Atmospheric Leaching Behavior and Kinetics of Nickel and Cobalt from Halmahera Limonite Ore

Corresponding email: bayupetrus@ugm.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.5607

Astuti, W., Avista, D., Prihutami, P., Wanta, K.C., Prakosa, A., Anggara, F., Petrus, H.T.B.M., 2024. Atmospheric Leaching Behavior and Kinetics of Nickel and Cobalt from Halmahera Limonite Ore. International Journal of Technology. Volume 15(4), pp. 824-833

| Widi Astuti | Research Center for Mining Technology, National Research and Innovation Agency (BRIN), Jl. Ir. Sutami Km. 15, Tanjung Bintang, Lampung Selatan, Lampung, 35361, Indonesia |

| Dira Avista | Research Center for Mining Technology, National Research and Innovation Agency (BRIN), Jl. Ir. Sutami Km. 15, Tanjung Bintang, Lampung Selatan, Lampung, 35361, Indonesia |

| Pramesti Prihutami | Sustainable Resources Engineering, Hokkaido University, Sapporo, Hokkaido, 060-8628, Japan |

| Kevin Cleary Wanta | Department of Chemical Engineering, Faculty of Industrial Technology, Parahyangan Catholic University, Jl. Ciumbuleuit 94, Bandung, 40141, Indonesia |

| Agus Prakosa | Research Center for Mining Technology, National Research and Innovation Agency (BRIN), Jl. Ir. Sutami Km. 15, Tanjung Bintang, Lampung Selatan, Lampung, 35361, Indonesia |

| Ferian Anggara | 1. Department of Geological Engineering, Faculty of Engineering, Universitas Gadjah Mada, Jl. Grafika 2, Bulaksumur, Yogyakarta, 55281, Indonesia 2. Faculty of Engineering, Unconventional Geo-Resourc |

| Himawan Tri Bayu Murti Petrus | 1. Faculty of Engineering, Unconventional Geo-Resources Research Group, Universitas Gadjah Mada, Jl. Grafika, No. 2, Yogyakarta, 55281, Indonesia 2. Department of Chemical Engineering, Faculty of Eng |

