Development of Sweat and Saliva Glucose Sensors as Alternative for Non-Invasive Blood Glucose Monitoring

Corresponding email: prasetyanto@atmajaya.ac.id

Published at : 17 May 2024

Volume : IJtech

Vol 15, No 3 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i3.5535

Lukito, A.A., Tyrayoh, M., Prasetyanto, E.A., Rukmini, E., 2024. Development of Sweat and Saliva Glucose Sensor as Alternative for Non-Invasive Blood Glucose Monitoring. International Journal of Technology. Volume 15(3), pp. 720-731

| Agrevina Ane Lukito | School of Medicine and Health Science, Atma Jaya Catholic University of Indonesia, 2 Pluit Raya str., North Jakarta 14440, Indonesia |

| Michelle Tyrayoh | School of Medicine and Health Science, Atma Jaya Catholic University of Indonesia, 2 Pluit Raya str., North Jakarta 14440, Indonesia |

| Eko Adi Prasetyanto | Department of Pharmacy, School of Medicine and Health Science, Atma Jaya Catholic University of Indonesia, 2 Pluit Raya str., North Jakarta 14440, Indonesia |

| Elisabeth Rukmini | Department of Civil Engineering and Center for Urban Studies, Pembangunan Jaya University, Cendrawasih Raya str., South Tangerang 15413, Indonesia |

