Assessing the Product–Service Systems Supply Chain Capabilities: Construct and Instrument Development

Corresponding email: dianretnosd@ukwms.ac.id

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.5581

Dewi, D.R.S., Hermanto, Y.B., Pittayachawan, S., Tait, E., 2023. Assessing the Product–Service Systems Supply Chain Capabilities: Construct and Instrument Development. International Journal of Technology. Volume 14(4), pp. 921-931

| Dian Retno Sari Dewi | Industrial Engineering Department, Widya Mandala Catholic University, Kalijudan 37, Surabaya 60114, Indonesia |

| Yustinus Budi Hermanto | Faculty of Economics and Business, Darma Cendika Catholic University, Dr. Ir. H. Soekarno 201, Surabaya 60117, Indonesia |

| Siddhi Pittayachawan | School of Accounting, Information Systems and Supply Chain, RMIT University, 124 La Trobe Street, Melbourne, Victoria 3000, Australia |

| Elizabeth Tait | School of Information and Communication Studies, Charles Sturt University, Boorooma, North Wagga, New South Wales 2650, Australia |

Product–service

systems (PSS) has become a major subject of concern for many industries because

of their benefits and the possibilities to reduce negative environmental

impacts and address environmental sustainability concerns. Despite the benefits

of PSS, little empirical research has been conducted to investigate the PSS

supply chain (SC) capabilities constructs. This study offers original

contributions to the valid and reliable construct and instrument development to

measure the PSS SC capabilities. A systematic approach was employed to develop

and validate an instrument for evaluating the PSS SC capabilities. This

comprises specifying domains of constructs, generating a sample of items,

conducting interrater agreement analysis, testing non-response bias, and

assessing the instrument using exploratory factor analysis (EFA) and

confirmatory factor analysis (CFA). The validity of the proposed model was

tested using structural equation modeling based on a large-scale online survey

from 447 participants working for motorcycle service partners. The result shows

seven distinctive PSS SC capabilities constructs, namely knowledge assessment,

partner development, co-evolving, reflexive control, re-conceptualization,

innovative service delivery, and sustainable product–service capability. The

development of the instrument contributes a validated tool for companies to

measure their PSS SC capabilities.

Instrument development; Product–service systems; Supply chain capabilities; Sustainability

Theoretical background

Manufacturers might not have the

capacity to provide all-around services as they focus more on production; their

resources and expertise to deliver PSS are limited (Ayala,

Gerstlberger, and Frank, 2018). They choose to develop their SC capability first by, for example,

transforming their business processes in order to enable PSS (Martinez et al., 2010). Meanwhile, other

manufacturers prefer to collaborate with intermediaries and a network of

service partners instead (Dewi et al., 2023; Dewi and Hermanto, 2022,

Dewi et al., 2020). This is because PSS is complex; for example, it

needs expertise in customer relationship building and assessment of customer

expectations about products and services (Moro, Cauchick-Miguel, and Mendes, 2022). Such requirements are likely to be met by a multi-actor SC network

comprising manufacturers, intermediaries, and service partners instead of by

manufacturers alone (Story et al., 2017).

A review of PSS studies shows that they

focus more on the development of PSS delivery capabilities (Story et al., 2017; Kindström,

Kowalkowski, and Sandberg, 2013), and less on the SC concept that is

associated with the collaboration of many companies in the SC network to

provide a broader perspective of product life cycle concept to achieve

sustainability. Studies using dynamic capabilities emphasize service

development; for example, Ayala Gerstlberger, and Frank (2018)

proposed four capabilities i.e., service offering, resource, activity,

and service supplier; whereas Raddats et al. (2017)

proposed that the four capabilities should be service enablement,

service development, knowledge assessment, and risk management. Story et al. (2017), on the other hand, claimed

that capabilities should be customer-focused, comprising customer intimacy,

coordination, and service delivery. Meanwhile, other studies have concentrated

on innovative service delivery, suggesting that service quality, the capability

to deliver PSS at the operational level and the capability to improve service

capacities and facilities, are crucial (Kindström, Kowalkowski, and Sandberg, 2013). Overall, the SC capabilities examined in the literature have not fully

performed PSS as most of the studies focus only on the economic aspect, and

less focus on the environmental aspect.

From the SC concept and sustainability

concern, this study looks into SSCM, which is a concept of management of

material, information, capital flow, and collaboration among companies in the

SC aiming to achieve sustainability (Seuring and Müller,

2008). For example, Beske

(2012) proposed three more variables to complement the SC

capabilities—knowledge assessment and collaboration—proposed by Defee and Fugate (2010). They argue that partner

development, reflexive control, and re-conceptualization are needed to improve

sustainability. Meanwhile, in their subsequent study, Beske,

Land, and Seuring (2014) enhanced

their model by adding SSCM practices. This study uses the SC capabilities postulated by Beske, Land, and Seuring (2014) and Kindström, Kowalkowski, and Sandberg, (2013) as the proposed conceptual framework since both

studies represent the overall SC capabilities required for PSS. Sustainable

product–service capability is also a key determinant for sustainability concerns (Garetti and Taisch, 2012); hence, it is included in the PSS SC

capabilities.

