Simulation-Based Optimization of Injection Molding Process Parameters for Minimizing Warpage by ANN and GA

Published at : 04 Apr 2023

Volume : IJtech

Vol 14, No 2 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i2.5573

Nitnara, C., Tragangoon, K., 2023. Simulation-Based Optimization of Injection Molding Process Parameters for Minimizing Warpage by ANN and GA. International Journal of Technology. Volume 14(2), pp. 422-433

| Chiwapon Nitnara | Department of Mechanical Engineering Technology, College of Industrial Technology, King Mongkut's University of Technology North Bangkok, 1518 Pracharat I, Bangsue, Bangkok 10800, Thailand |

| Kumpon Tragangoon | Department of Mechanical Engineering Technology, College of Industrial Technology, King Mongkut's University of Technology North Bangkok, 1518 Pracharat I, Bangsue, Bangkok 10800, Thailand |

Plastic injection molding is one of the most used

methods for producing plastic products because it can be produced at a high

production rate, low cost, and ease in manufacturing. However, one defect that

affects product quality is namely warpage. To reduce plastic product warpage,

the injection molding process is required optimal process control to

increase plastic product quality. The objective of this paper is to optimize

injection molding process parameters for minimizing the warpage of plastic

glass. The optimization process is divided into two phases.

The Finite Element Method (FEM) was employed in the first phase to

simulate 32 experiments under various parameters. The parameters of this

process consist of melt temperature ranging from 180 to 230 °C, mold

temperature in the range of 20 – 45 °C, filling time from 0.82 to 0.92 s,

packing time ranging from 5.88 to 7 s and cooling time of 14 to 18 s. In the

second phase, Artificial Neural Network (ANN) combined Genetic Algorithm (GA)

was developed to predict the warpage and solve the optimization process to find

optimal parameters. Combining the intelligent method shows that ANN and GA

effectively find the optimal process parameters that can reduce the warpage of

the product by 35.73% from the maximum value.

Artificial Neural Network (ANN); Finite Element Method (FEM); Genetic Algorithm (GA); Optimization; Plastic injection molding

Plastic

injection molding is the most popular process for producing plastic packaging,

medical equipment, automotive parts, and electronics. In the plastic injection

molding process, the plastic pellets are melted at high temperatures by a

heater of the injection machine. Subsequently, melted plastic is injected into

the mold cavity and core with specific injection pressure and packed by packing

pressure. Finally, the melted plastic is cooled down to transform into a

plastic product (Kitayama et al., 2020; Cheng

and Liu, 2018; Hasnan et al., 2017).

However, the process parameters, such as the melt temperature of the plastic,

injection pressure, packing pressure, packing time, and cooling time, affect

the resulting product's properties. The properties of plastic products from the

injection molding process are required a high strength-to-weight ratio and

durability. Controlling the process parameters is necessary for obtaining the

best plastic product property.

Traditionally, the conventional practice of determining injection molding

process parameters is adjusted through trial and error by experienced engineers

(Guo et al., 2019). However, this

method cannot precisely determine the optimal process parameters, resulting in

time-consuming, repetitive testing and easy occurring defect. The most common

type of defect that occurs in the plastic injection molding process is called

warpage which affects the quality of the product (Huang

et al., 2021; Gao

and Wang, 2008; Kurtaran and Erzurumlu,

2006; Hakimian and Sulong, 2012). The warpage of the product continues

occurring because several related process parameters and independent process

parameters intervene with the plastic injection molding process.

Computer-aided engineering

(CAE) was a technology for numerical simulation of the plastic injection

molding process (Hentati et al., 2019).

The advantage of CAE was less cost and faster experimenting virtually.

Additionally, CAE serves as a tool for predicting the behavior of defects that

may impact the product's quality, as well as for the validation and

optimization of the product's design. At present, the intelligent method is

widely used in combination with CAE to optimize the plastic injection molding

process for reducing defects such as artificial neural networks, genetic

algorithms, support vector machine, Etc (Zhao et

al., 2020).

Several studies have

investigated the optimization of the injection molding process by different

techniques. Shi, Xie, and Wang (2013) optimized plastic injection process parameters to reduce warpage by using

the Kriging surrogate model. Erzurumlu and Ozcelik

(2006) minimized warpage and sink marks of plastic parts under different

design rib cross-section types and rib layout angles by using Taguchi

optimization. Oliaei et al. (2016) optimized

plastic injection process parameters by Taguchi's orthogonal array, and ANN was

selected as the optimal parameter. Zhang et al.

