.90 |

0.0010 |

|

CC |

73.2902 |

1 |

73.2902 |

2.70 |

0.1186 |

|

Error |

461.064 |

17 |

27.1214 |

|

|

|

Total

(corr.) |

1376.0 |

26 |

|

|

|

Based on the optimization results, the polymerization time

values and concentrations of monomer and pyrrole to be used in the elaboration

of each sensor were established. Table 2 illustrates the conditions used while

also showing the new values for the percentage of intensity loss obtained by

optimizing the processing parameters. It can be observed that the stability

improved remarkably, and the intensity losses did not exceed 3% in any of the

sensors, with very low values of 1% were obtained in the case of PPy/SO4 and

PPy/AQDS.

After

the sensor array was optimized, the measurements were carried out on the milk

samples to evaluate the ability of the smart electronic tongue to classify

samples adulterated with sucrose. The data matrix for the

principal component analysis was created from the signal registers. The

correlation circle generated by the principal components analysis is depicted

in Figure 4. Figure 4 shows that the data recorded in the signals generated by

the sensor array provide a large amount of information because most of the

points in the correlation circle are distributed at values close to 1 and -1 of

the quadrants; that is, the circle has a radius close to 1, indicating that the

sensor array provides a large amount of helpful information for sample

discrimination. In addition, it can be seen that the sensors do not provide

redundant information; this is evidenced by the fact that the areas of overlap

of points are scarce in the circle, inferring that

all of the sensors provide important information about the samples analyzed.

The variance or information captured in

the first two components was 93.39%, the first principal component with 78.68%,

and the second principal component with 14.71%. Figure 5 displays a score graph

demonstrating the discrimination of the samples of milk adulterated with

sucrose. It can be clearly seen that the samples with the same amount or

concentration of adulteration (i.e., sucrose) are clearly grouped together,

forming clusters corresponding to the various concentrations of adulterant studied.

Furthermore, the clusters are well differentiated from one another,

establishing clear discrimination of the samples analyzed.

Figure 3 Response surface of the most significant processing

factors for the PPy/TSA sensor

Table 2

Parameters used in the process of elaboration of the sensor array obtained from

the optimization process

|

Sensor |

Acronym |

Monomer/Doping

agent concentration [M] |

Polymerization

time (s) |

Loss of

intensity (%) |

|

S1 |

PPy/SO4 |

0.10/0.05 |

55 |

0.39 |

|

S2 |

PPy/DBS |

0.10/0.10 |

50 |

2.50 |

|

S3 |

PPy/SF |

0.10/0.05 |

65 |

3.00 |

|

S4 |

PPy/FCN |

0.10/0.10 |

60 |

1.98 |

|

S5 |

PPy/PC |

0.10/0.10 |

60 |

2.15 |

|

S6 |

PPy/TSA |

0.10/0.10 |

70 |

2.56 |

|

S7 |

PPy/ AQDS |

0.10/0.05 |

60 |

0.91 |

The unadulterated samples (0%) and the adulterated with 1%

are separated in the negative quadrant of the two components (quadrant -: -).

The sample adulterated with 2% is found in the negative quadrant of the first

component and positive in the second component (-: + quadrant), while the

groups of adulterated samples with 3%, 4%, 5%, and 10% are found in the

positive quadrants of both components (quadrant +: +). The sample with the

largest amount of adulterant (20%) is separated into the positive quadrant of

the first component and the negative quadrant of the second component (quadrant

+: -).

Figure 4 Correlation circle of the variables generated by the

sensor array registered in the principal component analysis

Although samples with 4% and 5% sucrose

concentrations touch each other, they do not overlap so that they can be

distinguished easily. Thus, each sample group is well discriminated, and the

smart electronic tongue could classify each sample based on its adulterant

content.

