Characterization and Application of TiO2/ZnO Nanoparticles as Pigments in Matt-Type Water-Based Paint

Corresponding email: novesarjamarun@sci.unand.ac.id

Published at : 04 Apr 2023

Volume : IJtech

Vol 14, No 2 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i2.5501

Isfa, B., Jamarun, N., Emriadi, Arief, S., Ritonga, A.H., Tanjung, D.A., Sisca, V., 2023. Characterization and Application of TiO2/ZnO Nanoparticles as Pigments in Matt-Type Water-Based Paint. International Journal of Technology. Volume 14(2), pp. 320-329

| Boy Isfa | Department of Chemistry, Universitas Andalas, Padang-25163, Indonesia |

| Novesar Jamarun | Department of Chemistry, Universitas Andalas, Padang-25163, Indonesia |

| Emriadi | Department of Chemistry, Universitas Andalas, Padang-25163, Indonesia |

| Syukri Arief | Department of Chemistry, Universitas Andalas, Padang-25163, Indonesia |

| Ahmad Hafizullah Ritonga | Institut Kesehatan Medistra Lubuk Pakam, Deli Serdang-20512, Indonesia |

| Denny Akbar Tanjung | Faculty of Pharmacy, Institut Kesehatan Deli Husada Deli Tua, Deli Serdang-20355, Indonesia |

| Vivi Sisca | Department of Biology Education, Universitas Merangin, Jambi-37313, Indonesia |

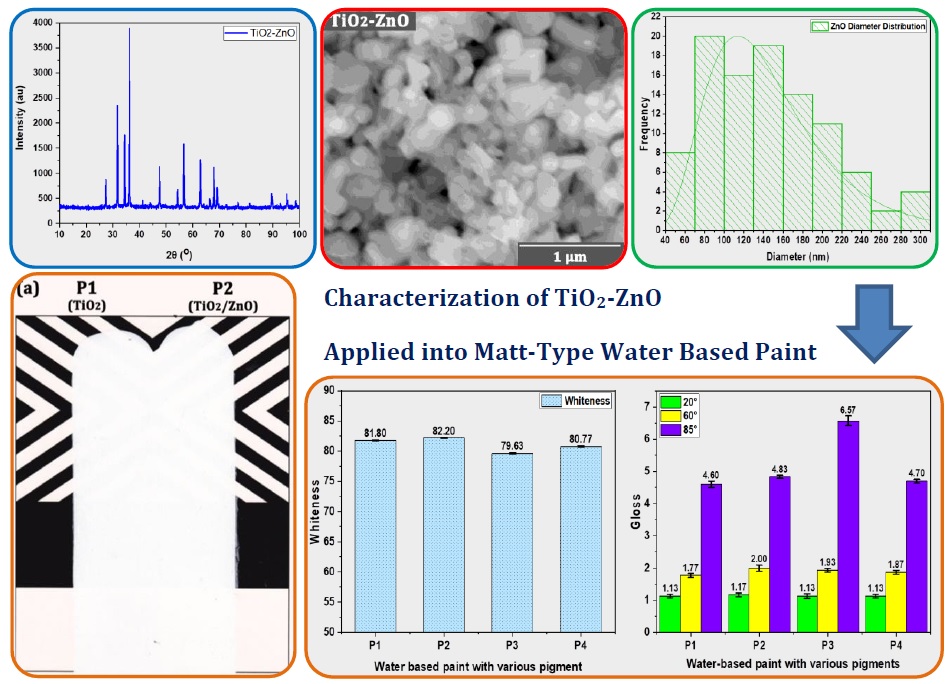

This study

investigates the characteristics of TiO2/ZnO nanoparticles and the

application of TiO2/ZnO in matt-type water-based paint as a pigment.

This study aims to determine the quality of TiO2-ZnO pigments in

water-based paints in terms of whiteness, hiding power, dispersibility, and

gloss. Matt-type water-based paint has been made by mixing water and additives

substances in a high-speed mixer to result in a mill base paste, which is mixed

with the pigment of TiO2/ZnO (25:75), CaCO3 filler,

water, and additives, then filtered and mixed again with the C-817 binder. The

characterization results showed that TiO2/ZnO nanoparticles

contained TiO2 of 18.62% and ZnO of 77.49%, with an average particle

diameter of 151.54 nm. TiO2/ZnO has a crystal size of 28.4 nm and a

crystallinity degree of 72.3%. The application of TiO2/ZnO

nanoparticles as a pigment in matt-type water-based paint resulted in good

dispersion and hiding power and achieved whiteness of 82.2 and gloss at 60° of

2.00 better than TiO2 of 81.8 and gloss at 60° of 1.77.