Defining

a theoretical construct is a critical stage in developing a valid instrument.

Based on the argument of the preceding two paragraphs, a bundle of product and

service required not only focuses on service delivery but also covers the

product life cycle. Hence, the PSS SC capabilities are defined as an SC

network capability deliver through a bundle of product and service performance,

covering the product life cycle to apply the responsibility of environmental

sustainability. PSS SC capabilities demonstrate the capabilities of the SC

network collaboration to deliver PSS to achieve the environmental

sustainability criteria. Operationalization of the PSS SC capabilities

constructs is guided by the extensive literature reviews from the PSS and SSCM capabilities

perspective. This infers that the environmental sustainability aspects should

be incorporated when generating items of the construct. Underpinned by the

concept of dynamic capabilities (DC), a framework that postulates various PSS

SC capabilities, including collaboration, knowledge assessment, partner

development, reflexive control, innovative service delivery,

re-conceptualisation, and sustainable product–service capability are developed.

DC works best with two or more organizations collaborating on capabilities and

resources in the SC to improve PSS SC capabilities together (Beske, 2012). The next paragraph discusses

the domain definition of each construct.

Collaboration (CO) is defined as a partnership

activity of creating new resources where two or more parties jointly work

together to achieve mutual benefit (Beske, 2012; Cao et al., 2010). Knowledge

assessment (KA) is the

capability to access and understand the knowledge from the strongest partners

in the SC (Beske, 2012). In this study, the

service partners (characterized as small partners) are usually the weakest in

the SC and do not have the capability to evaluate the knowledge available. They

are mostly receiving knowledge from manufacturers through the main dealers.

Hence, the operationalization of this construct is mostly based on knowledge

sharing from the manufacturers through intermediaries to service partners. Partner

development (PD) is defined as the capability to enhance the capabilities of

service partners (including their sustainability performance) that enhance harmony across the SC (Seuring and

Müller, 2008). Partner development programs are a way to

share knowledge in the SC network (Beske, Land, and

Seuring,

2014). Re-conceptualisation

(REC) is defined as the capability to change what the SC does by moving toward

closed-loop systems and servicing (Pagell and Wu, 2009). A product’s take-back program,

refurbished products, maintenance, adherence to environmental regulation, and

advice on efficient use are all parts of closed-loop SC activities (Kusrini et al.,

2020; Coenen, van Der

Heijden, and van Riel, 2018). Reflexive control (REF) is

defined as the

capability to gather, share information, monitor, and evaluate the performance of an SC. It aims to control SC

functionality (Beske,

Land, and Seuring, 2014). Partners’ activities are

controlled and audited through standards and certification by third parties

such as ISO 14001 or the European Union Eco-Management and Audit Scheme (Beske, Land, and Seuring, 2014). Innovative service delivery

(ISD) is defined as an inherently dynamic process, seeking to identify and

exploit the benefits of service innovation, by offering a bundle

product-service solution to fulfill customer needs (Kindström, Kowalkowski,

and Sandberg, 2013). Sustainable

product–service capability (SPSC) is defined as the capability of designing and

using natural resources for manufacturing and service, by creating an integrated

bundle of products

and services, which is designed to be a powerful tool for developing a more

sustainable solution (Garetti and

Taisch, 2012). SPSC can be categorized into four stages

following the product life cycle concept, namely product design and

development, the manufacturing process, and product end-of-life management (Hanim et al., 2017). Content validity is a basic

requirement for instrument development (Jarva et al., 2023). This was achieved

through the intensive literature reviews delivered in this section. Using the

PSS SC capabilities construct discussed above, an initial pool of items was

created (35 items in total) and is presented in Table 1.

Table

1 Summary of domain of constructs and items

|

Code |

Constructs |

Reference |

|

Collaboration | ||

|

CO1 |

We work jointly on the product–service systems planning with our main

dealer |

(Beske, Land, and Seuring, 2014) |

|

CO2 |

We

maintain a long-term collaborative relationship with the main dealer based on

mutual trust |

(Boon-itt, wong, and wong, 2017) |

|

CO3 |

Our logistics activities are well integrated with the main dealer’s logistics activities |

(Mandal et al.,

2016) |

|

CO4 |

We have the

same information technology platform as our main dealer that can share information |