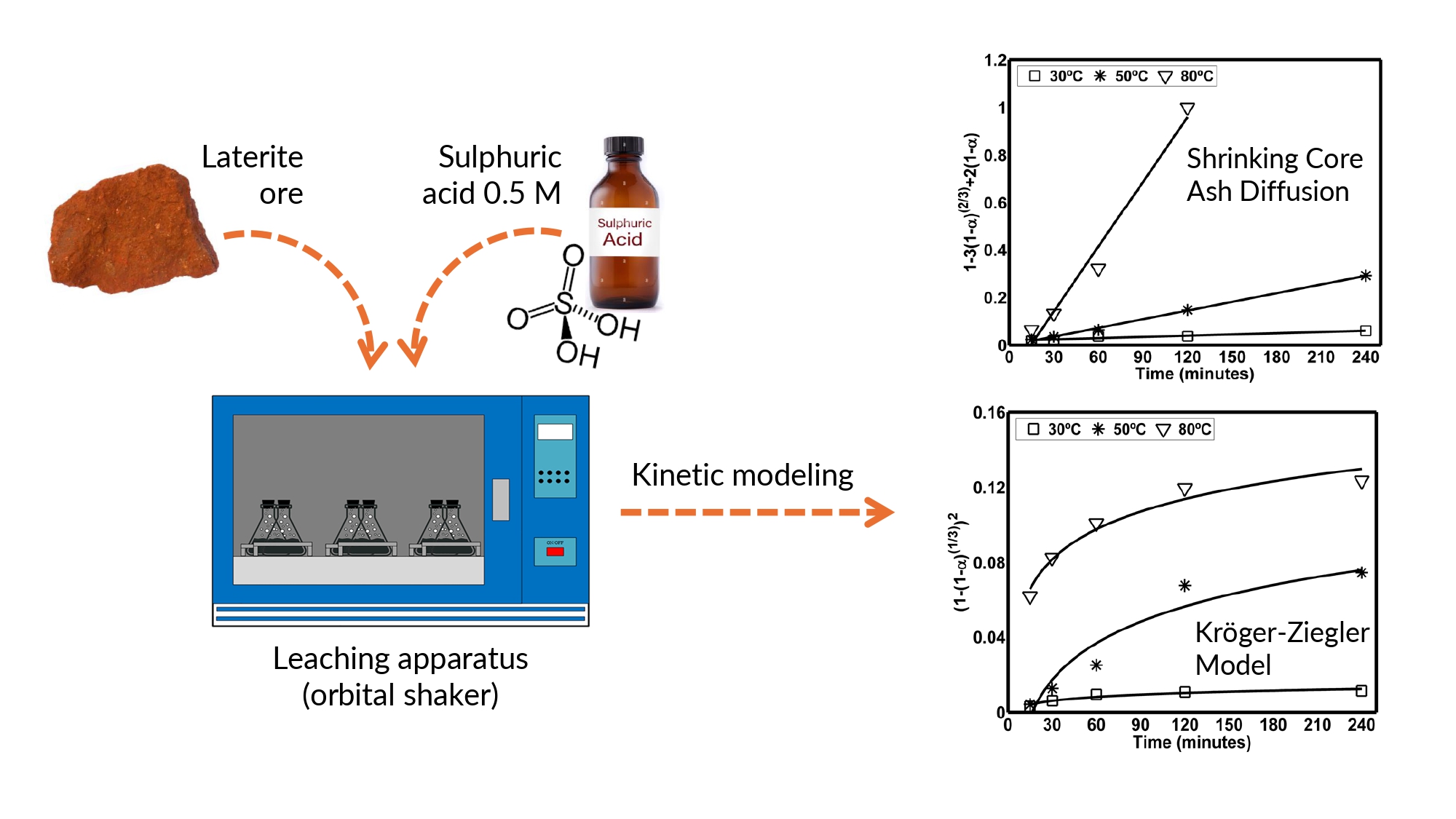

Halmahera Island in Indonesia holds great potential

for nickel laterite due to its geological setting. As the product of chemical

weathering, nickel laterite can be divided into saprolite and limonite. Despite

containing invaluable elements like nickel and cobalt, limonite ore is seldom

used in metal production. This study evaluates these two elements’ leaching

behavior and kinetics from the Halmahera deposit. Limonite ore was leached

using 50 mL of 0.5 M sulfuric acid at an S/L ratio of 10% and 20%. The leaching

process was conducted at 30°C, 50°C, and 80°C. The experimental results showed

that the highest recovery for cobalt and nickel was 100% in the adequate

presence of H+ ions. The result shows that sulfuric acid is more

selective to cobalt than a nickel. The shrinking core ash diffusion model

represents the leaching kinetics of cobalt, while nickel recovery follows the

Kröger-Ziegler kinetics model.

Cobalt; Kinetics; Leaching; Limonite; Nickel

Kinetic studies are the most important part of the design process of a processing unit. By studying the kinetics of this process, the physical phenomena in a deep process are known. Thus, the process of designing and scaling up a unit can be carried out according to the most real phenomena, and design errors can be minimized. Matching the most appropriate kinetics model from a shrinking core model (Mirwan et al., 2017) to the newest product diffusion developed model (Wanta et al., 2022; Prihutami et al., 2022), will be the objective of this study. Thus, the kinetics parameter needed for scale-up can be generated for sulfuric acid leaching on Halmahera limonite at atmospheric conditions.

2.1. Materials

The limonitic laterite ore used in this

study was from a mining area on Halmahera Island, Indonesia. A representative

sample was obtained by coning and quartering. The dried sample was crushed,

ground, ball milled, and sieved until the average size of the sample was < 74 The chemical components of the selected representative sample were

determined using X-ray Fluorescence (XRF, Epsilon 3XLE PANalytical). X-ray Diffraction (XRD, X’Pert

3 Powder from PANalytical, Netherlands) was also used to identify the

crystalline materials in limonite ore. The morphology and elemental map of the

sample were analyzed using FE-SEM/EDS Thermo Scientific Quattro S. Pregnant

leached solution in this study was prepared by diluting pro analytical sulfuric

acid (CAS RN of 7664-93-9, Merck, Germany) in aquadest.

