Fuzzy Logic Modelling for Microwave Heat Treatment of Aluminium Sheet

Corresponding email: pclingam@gmail.com

Published at : 04 Apr 2023

Volume : IJtech

Vol 14, No 2 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i2.5578

Azhar, N.A.C., Chockalingam, P., Wen, C.C., Perumal, L., 2023. Fuzzy Logic Modelling for Microwave Heat Treatment of Aluminium Sheet. International Journal of Technology. Volume 14(2), pp. 434-442

| Nur Afrina Che Azhar | Faculty of Engineering and Technology, Multimedia University, 75450 Melaka, Malaysia |

| Palanisamy Chockalingam | Faculty of Engineering and Technology, Multimedia University, 75450 Melaka, Malaysia |

| Chin Chee Wen | Faculty of Engineering and Technology, Multimedia University, 75450 Melaka, Malaysia |

| Logah Perumal | Faculty of Engineering and Technology, Multimedia University, 75450 Melaka, Malaysia |

Microwave energy heating is one of the

methods to improve product quality, faster processing, eco-friendliness, and

cost and energy savings. The unique heating ability leads to explore this heat

treatment method by exploiting its process parameters to improve its

effectiveness. This research aimed to predict the effect of microwave heat

treatment on aluminium alloy 6063-T6 sheets using fuzzy logic. Microwave

heat-treatment trials are designed using the Design of Experiment (DOE) method.

The input parameters are heating time, susceptor, and insulator. The non-heated

and heated aluminium 'specimen's mechanical properties have been tested using a

hardness and tensile testing machine. The experimental results are used to

develop a Mamdani fuzzy logic model system. The results indicate that the

mechanical properties in terms of tensile Load, and hardness of the specimen

have improved after being microwave heat-treated for a short time. The

susceptor material and insulator can assist in the microwave processing of

materials. The percentage difference between the experimental and simulation

values are 0.27 and 6.31%, respectively, for tensile Load and hardness. The

experimental and predicted results are still compatible with a small percentage

of errors. The fuzzy model can be used to predict the parameters.

Aluminium 6063; Fuzzy logic; Hardness; Insulator; Microwave heating; Susceptor; Tensile strength

Heating using microwave energy

is a faster, eco-friendly, cost effective and energy-saving method. Many

studies have discovered that microwave heat treatment can be used to enhance

metals' physical and mechanical properties. However, several significant parameters

must be considered when applying the method to achieve optimum microwave

heating. Consequently, sparking and arcing that looks like a miniature bolt of

lightning will occur when the microwave heats the metal. One of the numerous

effective ways to heat treat metals using microwave heating is the use of

microwave susceptor. Susceptors and insulators are critical in optimizing

microwave energy conversion and heating process (Bhattacharya

and Basak, 2016). Absorbent, also known as a susceptor,

effectively enhances microwave heating characteristics. Since metal will

reflect the microwave's energy, the susceptor can uniformly distribute

microwave energy and minimize escaping heating (Muhammad,

Idris, and Mohamad, 2016).

The

dielectric properties of the susceptor, namely graphite, silicon carbide, and charcoal, determine the material's ability to heat

in microwave fields. Seo et al. (2011) used

DOE to establish relationships between design factors and response values of

micro milling processes. Pavani, Rao, and Prasad

(2017) studied the

tribological properties using the design of an Experiment (DOE). Butdee and Khanawapee (2021) did a quality prediction using a fuzzy

inference system with multi-factors and developed a model to predict quality.

Design of experiments and simulations, such as the fuzzy logic model, is

suitable to analyze and predict the outcomes of a study depending on the input

parameters (Sengottuvel Satishkumar, and Dinakaran, 2013). In this research, a fuzzy logic

model is developed to predict the effect of microwave heat treatment on the

aluminium sheets mechanical properties under the studied parameters of

microwave heating time, susceptor material, and the amount of insulator. The accuracy of the fuzzy model will

be determined by comparing the measured values to the predicted output values.

Studies have proven that the fuzzy logic model is reliable since it can produce

accurate output values. Therefore, this research aimed to investigate the

effect of microwave heat treatment on the mechanical properties of aluminium

sheets and to develop a fuzzy logic model to predict the factors affecting the

microwave heat treatment process.

