Residual Stress and Texture Analysis of Leaf Spring Failure

Corresponding email: andoko.ft@um.ac.id

Published at : 10 Jul 2024

Volume : IJtech

Vol 15, No 4 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i4.5571

Andoko, A., Kurniawan, P., Suprayitno, S., Gapsari, F., Manawan, M., 2024. Residual Stress and Texture Analysis of Leaf Spring Failure. International Journal of Technology. Volume 15(4), pp. 1162-1172

| Andoko Andoko | Department of Mechanical and Industrial Engineering, State University of Malang, Jl. Semarang No. 5, 65146 Malang, Indonesia |

| Pradhana Kurniawan | Department of Mechanical Engineering, Faculty of Engineering, University of Merdeka Malang, Jl. Terusan Raya Dieng 62-64, 65146, Indonesia |

| Suprayitno Suprayitno | Department of Mechanical and Industrial Engineering, State University of Malang, Jl. Semarang No. 5, 65146 Malang, Indonesia |

| Femiana Gapsari | Department of Mechanical Engineering, Brawijaya University, Jl. Veteran No. 16, 65146, Malang, Indonesia |

| Maykel Manawan | Physics Department, Science Faculty, Pertahanan University, IPSC Sentul Sukahati, 16810, Bogor, Indonesia |

Failure; Leaf spring; Residual stress; Texture

Leaf springs are mostly used in heavy vehicle suspension systems because

of their low cost, easy maintenance, ability to accept higher loads and good

vibration damping (Kurniawan et al., 2021; Kong

et al., 2016; Scuracchio, de-Lima, and Schön, 2013). The

vibrations generated from the road surface and wheels are suppressed by the

leaf springs so that they are not transmitted to the vehicle body and are

stored in elastic deformation (Andoko, Puspitasari,

and Permanasari, 2017). These conditions make the leaf spring material

must have the characteristics of a combination of high strength and fatigue

resistance.

The

process of making leaf springs consists of several processes, namely the

selection of raw materials, mechanical formation, heat treatment and surface

treatment (Scuracchio Scuracchio, de-Lima, and

Schön, 2013). The fabrication process that is not well controlled

will cause non-uniform plastic deformation (residual stress) and microscopic

defects (Bozic, Schmauder, and Wolf, 2018; De-la-Rosa et al., 2016). The presence of residual stress

and microscopic defects with the breaking of bond chains can affect the

deterioration of the behavioral characteristics of the material.

Residual stress consists of two types, namely compressive residual

stress and tensile residual stress (Soyama,

Chighizola, and Hill, 2021; Fairfax and Steinzig, 2016). Compressive

residual stress is beneficial for leaf springs because, together with strain

hardening, it can increase fatigue life resistance (Xiao

et al., 2022; Soyama et al., 2011). Residual tensile

stress is detrimental because it impacts the formation of crack initiation and

the faster crack growth rate (Bozic, Schmauder, and

Wolf, 2018). The residual compressive stress generated in the shot

peening process will have an impact on increasing the fatigue resistance of

leaf springs (Shojaei et al., 2021). Increased

fatigue resistance is carried out through a shot peening process with different

depths of decaburization (Chadwick, 2016).

The low carburizing depth indicates an elastic deformation mechanism, whereas,

at a higher decaburization depth, there will be plastic deformation which

contributes to the compressive residual stress. Surface depths up to 0.02 mm of

compressive residual stress directly affect fatigue crack nucleation (Scuracchio, de-Lima, and Schon, 2013). Fabrication behavior such as cold press can increase

tensile residual stress and dislocation. High residual stress at the location

of stress concentration will accelerate the occurrence of failure (Pastor et al., 2020).