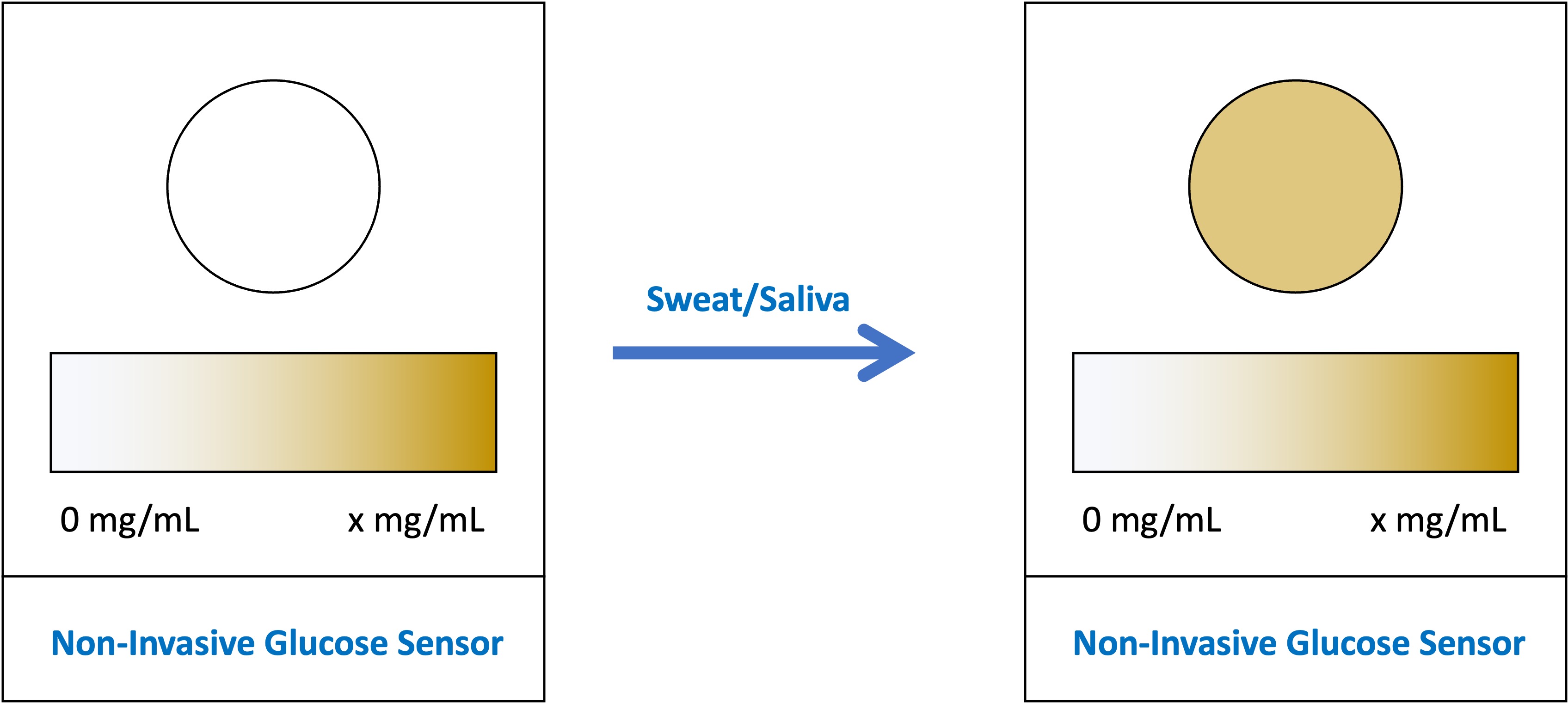

. This study aimed to

develop a paper-based glucose sensor using artificial sweat and saliva samples,

a non-invasive, practical, and affordable concept for measuring glucose levels.

The chosen method was the colorimetric method using the Glucose Oxidase (GOx)

enzyme, Horseradish Peroxidase (HRP) enzyme, and 3,3?-diaminobenzidine (DAB)

chromogen. The wax stamping method was utilized on a piece of filter paper to

test the glucose sensor. The test was carried out in several stages, including

testing various concentrations of reagents and wax stamping sizes, fabricating

the glucose sensors, and testing multiple concentrations of glucose, artificial

sweat, and artificial saliva. The RGB method was used to test the resulting

color. The data obtained were then validated using UV-Vis Spectrophotometry. The

GOx concentration on the glucose sensor affected the color change velocity. The

HRP, DAB, and wax stamping size concentration simultaneously indicated a strong

correlation with changes in the color intensity that appeared on the glucose

sensor. The glucose sensor in this study could measure the glucose

concentration of the artificial sweat and saliva samples, respectively, from

0-3000 and 0.9987. This study proved a

strong correlation between the reagents' concentration and the color intensity

on the developed glucose sensor.

Colorimetry; Glucose; Non-invasive; Saliva; Sweat

Diabetes Mellitus (DM) is

a global epidemic disease that affects blood glucose levels. According to the

2019 International Diabetes Federation (IDF) Diabetes Atlas, around 463 million

adults worldwide, whose ages range from 20-79 years old, suffer from DM. In

Indonesia, there are more than 10 million diabetes cases in adults, with a

prevalence of 6.2% (IDF, 2019).

Self-monitoring blood glucose is important for diabetics, which consists of

controlling sugar levels with the necessary diet and physical activity (Gordon,

2019; Meetoo et al., 2018; Dewi et al., 2017).

This study aimed to design a

non-invasive concept to measure the glucose levels in the body using

paper-based colorimetric methods. The developed device design is a practical,

harmless, and affordable device to simplify the process of routine glucose checks

by the entire community. In order to develop the design concept of the device,

it is essential to test both the reagents concentration, which is required to

measure the glucose levels optimally and the size of wax stamping, which is

required to accommodate the optimal reagents and samples. After obtaining the

most optimal concentration and size of wax stamping, the research was continued

using a paper-based glucose sensor. The glucose sensor was then used to test

samples of several concentrations of pure glucose, glucose in sweat, and

glucose in saliva using the RGB method. The study ended by validating the RGB

findings using UV-Vis Spectrophotometry in order to obtain more accurate and reliable data.

2.1. Materials and equipment

The

materials used to measure the glucose level included Glucose Oxidase (GOx),

Horseradish Peroxidase (HRP) as the enzyme, a chromogen namely

3,3'-diaminobenzidine (DAB), Chitosan powder as the solute, PBS buffer,

glucose, lactic acid, acetic acid, distilled water as the other solution, the

PBST solution which composed of 50 mM PBS, 0.9% NaCl, 0.1% Triton X-100, pH

7.4, and other compounds that consisted of NaCl, NH4Cl, NaOH, KCl,

CaCl2, NaHCO3, and Whatman filter paper no.4 whose

diameter of 110 mm.