Matt-type water-based paint; Pigment; TiO2; TiO2/ZnO; ZnO

Paint is a

complex mixture consisting of resins, pigments, solvents, fillers, and other

additives used to coat the surface of a material to beautify, strengthen, or

protect the material. There are two types of paint, namely water-based paint

and solvent-based paint. Water-based paint commonly used is the matt type which

gives an even and non-reflective finish. This matt water-based paint is the

most popular choice because it is easy to apply on smooth interior surfaces.

The matt-type application is generally used on ceilings and walls with an even

finish and a sheen level of less than 10%, giving it a non-reflective

appearance (Chen et al., 2022; Peruchi et al., 2021).

In the paint industry, the main white pigment popularly used is titanium dioxide (TiO2) because of its whiteness, high coverage, refractive index, covering power, achromatic force, good dispersion, and resistance to ultraviolet (UV) rays (Islam et al., 2020; Karakas and Çelik, 2018). These advantages have caused TiO2 to be widely developed and researched and become the main choice in its application as a pigment compared to zinc oxide (ZnO), lithopone, and others (Gao et al., 2022; Costa et al., 2017).

The TiO2 cannot be obtained naturally but is extracted from ilmenite ore. TiO2 can also be synthesized using the sol-gel method (Solanki et al., 2021; Yuwono et al., 2014), sonochemical (Rosales et al., 2021), hydrothermal, solvothermal (Mamaghani, Haghighat, Lee, 2019; Sofyan et al., 2018, 2019), microwave (Li et al., 2021), co-precipitation (Bhogaita and Devaprakasam, 2021), and direct oxidation (Daraee et al., 2018). However, the synthesis of TiO2 is limited by the environmental pollution generated by industrial processes, the shortage of titanium resources, and the high selling price. Therefore, it is necessary to develop TiO2 by mixing it with other white pigments with better or almost similar quality to reduce the high demand for TiO2 nanoparticles (Razali et al., 2022; Isfa et al., 2022; Dell’Edera et al., 2021; George et al., 2021).

Zinc oxide (ZnO) is the main white pigment that

has long been used in the organic paint industry because of its environmentally

friendly nature. ZnO is naturally found in the form of the mineral

zincite. The advantages of ZnO as a pigment are that it is

stable against UV rays (does not change color), long lasts on both water-based

and oil-based paints, and increases color retention. Compared with the other

white pigments, ZnO has the least tendency to turn yellow (Papp et

al., 2022; Ma et

al., 2019; Adiwibowo, Ibadurrohman, Slamet, 2018). Based on the advantages of ZnO as a

pigment, it is necessary to develop research related to ZnO combined with TiO2

to result in TiO2/ZnO nanoparticles and implement the use of

matt-type water-based paints. The novelty in this work is related to the

application of TiO2/ZnO mixtures as a pigment in matt-type

water-based paints.

A few previous studies related to the

development of TiO2/ZnO nanoparticles have been reported, including Miklecic et al.

(2015), which studied the effect of TiO2/ZnO nanoparticles on the

properties of waterborne polyacrylate coatings in outdoor conditions, where the

existence of ZnO nanoparticles reduced coating flow time, increased pH, and

decreased elongation. In contrast, the TiO2 increased the glass

transition so that the combination of TiO2/ZnO increased color

stability. El-Kader et al.

(2021) observed morphological, structural, and antibacterial on TiO2/ZnO

(50:50) nanocomposites from Hibiscus rosa-senensis extract, which

produced an increase in the crystal size growth of ZnO with uneven distribution

and irregular particle shape. It is different with the crystal size growth of

TiO2 was inhibited the distribution particles and shape were evenly

and uniform. Baudys et al.

(2015) conducted a weathering test and photocatalytic activity on

self-cleaning acrylic paint based on ZnO and TiO2, where the results

showed that the paint sample TiO2-based pigment increased

photoactivity during exposition on the QUV panel, while the paint sample

ZnO-based ones showed a high initial photocatalytic activity but decreased

during exposition in the QUV panel. Lv et al.

(2019) studied radiation stability in solar reflective coatings using TiO2

and ZnO pigments, where the particle size affects the stability of the paint

coating from radiation. Using TiO2/ZnO mixture as

pigments in acrylic paints has achieved better photocatalytic activity than

pure TiO2 and ZnO (Song et

al., 2021; Jašková, Hochmannová, Vytrasova, 2013). The objective of this study is to characterize TiO2/ZnO

nanoparticles and observe the quality improvement of TiO2/ZnO

nanoparticles applied as pigments in matt-type water-based paints.

2.1. Materials

Titanium dioxide rutile

(SR-2377) was obtained from Shandong Dongjia Group Co., Ltd. Shandong, China.

Zinc oxide (ZnO) was supplied by Evergreen Chemical Factory Co., Ltd. Shaanxi,

China. Calcium carbonate (Omyacarb-6 GD) as a filler was obtained from PT. Camco

Omya Indonesia, Jakarta, Indonesia.