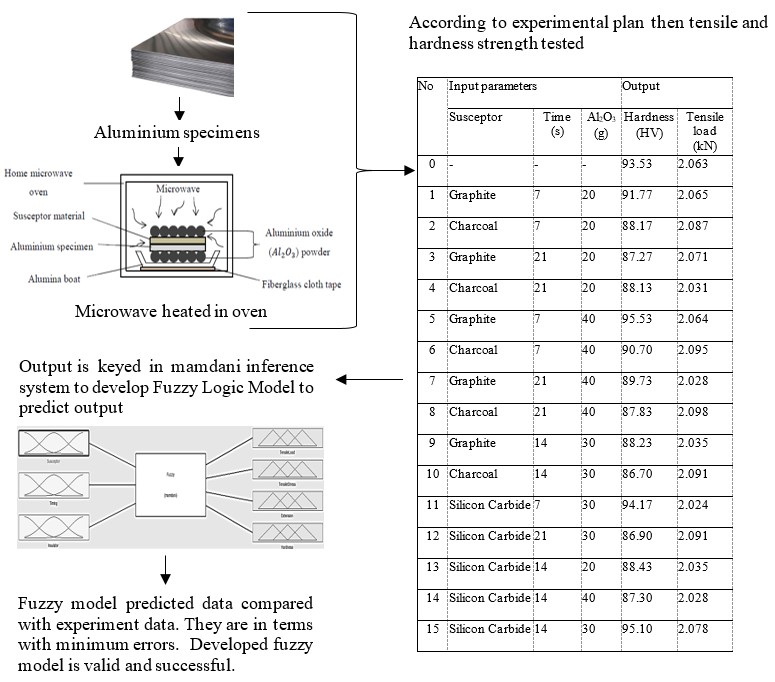

The microwave heat treatment experiment was carried

out in the home microwave oven with 950 W of power and a 2.45 GHz frequency (Palanisamy and Krishnan, 2021). The experimental setup

is shown in Figure 1. An Aluminium 6063-T6 sheet with a 1.5 mm thickness was

used in this experiment, which was purchased from Uniware Machinery Sdn. Bhd.

The material is prepared with a dimension of 25x25 mm and an ASTM E-8 standard

specimen. To prevent damage to the

microwave turntable from direct heating, a layer of alumina boat and fiberglass

was used as protection between the turntable and the specimens. An alumina boat

with a 100 x 30 x 20 mm dimension is used. Aluminium oxide (

Figure 1 Microwave heat treatment setup

The

Mamdani inference system was used to predict the output responses. all variables

were numerically divided into several fuzzy sets and labeled using appropriate

linguistic terms. The input variables were divided into three levels, while the

output variables were set to five levels. To achieve more accurate results, the

output membership functions were given more levels than the input membership

functions due to the variability of the experimental output results.

Table 1 Levels and code for input parameters

|

Parameter |

Levels |

||

|

Level and code |

Low (-1) |

Middle (0) |

High (1) |

|

Susceptor |

Graphite |

Silicon Carbide |

Charcoal |

|

Timing |

7 |

14 |

21 |

|

Insulator |

20 |

30 |

40 |

The tensile and hardness test results are

given in Table 2. Test specimen 8 recorded the highest tensile Load among all

specimens, which is 2.065 kN, where the difference is 1.68%.