The equipment used to measure the glucose level required some devices

consisting of a smartphone with Color Grab™ application (Lookmatix,

2020), several wax stamps, a black

box, some hot plates, an oven, an analytical scale with 0.001 mg precision, and

the UV-Vis Spectrophotometer.

2.2. Research procedures

2.2.1. Testing

with Various Reagent Concentrations

This research used several

concentrations, including GOx, HRP, and DAB, to start the test. In each trial

of a reagent concentration, the other reagents were used as the constant

(identical concentrations). First, a 5 L solution of GOx and a 5

L solution of HRP were

dropped into the sample reservoir on the filter paper until it dried (20

minutes) before the DAB (5

L) was

added. After the DAB dried, the same concentration of glucose solution (20

L) was dripped on each reservoir sample. The filter paper was then

incubated at room temperature for 20 minutes, followed by taking photographs of

the test results with the Color Grab™ application to obtain the RGB values. The

test was finalized by recording the results of each reaction to get the most

optimal concentrations of GOx, HRP, and DAB.

2.2.2. Testing of Wax

Stamping Sizes

After the most optimal GOx,

HRP, and DAB concentrations were obtained, the next step was to test various

diameters of the sample reservoir in the wax stamping. This step was conducted

to get the same volume of samples and reagents in each experiment. The first

step was to melt the paraffin at 130oC,

followed by heating the wax stamp on the melted hot paraffin to be attached to

the wax stamp. Later on, the pattern was formed by pressing the wax stamp on

the filter paper for 5 seconds. Following this, the filter paper was preheated

in the oven for 10 seconds at 100oC (if the

paraffin did not penetrate the back side of the filter paper). After the filter

paper was ready, the reagent and glucose were dropped into the sample reservoir

and incubated in the filter paper for 20 minutes at room temperature. Finally,

the pictures of the resulting color were taken using the Color Grab™

application, and the results were recorded.

2.2.3. Fabrication of

the Glucose Sensor

The fabricating process of

the paper-based glucose sensors began by preparing the filter paper in a round

shape, then printing a hydrophobic barrier with paraffin and anticipating the

complete absorption. Subsequently, the Chitosan was prepared in acetate

solution (5 L) to be dropped on the

sample reservoir until it dried at room temperature. Afterward, the other

materials, such as GOx, HRP, and DAB, were dropped on the sample reservoir and

allowed the sensor to dry further at room temperature. Lastly, the PBST

solution was sent to the sample reservoir until it dried at room temperature.

Figure 1

Paper-Based Glucose Sensor Fabrication Method (a) and Dropping Process on

Glucose Sensor (b)

2.2.4. Measurements with Various Concentrations of Glucose, Artificial

Sweat, and Artificial Saliva

Various glucose concentrations in distilled

water at concentrations of 0

and

were prepared. Furthermore, the glucose solution was

dropped onto different sensor reservoirs. While experimenting, the results of

each reaction were recorded. Afterward, artificial sweat was prepared with 20

g/L NaCl, 17.5 g/L NH4Cl, 5 g/L acetic acids, and 15 g/L lactic

acid. Furthermore, 0.1 mM NaOH solution was added to the artificial sweat

solution to make the sweat produce a pH of 6.0 (Xiao et al., 2019a). The artificial saliva with 36 grams of NaCl, 1.6 grams of KCl, 0.96

grams of CaCl2, 0.8 grams of NaHCO3, and 400 ccs of

equilibrated water was made using HCl until it reached a pH of 7 (Ramadhani,

Sulistiyani, and Hidayati, 2017). Then,

pure glucose was added to the artificial sweat and saliva in various

concentrations. Accordingly, artificial sweat and saliva with various glucose

concentrations were then dropped into different sample reservoirs. With that,

the sensors were incubated at room temperature for 20 minutes, then the sample

pictures of the color were taken to get the RGB value. The RGB results of each

reaction were recorded to be validated with UV-Vis Spectrophotometry as an

additional test. Before the test, the reagents and samples were mixed with PBS

and dropped into a micro cuvette. Lastly, the absorbance results of each

example were recorded.

2.2.5. Evaluation of the Experimental Results

The RGB value indicated the color intensity that appeared due to the glucose concentration in the sample. The RGB value obtained from each glucose sensor was described in a comparison graph. From these data, the concentration and volume of reagents that provided the most optimal measurement of glucose levels were determined. The wax stamping size was then also selected to obtain the optimal reagents and the samples of the artificial sweat and saliva.