(2016) presented particle swarm optimization on the oil cooler cover cooling

and a cooling channel to reduce warpage. Zhou, Turng,

and Kramschuster (2006) used SVR and GA to optimize the process

parameters. Dang (2014) used direct and

metamodel-based methods as optimization injection molding process parameters. Farshi, Gheshmi, and Miandoabchi (2011) presented

the Evolutionary Operation (EVOP) method used to minimize the warpage and

shrinkage defects of plastic parts. Lockner and

Hopmann (2021) used network-based transfer learning to reduce data of

artificial neural network training for optimizing injection machine parameters.

The objective of this paper

is to find the optimal injection molding process parameters for reducing

warpage by determining the injection molding process parameters of plastic

glass. we conducted experiments using a simulation method to assess warpage

under various process parameters, including melt temperature, mold temperature,

filling time, packing time, and cooling time. To further refine our results, we

used artificial neural networks (ANN) to predict warpage based on simulation

data and developed a Fitness Function Equation. Finally, we utilized the GA

method to identify the optimal injection molding process parameters that will

reduce warpage in plastic glass.

2.1. Sample Part

In this experiment, the part is a plastic glass used for an experimental simulation. The dimensions have a diameter of 97 mm, height of 70 mm, and thickness of 2 mm. Plastic glass is made of polystyrene (PS), which is widely used in consumer goods and commercial packaging. The general view of the part is presented in (Figure 1).

Figure 1 Plastic Glass

2.2. Experiment

The

Finite Element Method (FEM) was developed to simulate the behavior of plastic material

(Hashash, Jung, and Ghaboussi, 2004; Hung, Chen, and Lin, 2002). In addition, the FEM capability can

help improve the defects that may occur before actual production (Irsyad et al., 2020). A MOLDEX 3D software

was used to simulate the plastic injection molding process to determine the

defect of the sample part. This software uses the Finite Element Method to

analyze the plastic behavior of the injection molding process by a mathematical

function. In this simulation, various parameters are adjusted to determine the

minimum warpage value.

The experiment

simulation was created by the design of the experiment (DOE) method with 32

experiments. The process parameters of injection molding experiments consist of

the melt temperature, mold temperature, filling time, packing time, and cooling

time were chosen as input parameters as shown in Table 1.

Table

1 Process parameters

|

Process parameters |

Level | |

|

Low |

High | |

|

Melt temperature (degree) |

180 |

230 |

|

Mold Temperature (degree) |

20 |

45 |

|

Filling Time (mm/s) |

0.82 |

0.94 |

|

Packing Time (s) |

5.88 |

7 |

|

Cooling Time (s) |

14 |

18 |

2.3. Warpage

The warpage is a distortion of the dimension part on 3 axes consisting

of x, y, and z from the actual dimension of the part. Adjusting suitable

injection molding process parameters is essential to decrease the warpage of

parts, which is the main purpose of this paper. The warpage was measured as the

total displacements on 3 axes of the product. An equation for the warpage is (Mukras, Omar, and al-Mufadi, 2019):

TWsum =

? ymax i (1)

i = 1, 2, 3

where ymaxi is the

displacement on one axis of the product.