The styrene-acrylic binder

(C-817) and super-plasticizer (SPC) were received from PT. Inawan Chemtex

Sukses Abadi, Jakarta, Indonesia. The optical brightener agent (OBA) was

supplied by PT. Graha Jaya Chemical, Jakarta, Indonesia. Dispersing agents,

anti-foaming agents, wetting agents, coalescent agents, antimicrobial agents

(biocide), thickening agents, and ethylene glycol are used for commercial

water-based paint recipes.

2.2. Nanoparticles

Characterization

The chemical composition of the pigments

(TiO2, ZnO, and TiO2-ZnO) was analyzed by X-Ray

Fluorescence (XRF) - PANalytical Epsilon 3. The pigments' crystal structure,

size, and crystallinity degree were determined by X-Ray Diffraction (XRD) -

PANalitycal X'Pert PRO MPD. Morphological of the pigments were characterized by

Field Emission - Scanning Electron Microscope (FE-SEM) - FEI Inspect F50. The

TiO2-ZnO (25:75) nanoparticle pigments characterized were made from

a mixing process using a planetary mixer (KNS-60 LB).

2.3. Manufacturing Process of Matt-Type Water-Based Paint

Water, thickening agent,

wetting agent, dispersing agent, antimicrobial agent, anti-foaming agent, and

ethylene glycol were added to a high-speed mixer according to Table 1, stirred using a zirconium ball mill at 2000 rpm for

1 hour, filtered with a sieve (mesh 200) and allowed to cool at room

temperature. The results obtained are in the form of mill-base paste. The mill

base paste, pigment (TiO2, ZnO, or TiO2-ZnO), optical

brightener agent, super-plasticizer, CaCO3 filler, water, and

coalescing agent were added into a high-speed mixer according to Table 1,

stirred at 800 rpm for 30 min, filtered with a sieve (mesh 200), and

dispersibility of the pigment was observed. Next, the C-817 binder was added

and stirred at 100 rpm for 15 min. The results obtained are matt-type

water-based paint with various pigments, referred to as a P sample (Karakas and Celik, 2018; Somtürk et al., 2016).

Figure 1 Preparation

and application of TiO2/ZnO in matt-type water-based paint

2.4. Application of Nanoparticles in Matt-Type Water-Based

Paint

Matt-type water-based paint

is applied to the surface of the panel paper using a rod coating (100),

allowed for 24 h, and the obtained result was visually observed the hiding

power in panel paper. Next, whiteness and gloss were measured using a whiteness

meter (BGD 585) and a gloss meter (BGD 516).

3.1. XRF Analysis of Pigments

The results of XRF analysis on TiO2, ZnO, and TiO2/ZnO nanoparticles (Table 2) displayed that rutile had a TiO2 concentration of 94.57%. Zinc oxide nanoparticles had a ZnO concentration of 96.11%. In the TiO2-ZnO mixture, the concentration of TiO2 is 18.62%, and ZnO is 77.49%. These results indicate that the mixing of TiO2/ZnO with a composition of 25:75 showed no significant difference with the concentration of TiO2/ZnO in the mixture, which means that there is no chemical interaction. The concentration of TiO2 rutile was not significantly different from previous research (Sisca et al., 2021; Miklecic et al., 2015).

Table 2 Chemical Composition of TiO2, TiO2/ZnO, and ZnO

The

crystallinity degree, size, and shape crystal of TiO2, TiO2/ZnO,

and ZnO were analyzed by XRD. The XRD pattern is displayed in Figure 2. The

characteristic peaks of TiO2 at 2 are 27.43°, 36.08°, 39.21°,

41.26°, 44.09°, 54.36°, 56.67°, 62.81°, 64.11°, 69.06°, 69.86°, 82.40°, and

89.63°. The peaks are suitable to the characteristic peak of rutile

(01-087-0290), which has a crystallinity degree of 24.0 % and a crystal size of

29.8 nm with a tetragonal shape. This result also corresponds to previous

reports (Razali et al., 2022; Daniyal, Akhtar, Azam, 2019).

The

characteristic peaks of TiO2/ZnO at 2? are 27.41°, 31.74°, 34.40°,

36.23°, 44.00°, 47.54°, 54.33°, 56.61°, 62.87°, 66.40°, 67.99°, 69.10°, 72.47°,

76.99°, 89.62°, 92.71°, 95.34°, and 98.57°. The peaks are suitable to the

characteristic peak of TiO2 rutile (01-072-4814) and zincite

(03-065-3411), which has a crystallinity degree of 72.3 %, a crystal size of

28.4 nm with tetragonal and hexagonal shapes. This result corresponds to

crystals of TiO2/ZnO (El-Kader et al., 2021; Mazabuel-Collazos, Gómez, Rodríguez-Páez, 2019).