Various studies on residual stress have attracted the attention of

researchers in increasing the fatigue strength of leaf springs. Besides fatigue

strength, other characteristics such as strength, stress corrosion cracking and

deformation are also highly dependent on the pole figure texture of the

material (Wenk, 2016). Pole figure texture

is a graphical representation of the orientation of objects in space by

recording the intensity of the given Bragg reflection as a function of the

rotation and slope of the sample (Ren et al.,

2021; Bunge, 2013). The results of the graphic image through the X-Ray

Diffraction experimental method will produce a preferred crystal orientation

that can affect the material properties. Material properties that have low

strength occur when the material's texture pattern is imperfect, which will

create weaknesses in the crystal lattice structure and cause failure (Liu et al., 2018). The development of

microstructure, mechanical properties and texture on automotive grade AISI 4130

steel is through the austenitization process (Heidary

et al., 2020). Texture components change substantially by

changing the austempering temperature and time. Hot-rolled steel has higher

strength but lower ductility in TD (transverse direction) (Li et al., 2021). The effect of

crystallographic texture is seen in the anisotropic properties of hot-rolled

steel (Chen et al., 2020). Anisotropy

with a lower Taylor factor value in austenite along the RD (rolling direction)

will result in the formation of an early slip.

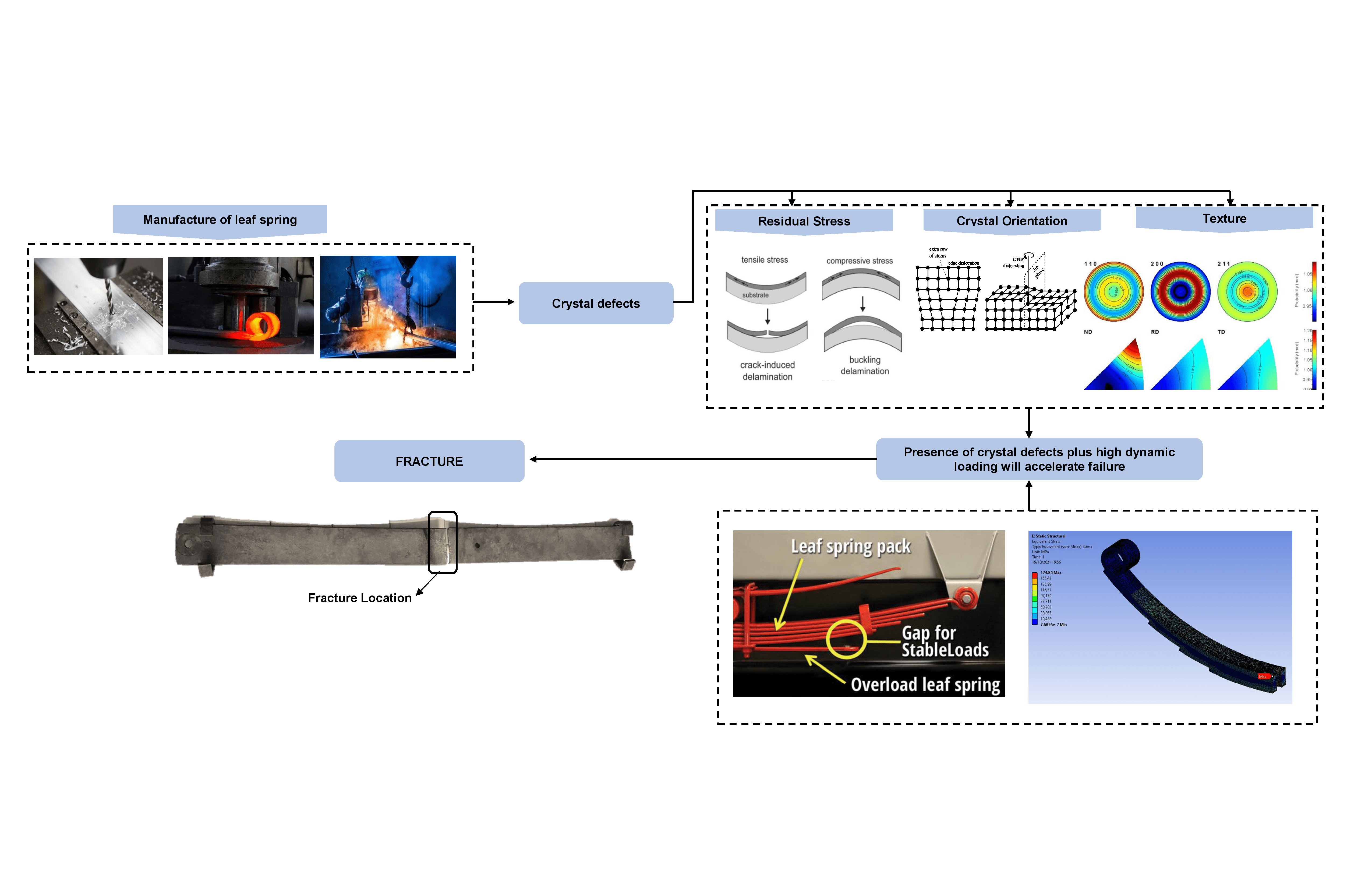

This study intends to provide novelty findings related to residual

stress analysis and crystallography for further failure analysis on leaf

springs. This study aimed to analyze the cause of the failure of a broken leaf

spring through an experimental method. Experimental methods include residual

stress analysis, crystal orientation, texture, hardness and fracture

morphology. The experimental analysis results are useful in further improving

the leaf springs' mechanical properties.

2.1. Materials

Figure 1 Leaf Spring Failed

2.2. Chemical Composition

The

chemical composition of the broken leaf springs was analyzed using a

spectrometer (Hilger Emissions, Type E-9 OA701, Margate, UK). The specimens

were standardized with ASTM E 350 testing. The chemical composition of the leaf

material can be seen in Table 1, which will then be compared with the

standardization of spring steel material.

The

results of the chemical composition test (Table 1) show that the failed leaf

spring materials are grade spring steel with SUP 10 standardization (C = 0,47 –

0,55%, Si = 0,15 – 0,35% Mn = 0,65 – 0,95%, Cr = 0,80

-1,10% and V = 0,15 – 0,250%).

2.3. Residual Stress, Crystal Orientation

and Texture