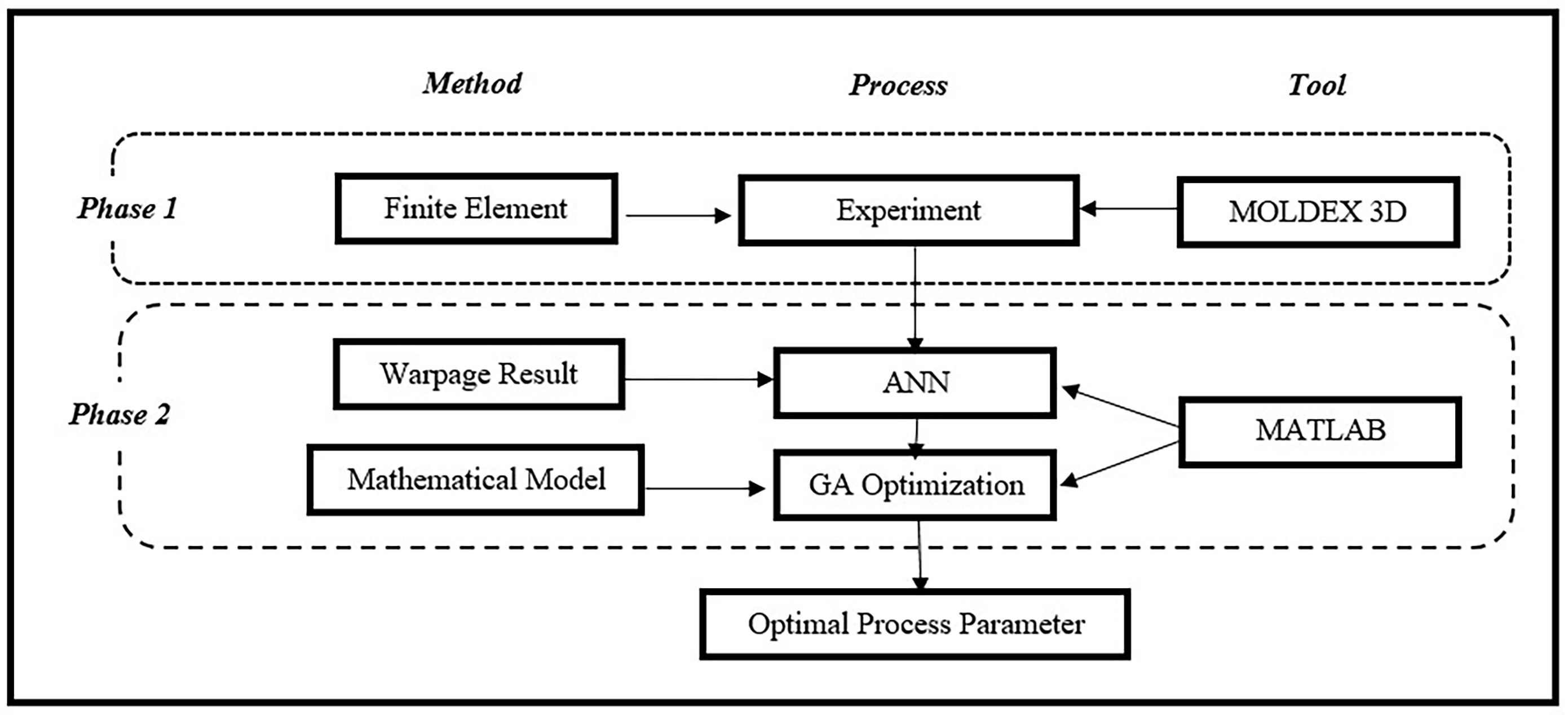

This paper consists of two phases: First, a simulation of injection molding process experiments. It has 32 experiments under different parameter setting values to determine the warpage value. Second, ANN has conducted predicted warpage from the simulation result of the experiment. The result from predicting the warpage value of ANN has created a mathematical model by coefficient value for fitness function of GA. Optimization by the GA method was performed to find the optimal injection molding parameter using a mathematical model from the ANN method, which results in the lowest warpage. (Figure 2) shows the process of this paper.

Figure 2 Process of paper

3.1. Simulation

Moldex3D software was used

in this experiment to simulate the injection molding process (Sun et al., 2021; Quintana and Frontini, 2020; Tseng,

Chang, and Hsu, 2017) with 32 experiments in order to find out the

warpage value. Table 2 shows results gained from the simulation, and mold base

for analysis were used for the ANN method. (Figure 3) depicts the maximum

warpage result that occurs on the red color area of the example plastic glass

in experiment No. 1, which is 0.809 mm after the experiment simulation was

conducted, and the mold base for analysis has 8 cooling channels used to heat

transfer.