Table 2 Experimental table and output

|

No |

Input parameters |

Output | |||

|

Susceptor |

Time (s) |

Al2O3 (g) |

Hardness (HV) |

Tensile Load (kN) | |

|

0 |

- |

- |

- |

93.53 |

2.063 |

|

1 |

Graphite |

7 |

20 |

91.77 |

2.065 |

|

2 |

Charcoal |

7 |

20 |

88.17 |

2.087 |

|

3 |

Graphite |

21 |

20 |

87.27 |

2.071 |

|

4 |

Charcoal |

21 |

20 |

88.13 |

2.031 |

|

5 |

Graphite |

7 |

40 |

95.53 |

2.064 |

|

6 |

Charcoal |

7 |

40 |

90.70 |

2.095 |

|

7 |

Graphite |

21 |

40 |

89.73 |

2.028 |

|

8 |

Charcoal |

21 |

40 |

87.83 |

2.098 |

|

9 |

Graphite |

14 |

30 |

88.23 |

2.035 |

|

10 |

Charcoal |

14 |

30 |

86.70 |

2.091 |

|

11 |

Silicon Carbide |

7 |

30 |

94.17 |

2.024 |

|

12 |

Silicon Carbide |

21 |

30 |

86.90 |

2.091 |

|

13 |

Silicon Carbide |

14 |

20 |

88.43 |

2.035 |

|

14 |

Silicon Carbide |

14 |

40 |

87.30 |

2.028 |

|

15 |

Silicon Carbide |

14 |

30 |

95.10 |

2.078 |

Specimen

8 was heated with 40 g of alumina powder and charcoal powder for 21 seconds, as

compared to the unheated specimen. On the other hand, the lowest tensile Load

is for specimen number 11, which is 2.024 kN, which is 1.91% lower than the

unheated specimen. This specimen was heated with a silicon carbide susceptor

and a 30 g insulator for 7 s. The hardness test for each aluminum specimen was

conducted under the same load and repeated three times to average the values

for accuracy. The hardness value of the unheated specimen will be compared to

that of the heated specimen. Based on the data in Table 2, the hardness values

between the specimens have slight differences. Some of them have higher or

lower hardness than the non-heated specimen, named specimen 0, with a hardness

value of 93.53 HV. The hardest specimen, 95.53 HV, was heated for 7 seconds and

mixed with graphite susceptor and 40 g of alumina powder. Its hardness value

has increased by 2.14% compared to the unheated specimen. Furthermore, the

hardness values of specimens 11 and 15 were higher than that of the non-heated

specimen by 0.68% and 1.67%, respectively, with hardness values of 94.17 HV and

95.10 HV. During the microwave heating, the specimens were mixed with silicon

carbide susceptor and 30g alumina powder, but specimen 11 was only heated for 7

s and specimen 15 for 14 s. Meanwhile, specimen 10 was heated for 14 s with a

charcoal susceptor, and 30 g of alumina powder, had the lowest hardness value,

86.70 HV. The hardness of the specimen has dropped by 7.31% compared to the

unheated specimen. Among the specimens with decreased hardness value, all

heated specimens with added charcoal susceptor have a low hardness value. These

specimens are 2, 4, 6, 8, and 10, with a hardness value that dropped to 5.74%

(88.17 HV), 5.77% (88.13 HV), 3.03% (90.70 HV), 6.09% (87.83 HV), and 7.31%

(86.70 HV), respectively. Moreover, except for specimen 5, other specimens with

graphite sheets, such as 1, 3, 7, and 9, have a lower hardness value than the

non-heated specimen. The reduction in hardness value of these specimens is 1.89%,

6.70%, 4.06%, and 5.67%, where their hardness is 91.77 HV, 87.27 HV, 89.73 HV,

and 88.23 HV. Finally, the specimen's heat treated with silicon carbide decreed

in hardness compared to the unheated specimen is 12, 13, and 14, with a value

of 86.90 HV, 88.43 HV, and 87.30 HV. These specimens differ from the non-heated

specimen by 7.09%, 5.45%, and 6.66%, respectively.

Table 3 Linguistic

terms of range for output variables

|

Output Parameter |

Range |

Linguistic Terms |

|

Tensile

load (kN) |

2.024-2.041 |

Lowest |

|

2.034-2.056 |

Low | |

|

2.049-2.071 |

Middle | |

|

2.064-2.094 |

High | |

|

2.079-2.1 |

Highest | |

|

Hardness

(HV) |

9.69-13.1 |

Lowest |

|

11.13-15.26 |

Low | |

|

13.28-17.42 |

Middle | |

|

15.44-19.57 |

High | |

|

17.6-21.1 |

Highest |

Based on the tensile and hardness test results, AL-Qaisy, Hasan, and Mahmood (2017) developed a fuzzy logic model for the microwave heat treatment of the aluminum sheet using "if-then" rules. These fuzzy rules are evaluated and combined to generate a set of fuzzy outputs. The input variables and their terms are shown in Table 1. The output variables were categorized into five linguistic terms, as shown in Table 3, and Table 4 shows the fifteen fuzzy rules. Finally, the model is used to predict the output. The fuzzy prediction values for all 15 runs are shown in Table 5. The accuracy of the fuzzy logic values was investigated by calculating the percentage errors.