Residual

stress testing was performed using XRD (Bruker, Type D8 Advance, Karlsruhe,

Germany). The residual stress test was measured using the method with

-20°, -16°, -12°, -4°, 0°, 4°, 12°, 16°, 20° (Figure 2 a). The test

was carried out with

radiation, wavelength 1.5046 and the test was

carried out with the standardization of ASTM E2860. the remaining size

connection in the crystal orientation plane (211), a 5 second step speed in an

angle of

The XRD data was then processed using Qualx 2.1 and MAUD

2.94 software to analyze the smoothness, crystal orientation and texture. The

texture is plotted into two parts, namely the polar image texture and the

inverted polar image based on ND (Normal Direction), TD (Transverse Direction)

and RD (Rolling Direction).

2.4. Hardness Test

Hardness testing was done

with several leaf spring material indentation points using the Micro Vickers

Hardness Tester Machine (Mitutoyo, Type HM-200, Kanagawa, Japan). The

indentation points start near the fracture and away from the fracture in Figure

2b. This test used the micro Vickers method with ASTM E 384 standardization.

2.5. Fracture Morphology

Morphological observations, both macroscopically and microscopically, were carried out to analyze the characteristics of the fracture form—macro photo using a camera (Canon DSLR, Type EOS 1300D, Tokyo, Japan). Fracture morphology using Scanning (SEM) (Field Electron and Ion Company Hillsboro, Type Inspect-S50, Oregon, United States) with ASTM STP 827 standardization.

Figure 2 a) Residual Stress Test Results b) Position of Hardness

Indentation Point

3. Results

3.1. Residual Stress

Figure 3 a) Peak Diffraction Results from Residual Stress b) XRD results of a

broken leaf spring

The residual stress measurement data is

then plotted on a graph of strain versus as shown in Figure 2a.

Figure 2a shows an elliptical category curve with normal stress on a negative

slope. The shear stress (blue curve) is elliptical, and the texture shows a

wavy curve. Elliptical curves are defined as splitting as evidence of the presence

of shear stress. Shear stress is generated due to the mechanical surface

treatment of leaf springs, such as rolling. The resulting shear stress on the

curve above is 5±1.7, while the normal stress generated is -278.5±17.4.

3.2. Crystal

Orientation

Based on the results of the sequential research

field refinement (Figure 3b), the largest peak angle is produced at an angle of with a crystal orientation

of (110). Crystal plane (211) with angle

and crystal plane (200) with

angle

Crystal orientation (110) resulted in high crystal

size and spacing (Table 3). High lattice strains and dislocations were produced

at the crystal orientation (200). Crystal orientation (211) has the lowest

dislocation and lattice strain.