(Boon-itt, wong, and wong, 2017) |

|

CO5 |

We share the

measurement of customer satisfaction and expectation with our main dealer |

(Haque and Islam,

2018) |

|

CO6 |

We share

demand forecasting and planning with our main dealer |

(Hong, Zhang, and

Ding, 2018) |

|

Knowledge assessment | ||

|

KA1 |

We have access to our main dealer’s knowledge and technical expertise of

the product |

(Defee and

Fugate, 2010) |

|

KA2 |

Our main dealer enhances our knowledge about the benefit of

sustainability |

(Beske, Land, and Seuring, 2014) |

|

KA3 |

Our main dealer provides us with knowledge

of information technology to provide the bundle of product and service

offerings |

(Beske, Land, and Seuring, 2014) |

|

KA4 |

We learn about customers’ needs

and requirements from our main dealer |

(Kindström, Kowalkowski and

Sandberg, 2013) |

|

KA5 |

We learn about innovations

related to product–service bundling from our main dealer |

(Hong, Zhang, and

Ding, 2018) |

|

Partner

development | ||

|

PD1 |

Our main

dealer has the capability to continuously

improve our knowledge |

(Beske, Land, and Seuring, 2014) |

|

PD2 |

Our main

dealer provides us with a variety of training

courses to increase our capabilities |

(Boon-itt, wong, and wong, 2017) |

|

PD3 |

Our main

dealer provides partner development programs

to learn about the product–service systems |

(Ayala, Gerstlberger, and

Frank, 2018) |

|

PD4 |

Our main

dealer enhances service partner’s capabilities to achieve the sustainability

goal in our supply chain |

(Beske, Land, and Seuring, 2014) |

|

PD5 |

Our main dealer strengthens our

technical expertise related to the product’s service and maintenance |

(Paiola

et al., 2013) |

|

Re-conceptualisation | ||

|

REC1 |

We have

the capability to follow the environmental regulation determined by the

Indonesian government |

(Kumar, Subramanian, and Arputham, 2018) |

|

REC2 |

Our main

dealer offers a product take-back program |

(Coenen, van Der Heijden, and van Riel,,2018) |

|

REC3 |

We have

advised customers on how to use our products in an energy-efficient manner |

(Jadhav, Orr, and Malik, 2018) |

|

REC4 |

We have suggested customers

regularly maintain their products |

(Dewi and Hermanto 2022; Dewi et al., 2023) |

|

REC5 |

Our manufacturing partner

offers refurbished motorcycles |

(Blome Paulraj, and Schuetz, 2014) |

|

Code |

Constructs |

Reference |

|

Reflexive

control | ||

|

REF1 |

Our main dealer shares

information with us about product–service

offerings |

(Haque and Islam,

2018) |

|

REF2 |

Our main dealer and we have

systems for monitoring and evaluating supply chain performance |

(Mandal et al.,

2016) |

|

REF3 |

Our main

dealer evaluates our performance by its standards |

(Beske, Land, and Seuring, 2014) |

|

REF4 |

We are capable

of fulfilling certifications required by the main dealer for evaluating our

performance |

(Beske, Land, and Seuring, 2014) |

|

Innovative