3.1. The Relation Between Reagent Concentration and

Color Change Intensity

There were three variations of

concentrations for each of the reagents used in this test. GOx and HRP had

concentrations of Meanwhile, 3,3?-diaminobenzidine (DAB) had

concentrations of

The test of various concentrations of GOx showed no

significant relationship between various concentrations of GOx and the

intensity of color change. However, GOx concentrations could affect the speed

of the color change. The higher the GOx concentration, the faster the color

change occurred. This finding was in line with the function of the enzyme

glucose oxidase as a catalyst for the oxidation of glucose to gluconic acid and

hydrogen peroxide (Yee et al., 2019; Lee et al., 2018).

Therefore, the GOx concentration of

was the concentration that could cause a fast color

change.

3.2. Stamping Wax Size was Required to Get the Optimal

Volume of Reagents and Samples

This study tested three different wax stamping diameter sizes, which were 5.5 mm, 8 mm, and 10 mm, using the RGB method. Based on the results of RGB value analysis, the most optimal wax stamping diameter was 5.5 mm. However, in this study, the wax stamping size with a diameter of 5.5 mm did not accommodate the entire volume of reagents and samples as it caused leakage. Therefore, the diameter of the wax stamping optimal for use in this study was 8 mm. The findings of this study were consistent with previous studies that predicted dimensions could affect the results in paper-based microfluidic devices. According to the study results, the error on paper-based sensor devices with a circular area of ??more than 25 mm2 was less than 10%, while the device error was 20% with a circular area of ??more than 15 mm2 (Catalan-Cario et al., 2020). The area of ??a circle used in this sensor was 50.24 mm2 (circle diameter = 8 mm). With this area of the circle, the total error was less than 10% and would be considered an optimal wax stamping size.

According to another study, Santana-Jimenez et

al. used wax stamping with a diameter of 3 mm. With this diameter, the

amount of enzyme solution, reagent, and sample dripped was 5?L (Santana-Jimenez et al.,

2018), and the area of the wax stamping was ??7 mm2.

Therefore, the ratio between the amount of dripped volume and the circle area (7 mm2) in the

Santana-Jimenez study was 1:1.4. In this study, the optimal diameter was 8 mm

with a circular area of ??50 mm2. Thus, we obtained a comparison

between the amount of volume that dripped

and the area of the circle (50 mm2) in this

research was approximately 1:1.4. From the results of these calculations, the

diameter size of this study was in accordance with the diameter of the

reference journal.

3.3. The Correlation of Glucose Concentration in

Samples and Intensity of Color Change

3.1.1. Pure

Glucose

3.3.2. Artificial

Sweat

This study utilized 11 glucose

concentration variations in artificial sweat. It was the same as in the pure

glucose test. The test results using the RGB method showed a strong negative

correlation between the glucose concentration in artificial sweat and the three

RGB values. The researchers succeeded in proving this correlation with the

Spearman correlation coefficient of -0.9931 (R2 = 0.9862) for RGB-R,

and the Pearson correlation coefficient, respectively, for RGB-G and RGB-B were

-0.9469 and -0.9048 (R2 = 0.8966 and 0.8187). The linear regression

equation of the RGB-R data calibration curve is y = -0.011x + 189.664 (figure

3a). The equation was made based on RGB-R data because the RGB-R values

??provided the most visible difference and significantly contributed to color

changes caused by enzyme catalytic reactions (Xiao et al., 2019a). The findings in this study were in accordance

with the findings by Xiao et al., who found something similar, which had

a negative linear relationship between the RGB-R values ??and 0 to 1500 uM

glucose concentrations in artificial sweat. Therefore, paper-based sensors can

be relied upon to detect glucose in sweat (Xiao et al., 2019a).