3.3. Texture

Figure 4 a) Crystal Oriented Texture (110) and Inverse on ND (110) b) Crystal Oriented Texture (200) and Inverse on RD (200)

c) Crystal Oriented

Texture (211) and Inverse

on ND (211)

3.4. Hardness

The results of the hardness of

the failed leaf spring can be seen in Table 4. Based on the results of the

hardness test on the leaf spring shows that the hardness near the fracture has

a higher value than that at the distance of the fracture.

Discussion

Previous studies on the

analysis of the causes of leaf spring failure have only been investigated

through general experimental characteristics of materials, such as analysis of

the chemical composition, microstructure, hardness and fracture morphology. However,

this study will analyze the failure further through residual stress, crystal

orientation and texture. This condition was investigated because the leaf

spring has a complex manufacturing process. This process will likely occur

atomic defects and residual tensile stresses, which reduce fatigue strength.

Based on testing the chemical composition of the leaf spring material, it is

included in the standard specification for spring steel SUP 10. The composition

of C, Si, Mn, P and S is in the range of SUP 10 spring steel materials.

However, the Cr element is slightly below the SUP 10 standard, and V has a high

amount. The low Cr element will impact the slow transformation of austenite to

ferrite (Zhang et al., 2019). Ferrite

and residual austenite are ductile constituents which are more ductile than

martensite (Xie et al., 2020). The

amount of ferrite and residual austenite, which is dominant compared to

martensite, will have an adverse effect on reducing fatigue strength (Fuentes et al., 2009). These conditions

indicate that the quenching process in the leaf spring is imperfect due to

various factors such as temperature austenitization time and cooling rate (Peng et al., 2010). Martensite is also

affected by the high alloy content after the cold rolling process

and impacts increasing the degree of strain-induced martensite (SIM) (Anwar et al., 2021). This imperfection can

also be seen from the hardness results near and far from the fracture, which

has a difference of 22.1%, where the position near the fracture has a higher

value than the standard spring steel JASO C 601 (406 – 448). Uncontrolled local

heating of the leaf springs during the rolling, bending and heat treatment

processes causes decaburization and softening at some points on the surface.

The high hardness of the part near the fracture causes the material

characteristics to become more brittle and reduces the ductility of the leaf

spring. The decrease in ductility impacts the decrease in the elasticity function

of the leaf spring at the time of maximum loading so that it can cause crack

initiation (Fragoudakis et al., 2013).

Higher hardness is synonymous with increased tensile strength, where the

microstructure grains under these conditions are finer (Abdul

et al., 2021; Purnama et al., 2020).

Figure

5 a) Macro photo of the surface of a broken leaf spring,

b) The orange dashed line is a 45 x magnification at the center of the fault

surface, c) The green dashed line is a 500 x magnification of the part of the

fault surface indicated by the green box, d) The red dashed line is a 45 x

magnification at the end of the fault surface, e) The blue dashed line is a 500

x magnification of the fault surface marked with a blue box

Crack

initiation is done by observing the fracture morphology through macro and

micro. The fracture morphology shows that crack initiation originates from

voids evenly distributed on the leaf spring surface. Voids originating from

material defects are most susceptible to dynamic loading and trigger the

formation of crack nucleation and become the center of stress concentration.

The initiation of voids causes brittleness of the martensite phase in the steel

microstructure (Kadkhodapour, Butz, and Rad, 2011).

The formation of voids often occurs in the fracture of martensite lath

particles and interfacial decohesion (Zhang et

al., 2015). Intercritically treated structural fractures in medium

carbon steels indicate that martensitic interfacial decohesion is the main mode

of nucleation and void growth (Bag, Lévesque, and

Brochu, 2020). Three modes of formation of void nucleation, namely

martensite crack, ferrite-martensite interface decohesion, and ferrite-ferrite

interface decohesion with minimum plastic deformation (Xie

et al., 2020). The higher stress concentration in the voids due

to fatigue loading will impact crack propagation. Fatigue crack propagation can

be seen based on benchmarks and striations (Aliakbari,

2019). The striations indicate slow crack propagation due to compressive

residual stress and good ductility. Good ductility was demonstrated on SEM

observations by the presence of uneven surfaces and dimple fractures (Figure 5b

and Figure 5d).