Table 4 List of fuzzy rule base for input and

output parameters

|

No |

Input Parameter |

Output | ||

|

Susceptor |

Timing |

Insulator |

Tensile Load | |

|

1 |

Graphite |

Short |

Small |

High |

|

2 |

Charcoal |

Short |

Small |

Highest |

|

3 |

Graphite |

Long |

Small |

Middle |

|

4 |

Charcoal |

Long |

Small |

Lowest |

|

5 |

Graphite |

Short |

High |

High |

|

6 |

Charcoal |

Short |

High |

Highest |

|

7 |

Graphite |

Long |

High |

Lowest |

|

8 |

Charcoal |

Long |

High |

Highest |

|

9 |

Graphite |

Middle |

Average |

Low |

|

10 |

Charcoal |

Middle |

Average |

Highest |

|

11 |

Silicon

Carbide |

Short |

Average |

Lowest |

|

12 |

Silicon

Carbide |

Long |

Average |

Highest |

|

13 |

Silicon

Carbide |

Middle |

Small |

Low |

|

14 |

Silicon

Carbide |

Middle |

High |

Lowest |

|

15 |

Silicon

Carbide |

Middle |

Average |

High |

Table 5 shows that the majority of

percentage errors are less than 10%, except the hardness outputs of specimens 1

and 2, which have 14.26% and 14.20%, respectively. This might be due to errors

in the hardness test on specimen 1 since the specimen's hardness value was set

as the upper limit of the range for hardness output in the developed fuzzy

model. Thus, the error has affected the rest of the predicted hardness output

values, as most have more than 1% error. However, the fuzzy logic results for

tensile load are reliable since it is no higher than 10%, according to the

claim by (Vasudev et al.,

2019; Tanyildizi, 2009). Figure 2(a)-(b) depict the predicted fuzzy

logic values of output parameters alongside experimental results. We can

determine the absolute percentage errors between the experimental and estimated

results by averaging the individual percentage errors. It has been observed

that the error is 0.27%, 0.35%, 1.23%, and 6.31% for a tensile load. The output

is small despite a few significant individual percentage errors for the

hardness test. Therefore, the fuzzy logic model predicted values are close to

the experimental data. This shows that the developed fuzzy logic model can

predict the output values of tensile load and hardness within the considered

range of input parameters.

Figure 2 Experimental with fuzzy predicted

results comparison (a) Tensile load (b)

Hardness

Table 5 Experimental and fuzzy predicted

values

|

No |

Experimental |

Fuzzy |

Errors (%) | |||

|

Tensile (kN) |

Hardness (HV) |

Tensile (kN) |

Hardness (HV) |

Tensile |

Hardness | |

|

1 |

2.065 |

9.69 |

2.080 |

11.30 |

0.73 |

14.26 |

|

2 |

2.087 |

9.70 |

2.090 |

11.30 |

0.13 |

14.20 |

|

3 |

2.071 |

14.36 |

2.060 |

15.30 |

0.55 |

6.16 |

|

4 |

2.031 |

14.34 |

2.030 |

15.30 |

0.05 |

6.25 |

|

5 |

2.064 |

16.35 |

2.080 |

17.50 |

0.77 |

6.54 |

|

6 |

2.095 |

16.37 |

2.090 |

17.50 |

0.26 |

6.48 |

|

7 |

2.028 |

21.01 |

2.030 |

19.40 |

0.09 |

8.30 |

|

8 |

2.098 |

21.03 |

2.090 |

19.40 |

0.37 |

8.42 |

|

9 |

2.035 |

15.35 |

2.040 |

15.30 |

0.24 |

0.29 |

|

10 |

2.091 |

15.36 |

2.090 |

15.30 |

0.05 |

0.42 |

|

11 |

2.024 |

13.01 |

2.030 |

13.20 |

0.31 |

1.46 |

|

12 |

2.091 |

17.70 |

2.090 |

19.40 |

0.06 |

8.78 |

|

13 |

2.035 |

12.01 |

2.040 |

13.20 |

0.25 |

9.00 |

|

14 |

2.028 |

18.68 |

2.030 |

19.40 |

0.11 |

3.73 |

|

15 |

2.078 |

15.36 |

2.080 |

15.30 |

0.09 |

0.39 |

The

response plot developed by the fuzzy logic system depicts the changes in

mechanical properties in the specimen due to the microwave heat treatment's

independent variables. Figure 3 (a) shows that the most

favorable tensile load is achieved with a heat timing range of 14 to 21 s and a

susceptor value of 1.25 to 1.5. This suggests that the highest tensile load is

obtained at the maximum heat timing, while using a susceptor made of silicon

carbide or charcoal. Simultaneously, using 30g of insulator increased the

specimen's tensile load, as shown in Figure 3(b). In

addition, a susceptor can increase the tensile load of the specimen when heated

for a longer period of time, specifically in the range of 14 to 21 seconds.