service delivery | ||

|

ISD1 |

We always

improve service quality to fulfill customer needs |

(Ayala, Gerstlberger, and

Frank, 2018) |

|

ISD2 |

We always

deliver our service on time |

(Kindström, Kowalkowski, and

Sandberg, 2013) |

|

ISD3 |

We are proficient to deliver an

innovative bundling of product–service, particularly in providing maintenance

and repair services |

(Paiola

et al., 2013) |

|

ISD4 |

We manage service capacity with

uncertain demand |

(Boon-itt, wong, and wong, 2017) |

|

ISD5 |

We always

improve service management facilities |

(Ayala, Gerstlberger, and

Frank, 2018) |

|

Sustainable

product-service capability | ||

|

SPSC1 |

Our manufacturing partner

designs products that will prolong the life of materials |

(Hanim et al., 2017) |

|

SPSC2 |

Our manufacturing partner

designs products that will enable repair, rework, and recycling |

(Blome Paulraj, and Schuetz, 2014) |

|

SPSC3 |

Our manufacturing partner

designs products that facilitate disassembly |

(Hanim et al., 2017) |

|

SPSC4 |

Our manufacturing partner

adheres to environmentally related programs, standards, and regulations |

(Hanim et al., 2017) |

|

SPSC5 |

We prolong the

service life of products by providing maintenance and support to customers |

(Hanim et al., 2017) |

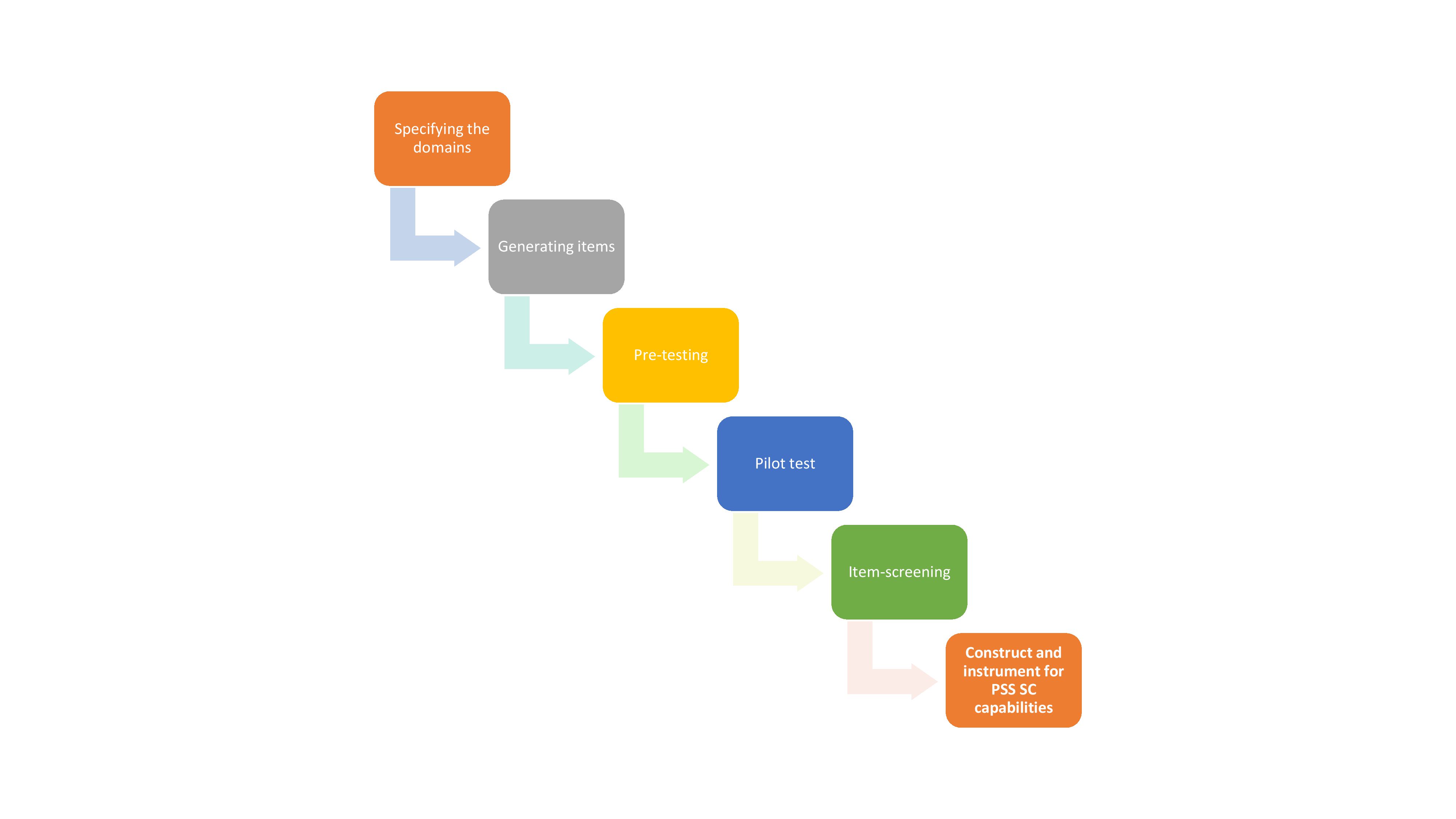

Methods

To develop the PSS SC capabilities framework and to ensure the

validity and reliability of the framework, the procedure developed by Lewis, Templeton, and Byrd (2005) is utilized. The first stage is

to specify the domains of each construct. The second stage for developing

better measures is to generate items that capture the domain as specified (Jarva et al., 2023). The third and fourth stages

are pre-testing, followed by a pilot test, and the fifth stage is item

screening (Lewis, Templeton,

and Byrd,

2005). In the sixth stage, sample

design and data collection are covered. The seventh stage is data analysis to

test the validity and reliability of the instrument.

EFA and CFA were employed as the validity tests. Initially, the EFA was utilized by SPSS version 26 to assess the dimensionality of the measurement, followed by running the CFA in AMOS version 26 to evaluate the convergent validity, discriminant validity, and factorial validity. To evaluate the internal consistency and reliability, coefficient H was utilized. Finally, common method bias was tested with CFA (Podsakoff et al., 2003).

The first stage as mentioned in the

methods is to specify the domain of each construct. The purpose of the domain

specification step is to deliver a clear conceptual meaning and definition of

each construct by specifying its dimensions (Jarva et

al., 2023). This required a review of the existing literature and,

when suitable, taking items from existing measurements. Each construct was

modified to accommodate the context of the Indonesian motorcycle industry. This

has been done in the theoretical background section.