The resulting compressive residual

stress is related to the slope of the elliptical curve on the strain versus the graph. The slope of the ellipse to the left indicates that the

microstrain is negative. The negative microstrain value is related to the

distance between the crystal planes, which are identical on the atomic scale;

there is no local distortion in the lattice plane (Bruno

et al., 2011). This condition shows that the microstrain that

occurs is more dominantly uniform. Microstrain uniformity can also be seen in

the (110) and (211) crystal planes. The (200) crystal planes have different

microstrains and indicate possible defects. Indications of defects show a

sudden change in the arrangement of atoms at low-stress levels, and an

irregular crystallographic texture occurs (Li et

al., 2021). The crystallographic texture in the (200) plane also has

a high probability, and means that the field has a weak texture. Weak texture (200)

occurs due to the deformation of the rolling process (Priyanto,

Effendi, and Parikin, 2015). The weak texture is related to the presence

of voids (Figure 5b and 5c) in the fracture morphology. Voids will trigger

stress concentrations, impact strength reduction and fatigue, and become the

initial formation of crack nucleation (Andoko, 2019). The crack then propagates based on the movement of

the direction of the striations, which can be seen in Figure 5d.

This study aimed to analyze

the causes of leaf spring failure through residual stress, crystal orientation,

texture, hardness and fracture morphology. Residual stress shows compressive

properties with a value of -278.5 ± 17.4, which indicates that it is not a

factor causing failure. This is reinforced by the crystal orientation of (110),

(211), which has a low probability (compressive) with values of 1.043 and

1.021. A high probability is obtained at the crystal orientation (200) with a

value of 1.063 and indicates the presence of texture irregularities.

Irregularity of texture can be suspected as a defect in the leaf spring.

Defects can also be seen in the observation of fracture morphology by the

appearance of voids. The voids are scattered randomly on the surface of the

leaf spring and become the center of stress concentration. High-stress

concentrations trigger crack nucleation. In addition, failure is also caused by

fatigue, which can be observed in the morphology of the SEM fracture in the

presence of striations. Hardness testing shows that the leaf spring material

complies with the standardization of spring steel grade SUP 10 (406 – 448 HV).

Abdul, A., Yang, M.,

Shimizu, T., Furushima, T., 2021. Effect of Grain Misorientation and

Martensitic Transformation on Surface Roughening Behavior in Thin Austenitic

Stainless Steel Foils. International Journal of Technology, Volume 12(6), pp. 1161–1167

Ahn, Y.-K., Jeong, Y.-K.,

Kim, T.-Y., Cho, J.-U., Hwang,

N.-M., 2020. Texture evolution of

non-oriented electrical steel analyzed by EBSD and in-situ XRD during the phase

transformation from Materials Today Communications, Volume 25, p. 101307

Aliakbari, K., 2019. Failure Analysis of Base Plate Bolts of

Radial Forging Machine. Journal of Stress Analysis, Volume 4(1), pp. 89–98

Andoko, A., 2019. The Effects of Strain Amplitude

and Low Cycle Fatigue

(LCF) Behavior on Nodular Cast

Iron with Two-step Austempering (TSA) Process. Materials Research Express,

6(9), 095705

Andoko, A., Puspitasari,

P., Permanasari, A.A., 2017. Analysis of Strength of Glass Fibre

Composite Leaf Spring Using Finite Element Method. Journal of Mechanical

Engineering Science and Technology (JMEST), Volume (1), pp. 1–8

Anwar, M.S., Melinia,

R.K., Pradisti, M.G., Siradj,

E.S., 2021. Effect of Prior

Austenite Grain-Size on the Annealing Twin Density and Hardness in the

Austenitic Stainless Steel. International Journal of Technology, Volume 12(6), pp. 1149–1160

Bag, A., Levesque, M., Brochu, M., 2020. Effect of Shot Peening

on Short Crack Propagation

in 300M Steel. International

Journal of Fatigue, Volume 131,

p. 105346

Bozic, Z., Schmauder, S., Wolf, H., 2018. The Effect of Residual Stresses on Fatigue Crack

Propagation in Welded Stiffened

Panels. Engineering

Failure Analysis, Volume 84,

pp. 346–357

Bruno, G., Efremov, A.M.,

Levandovskyi, A.N., Clausen, B., 2011. Connecting the Macro- and Microstrain

Responses in Technical Porous Ceramics: Modeling and Experimental Validations. Journal

of Materials Science, Volume 46, pp. 161–173

Bunge, H.-J., 2013. Texture Analysis in Materials Science:

Mathematical Methods. In: Butterworth-Heinemann

2rd Edition

Chadwick, D.J., 2016. Mechanism

of Shot Peening Enhancement for The Fatigue Performance of AA7050-T7451.