2.2. Menthods

Halmahera limonite ore was put into an Erlenmeyer, and 50 mL of 0.5 M sulfuric acid was added. The atmospheric leaching was done for 4 hours in an orbital shaker, as shown in Figure 1. The shaker speed was kept constant at 200 rpm, while the S/L ratio and leaching temperature varied from 30 to 80°C. The concentration of leached nickel and cobalt at any designated time (15 minutes, 30 minutes, an hour, 2 hours, and 4 hours) was determined using ICP-Optical Emission Spectrometer PQ 9000 from Analytik Jena AG, Germany.

Figure 1 The experimental apparatus for

nickel and cobalt leaching: (1) orbital shaker; (2) Erlenmeyer flask

where C is the element concentration in

the liquid sample (g/mL), V is the volume of sulfuric acid solution (50 mL), X

is the element concentration in ore, and m is the mass of the limonite ore (g).

kK is the leaching rate

constant for the Kröger-Ziegler model, t is the leaching time (min), is the

recovery value of either nickel or cobalt, and kD is the leaching rate constant

for the ash diffusion controls model.

3.1. Ore Characterization

Figure 3 Elemental Mapping of Limonite Ore: Cr (dark blue); O (light green); Mg

(blue); Si (tosca); Fe (purple); Ni (yellow); Al (orange); Mn (green)

XRF analysis shows that

Halmahera limonite ore contains 0.12% of cobalt. This element is mainly carried

by Mn-oxyhydroxides, like asbolane and lithiophorite-asbolane (Sagapoa, Imai, and Watanabe, 2011; Tupaz et al.,

2020). These minerals have poor crystallinity and thus hardly appear on

diffractograms (Burlet and Vanbrabant, 2015; Maci?g

et al., 2019).

However, the XRF result indicates the presence of manganese

oxides, which undergo coprecipitation with cobalt and other elements, such as

Ni (1.73 wt%), Co (0.12 wt%), Fe (34.12 wt%), Mn (0.99 wt%), Si (3.46 wt%), and

Al (1.46 wt%). Aside from Mn-oxyhydroxides, cobalt is also hosted in lizardite

and some in goethite (Tang and Valix, 2004;

Sufriadin et al., 2020). FE-SEM/EDS analysis was also used to

confirm the XRF data. FE-SEM/EDS result indicates the presence of Ni (1.72

wt%), Fe (26.17 wt%), Mg (10.80 wt%), Al (1.39 wt%), Cr (0.37 wt%), Mn (0.47

wt%), and Si (9.86 wt%) (Astuti et al.,

2021).

3.2. Nickel and Cobalt

Leaching

The leaching process of nickel and cobalt from

Halmahera limonite ore by sulfuric acid was done at 30°C, 50°C, and 80°C. Along

with the increase in temperature, the recovery of both elements also increases.

Higher temperature provides greater kinetic energy, which allows rapid

molecular movement. The fast movement accelerates molecular diffusion and

surface reaction. This trend is the same at an S/L ratio of 10% (Figure 4) and

20% (Figure 5).

Unlike temperature, the S/L ratio is inversely

proportional to nickel and cobalt recovery. At 10% of the S/L ratio, sulfuric

acid can recover 100% of cobalt after an hour. Meanwhile, the same value is

achieved by nickel after 4 hours at 80°C. Complete recoveries are possible

since there are adequate hydrogen ions (H+) to leach both elements

from their carrier. However, a distinct case is found using a higher S/L ratio.

Loading more solids into the system raises the number of leachable materials.

However, the amount of H+ is insufficient to recover all available

nickel and cobalt. At this point, leached solution selectively reacts with the

host mineral that is easier to dissolve.