The second stage presents the

operationalization of the seven theoretical constructs discussed in the

previous section. Based on a comprehensive review of the literature on SC

capabilities and considerable discussion with two academics, an initial pool of

35 items from 7 constructs was created (Table 1).

In

the third stage, a pre-test was conducted as the first attempt aiming for

empirical feedback to evaluate the instrument (Lewis,

Templeton, and Byrd 2005). Five academic experts were recruited for pre-testing. An

adjustment to the instrument was then undertaken, which included changes in the

terminology and modified sentences. There were no added new items and deleted

irrelevant items so the initial pool of 35 items remained.

Next,

a pilot test was undertaken to purify the instrument (Lewis,

Templeton, and Byrd, 2005). Ten persons from official motorcycle

service partners were asked to fill out the instrument. A questionnaire written

in English was translated into Bahasa and then back-translated to English to

ensure the meaning was the same in the Bahasa and English version. The

participants were asked to complete the instrument. Once complete, the

participants were asked about their difficulties in completing the instrument

and gave suggestions regarding the improvement of item statements. The pilot

study confirmed that the motorcycle service partners did not recognize the

authority of manufacturers as they did not have a direct relationship with the

manufacturers. Instead, the main dealers as intermediaries acted as the

manufacturer’s representatives and they were the ones expected to provide the

SC capabilities to the service partners. Again, an adjustment to the wording

and terms was applied to the instrument (Lewis, Templeton, and Byrd, 2005) and 35 items remained.

In the fifth stage, an interrater agreement

survey with 20 participants who have expertise in the SC field was asked to

participate (Lewis, Templeton,

and Byrd,

2005). These experts were the head of

the SC, the head of the service department, the main dealer head of service

partners from the motorcycle industry, and academic experts. The five-point

rating scale was used to evaluate the relevance of items (i.e., 0 = not

relevant, 1= minimally relevant, 2=moderately relevant, 3= substantially relevant,

4 = extremely relevant).

A mean score was evaluated to

discover the level of homogeneity in the rating given. If raters do not have an

agreement and the value of the mean score is below the mean point then the

items must be dropped (Lindell, 2001).

Similarly, the result of interrater agreement corresponding with the p-value

must be below 0.05 (Lindell, 2001). An index

to evaluate a single target using a multi-item rating scale was used (Lindell, 2001). A test of the equality variances

is proposed to delete items with a low level of interrater agreement. The

variance of rater means scale scores are employed as the numerator of the

agreement index. A chi-squared test can direct whether an item has a value

significantly different from zero by comparing the variance of rater mean scale

scores and expected variance under the uniform distribution. The inter-rater

agreement

was estimated by Lindell

(2001)’s formula. There were three criteria suggested for dropping

items: (1) drop items when their mean value is less than the midpoint, (2) drop

items left from (1) when p> 0.05 and (3) drop items left from (2) when power

< 0.8 (Sud-on et al., 2013). The

results show a mean value of 3.05–3.70, all p-value < 0.05, and a power of

0.80–1. According to the three criteria for dropping items discussed above, no

items were removed so a total of 35 items remained in the final questionnaire.

In the sixth stage, 1,300 invitations were

sent using a simple random sampling to collect the data from the Indonesian

motorcycle service partners. The

population was established by the researcher by collecting service partner data

from the website of the five motorcycle brands with the proportion of their

market share (AHM 75%, YIMM 22%, SIM 1%, KMI 1%, and TVS 1%); a sampling frame

is about 6,800 service partners. This study used a combination of a

six-point Likert and rating scale. The questionnaire was distributed online in

the Bahasa version and sent to the list of email addresses that were generated

in the sampling frame. Two follow-up emails were then sent when necessary,

after the first email. The data collection was undertaken between August 2019

and July 2020. The online survey was developed electronically using Qualtrics.

The survey participants were managers or heads of Services in the official

service partners of the motorcycle manufacturers in Indonesia. The inclusion

criteria for these managers were that they must be working in this field for at

least one year. A total of 447 responses were recorded for analysis.

With

the frequency of 447 participants, the sample's demographic profile indicates

that 87.5% are service partners with the employee less than 10. This was within

our expectation since most service partners are categorized as small or medium

enterprises. The majority of the surveyed motorcycle service partners are based

in Java (65.5%), followed by Sumatera (14.1%), Sulawesi (7.2%), Kalimantan

(5.6%), Bali-NT (5.6%) and Maluku-Papua (2%). Interestingly, many service

partners have collaborated with the manufacturers for more than ten years

(63.3%).

To

further ensure that the data are free from non-response bias, the t-test for

the equality of means on seven constructs was conducted by comparing early (n =

226) and late waves (n = 221). The result showed the early and late waves were

not statistically significant, with p-values greater than 0.05 for the six

constructs. These output results affirmed that non-response bias was not a

concern in this study.