Theses and Dissertations, Purdue University

Chen, Huang, C.-Y., Wang,

Y.-T., Huang, C.-Y., Yen, H.-W., 2020.

Role of the Crystallographic Texture in Anisotropic Mechanical Properties of a Newly-developed Hot-rolled Transformation-induced Plasticity (TRIP) Steel. Materials Science and Engineering: A,

Volume 790, p. 139683

De-la-Rosa, C.E.F.,Trejo,

M.H., Román, M.C., López, E.A., 2016. Effect of Decarburization on the Residual

Stresses Produced by Shot Peening in Automotive Leaf Springs. Journal of

Materials Engineering and Performance, Volume 25(7), p. 2596–2603

Fairfax, E.J., Steinzig, M., 2016. A Summary of Failures Caused by

Residual Stresses. In:

Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and

Inverse Problems, Volume 9, pp.

209–214. Springer International Publishing

Fragoudakis, R., Saigal,

A., Savaidis, G., Malikoutsakis, M., Bazios, I., Savaidis, A., Pappas, G., Karditsas, S., 2013. Fatigue Assessment and Failure Analysis

of Shot-peened Leaf Springs. Fatigue Assessment And

Failure Analysis. Fatigue & Fracture of Engineering Materials &

Structures, Volume 36(2),

pp. 92–101

Fragoudakis, R., Savaidis,

G., Michailidis, N., 2017. Optimizing the Development and Manufacturing of 56SiCr7 Leaf Springs.

International Journal of Fatigue, Volume

103, pp. 168–175

Fuentes, J.J., Aguilar,

H.J., Rodríguez, J.A., Herrera,

E.J., 2009.

Premature Fracture in Automobile Leaf Springs.

Engineering Failure Analysis, Volume

16(2),pp. 648–655

Heidary, O., Mirzaee, O.,

Honarbakhsh Raouf, A., Borhani,

E., 2020. Textu (AISI)

4130 Steel. Materials Science

and Engineering: A, Volume 793,

p. 139751

Hossain, R., Pahlevani,

F., Quadir, M.Z., Sahajwalla, V., 2016. Stability of Retained Austenite in High Carbon

Steel Under Compressive

Stress: An Investigation from Macro to Nano Scale.

Scientific Reports, Volume 6(1), p. 34958

Kadkhodapour, J., Butz,

A., Rad, S.Z., 2011. Mechanisms of Void

Formation During Tensile

Testing in a Commercial, Dual-phase Steel. Acta Materialia, Volume 59(7), pp. 2575–2588

Kong, Y.S., Abdullah, S.,

Omar, M.Z., Haris, S.M., 2016. Failure Assessment of a Leaf Spring

Eye Design Under

Various Load Cases.

Engineering Failure Analysis, Volume

63, pp. 146–159

Kurniawan,

P., Andoko, A., Sunu, P.W., 2021. Leaf spring type simulation with finite

element method approach. Institute of Physics (IOP) Conference Series:

Materials Science and Engineering, Volume 1034(1), p. 012015

Li,

X., Zhang, L., Dong, Y., Wei, Z., Que, Z., Qu, X., 2021. Orientation Relationship of Texture Development in Hot-rolled W During Annealing. International

Journal of Refractory Metals and Hard Materials, Volume 97, p. 105527

Liu, Y., Yang, C.D., Liu,

M., Wang, C.H., Dai, Y.C., Li, X., Russell, A.M., Zhang, C.X., Zhang, Z.H.,

Cao, G.H., 2018. Effects of Microstructure and Crystallography on Mechanical Properties of Cold-rolled SAE1078 Pearlitic Steel. Materials Science and Engineering: A,

Volume 709, pp. 115–124

Manawan, M., Aritonang,

S., Elita Hafizah, M.A., Hali, A.S., Darsono, N., Sudiro, T., Putro, P.A., Risdiana, R., 2021. XRD Residual Stress and