The glucose level in sweat is 10-1110 ?M (Xiao et al., 2019b). The sweat glucose level of normal people is 60-110 ?M, while the sweat glucose level of diabetic patients is 10-1000 ?M (Bruen et al., 2017). The glucose sensor in this study could detect glucose levels in artificial sweat with a concentration of 0 to 3000 ?M. Therefore, it could detect sweat glucose levels in normal people to diabetic patients. In addition, the difference in color intensity could be seen visually. The higher the glucose concentration in artificial sweat, the more pronounced the brown color on the glucose sensor (Figure 2). This color changed because the glucose in the artificial sweat samples activated a reagent-chromogen system reaction that resulted in an increased color intensity along with an increase in glucose concentration. Based on these findings, the strong correlation between glucose concentration in artificial sweat and color intensity could be the basis for the design concept of a glucose sensor using paper-based colorimetric methods.

Figure 2 Color Differences in Four Different Concentrations of Glucose in Artificial Sweat

Figure 3 Linear Regression Graph of

Artificial Sweat RGB Test (a) and Linear Regression Graph of Artificial Sweat

Spectrophotometric UV-Vis Test (b)

The

last step of this research was validating the RGB test results using the UV-Vis

Spectrophotometry method. First, we determined the appropriate wavelength of

the reaction between the reagent-chromogen and glucose in the sample. The peak

absorbance value of the reaction was at a wavelength of 419 nm. Then, we

proceeded with testing artificial sweat samples with five glucose

concentration variations (0, 300 ?M, 1500 ?M, 2400 ?M, and 3000 ?M) at a

wavelength of 419 nm. Based on the results, there was a strong positive

correlation between glucose concentration in artificial sweat and light

absorbance at 419 nm with a Spearman correlation coefficient of 0.993 (R2

= 0.985) and a linear regression equation y = 0.00006x + 0.025 (Figure 3b). The

positive correlation explains that the higher the glucose concentration in

artificial sweat, the higher the light absorbance value at a wavelength of 419

nm. In comparison, the negative correlation in the RGB equation illustrates

that the higher the glucose concentration, the lower the RGB value. This study

proved that the RGB method was valid. Therefore, the RGB approach can be

applied to the design concept of detecting glucose in sweating paper-based

colorimetry.

3.3.3. Artificial Saliva

In the test of artificial saliva samples

with RGB, the researcher made the saliva glucose concentration in 11

concentration variations as in the pure glucose test. Based on the experimental

results, a strong correlation was found between various glucose concentrations

in artificial saliva and the intensity of the color change. The higher the sample

concentrations, the higher the intensity of the color formed. In previous

research from Xiao et al., the linear regression equation y = -0.19x + 231.68

was obtained with a value of R2 = 0.9896. This value indicated that

the R (red) value provided a good linear relationship (Xiao et al., 2019a). In this study, we

obtained a linear regression equation from the calibration curve of R(red) data

on RGB, namely y = -0.015x + 192.686, with a value of R2 = 0.991 (Figure 5a). This value indicates a good

correlation between the intensity of the color produced and various glucose

concentrations in artificial saliva. This correlation was even better than the

previous research conducted by reference journals.

The high correlation proves that the

prototype can significantly measure saliva glucose concentrations from 0-3000

?M. The average saliva concentration in normal people is 8-210 ?M. While in

diabetes patients, the saliva glucose concentration was 100-700 ?M (Siddiqui et al., 2018). Therefore, this

prototype can detect salivary glucose levels in people with diabetes. Color

gradations from the artificial saliva glucose test results with concentrations

of can also be seen with the naked eye (Figure

4).

Figure 4 Color Differences in Four Different Concentrations

of Glucose in Artificial Saliva

After testing with RGB,

UV-Vis spectrophotometry was used to validate all the results obtained using an

artificial saliva sample that consisted of 5 glucose concentration variations consisted of 5 glucose concentration variations (0,

300 ?M, 1500 ?M, 2400 ?M, and 3000 ?M). With a wavelength of 419 nm, the trial

results showed a strong correlation between the various glucose concentrations

in the artificial saliva and the resulting color intensity. All data from this

experiment were made in the form of a calibration curve and obtained a linear

regression equation y = 0.0006x + 0.025 with a value of R2 = 0.9831

(Figure 5b). This value indicated a good correlation between the absorbance value

??and the various glucose concentrations inartificial saliva samples. Similar to the study on sweat, the results of the data obtained in the

assay with RGB and UV-Vis spectrophotometry gave inversely correlated results.