Figure 5 Nickel and Cobalt Recovery using an S/L Ratio of 20% at a) 30°C, b)

50°C, and c) 80°C

Using 20% of the S/L ratio at any temperature, the leaching process shows that cobalt recovery increases proportionally with time. Meanwhile, the recovery of nickel initially surges but slows down after some time. At 80°C, the leaching of nickel does not surpass 72.72% even after 4 hours, while cobalt achieves complete recovery only after 2 hours. This phenomenon indicates that sulfuric acid dissolves cobalt-rich minerals, like lizardite and manganese oxide, more quickly than nickel-rich minerals (Astuti et al., 2016). As goethite is the main component in Halmahera limonite ore, a great amount of acid will be needed to dissolve said mineral and recover nickel, according to Equations 5 and 6 (Senanayake et al., 2011).

3.3. Leaching Kinetics

Knowing the leaching kinetics of elements will

be useful for the industrialization process. In this study, leaching kinetics

are evaluated using a high S/L ratio. It is assumed that the rate-controlling

step would be diffusional mass transfer through an ash layer. According to the

data processing result, the recovery of cobalt and nickel from Halmahera

limonite ore follows this assumption. However, these two elements have a

slightly different phenomena during the leaching process.

Figure 6 (a) Shrinking Core Ash Diffusion Model for Cobalt

Leaching at Various Temperatures, and (b) Kröger-Ziegler Model for

Nickel Leaching at Various Temperature

One thing that differentiates the shrinking

core model from the Kröger-Ziegler model is that its effective diffusion

coefficient is assumed to be constant (Levenspiel,

1999). In the Kröger-Ziegler model, the effective diffusion coefficient

is inversely correlated with leaching time (Prihutami

et al., 2021). In a condition that lacks acid, the leaching of

limonite leaves behind unreacted goethite (Sahu, Kavuri, and Kundu, 2011). This ash layer thickens with time, hinders

molecular diffusion, and lowers nickel’s diffusion coefficient, which mainly

exists in goethite. This phenomenon does not happen to cobalt as it is mainly

hosted in much more leachable minerals.

In

this work, temperature positively affects nickel and cobalt recovery, unlike

the S/L ratio. At a high S/L ratio, the system lacks H+ activity,

and sulfuric acid selectively leaches more cobalt than a nickel. Due to the

formation of an ash layer (unreacted goethite), the leaching kinetics is

controlled by molecular diffusion through the ash layer. However, the host

mineral greatly determines the leaching phenomenon. Thus, cobalt and nickel

have two different kinetics models. The shrinking core model suits cobalt

leaching well, while the Kröger-Ziegler model best describes the nickel

leaching phenomenon. Furthermore, in future work, the mathematical models will

be explored further so that kinetic information which describes the actual

physical phenomena of this leaching process can be obtained. The model can then

be applied to the design extractor.

Highly appreciation

to BRIN for the analytical instruments provided as well as RIIM (Riset dan

Inovasi Indonesia Maju) LPDP for the financial support with contract B-807/II.7.5/FR/6/2022 and B-6952/III.10/KS.00.00/6/2022.

Aarabi-Karasgani, M., Rashchi, F., Mostoufi, N.,

Vahidi, E., 2010. Leaching of Vanadium from Linz–Donawitz (LD) Converter Slag using Sulfuric Acid. Hydrometallurgy,

Volume 102(1-4), pp. 14–21

Ahmed, I.M., Nayl, A.A., Daoud, J.A., 2016.

Leaching and Recovery of Zinc and Copper from Brass Slag by Sulfuric Acid. Journal of Saudi Chemical Society,

Volume 20, pp. S280–S285

Astuti, W., Hirajima, T., Sasaki, K., Okibe, N.,

2016. Comparison of Atmospheric Citric Acid Leaching Kinetics of Nickel from Different Indonesian Saprolitic Ores. Hydrometallurgy, Volume 161, pp. 138–151

Astuti, W., Mufakhir, F.R., Nurjaman, F.,

Sumardi, S., Herlina, U., Bahfie, F., Petrus, H.T.B.M., 2021. Pengaruh Karakteristik