Texture Analysis on 6082T Aluminum Alloy. Materials Science Forum, Volume 1028, pp. 409–414

Minamizawa,

K., Arakawa, J., Akebono, H., Nambu, K., Nakamura, Y., Hayakawa, M., Kikuchi,

S., 2022. Fatigue Limit Estimation for Carburized Steels with Surface Compressive

Residual Stress Considering Residual Stress Relaxation. International

Journal of Fatigue, Volume 160, p. 106846

Pastor,

M., Lengvarsky, P., Trebuna, F., Carak, P., 2020. Prediction of Failures in Steam

Boiler using Quantification of Residual Stresses. Engineering Failure

Analysis, Volume 118, p. 104808

Peng,

W., Zhang, J., Yang, X., Zhu, Z., Liu, S., 2010. Failure Analysis on the Collapse

of Leaf Spring Steels During Cold-punching. Engineering Failure Analysis,

Volume 17(4), pp. 971–978

Priyanto,

T.H., Effendi, N., Parikin., 2015. Texture Analysis of the Hot Rolling

Austenitic Cr-Ni Steel Using Neutron Diffraction Method. Advanced Materials

Research, Volume 1123, pp. 104–108

Purnama,

D., Winarto, W., Sofyan, N., Prihastomo, A., Ito, K., 2020. Microstructure and

Mechanical Properties of Ah-36 Steel Weldment Welded using Magnesium Modified

E6013 Electrode. International Journal of Technology, Volume 11(1), pp. 48–59

Ren,

P., Chen, X.P., Wang, C.Y., Zhou, Y.X., Cao, W.Q., Liu, Q., 2021. Evolution of Microstructure, Texture and Mechanical Properties of

Fe–30Mn–11Al–1.2C Low-density Steel During Cold Rolling. Materials Characterization, Volume 174, p. 111013

Scuracchio,

B.G., de-Lima, N.B., Schön, C.G., 2013. Role of Residual Stresses Induced by Double Peening on Fatigue Durability of Automotive Leaf Springs. Materials and Design, Volume 47, pp. 672–676

Shojaei,

M., Khayati, G.R., Khorasani, S.M.J., Hernashki, R.K., 2021. Investigation of Spring Back Phenomenon in the 316L Stainless Steel Cathode Blank Based on the Changes in Electrical Resistivity and Magnetic Properties Due to the Residual Stress and Martensite Phase Formation: An Industrial Failure. Engineering

Failure Analysis, Volume 126, p. 105473

Soyama,

H., Chighizola, C.R., Hill, M.R., 2021. Effect of Compressive Residual Stress Introduced by Cavitation Peening and Shot Peening on the Improvement of Fatigue Strength of Stainless Steel. Journal of Materials Processing Technology, Volume 288, p. 116877

Soyama,

H., Kikuchi, T., Nishikawa, M., Takakuwa, O., 2011. Introduction of Compressive Residual Stress Into Stainless Steel by Employing a Cavitating Jet in Air. Surface and Coatings Technology, Volume 205(10), pp. 3167–3174

Wenk,

H.R., 2016. Preferred Orientation in Deformed Metal and Rocks: An

introduction to Modern Texture Analysis. In: Academic Press, Orlando, Florida

Xiao,

G., Chen, B., Li, S., Zhuo, X., 2022. Fatigue Life Analysis of Aero-engine Blades for Abrasive Belt Grinding Considering Residual Stress. Engineering Failure Analysis, Volume 131, p. 105846

Xie,

C., Liu, Z., He, X., Wang, X., Qiao, S., 2020. Effect of Martensite–austenite Constituents on Impact Toughness of Pre-tempered MnNiMo Bainitic Steel. Materials Characterization, Volume 161, p. 110139

Zhang, J., Di, H., Deng, Y., Misra, R.D.K., 2015. Effect of Martensite Morphology and Volume Fraction

on Strain Hardening and Fracture Behavior of Martensite–ferrite Dual Phase

Steel. Materials Science

and Engineering: A, Volume 627,

pp. 230–240

Zhang,

Z., Hu, Z., Schmauder, S., Zhang, B., Wang, Z., 2019. Low Cycle Fatigue Properties and Microstructure of P92 Ferritic-martensitic Steel at Room Temperature and 873 K. Materials Characterization, Volume 157, p. 109923