The higher the glucose concentration, the lower the RGB value, while the

absorbance value of the UV-Vis spectrophotometric test was lower. The results of this trial have proven to validate the results

obtained in research with RGB.

Figure 5 Linear

Regression Graph of the RGB Test of Artificial Saliva (a) and Linear Regression

Graph of the UV-Vis Spectrophotometric Test of Artificial Saliva (b)

3.3.4. Sensor

Sensitivity and Accuracy

The smartphone device used

in this study would help glucose detection be more practical. Therefore, there

are several things to note. First, taking pictures will be different if you do

not follow the black box instructions correctly. In addition, the RGB value in

the application will change if the user uses the zoom-in/out feature, which

will reduce the validity of reading the glucose concentration results in the

sample. Therefore, adjustments are needed to the black box to help provide

similar image results for each type of smartphone used.

In addition to using a

black box, wax stamping could also affect the sensitivity and accuracy of the

glucose sensor. The first was about the successful penetration of paraffin on

the filter paper. In our research, the paraffin occasionally did not penetrate

the back of the filter paper, reducing the sensitivity and accuracy of the

results. The second was the possibility of paraffin entering the sample

reservoir circle during the wax stamping process. Paraffin droplets that

accidentally dropped into the sample reservoir could also reduce the accuracy

of the glucose sensor. Therefore, it is more advisable to use a more guaranteed

method in terms of shape and print results, such as wax printing or beeswax printing which are useful for biological detection (Nunut et

al., 2020).

This

study proved a highly correlated relationship between the concentration of

Horseradish Peroxidase (HRP) as an enzyme and 3,3'-diaminobenzidine (DAB) as a

chromogen with the color change intensity by the colorimetric method. Glucose

Oxidase (GOx) affected the speed of color changes on the glucose sensor. The

size of the hydrophobic barrier can also affect the intensity of the resulting

color. The size of the wax stamping that gave optimal results had a ratio of

1:1.4 between the area of the circle formed by wax stamping and the volume of

liquid that was dropped. In addition, this study proved a strong correlation

between various glucose concentrations and color intensity. The solutions used

in this research consist of variations of pure glucose solutions, artificial

sweat, and saliva solutions concentrations. R2 values proved a

strong correlation, 0.9928 for pure glucose, 0.9862 for glucose in artificial

sweat, and 0.991 for artificial saliva. The glucose sensor in this study has

been proven to measure glucose levels with a concentration of 0 to optimally, including normal glucose levels and glucose levels in diabetic

patients in sweat and saliva. This finding could be the basis for developing a

non-invasive glucose level detection device in sweat and saliva.

This research was funded by the Indonesian Ministry

of Research and Technology/National Research and Innovation Body in 2021

(contract no. 1208/LL3/PG/2021).

Altundemir, S., Uguz,

A.K., Ulgen, K., 2017. A Review on Wax Printed Microfluidic Paper-Based Devices

for International Health. Biomicrofluidics, Volume 11(4), p. 041501-23

Bruen, D., Delaney,

C., Florea, L., Diamond, D., 2017. Glucose Sensing for Diabetes Monitoring:

Recent Developments. Sensors, Volume 17(8),

p. 1866

Catalan-Carrio, R.,

Akyazi, T., Basabe-Desmonts, L., Benito-Lopez, F., 2020. Predicting Dimensions

in Microfluidic Paper Based Analytical Devices. Sensors, 21(1), p. 101

Dewi,

D.S., Irfoni, A.R., Rahman, A., 2017. Kansei Engineering Approach for Designing

a Self-Monitoring Blood Glucose Application. International Journal of

Technology, Volume 8(2), pp. 272–282

Dominguez,

R.B., Orozco, M.A., Chavez, G., Marquez-Lucero, A., 2017. The Evaluation of a

Low-Cost Colorimeter for Glucose Detection in Salivary Samples. Sensors, Volume

17(11), pp. 2495

Ekawita, R., Nasution,

A.A., Yuliza, E., Suardi, N., Suwarsono, 2020. Development of Non-Invasive

Blood Glucose Level Monitoring System using Phone as a Patient Data Storage. Jurnal

Penelitian Fisika dan Aplikasinya (JPFA), Volume 10(2), pp. 103–113

Gabriel, E.F.M.,

Garcia, P.T., Lopes, F.M., Coltro, W.K.T., 2017. Paper-Based Colorimetric

Biosensor for Tear Glucose Measurements. Micromachines, Volume 8(4), p.