Bijih pada Ekstraksi Nikel dari Bijih Limonit Indonesia Menggunakan Pelindian

Atmosferik (The Effect of Ore

Characteristics on Nickel Extraction from Indonesian Limonite Ore Using

Atmospheric Leaching). Metal Indonesia, Volume

43(1), pp. 9–16

Botelho Junior, A.B., Dreisinger, D.B., Espinosa,

D.C.R., Tenório, J.A.S., 2018. Pre-reducing Process Kinetics to Recover Metals from Nickel Leach Waste using Chelating Resins. International Journal of Chemical Engineering, Volume 2018, pp. 1–7

Burlet, C., Vanbrabant, Y., 2015. Study of the Spectro-Chemical Signatures of Cobalt-Manganese Layered Oxides (Asbolane-Lithiophorite and Their Intermediates) by

Raman Spectroscopy. Journal of Raman Spectroscopy, Volume 46(10), pp. 941–952

Butt, C.R.M., Cluzel, D., 2013. Nickel Laterite Ore Deposits: Weathered Serpentinites. Elements, Volume 9(2), pp. 123–128

Cao, C., Xue, Z., Duan, H., 2016. Making

Ferronickel from Laterite Nickel Ore by Coal-Based Self-Reduction and High

Temperature Melting Process. International Journal of Nonferrous Metallurgy, Volume 5(2), pp. 9–15

Carmignano, O.R.D.R., Vieira, S.S., Brandão, P.R.G., Bertoli, A.C., Lago, R.M., 2020.

Serpentinites: Mineral Structure, Properties and Technological Applications. Journal of the Brazilian Chemical

Society, Volume 31, pp. 2–14

Elliott, R., Pickles, C.A., Forster, J., 2016.

Thermodynamics of the Reduction Roasting of Nickeliferous Laterite Ores. Journal

of Minerals and Materials Characterization and Engineering, Volume 4(6), pp. 320–346

Ersoy, B., Dikmen, S., Yildiz, A.,

Gören, R., Elitok, Ö., 2013. Mineralogical and Physicochemical Properties of Talc

from Emirda?, Afyonkarahisar, Turkey. Turkish Journal

of Earth Sciences, Volume 22(4,) pp. 632–644

Farrokhpay, S., Cathelineau, M., Blancher, S.B.,

Laugier, O., Filippov, L., 2019. Characterization of Weda Bay Nickel Laterite Ore from Indonesia. Journal

of Geochemical Exploration, Volume 196, pp. 270–281

Gourley, S.W.D., Or, T., Chen, Z., 2020. Breaking

Free from Cobalt Reliance in Lithium-Ion Batteries. Iscience, Volume 23(9), pp. 1–12

Hosseini Nasab, M., Noaparast, M., Abdollahi, H.,

2020. Dissolution Optimization and Kinetics of Nickel and Cobalt from Iron-rich Laterite Ore, using Sulfuric Acid at Atmospheric Pressure. International

Journal of Chemical Kinetics, Volume 52(4), pp. 283–298

Hosseini, S.A., Raygan, S., Rezaei, A., Jafari,

A., 2017. Leaching of Nickel from a Secondary Source by Sulfuric Acid. Journal of

Environmental Chemical Engineering, Volume 5(4), pp. 3922–3929

Ilyas, A., Kashiwaya, K., Koike, K., 2016. Ni Grade Distribution in Laterite Characterized from Geostatistics, Topography and

the Paleo-groundwater System in Sorowako,

Indonesia. Journal of Geochemical Exploration, Volume 165, pp. 174–188

Ito, A., Otake, T., Maulana, A., Sanematsu, K.,

Sufriadin, Sato, T., 2021. Geochemical Constraints on the Mobilization of Ni and Critical Metals in Laterite Deposits, Sulawesi,

Indonesia: A Mass-balance Approach. Resource Geology, Volume 71(3), pp. 255–282

Kusrini, E., Usman, A., Trisko, N., Harjanto, S.,

Rahman, A., 2019. Leaching Kinetics of Lanthanide in Sulfuric Acid from Low

Grade Bauxite. Materials Today: Proceeding,

Volume 18, pp. 462–467

Kusrini, E., Zulys, A., Rachmana, A., Wulandari,

D.A., Muharam, Y., Usman, A., Rahman, A., 2020. Enrichment and Extraction of Lanthanum from Belitung Silica Sand using Sulfuric Acid Heap Leaching, Precipitation and Complexation with Phytic Acid. Materials Today: Proceeding, Volume 31, pp. 421–425