Table 2 Results of experiments simulation

|

No. |

Melt Temperature |

Mold Temperature |

Filling Time |

Packing Time |

Cooling Time |

Warpage | |||||||

|

1 |

180 |

20 |

0.82 |

5.88 |

14 |

0.809 | |||||||

|

2 |

230 |

20 |

0.82 |

5.88 |

14 |

1.119 | |||||||

|

3 |

180 |

45 |

0.82 |

5.88 |

14 |

0.848 | |||||||

|

4 |

230 |

45 |

0.82 |

5.88 |

14 |

1.205 | |||||||

|

5 |

180 |

20 |

0.94 |

5.88 |

14 |

0.823 | |||||||

|

6 |

230 |

20 |

0.94 |

5.88 |

14 |

1.122 | |||||||

|

7 |

180 |

45 |

0.94 |

5.88 |

14 |

0.854 | |||||||

|

8 |

230 |

45 |

0.94 |

5.88 |

14 |

1.198 | |||||||

|

9 |

180 |

20 |

0.82 |

7 |

14 |

0.801 | |||||||

|

10 |

230 |

20 |

0.82 |

7 |

14 |

1.09 | |||||||

|

11 |

180 |

45 |

0.82 |

7 |

14 |

0.842 | |||||||

|

12 |

230 |

45 |

0.82 |

7 |

14 |

1.154 | |||||||

|

13 |

180 |

20 |

0.94 |

7 |

14 |

0.828 | |||||||

|

14 |

230 |

20 |

0.94 |

7 |

14 |

1.124 | |||||||

|

15 |

180 |

45 |

0.94 |

7 |

14 |

0.84 | |||||||

|

16 |

230 |

45 |

0.94 |

7 |

14 |

1.165 | |||||||

|

17 |

180 |

20 |

0.82 |

5.88 |

18 |

0.8 | |||||||

|

18 |

230 |

20 |

0.82 |

5.88 |

18 |

1.096 | |||||||

|

19 |

180 |

45 |

0.82 |

5.88 |

18 |

0.843 | |||||||

|

20 |

230 |

45 |

0.82 |

5.88 |

18 |

1.176 | |||||||

|

21 |

180 |

20 |

0.94 |

5.88 |

18 |

0.815 | |||||||

|

22 |

230 |

20 |

0.94 |

5.88 |

18 |

1.09 | |||||||

|

No. |

Melt Temperature |

Mold Temperature |

Filling Time |

Packing Time |

Cooling Time |

Warpage |

| ||||||

|

23 |

180 |

45 |

0.94 |

5.88 |

18 |

0.845 |

| ||||||

|

24 |

230 |

45 |

0.94 |

5.88 |

18 |

1.162 |

| ||||||

|

25 |

180 |

20 |

0.82 |

7 |

18 |

0.795 |

| ||||||

|

26 |

230 |

20 |

0.82 |

7 |

18 |

1.076 |

| ||||||

|

27 |

180 |

45 |

0.82 |

7 |

18 |

0.834 |

| ||||||

|

28 |

230 |

45 |

0.82 |

7 |

18 |

1.115 |

| ||||||

|

29 |

180 |

20 |

0.94 |

7 |

18 |

0.812 |

| ||||||

|

30 |

230 |

20 |

0.94 |

7 |

18 |

1.097 |

| ||||||

|

31 |

180 |

45 |

0.94 |

7 |

18 |

0.835 |

| ||||||

|

32 |

230 |

45 |

0.94 |

7 |

18 |

1.129 |

| ||||||

Figure 3

Simulation Analysis: (a)

Warpage; and (b) Mold base

3.2. Artificial Neural Network (ANN)

ANN is widely used in engineering because ANN ability can analyze

information by detecting data patterns and relationships through learning. It

is easier to analyze and improve engineering processes (Hemmati

et al., 2020; Alas and Ali, 2019;

Rafiq, Bugmann, and Easterbrook, 2001).

This section uses the ANN to predict the warpage results from the experiment simulation by MATLAB software. The experimental parameters are an input of ANN, consisting of melt temperature, mold temperature, filling time, packing time, and cooling time. During the network training, the weight (w) of the network is calculated by minimizing the error value between the predicted warpage value, which is called the output of ANN, and the actual warpage value (Chen et al., 2008; Lee and Lin, 2006; Sadeghi, 2000). (Figure 4) shows the ANN model consists of five inputs, the transfer function is sigmoid, ten hidden layers, and one output. A Backpropagation network (BPN) has been adopted because it has the ability of fast responsiveness and high accuracy (Asmael et al., 2022).

Figure 4

ANN Model

Using the warpage results

obtained by the simulation experiment to predict by ANN, Table 3 shows the

resulting warpage of ANN compared with the finite element method analysis of

the experiment.