Each rise or fall in the tensile and hardness is related to one another

depending on the microwave parameters. According to the experimental results,

the addition of a susceptor and insulator can improve the aluminium specimen's

mechanical properties as the microwave heating process takes longer (Leong-Eugene and

Gupta, 2010). The experimental results supported the

finding as they showed an increase of 0.08% in the tensile load and tensile

stress of specimen 1.

The experimental results also show that using charcoal as a susceptor is better than using graphite during the microwave heating. It can produce a higher tensile load, and tensile stress than a specimen made using graphite. Specimen 2 used the same amount of insulator and heated for the same amount of time as specimen 1 but used charcoal as the susceptor. Charcoal material has proven to be a good electromagnetic absorber due to its lower range of loss tangent factor, 0.14 to 0.38, with a penetration depth of 6–11 cm (Bhattacharya and Basak, 2016). The material's ductility also increases as the hardness value has dropped 5.74% with an 88.17 HV value. The hardness value of specimen 2 is lower than that of specimen 1. In other words, charcoal powder is a more effective susceptor material compared to graphite sheet. Moreover, charcoal powder is commonly used in cladding and joining applications. During the microwave heating process, some of the specimens developed cladding on their surfaces as a result of using charcoal powder as the susceptor.

The higher amount of insulator used during microwave heat treatment also improved the material's mechanical properties. By taking an example case of the highest amount of insulator but still using the same susceptor material and heated in the same short time as specimen 2, the tensile load of specimen 6 is higher than the former specimen. The tensile load of the material has improved by 1.17%, with a value of 2.087 kN. The specimen used the highest amount of aluminium oxide powder, 40 g, which caused the insulator's thickness that covered the specimen to be increased. As the insulator's quantity increases, the thermal heat loss rate will decrease. Aluminium oxide is considered one of the electro-conductive materials that can resist high temperatures from microwave energy. Therefore, more microwave heat can be generated and transferred to the specimen in a short time. Furthermore, a higher amount of insulator can cover more metal surfaces to prevent the microwave's electromagnetic energy from contacting the heated specimen. Subjecting a wrapped specimen with sufficient insulator thickness can cause a non-sparking microwave heating process, preventing the microwave furnace from damage and saving time and money.

|

|

Figure 3 The Surface plots (a) timing and susceptor for tensile load (b) insulator and timing for tensile load (c) timing and susceptor for hardness (d) insulator and timing for hardness

A brittle material can be produced from the microwave heat treatment by the increased material hardness , leading to a lower tensile load in the heated specimen (Padmavathi, Upadhyaya, and Agrawal, 2011). The susceptor can increase the specimen's toughness due to the higher value of hardness, 13.01 HV, with a difference of 0.68% to the non-heated specimen (Meunier et al., 2017). Brittle aluminium is suitable for high strain-rate construction and military applications. The material has a higher resistance to bending and wear. From the data, specimen 8 has the highest tensile load and tensile strength with low hardness. Thus, microwave heat treatment's optimum input parameters are charcoal susceptor, 21-second heating time, and 40 g of the insulator. In addition, specimen 11 has the lowest tensile load with high hardness. This demonstrates that the input parameters of silicon carbide susceptor, 7 s heat timing, and 30 g insulator are the least suitable parameters to achieve optimum microwave heat treatment effectiveness. The changes in these specimens' mechanical properties depend on the input parameters: heat timing and susceptor material. In a short heating time, the charcoal susceptor will increase the tensile load.

Aluminium alloy 6063-T6 has been heat treated

by a microwave heating process and the heat treatment trials were conducted

based on a central composite design. The input parameters are susceptor

material, heat timing, and amount of aluminium oxide. A tensile and hardness

test was conducted on both non-heated and heat-treated aluminium specimens to

compare the results of mechanical properties such as tensile load and hardness.