Kusrini, E., Zulys, A., Yogaswara, A.,

Prihandini, W.W., Wulandari, D.A., Usman, A., 2020. Extraction and Enrichment

of Lanthanide from Indonesian Low Grade Bauxite using Sulfuric Acid Heap

Leaching and Phytic Acid. Engineering journal,

Volume 24(4). pp. 305–314

Levenspiel, O., 1999. Chemical Reaction

Engineering, 3rd ed. In: John Wiley & Sons, Inc., New York

Li, G.H., Rao, M.J., Li, Q.,

Peng, Z.W., Jiang, T., 2010. Extraction of cobalt from laterite ores by citric

acid in presence of ammonium bifluoride. Transactions of Nonferrous Metals

Society of China. Volume 20(8), 1517–1520

Liu, F., Peng, C., Porvali,

A., Wang, Z., Wilson, B.P., Lundström, M., 2019. Synergistic Recovery of

Valuable Metals from Spent Nickel-Metal Hydride Batteries and Lithium-Ion

Batteries. ACS (American Chemical Society) Sustainable Chemistry &

Engineerin, Volume 7(19), pp. 16103–16111

Maciag, L., Zawadzki, D.,

Kozub-Budzyn, G.A., Piestrzynski, A., Kotlinski, R.A., Wróbel, R.J., 2019.

Mineralogy of Cobalt-rich ferromanganese crusts from the Perth Abyssal plain (E

Indian Ocean). Minerals, Volume 9(2), p. 84

Mirwan, A., Susianto,

Altway, A., Handogo, R., 2017. A Modified Shrinking Core Model for Leaching of

Aluminum from Sludge Solid Waste of Drinking Water Treatment. International

Journal of Technology, Volume 8(1), pp. 19–26

Mohammadreza, F., Mohammad,

N., Ziaeddin, S.S., 2014. Nickel Extraction From Low Grade Laterite by

Agitation Leaching at Atmospheric Pressure. International Journal of Mining

Science and Technology, Volume 24(4), pp. 543–548

Ning, Z.Q., Xie, H.W., Song,

Q.S., Yin, H.Y., Zhai, Y.C., 2019. Nickel Leaching From Low-Grade Nickel Matte

Using Aqueous Ferric Chloride Solution. Rare Metals, Volume 38, pp. 1199–1206

Prihutami, P., Prasetya, A.,

Sediawan, W.B., Petrus, H.T.B.M., Anggara, F., 2021. Study on Rare Earth

Elements Leaching from Magnetic Coal Fly Ash by Citric Acid. Journal of

Sustainable Metallurgy. Volume 7(3), pp. 1241–1253

Prihutami, P., Sediawan,

W.B., Petrus, H.T.B.M., Prasetya, A., 2022. A Product Diffusion Model for the

Extraction of Cerium and Yttrium from Magnetic Coal Fly Ash Using Citric Acid

Solution. International Journal of Technology Volume 13(4), pp. 921–930

Purwanto, A., Nisa, S.S.,

Lestari, I.P., Ikhsanudin, M.N., Yudha, C.S., Widiyandari, H., 2021. High

Performance Nickel Based Electrodes in State-of-the-Art Lithium-ion Batteries:

Morphological Perspectives. KONA Powder and Particle Journal, Volume 38,

pp. 130–149

Sagapoa, C.V., Imai, A., Watanabe, K., 2011. Laterization Process of Ultramafic

Rocks in Siruka, Solomon Islands. Journal of Novel Carbon Resource Sciences,

Volume 3, pp. 32–39

Sahu, S., Kavuri, N.C.,

Kundu, M., 2011. Dissolution Kinetics of Nickel Laterite Ore using Different Secondary

Metabolic Acids. Brazilian Journal of Chemical Engineering, Volume 28, pp.