Table

3 Results of ANN prediction

|

No. |

Melt Temperature |

Mold Temperature |

Filling Time |

Packing Time |

Cooling Time |

Warpage |

ANN Warpage |

|

1 |

180 |

20 |

0.82 |

5.88 |

14 |

0.809 |

0.804 |

|

2 |

230 |

20 |

0.82 |

5.88 |

14 |

1.119 |

1.028 |

|

3 |

180 |

45 |

0.82 |

5.88 |

14 |

0.848 |

0.847 |

|

4 |

230 |

45 |

0.82 |

5.88 |

14 |

1.205 |

1.223 |

|

5 |

180 |

20 |

0.94 |

5.88 |

14 |

0.823 |

0.846 |

|

6 |

230 |

20 |

0.94 |

5.88 |

14 |

1.122 |

1.022 |

|

7 |

180 |

45 |

0.94 |

5.88 |

14 |

0.854 |

0.87 |

|

8 |

230 |

45 |

0.94 |

5.88 |

14 |

1.198 |

1.248 |

|

9 |

180 |

20 |

0.82 |

7 |

14 |

0.801 |

0.81 |

|

10 |

230 |

20 |

0.82 |

7 |

14 |

1.09 |

1.102 |

|

11 |

180 |

45 |

0.82 |

7 |

14 |

0.842 |

0.847 |

|

12 |

230 |

45 |

0.82 |

7 |

14 |

1.154 |

1.148 |

|

13 |

180 |

20 |

0.94 |

7 |

14 |

0.828 |

0.813 |

|

14 |

230 |

20 |

0.94 |

7 |

14 |

1.124 |

1.118 |

|

15 |

180 |

45 |

0.94 |

7 |

14 |

0.84 |

0.838 |

|

16 |

230 |

45 |

0.94 |

7 |

14 |

1.165 |

1.216 |

|

17 |

180 |

20 |

0.82 |

5.88 |

18 |

0.8 |

0.809 |

|

18 |

230 |

20 |

0.82 |

5.88 |

18 |

1.096 |

1.1 |

|

19 |

180 |

45 |

0.82 |

5.88 |

18 |

0.843 |

0.846 |

|

20 |

230 |

45 |

0.82 |

5.88 |

18 |

1.176 |

1.137 |

|

21 |

180 |

20 |

0.94 |

5.88 |

18 |

0.815 |

0.821 |

|

22 |

230 |

20 |

0.94 |

5.88 |

18 |

1.09 |

1.084 |

|

23 |

180 |

45 |

0.94 |

5.88 |

18 |

0.845 |

0.86 |

|

24 |

230 |

45 |

0.94 |

5.88 |

18 |

1.162 |

1.126 |

|

25 |

180 |

20 |

0.82 |

7 |

18 |

0.795 |

0.789 |

|

26 |

230 |

20 |

0.82 |

7 |

18 |

1.076 |

1.063 |

|

27 |

180 |

45 |

0.82 |

7 |

18 |

0.834 |

0.827 |

|

28 |

230 |

45 |

0.82 |

7 |

18 |

1.115 |

1.105 |

|

29 |

180 |

20 |

0.94 |

7 |

18 |

0.812 |

0.819 |

|

30 |

230 |

20 |

0.94 |

7 |

18 |

1.097 |

1.066 |

|

31 |

180 |

45 |

0.94 |

7 |

18 |

0.835 |

0.818 |

|

32 |

230 |

45 |

0.94 |

7 |

18 |

1.129 |

1.168 |

The results showed that the mean square

error (MSE) of validation is 0.004, and the overall R-square value is 0.97985.

The mean square error (MSE) of ANN has a value of close to 0, and the R-square

is near 1. The average prediction error % of the ANN model was 1.97%. It

clearly shows that the ANN has a high performance in predicting the result of

the warpage as shown in (Figure

5).

Figure

5

ANN Model performance: (a) Validation; (b)

Overall data; and (c) Cross plot data

In this section, MATLAB software was

used to analyze coefficients of the multiple linear regression equation for the

objective function of GA. To create the mathematical model, a multiple linear

regression equation was established to show the relationship of the injection

molding processing parameters on the warpage by Equation 2 (Ozcelik and Sonat, 2009).

where y is the value of the warpage, is intercept,

are coefficients values

obtained from MATLAB software, x1, x2, …, xn

are process parameters factors.