104

Gordon, C, 2019.

Blood Glucose Monitoring in Diabetes: Rationale and Procedure. British

Journal of Nursing, Volume 28(7), pp. 434–439

Gupta, S., Nayak, M.,

Sunitha, J., Dawar, G., Sinha, N., Rallan, N.S., 2017. Correlation Of Salivary

Glucose Level With Blood Glucose Level In Diabetes Mellitus. Journal of Oral

and Maxillofacial Pathology, Volume 21(3), p. 334

He, Y., Wu, Y., Fu, J.-Z.,

Wu, W.-B., 2015. Fabrication of Paper-Based Microfluidic Analysis Devices: a

Review. RSC Advances, Volume 5(95), pp. 78109–78127

International

Diabetes Federation (IDF), 2019. IDF Diabetes Atlas. 9th edition.

Available online at: https://www.diabetesatlas.org

Jangi, A.R.H., Jangi, M.R.H., Jangi, S.R.H. 2020. Detection

Mechanism and Classification Of Design Principles of Peroxidase Mimic Based

Colorimetric Sensors: A Brief Overview. Chinese Journal of Chemical

Engineering, Volume 28(6) pp. 1492–1503

Jangi, A.R.H., Jangi,

M.R.H., Jangi, S.R.H., 2020. Detection Mechanism and Classification of Design

Principles of Peroxidase Mimic Based Colorimetric Sensors. Chinese Journal

of Chemical Engineering, Volume 28(6), pp. 1492–1503

Jin, S., Liu, L., Fan,

M., Jia, Y., Zhou, P., 2020. A Facile Strategy for Immobilizing GOD and HRP

Onto Pollen Grain and Its Application to Visual Detection of Glucose. International

Journal of Molecular Sciences, Volume 21(24), p. 9529

Karpova, E.V.,

Shcherbacheva, E.V., Galushin, A.A., Vokhmyanina, D.V., Karyakina, E.E.,

Karyakin, A.A., 2019. Noninvasive Diabetes Monitoring through Continuous

Analysis of Sweat Using Flow-Through Glucose Biosensor. Analytical

Chemistry, Volume 91(6), p. 3778

Lee, H., Hong, Y.J.,

Baik, S., Hyeon, T., Kim, D.-H., 2018. Enzyme-Based Glucose Sensor: From

Invasive to Wearable Device. Advanced

Healthcare Materials, Volume 7(8), pp. 1701150

Liu, S., Su, W., Ding.

X., 2016. A Review on Microfluidic Paper-Based Analytical Devices for Glucose

Detection. Sensors. Volume 16(12) p. 2086

Lookmatix, 2020. Color

Grab™ [Mobile app]. Google Play. Available online at: https://play.google.com/store/apps/details?id=com.loomatix.colorgrab&hl=id

Meetoo, D., Wong, L.,

Fatani, T., 2018. 'Knowing Where I am': Self-Monitoring of Blood Glucose in

Diabetes. British Journal of Nursing, Volume 27(10), pp. 537–541

Nadaf, A., Hassan,

Z., Farooq, S., 2017. Salivary Glucose Level and its Correlation with Blood

Glucose Level in Patients with Diabetes Mellitus-an in-Vivo Study. International

journal of Contemporary Medical Research, Volume 4(12), pp. 17–20

Nunut,

I., Whulanza, Y., Kassegne, S., 2020. Testing of Beeswax Printing Technology in

the Design of a Paper-Based Microfluidic System. International Journal of

Technology, Volume 11(5), pp. 1036–1045

Perdani, M.S.,

Juliansyah, M.D., Putri, D.N., Utami, T.S., Hudaya, C., Yohda, M., Hermansyah,

H., 2020. Immobilization of Cholesterol Oxidase in Chitosan Magnetite Material

for Biosensor Application. International Journal of Technology, Volume 11(4),

pp. 754–763

Ramadhan, A.,

Sulistiyani, S., Hidayati, L., 2017. Uji Kedalaman Porositas Permukaan Bahan

Pit dan Fissure Sealant Berbasis Resin Komposit dan Ionomer Kaca Setelah

Direndam Saliva Buatan pH 5,5 (Depth Porosity Test of Surface Materials Pit

and Fissure Sealant Based Resin Composite and Glass Ionomer After). Pustaka Kesehatan, Volume 5(3), pp. 454–460