Figure 5 Correlation circle of the variables generated by the

sensor array registered in the principal component analysis

By using a smart electronic

tongue integrated with a polypyrrole sensor array, a portable measurement

device, and a smartphone made it possible to carry out measurements on

adulterated milk samples, obtaining well-defined signals. The elaboration

parameters of the sensors, such as polymerization time, monomer concentration,

and doping agent concentration, affect the stability of their voltammetric

signals against milk samples. Thereby, an optimization process had to be

carried out by applying an experimental design that allowed obtaining

well-defined signals with high stability. The optimal value of monomer

concentration was 0.10 M, the polymerization time was between 50 and 70 s, and

the doping agent concentration was between 0.05 and 0.10 M. The measurements on

the sucrose-adulterated samples allowed to register signals that contained

enough information to be able to differentiate them. Principal components 1 and

2 recorded a total of 93.39% variance, with 78.68% in principal component 1 and

14.71% in principal component 2. Thus, the result of the principal component

analysis demonstrated the discrimination capacity of the smart electronic

tongue on sucrose-adulterated samples.

The authors acknowledge the University of Sucre for the financial

support of this research.

| Filename | Description |

|---|---|

| R1-CE-5613-20220526233751.png | Figure 1 |

| R1-CE-5613-20220526233810.png | Figure 2 |

| R1-CE-5613-20220526233847.png | Figure 3 (R1) - New |

| R1-CE-5613-20220526233907.png | Figure 4 |

| R1-CE-5613-20220526233950.png | Figure 5 |

Alcañiz, M., Vivancos, J., Masot, R., Ibañez, J., Raga, M., Soto, J.,

Martínez-Máñez, R., 2012. Design of an Electronic System and its Application to

Electronic Tongues Using Variable Amplitude Pulse Voltammetry and Impedance

Spectroscopy. Journal of Food Engineering, Volume 111(1), pp. 122–128

Arrieta, A.A., Fuentes, O., 2016. Portable Electronic Tongue for the

Analysis of Raw Milk Based on PSoC (Programmable System on Chip) and Android Technology.

Ingeniare: Journal Chilean engineering, Volume 24(3), pp. 445–453

Arrieta, A.A., Fuentes, O., Palencia, M., 2015. Android and PSoC

Technology Applied to Electronic Tongue Development. Journal of Applied

Sciences, Engineering and Technology, Volume 10(7), pp. 782–788

Arrieta, A.A., Nuñez, Y.E., Mendoza, J.M., 2020.

Mini-electronic Tongue Used to Discriminate between Coffee Samples of Different

Geographical Origin. International Journal of Technology, Volume 11(2),

pp. 288–298

Arrieta, A.A., Palencia, M., Fuentes, O., 2018. Miniaturised Multi-Channel

System of Electrochemical Measurements for an Electronic Tongue for Milk

Samples. Maejo International Journal of Science and Technology, Volume

12(1), pp. 28–35

Azad, T., Ahmed, S., 2016. Common Milk Adulteration and Their Detection

Techniques. International Journal of Food Contamination, Volume 3(1),

pp. 1–9

Borges, T.H., Peres, A.M., Dias, L.G., Seiquer, I., Pereira, J.A., 2018.

Application of a Potentiometric Electronic Tongue for Assessing Phenolic and

Volatile Profiles of Arbequina Extra Virgin Olive Oils. LWT, Volume 93,

pp. 150–157

Dos-Santos, P.M., Costa, L.F., Pereira-Filho, E.R., 2012. Study of

Calcium and Sodium Behavior to Identify Milk Adulteration Using Flame Atomic

Absorption Spectrometry. Food and Nutrition Sciences, Volume 3(9), pp.

1228–1232

Facure, M.H.M., Schneider, R., Dos-Santos, D., Correa, D.S., 2020.

Impedimetric Electronic Tongue Based on Molybdenum Disulfide and Graphene Oxide

for Monitoring Antibiotics in Liquid Media. Talanta, Volume 217, pp. 1–9

Foroughi, J., Spinks, G.M., Wallace, G.G., 2009. Effect of Synthesis

Conditions on the Properties of Wet Spun Polypyrrole Fibers. Synthetic

Metals, Volume 159(17), pp. 1837–1843

Guetouache, M., Guessas, B., Medjekal, S., 2014. Composition and

Nutritional Value of Raw Milk. Issues in Biological Sciences and

Pharmaceutical Research, Volume 2(10), pp. 115–122

Hayat, M., Saepudin, E., Einaga, Y., Ivandini, T.A., 2019. CdS Nanoparticle-based