3.3. Genetic Algorithm (GA) Optimization

GA is an

optimization technique that uses a randomized search method to achieve optimal

values. It is based on a model of a natural genetic selection mechanism that

has the ability to survive and pass on to the next generation (Eusuff, Lansey, and Pasha, 2006).

The optimization injection molding

process parameters problem in Equation 3 was solved by a GA created by the

MATLAB Optimization toolbox. The parameter value used for the GA is 100 for the

population size, 0.6 for the crossover rate, and 0.05 for the mutation rate.

The roulette wheel method was used to select the next generation. (Figure 6)

shows the GA optimization terminates at generation no. 140 from 500 generations,

which are the results of the objective function.

Minimize Warpage (Z). Z = (Melt Temperature, Mold Temperature, Filling

Time, Packing Time, Cooling Time);

Subject

to

180 Melt Temperature

230oC

20 Mold Temperature

45oC

0.82 Filling Time

0.94 mm/s (3)

5.88 Packing Time

7 mm/s

14 Cooling Time

18 s

Figure

6 Result of GA

optimization process parameter

From (Figure 6), the GA optimization process

parameters result include melt temperature of 192oC, mold temperature of 23oC,

filling time of 0.865 mm/s, packing time of 6.72 mm/s, and cooling time is 16 s

which affects warpage that is 0.770 mm. The process parameters of experiment

simulation no.8 consist of a melt temperature of 230oC, mold temperature of

45oC, filling time of 0.940 mm/s, packing time of 5.88 mm/s, and cooling time

is 14 s have a maximum warpage value of 1.198 mm compare with the result of GA

as shown in Table 4.

Table

4 Process parameter of

experiment simulation and GA

|

|

Melt

Temperature |

Mold Temperature |

Filling

Time |

Packing

Time |

Cooling

Time |

Warpage |

|

Experiment

Simulation |

230 |

45 |

0.940 |

5.88 |

14 |

1.198 |

|

GA |

192 |

23 |

0.865 |

6.72 |

16 |

0.770 |

To confirm the result of this method, the optimal plastic injection molding process of GA consists of a melt temperature of 192oC, mold temperature of 23oC, filling time of 0.865 mm/s, packing time of 6.72 mm/s, and cooling time is 16 s were simulated by MOLDEX3D software as shown in (Figure 7).

Figure

7 Confirmation optimal

process parameters

The confirmation result shows that the warpage of the simulation is 0.770 mm, which equal to the results of GA. When the maximum warpage of the experiment simulation is considered, it depicts the maximum warpage on a plastic glass of experiment simulation, which is 1.198 mm before the optimization. After optimization, it was found that the warpage is reduced to 0.770 mm, which is about 35.73% of the maximum warpage. (Figure 8) shows a comparison of the warpage experiment simulation with GA.

Figure 8 Result of GA optimization process parameter

The objective of this paper was to determine the optimal injection

molding process parameters for minimized plastic glass warpage through a Finite

Element, ANN and GA. The finite element method simulated five process

parameters (melt temperature, mold temperature, filling time, packing time, and

cooling time) for finding warpage under various parameters. The results of the

experiment simulation were used for predictive models were established using

ANN. The average prediction error of the ANN was 1.97%, with a mean square

error (MSE) of 0.004. It shows that obtained results showed good prediction

accuracy. After the prediction warpage by ANN, A mathematical was created for a

Fitness Function of GA. In the optimization process, GA was utilized for the

optimal selection of the plastic injection molding process parameters that

reduced the warpage of the product by 35.73% from the maximum warpage of the

simulation. It clearly shows that GA has high efficiency in finding the optimal

injection molding process parameters. Moreover, it is a guideline for

optimizing the process parameters of another plastic part with speed and

accuracy. However, this simulation with the finite element method is prediction

the behaviour of defects in the pre-production process where the simulation

process parameters are stable and independent from interference complications.

On the other hand, a higher defect value ??may occur in the experiment as other

factors such as machinery deterioration, air

humidity, and air temperature can easily intervene in the plastic injection molding process. Moreover,

the current simulation did not include optimization of the injection and

packing pressures by setting pressure following plastic melt flow behavior fill

to the mold impression in the setting pressure process of the injection

machine. The pressure values used in the simulation were based on the material

profile within the simulation software. Thus, determining appropriate pressure

values following plastic melt flow behavior may further enhance the efficiency

of reducing product warpage.

| Filename | Description |

|---|---|

| R1-IE-5573-20220502232944.pdf | --- |

Alas, M., Ali, S.I.A., 2019. Prediction of the high-temperature

performance of a geopolymer modified asphalt binder using artificial neural

networks. International Journal of Technology. Volume 10(2), pp.