Santana-Jiménez L.,

Márquez-Lucero A., Osuna V., Estrada-Moreno I., Dominguez R., 2018. Naked-Eye

Detection of Glucose in Saliva with Bienzymatic Paper-Based Sensor. Sensors, Volume 18(4), p. 1071

Siddiqui, S., Zhang,

Y., Lloret, J., Song, H., Obradovic, Z., 2018. Pain-Free Blood Glucose

Monitoring Using Wearable Sensors: Recent Advancements and Future Prospects. IEEE

Reviews in Biomedical Engineering, Volume 11, pp. 21–35

Singh, A., Lantigua,

D., Meka, A., Taking, S., Pandher, M., Camci-Unal, G., 2018. Paper-Based

Sensors: Emerging Themes and Applications. Sensors,

Volume 18(9), pp. 2838

Soum, V., Park, S.,

Brilian, A.I., Kwon, O.-S., Shin, K., 2019. Programmable Paper-Based

Microfluidic Devices for Biomarker Detections. Micromachines, Volume10(8), p. 516

Vaquer, A., Barón,

E., Rica, R., 2021. Detection of Low Glucose Levels in Sweat with Colorimetric

Wearable Biosensors. The Analyst, Volume 146(10), p. 3273

Wang, T., Guo, K.,

Hu, X., Liang, J., Li, X., Zhang, Z., Xie, J., 2020. Label-Free Colorimetric

Detection of Urine Glucose Based on Color Fading Using Smartphone Ambient-Light

Sensor. Chemosensors, Volume 8(1), p. 10

Wei, X., Tian, T.,

Jia, S., Zhu, Z., Ma, Y., Sun, J.-J., Lin, Z., Yang, C.J., 2016. Microfluidic

Distance Readout Sweet Hydrogel Integrated Paper-Based Analytical Device

(µDiSH-PAD) for Visual Quantitative Point-of-Care Testing. Analytical Chemistry, Volume 88(4), pp. 2345–2352

Xiao, G., He, J.,

Chen, X., Qiao, Y., Wang, F., Xia, Q., Yu, L., Lu, Z, 2019a. A Wearable, Cotton

Thread/Paper-Based Microfluidic Device Coupled with Smartphone for Sweat

Glucose Sensing. Cellulose, Volume 26(7),

pp. 4553–4562

Xiao, J., Liu, Y., Su,

L., Zhao, D., Zhao, L., Zhang, X., 2019b. Microfluidic Chip-Based Wearable

Colorimetric Sensor for Simple and Facile Detection of Sweat Glucose. Analytical Chemistry, Volume 91(23), pp.

14803–14807

Xiong, Y., Pei, K.,

Wu, Y., Xiong, Y., 2017. Colorimetric ELISA Based on Glucose Oxidase- Regulated

The Color of Acid–Base Indicator For Sensitive Detection of Aflatoxin B1 in

Corn Samples. Food Control, Volume 78(1),

pp. 317–323

Yee, Y., Hashim, R.,

Mohd, A., Bustami, Y., 2019. Colorimetric Analysis of Glucose Oxidase-Magnetic

Cellulose Nanocrystals (CNCs) for Glucose Detection. Sensors, Volume 19(11)

p. 2511

Zafar, H., Channa,

A., Jeoti, V., Stojanovi?, M., 2022. Comprehensive Review on Wearable

Sweat-Glucose Sensors for Continuous Glucose Monitoring. Sensors, Volume

22(2), p. 638

Zheng, H., He, J., Li, P., Guo, M., Jin, H., Shen, J., Xie, Z., Chi, C.,

2018. Glucose Screening Measurements and Non-invasive Glucose Monitor Methods. Procedia

Computer Science, Volume 139, pp. 613–621