Biosensor Development for Aflatoxin Determination. International Journal of

Technology. Volume 10(4), pp. 787–797

Katseli, V., Thomaidis, N., Economou, A., Kokkinos, C., 2020. Miniature

3D-Printed Integrated Electrochemical Cell for Trace Voltammetric Hg(II)

Determination. Sensors and Actuators B: Chemical, Volume 308, p. 127715

Khalil, M., Liu, N., Lee, R.L., 2018. Super-Nernstian Potentiometric pH

Sensor Based on the Electrodeposition of Iridium Oxide Nanoparticles. International

Journal of Technology. Volume 9(3), pp. 446–454

Lipkowitz, J.B., Ross, C.F., Diako, C., Smith, D.M., 2018. Discriminating

Aging and Protein-To-Fat Ratio in Cheddar Cheese using Sensory Analysis and

Potentiometric Electronic Tongue. Journal of Dairy Science, Volume

101(3), pp. 1990–2004

Medina-Plaza, C., García-Hernandez, C., De Saja, J.A.,

Fernández-Escudero, J.A., Barajas, E., Medrano, G., García-Cabezón, C.,

Martin-Pedrosa, F., Rodriguez-Mendez, M.L., 2015. The Advantages of Disposable

Screen-Printed Biosensors in a Bioelectronic Tongue for the Analysis of Grapes.

LWT-Food Science and Technology, Volume 62(2), pp. 940–947

Oroian, M., Ropciuc, S., 2019. Romanian Honey Authentication using a

Voltammetric Electronic Tongue. Correlation of Voltammetric Data with Physico-Chemical

Parameters and Phenolic Compounds. Computers and Electronics in Agriculture,

Volume 157, pp. 371–379

Song, X., She, S., Xin, M., Chen, L., Li, Y., Vander-Heyden, Y., Rogers,

K.M., Chen, L., 2020. Detection of Adulteration in Chinese Monofloral Honey

Using 1H Nuclear Magnetic Resonance and Chemometrics. Journal of

Food Composition and Analysis, Volume 86, p. 103390

Vlasov, Y., Legin, A., Rudnitskaya, A., Di-Natale, C., D'Amico, A.,

2005. Nonspecific Sensor Arrays ("Electronic Tongue") for Chemical

Analysis of Liquids (IUPAC Technical Report). Pure Applied Chemistry,

Volume 77(11), pp. 1965–1983

Wang, Y., Wang, L., Li, Z., 2020. Dynamic Analysis of China’s Imported

Raw Milk Powder Consumption. Sustainability, Volume 12(4), pp. 1542–1557

Wei, Z., Wang, J., Zhang, X., 2013. Monitoring of Quality and Storage

Time of Unsealed Pasteurized Milk by the Voltammetric Electronic Tongue. Electrochimica

Acta, Volume 88, pp. 231–239

Winquist, F., Bjorklund, R., Krantz-Rülcker, C., Lundström, I.,

Östergren, K., Skoglund, T., 2005. An Electronic Tongue in the Dairy Industry. Sensors

and Actuators B: Chemical, Volume 111, pp. 299–304

Witkowska, E., Kubota, L., 2016. Integrated, Paper-Based Potentiometric

Electronic Tongue for the Analysis of Beer and Wine. Analytica Chimica Acta,

Volume 918, pp. 60–68

Yang, Y., Huisman, W., Hettinga, K.A., Zhang, L., Van-Ruth, S.M., 2020.

The Chinese Milk Supply Chain: A fraud perspective. Food Control, Volume

113, pp. 1–10

Zabadaj, M., Szuplewska, A., Kalinowska, D., Chudy, M.,

Ciosek-Skibi?ska, P., 2018. Studying Pharmacodynamic Effects in Cell Cultures

by Chemical Fingerprinting?SIA Electronic Tongue Versus 2D Fluorescence Soft

Sensor. Sensors and Actuators B: Chemical, Volume 272, pp. 264–273