417–427

Asmael, M., Nasir, T., Zeeshan, Q., Safaei, B., Kalaf, O.,

Motallebzadeh, A., Hussain, G., 2022. Prediction of properties of friction stir

spot welded joints of AA7075-T651/Ti-6Al-4V alloy using machine learning

algorithms. Archives of Civil and Mechanical Engineering, Volume

22(2), pp. 1–19

Chen, W.C., Tai, P.H., Wang, M.W., Deng, W.J., Chen, C.T., 2008. A

neural network-based approach for dynamic quality prediction in a plastic

injection molding process. Expert systems with Applications, Volume

35(3), pp. 843–849

Cheng, C.C., Liu, K.W., 2018. Optimizing energy savings of the

injection molding process by using a cloud energy management system. Energy

Efficiency, Volume 11(2), pp. 415–426

Dang, X.P., 2014. General frameworks for optimization of plastic

injection molding process parameters. Simulation Modelling Practice and

Theory, Volume 41, pp. 15–27

Erzurumlu, T., Ozcelik, B., 2006. Minimization of warpage and sink

index in injection-molded thermoplastic parts using Taguchi optimization

method. Materials & design, Volume 27(10), pp. 853–861

Eusuff, M., Lansey, K., Pasha, F., 2006. Shuffled frog-leaping

algorithm: a memetic meta-heuristic for discrete optimization. Engineering

optimization, Volume 38(2), pp. 129–154

Farshi, B., Gheshmi, S., Miandoabchi,

E., 2011. Optimization of injection molding process parameters using sequential

simplex algorithm. Materials & Design, Volume 32(1), pp.

414–423

Gao, Y., Wang, X., 2008. An effective warpage optimization method

in injection molding based on the Kriging model. The International

Journal of Advanced Manufacturing Technology, Volume 37, pp.

953–960

Guo, F., Zhou, X., Liu, J., Zhang, Y., Li, D., Zhou, H., 2019. 1A reinforcement

learning decision model for online process parameters optimization from offline

data in injection molding. Applied Soft Computing, Volume 85,

p.105828

Hakimian, E., Sulong, A.B., 2012. Analysis of warpage and shrinkage

properties of injection-molded micro gears polymer composites using numerical

simulations assisted by the Taguchi method. Materials & Design, Volume

42, pp. 62–71

Hashash, Y.M.A., Jung, S., Ghaboussi, J., 2004. Numerical

implementation of a neural network based material model in finite element

analysis. International Journal for numerical methods in engineering, Volume

59(7), pp. 989–1005

Hasnan, A., Putra, N., Septiadi, W.N., Ariantara, B., Abdullah,

N.A., 2017. Vapor chamber utilization for rapid cooling in the conventional

plastic injection molding process. International Journal of Technology, Volume

8(4), pp. 690–697

Hemmati-Sarapardeh, A., Varamesh, A., Amar, M.N., Husein, M.M.,

Dong, M., 2020. On the evaluation of thermal conductivity of nanofluids

using advanced intelligent models. International Communications in Heat

and Mass Transfer, Volume 118, p. 104825

Hentati, F., Hadriche, I., Masmoudi, N., Bradai, C., 2019.

Optimization of the injection molding process for the PC/ABS parts by

integrating Taguchi approach and CAE simulation. The International

Journal of Advanced Manufacturing Technology, Volume 104(9), pp. 4353–4363

Hung, C., Chen, R.H., Lin, C.R., 2002. The characterisation and finite-element

analysis of a polymer under hot pressing. The International Journal of

Advanced Manufacturing Technology, Volume 20, pp. 230-235

Huang, X. L., Yang, J. R., Sun, Y.X., Chen, Y.W., Wang, X.M., Du,

S.M., Hua, Z.K., 2021. Novel combined shield design for eye and face protection

from COVID-19. Advances in Manufacturing, Volume 9(1), pp. 130–135

Irsyad, M., Nadhif, M.H., Rahyussalim, A.J., Assyarify, H., Utomo,

M.S., 2020. Material Selection Techniques for Polymer Hubs of Novel Spinal Stem

Cell Introducers using Finite Element and Weighted Property Method. International