In

the seventh stage, an instrument assessment was conducted through EFA followed

by CFA. EFA was utilized to evaluate the measurement properties of all

constructs. The factorability of the data was tested using Kaiser’s criterion

(eigenvalue >1) and parallel analysis to investigate the number of factors

that can be extracted (Bandalos et al.,

2009). Maximum likelihood extraction and Promax rotation were utilized

to verify the scale’s dimensionality. Seven constructs produced a one-factor

solution which explained 53.4 to 68.8 % of the variance, so the seven

constructs were considered valid by Howard and Henderson (2023). During the process of assessing the

dimensionality through EFA, no items were deleted, because no factor loading

was below 0.4 which is considered statistically significant (0.435– 0.869).

CFA using AMOS (version 26) was

utilized to evaluate the convergent, discriminant, and factorial validity of

the measurement. Convergent validity is the degree of agreement for a set of

indicators to measure the same construct. The convergent validity test consisted

of three steps. First is to calculate the chi-squared values of each construct;

and second, if the chi-squared rejects a factor at p<0.01 then we use the

modification indices to identify common factors among items. As a precaution,

the items that were dropped should have a low validity (i.e. from the validity

index of the interrater agreement). This process resulted in 7 constructs and

29 items. It dropped 6 items: CO4, CO6, PD4, REC5, ISD2 and SPSC1. These

findings are confirmed as evidence of convergent validity (Hair et al., 2010) with the goodness of

fit indices cut-off values: p> 0.01,

norm RMSEA< 0.05, SRMR< 0.07, CFI> 0.96

and TLI> 0.95. Discriminant validity among the seven constructs was achieved

as the value of AVE for each construct was greater than the value of the square

correlation between the respective construct with the other constructs. Since

the measurement model of the constructs in this study is congeneric,

coefficient H is considered the best measurement of reliability for this case (Hancock and Mueller, 2001). The result confirmed

that the scales were reliable as H in the range of 0.859–0.926 (H>0.80). The

seven constructs reported factor loading 0.50–0.87, p-value 0.173–0.467, RMSEA

0.00–0.038, SRMR 0.004–0.018, CFI 0.997–1.0, and TLI 0.994–1.0. Finally,

factorial validity examines whether a set of latent variables demonstrate an

underlying pattern by evaluating the fit statistics of the full measurement

model. The result confirmed a good fit of the measurement model that supported

the factorial validity of the measurement (normed X2 = 1.557, SRMR = 0.025,

RMSEA = 0.035, CFI = 0.977, and TLI = 0.974).

This study, drawn from the PSS, SSCM, and

dynamic capabilities theories, develops the PSS SC capabilities model. The

theories provide a stringent foundation for the conceptualization of PSS SC

capabilities. Likewise, the definition of PSS SC capabilities helps to

conceptualize that the implementation of PSS covers the whole product life

cycle to apply the responsibility of environmental sustainability. This follows

the recent definition of PSS by Annarelli, Battistella, and Nonino (2016) to consider the sustainability in offering the PSS. The proposed

model provides that PSS SC capabilities can be measured by seven constructs:

collaboration, knowledge assessment, partner development, reflexive control,

re-conceptualization, innovative service development, and sustainable

product–service capability. The final solution is comprised of 29 items to

support the seven constructs.

Studies investigating PSS SC

capabilities among manufacturers, intermediaries, and service partners are

relatively recent, hence a developing research area. There are few research

papers published in this field, therefore this study contributes by developing

the PSS SC capabilities model and identifying its constructs. The model is

based on previous literature on PSS and SSCM. This study contributes to the

theoretical development of the body of knowledge by conceptualizing the PSS SC

capabilities as holistic capabilities of a network comprised of manufacturers,

intermediaries, and service partners. Likewise, the study contributes clear

definitions of PSS SC capabilities applying the environmental sustainability

concept so that, by this definition, PSS SC capabilities can be used as part of

solutions to improve sustainability. The theoretical hypothesis for the PSS SC

capabilities is that they comprise seven constructs that demonstrate network SC

capabilities to deliver PSS by considering the environmental sustainability

concerns. This study has significant contributions in defining the PSS SC

capabilities and developing the dimensions that comprise it. Furthermore, it

provides ready-instrument development whose properties are sufficiently

validated. A rigorous procedure subsequently assessed the instrument's

reliability and validity. The model can be used by other researchers to build

the theoretical relationship model and can help practitioners as a decision

tool to develop strategies, and manage and measure the PSS SC capabilities

required by taking into account the environmental sustainability notion. Future

tests and refinement of the proposed model will be beneficial to the knowledge

development of PSS SC capabilities. Given the state of a PSS SC capabilities changes over time, it would be

interesting to take a longitudinal approach to examine how the SC capabilities

changed and evolved during the process of delivering the PSS. This can

be achieved by continuously exploring the relationship between PSS SC

capabilities components and other antecedents.