The experimental results were used to develop a fuzzy model. It is proven that

the fuzzy model is highly reliable as the experimental and predicted results are

compatible with each other. The absolute errors between the experimental and

predicted values are 0.27 and 6.31%, respectively, for tensile load and

hardness. The experimental results show an improvement in the mechanical

properties of the microwave heat-treated aluminium specimen. The material's

mechanical properties increased as the susceptor absorbed and transferred a

high density of microwave heat to the specimen. Under the same amount of

insulator case, the changes in the mechanical properties depend on the heating

time and susceptor material parameters. An insulator helps prevent sparks or

flames from occurring during microwave heat treatment. It was found that the

susceptor and insulator could improve the mechanical properties of the

microwave heated aluminium material. The experimental and predicted results are

still compatible with each other because of the relatively small percentage of

errors between both values. Thus, the fuzzy model can be used in the industries

in microwave heat treatment applications to predict the effect of microwave

heat treatment on aluminium sheets.

| Filename | Description |

|---|---|

| R2-ME-5578-20220616161047.jpg | Supplementary file |

AL-Qaisy, A.A., Hasan, S.F., Mahmood, N.Y., 2017.

Study the effects of microwave furnace heat on the mechanical properties and

estimated fatigue life of AA2024-T3. Journal of Engineering, Volume

23(10), pp. 146–156

Bhattacharya, M., Basak, T., 2016. A review

on the susceptor assisted microwave processing of materials. Energy, Volume

97, pp. 306–338

Butdee, S., Khanawapee, U., 2021. Quality

prediction modeling of a preform fastener process using fuzzy logic and DEFORM simulation. International

Journal of Technology, Volume 12(1), pp. 33–42

Leong-Eugene, W.W., Gupta, M., 2010.

Characteristics of aluminium and magnesium based nanocomposites processed using

hybrid microwave sintering. Journal of Microwave Power and Electromagnetic

Energy, Volume 44(1), pp. 14–27

Meunier, C., Zuo, F., Peillon, N., Saunier,

S., Marinel, S., Goeuriot, D., 2017. In situ study on microwave sintering of

ZTA ceramic: Effect of ZrO2 content on densification, hardness, and

toughness. Journal of the American Ceramic Society, Volume 100(3), pp.

929–936

Muhammad, W.N.A.B.W.,

Idris, M.F.B, Mohamad, M.N.A.B, Osman, S.A.B., 2016. Effect of

bottom ash and fly ash as a susceptor material on the properties of aluminium

based composites prepared by microwave heating, In: MATEC Web of

Conferences, Volume 87, p. 02023

Padmavathi, C., Upadhyaya, A., Agrawal, D., 2011.

Effect of microwave and conventional heating on sintering behaviour and

properties of Al–Mg–Si–Cu alloy. Materials Chemistry and Physics, Volume

130(1-2), pp. 449–457

Palanisamy, C., Krishnan, G.K., 2021.

Experimental classification and response surface modelling of compression

property of 3D printed polylactic acid parts. In: AIP Conference

Proceedings, Volume 2339(1) p. 020070

Pavani, P.N.L., Rao, R.P., Prasad,

C.L.V.R.S.V., 2017. Synthesis and experimental investigation of tribological

performance of a blended (palm and mahua) bio-lubricant using the taguchi

design of experiment (DOE). International Journal of Technology,

Volume 8(3), pp. 418–427

Sengottuvel, P., Satishkumar, S., Dinakaran,

D., 2013. Optimization of multiple characteristics of EDM parameters based on

desirability approach and fuzzy modelling. Procedia Engineering, Volume

64, pp. 1069–1078

Seo, T., Song, B., Seo, K., Cho, J., Yoon,

G., 2011. A study of optimization of machining conditions in micro end-milling

by using response surface design. International Journal of Technology,

Volume 2(3), pp. 248–256

Tanyildizi, H., 2009. Fuzzy logic model for

prediction of mechanical properties of lightweight concrete exposed to high

temperature. Materials & Design, Volume 30(6), pp. 2205–2210

Vasudev, H., Singh, G., Bansal, A., Vardhan,

S., Thakur, L., 2019. Microwave heating and its applications in surface

engineering: a review. Materials Research Express, Volume 6(10),

p. 102001