Journal of Technology. Volume 11(5), pp. 1056–1065

Kitayama, S., Hashimoto, S., Takano, M., Yamazaki, Y., Kubo, Y.,

Aiba, S., 2020. Multi-objective optimization for minimizing weldline and cycle

time using variable injection velocity and variable pressure profile in plastic

injection molding. The International Journal of Advanced Manufacturing

Technology, Volume 107(7), pp. 3351–3361

Kurtaran, H., Erzurumlu, T., 2006. Efficient warpage optimization

of thin shell plastic parts using response surface methodology and genetic

algorithm. The International Journal of Advanced Manufacturing

Technology, Volume 27(5), pp. 468–472

Lee, K. S., Lin, J. C., 2006. Design of the runner and gating

system parameters for a multi-cavity injection mold using FEM and neural

network. The International Journal of Advanced Manufacturing Technology, Volume

27(11-12), pp. 1089–1096

Lockner, Y., Hopmann, C., 2021. Induced network-based transfer

learning in injection molding for process modelling and optimization with

artificial neural networks. The International Journal of Advanced

Manufacturing Technology, Volume 112(11), pp. 3501–3513

Mukras, S.M., Omar, H.M., al-Mufadi, F.A., 2019. Experimental-based

multi-objective optimization of injection molding process parameters. Arabian

Journal for Science and Engineering, Volume 44(9), pp. 7653–7665

Oliaei, E., Heidari, B. S., Davachi, S. M., Bahrami, M., Davoodi,

S., Hejazi, I., Seyfi, J., 2016. Warpage and shrinkage optimization of

injection-molded plastic spoon parts for biodegradable polymers using taguchi,

ANOVA and artificial neural network methods. Journal of Materials

Science & Technology, Volume 32(8), pp. 710–720

Ozcelik, B., Sonat, I., 2009. Warpage and structural analysis of

thin shell plastic in the plastic injection molding. Materials &

Design, Volume 30(2), pp. 367–375

Quintana, M. C., Frontini, P., 2020. Weld line strength factors in

a reinforced injection molded part: Relationship with predicted fibre

orientation. Journal of Reinforced Plastics and Composites, Volume

39(5-6), pp. 219–230

Rafiq, M.Y., Bugmann, G., Easterbrook, D.J., 2001. Neural network

design for engineering applications. Computers & Structures, Volume

79(17), pp. 1541–1552

Sadeghi, B.H.M., 2000. A BP-neural network predictor model for

plastic injection molding process. Journal of materials processing

technology, Volume 103(3), pp. 411–416

Shi, H., Xie, S., Wang, X., 2013. A warpage optimization method for injection molding using artificial neural network with parametric sampling evaluation strategy. The International Journal of Advanced Manufacturing Technology, Volume 65(1-4), pp. 343–353

Sun, C., Gergely, R., Okonski, D.A., Min, J., 2021. Experimental

and numerical investigations on thermoforming of thermoplastic prepregs of

glass fibre reinforced nylon 6. Journal of Materials Processing

Technology, Volume 295, p. 117161

Tseng, H.C., Chang, R.Y., Hsu, C.H., 2017. Numerical prediction of

fibre orientation and mechanical performance for short/long glass and carbon

fibre-reinforced composites. Composites Science and Technology, Volume

144, pp. 51–56

Zhang, J., Wang, J., Lin, J., Guo, Q., Chen, K., Ma, L., 2016.

Multiobjective optimization of injection molding process parameters based on

Opt LHD, EBFNN, and MOPSO. The International Journal of Advanced

Manufacturing Technology, Volume 85(9), pp. 2857–2872

Zhao, N.Y., Lian, J.Y., Wang, P.F., Xu, Z.B., 2022. Recent progress

in minimizing the warpage and shrinkage deformations by the optimization of

process parameters in plastic injection molding: a review. The

International Journal of Advanced Manufacturing Technology, Volume

120, pp. 85–101

Zhou, J., Turng, L.S., Kramschuster, A., 2006. Single and

multi-objective optimization for injection molding using numerical simulation

with surrogate models and genetic algorithms. International Polymer

Processing, Volume 21(5), pp. 509–520