251–258

Senanayake, G., Childs, J.,

Akerstrom, B.D., Pugaev, D., 2011. Reductive Acid Leaching of Laterite and Metal

Oxides - A Review with New Data for Fe(Ni,Co) OOH and a Limonitic Ore. Hydrometallurgy,

Volume 110, pp. 13–32

Setiawan, H., Petrus,

H.T.B.M., Perdana, I., 2019. Reaction Kinetics for Lithium and Cobalt Recovery

from Spent Lithium-Ion Batteries using Acetic Acid. International Journal of

Minerals, Metallurgy, and Materials, Volume 26(1), pp. 98–107

Sufriadin, Widodo, S., Nur,

I., Ilyas, A., Ashari, M.Y., 2020. Extraction of Nickel and Cobalt from

Sulawesi Limonite Ore in Nitric Acid Solution at Atmospheric Pressure. In:

IOP Conference Series: Materials Science and Engineering, Volume 875(1), p.

012053

Sun, Q., Cheng, H., Mei, X.,

Liu, Y., Li, G., Xu, Q., Lu, X., 2020. Efficient Synchronous Extraction of

Nickel, Copper, and Cobalt from Low–Nickel Matte by Sulfation Roasting-Water

Leaching Process. Scientific Reports, Volume 10(1), p. 9916

Sverdrup, H.U., Olafsdottir,

A.H., 2019. Assessing the Long-Term Global Sustainability of the Production and

Supply for Stainless Steel. BioPhysical Economics and Resource Quality, Volume

4, pp. 1–29

Tang, J., Valix, M., 2004.

Leaching of Low- Grade Nickel Ores by Fungi Metabolic Acids. In:

Separations Technology VI: New Perspectives on Very Large-Scale Operations,

ECI (Engineering Conferences Internasional) Digital Archives, pp. 1–16

Trisnawati, I., Prameswara,

G., Mulyono, P., Prasetya, A., Petrus, H.T.B.M., 2020. Sulfuric Acid Leaching

of Heavy Rare Earth Elements (HREEs) from Indonesian Zircon Tailing. International

Journal of Technology, Volume 11(4), pp. 804–816

Tupaz, C.A.J., Watanabe, Y.,

Sanematsu, K., Echigo, T., Arcilla, C., Ferrer, C., 2020. Ni-co Mineralization

in the Intex Laterite Deposit, Mindoro, Philippines. Minerals, Volume 10(7),

p. 579

Van der Ent, A., Baker,

A.J.M., van Balgooy, M.M.J., Tjoa, A., 2013. Ultramafic Nickel Laterites in

Indonesia (Sulawesi, Halmahera): Mining, Nickel Hyperaccumulators and Opportunities

for Phytomining. Journal of Geochemical Exploration, Volume 128, pp. 72–79

Wanta, K.C., Perdana, I.,

Petrus, H.T.B.M., 2016. Evaluation of Shrinking Core Model in Leaching Process

of Pomalaa Nickel Laterite using Citric Acid as Leachant at Atmospheric Conditions.

In: IOP Conference Series: Materials Science and Engineering, Volume

162(1), p. 012018

Wanta, K.C., Astuti, W.,

Perdana, I., Petrus, H.T.B.M., 2020. Kinetic Study in Atmospheric Pressure

Organic Acid Leaching: Shrinking Core Model. Minerals, Volume 10(7) pp.

1–10

Wanta, K.C., Astuti, W.,

Petrus, H.T.B.M., Perdana, I., 2022. Product Diffusion-Controlled Leaching of

Nickel Laterite using Low Concentration Citric Acid Leachant at Atmospheric

Condition. International Journal of Technology, Volume 13(2), pp.

410–421

Xiao, J., Ding, W., Peng,

Y., Chen, T., Zou, K., Wang, Z., 2020. Extraction of Nickel from Garnierite

Laterite Ore using Roasting and Magnetic Separation with Calcium Chloride and Iron

Concentrate. Minerals, Volume 10(4), p. 352