This research is supported by the Indonesian

Education Scholarship (LPDP) under Beasiswa Unggulan Dosen Indonesia (BUDI)

scheme.

Annarelli, A., Battistella,

C., Nonino, F., 2016. Product Service System: A Conceptual Framework from a

Systematic Review. Journal of Cleaner Production,

Volume 139, pp. 1011–1032

Ayala, N.F., Gerstlberger,

W., Frank, A.G., 2018. Managing Servitization

in Product Companies: The Moderating Role of Service Suppliers. International

Journal of Operations & Production Management, Volume 39(1), pp.43–74

Bandalos, D., Boehm-Kaufman, M., Lance, C.,

Vandenberg, 2009. Four Common Misconceptions in Exploratory Factor Analysis.

Taylor and Francis, pp.63–88

Berawi, M.A. 2021a. Managing Cross-Sectoral

Coordination in Accelerating The Sustainable Development Agenda. International

Journal of Technology, Volume 12(2), pp. 228–231

Berawi, M.A., 2021b. World Agenda on

Sustainable Recovery from The Ovid-19 Pandemic: Recover Together, Recover

Stronger. International Journal of Technology, Volume 12(4), pp. 671–675

Beske, P., 2012. Dynamic Capabilities and

Sustainable Supply Chain Management. International Journal of Physical

Distribution & Logistics Management, Volume 42(4), pp. 372–387

Beske, P., Land,

A., Seuring, S., 2014. Sustainable Supply

Chain Management Practices and Dynamic Capabilities in The Food Industry: A Critical

Analysis of The Literature. International

Journal of Production Economics, Volume 152, pp. 131–143

Blome, C., Paulraj, A., Schuetz, K., 2014.

Supply Chain Collaboration and Sustainability: A Profile Deviation Analysis. International Journal of Operations &

Production Management, Volume 34(5), pp. 639–663

Boon-itt, S., Wong, C.Y., Wong, C.W., 2017.

Service Supply Chain Management Process Capabilities: Measurement Development. International Journal of Production

Economics, Volume 193, pp.1–11

Cao, M., Vonderembse, M.A., Zhang, Q.,

Ragu-Nathan, T.S., 2010. Supply Chain Collaboration: Conceptualisation and

Instrument Development. International Journal Of Production Research,

Volume 48, pp. 6613–6635

Coenen, J., van Der

Heijden, R.E.C.M., van Riel, A.C.R., 2018. Understanding Approaches to

Complexity and Uncertainty in Closed-Loop Supply Chain Management: Past Findings

and Future Directions. Journal of Cleaner

Production, Volume 201, pp. 1–13

Defee, C., Fugate, B.S., 2010. Changing Perspective

of Capabilities in The Dynamic Supply Chain Era. The International Journal of Logistics Management, Volume 21(2),

pp. 180–206

Dewi. D.R.S., Pittayachawan, S., Tait. E.,

2020. A conceptual framework for Servitisation of the manufacturing companies

to deliver Product–Service Systems solutions: A study case of the Indonesian

Motorcycle Industry, IOP Conference

Series: Materials Science and Engineering, Volume 847(1), pp.012056.

Dewi, D.R.S., Hermanto, Y.B., 2022. Supply Chain

Capabilities to Improve Sustainability Performance of Product–Service Systems. International Journal of Sustainable

Development and Planning, Volume 17(8), pp. 2561–2569

Dewi, D. R. S., Hermanto, Y. B., Tait, E.,

Sianto, M. E., 2023. The Product–Service System Supply Chain Capabilities and Their

Impact on Sustainability Performance: A Dynamic Capabilities Approach. Sustainability, Volume 15(2), pp. 1148

Garetti, M., Taisch, M., 2012. Sustainable Manufacturing:

Trends and Research Challenges. Production

Planning & Control, Volume 23(2-3), pp. 83–104

Hair, J.F., Anderson, R.E., Babin, B.J.,

Black, W.C., 2010. Multivariate Data

Analysis. Pearson Prentice Hall, Upper Saddle River, New Jersey, United

States

Hancock, G., Mueller, R., 2001. Rethinking Construct

Reliability within Latent Variable Systems. Structural

equation modeling: Present and future, Volume 1, pp. 195–216

Hanim, A.R.S., Sakundarini, N., Raja, G.R.A.,

Thurasamy, R., 2017. The Impact of Sustainable Manufacturing Practices on

Sustainability Performance: Empirical Evidence from Malaysia. International Journal of Operations &

Production Management, Volume 37(2), pp. 182–204

Haque, M., Islam, R., 2018. Impact of Supply

Chain Collaboration and Knowledge Sharing on Organizational Outcomes in

Pharmaceutical Industry of Bangladesh. Journal of Global Operations and

Strategic Sourcing, Volume 11 (3), pp. 301–320

Hong, J., Zhang, Y., Ding, M., 2018.

Sustainable Supply Chain Management Practices, Supply Chain Dynamic

Capabilities, and Enterprise Performance. Journal of Cleaner Production,

Volume 172, pp. 3508–3519

Howard, M.C., Henderson, J., 2023. A Review of

Exploratory Factor Analysis In Tourism And Hospitality Research: Identifying Current

Practices And Avenues for Improvement. Journal

of Business Research, Volume 154, p. 113328

Jadhav, A., Orr, S., Malik, M., 2018. The Role

of Supply Chain Orientation in Achieving Supply Chain Sustainability. International

Journal of Production Economics, Volume 217, pp. 112–125

Jarva, E.,, Oikarinen, A., Andersson, J.,

Tomietto, M., Kääriäinen, M., Mikkonen, K., 2023. Healthcare Professionals’

Digital Health Competence and its Core Factors; Development and Psychometric

Testing of Two Instruments. International

Journal of Medical Informatics, Volume 171, pp. 104995

Kindström, D., Kowalkowski, C., Sandberg, E.,

2013. Enabling Service Innovation: A Dynamic Capabilities Approach. Journal of Business Research, Volume

66(8), pp. 1063–1073

Kumar, G., Subramanian, N., Arputham, R.,

2018. Missing Link Between Sustainability Collaborative Strategy and Supply

Chain Performance: Role of Dynamic Capability. International Journal of

Production Economics, Volume 203, pp.96–109

Kusrini, E., Kartohardjono, S., Putra, N.S.D.,

Budiyanto, M.A., Wulanza, Y., Berawi, M.A., Suwartha, N., Maknun, I.J., Asvial,

M., Setiawan, E.A., Suryanegara, M., Harwahyu, R., Yatmo, Y.A., Atmodiwiryo,

P., 2020. Science, Engineering and Technology for Better Future. International

Journal of Technology, Volume 11(7), pp.1286–1291

Lewis, B.R., Templeton,

G.F., Byrd, T.A., 2005. A Methodology For Construct Development in MIS Research.

European Journal of Information Systems, Volume 14(4) pp. 388–400

Lindell, M., 2001. Assessing and Testing

Interrater Agreement on A Single Target Using Multi-Item Rating Scales. Applied Psychological Measurement,

Volume 25(1), pp. 89–99

Mandal, S., Sarathy, R., Korasiga, V.R.,

Bhattacharya, S., Dastidar, S.G. 2016. Achieving Supply Chain Resilience: The

Contribution of Logistics and Supply Chain Capabilities. International

Journal of Disaster Resilience in the Built Environment, Volume 7(5), pp.

544–562

Martinez, V., Bastl, M., Kingston, J., Evans,

S., 2010. Challenges in Transforming Manufacturing Organisations into

Product-Service Providers. Journal of Manufacturing

Technology Management, Volume 21(4), pp. 449–469

Moro, S.R., Cauchick-Miguel,

P.A., Mendes, G.H.S., 2022. Literature Analysis on Product-Service Systems

Business Model: A Promising Research Field. Brazilian Journal of Operations

& Production Management, Volume 19(1), p.1–18

Pagell, M., Wu, Z., 2009. Building a More

Complete Theory of Sustainable Supply Chain Management Using Case Studies of 10

Exemplars. Journal of Supply Chain

Management, Volume 45(2), pp. 37–56

Paiola, M., Saccani, N., Perona, M., Gebauer,

H., 2013. Moving from Products to Solutions: Strategic Approaches for

Developing Capabilities. European

Management Journal, Volume 31(4), pp. 390–409

Podsakoff, P., MacKenzie, S.B., Lee, J.Y.,

Podsakoff, N.P., 2003. Common Method Biases in Behavioral Research: A Critical

Review of The Literature and Recommended Remedies. Journal of applied psychology, Volume 88(5), p. 879

Raddats, C., Zolkiewski, J., Story, V.M.,

Burton, J., Baines, T., Ziaee Bigdeli, A., 2017. Interactively Developed

Capabilities: Evidence from Dyadic Servitization Relationships. International Journal of Operations &

Production Management, Volume 37(3), pp. 382–400

Seuring, S., Müller, M., 2008. From a Literature

Review to a Conceptual Framework for Sustainable Supply Chain Management. Journal

of Cleaner Production, Volume 16(15), pp. 1699–1710

Story, V.M., Raddats, C., Burton, J.,

Zolkiewski, J., Baines, T., 2017. Capabilities for Advanced Services: A

Multi-Actor Perspective. Industrial

Marketing Management, Volume 60, pp. 54–68

Sud-on, P., Abareshi, A., Pittayachawan, S.,

Teo, L., 2013. Manufacturing Agility: Construct and Instrument Development. World Academy of Science, Engineering

Technology, Volume 82, pp. 754–762