The

characteristic peaks of ZnO at 2are 31.70°, 34.36°, 36.19°, 47.49°, 56.56°,

62.83°, 66.37°, 67.92°, 69.05°, 72.58°, 76.90°, 81.43°, 89.61°, 92.65°, 95.24°,

and 98.55°. The peaks are suitable to the characteristic peak of zincite

(01-075-7917), which has a crystallinity degree of 64.1 % and a crystal size of

25.4 nm with a hexagonal shape. This result corresponds to previous reports (El-Kader et al.,

2021).

Figure 2 XRD of (a) TiO2; (b) TiO2/ZnO; and (c) ZnO

3.3. SEM

Analysis of Pigments

The morphological analysis results of nanoparticles

using FE-SEM with a magnification of 10,000x (10 µm) and 100,000x (1 µm) (Figure 3) has displayed that all pigments have very small

sizes (<200 nm), smooth, and uniform shapes (Mazabuel-Collazos, Gómez, Rodríguez-Páez, 2019; Karakas and Çelik, 2018; Mikle?i? et al., 2015).

Figure 4 Diameter distribution of (a) TiO2;

(b) TiO2/ZnO, and (c) ZnO

3.4. Application of Nanoparticles as Pigments in Matt-Type

Water-Based Paint Against Dispersibility, Hiding Power, Whiteness, and Gloss

|

Recipe Name |

Whiteness |

Gloss |

Hiding Power |

Dispersibility | ||

|

20° (95.1) |

60° (96.3) |

85° (99.7) | ||||

|

P1 |

81.80 + 0.10 |

1.13 + 0.06 |

1.77 + 0.06 |

4.60 + 0.10 |

Good* |

Good** |

|

P2 |

82.20 + 0.10 |

1.17 + 0.06 |

2.00 + 0.10 |

4.83 + 0.05 |

Good* |

Good** |

|

P3 |

79.63 + 0.15 |

1.13 + 0.07 |

1.93 + 0.06 |

6.57 + 0.15 |

Good* |

Good** |

|

P4 |

80.77 + 0.15 |

1.13 + 0.06 |

1.87 + 0.06 |

4.70 + 0.06 |

Medium* |

Good** |

Note:

* Evaluation

of hiding power results is carried out based on visual observations of the

paint coating on panel paper, which refers to the standard color of white and black.

** Evaluation of pigment dispersibility was carried out based on the number of nanoparticles left on the sieve (mesh 200), which were observed visually.

Figure 5 A Hiding Power of (a) P1 (TiO2) & P2 (TiO2/ZnO);

(b) P1 (TiO2) & P3 (TiO2/ZnO/OBA/SPC); and (c) P1

(TiO2) & P4 (ZnO/OBA)

Figure 6 (a) Whiteness and (b) Gloss of Water-Based Paint

with Various Pigments

Reflection

angles of 20° and 60° in sample P2 have resulted in better gloss values ??than

other samples (Figure 6b), which is

influenced by the high crystallinity degree of TiO2/ZnO

nanoparticles. Meanwhile, at a reflection angle of 85°, sample P3 has resulted

in a significant increase in the gloss value of 6.57, which was influenced by

the presence of OBA and SPC in sample P3.

In terms of

dispersibility, hiding power, whiteness, and gloss, it is known that sample P1

using TiO2/ZnO nanoparticles as a pigment has better quality than

sample P1 when applied to matt-type water-based paint. The amount of pigment in

water-based paint formulas commonly for the matt-type is 7-10%, semi-gloss is

20-25%, and gloss is above 35%. With a gloss value below 10%, the water-based

paint was categorized as a matt-type.

The TiO2/ZnO nanoparticles have been successfully combined with

the composition (25:75), which resulted in a crystallinity degree of 72.3%, a

crystal size of 28.4 nm with tetragonal and hexagonal shapes. These

nanoparticles contain 18.62% TiO2 and 77.49% ZnO compounds, with an

average particle diameter of 151.54 nm. TiO2/ZnO nanoparticles also

have been successfully applied as pigment to a matt-type water-based paint

which achieved good dispersibility and hiding power and resulted in a whiteness

of 0.48% and a gloss at 60° of 12.99% were better than TiO2. In the

future, a TiO2/ZnO mixture will be made using a chemical method

applied to a matt-type water-based paint with a composition according to the

current works.

The author would like to thank PT.

Inawan Chemtex Sukses Abadi for the opportunity to conduct research and use

the facilities in the Technical Department Laboratory.

Adiwibowo, M.T., Ibadurrohman, M., Slamet,

2018. Synthesis of ZnO nanoparticles and their nanofluid stability in the presence of a palm

oil-based primary alkyl sulphate surfactant for detergent application. International

Journal of Technology, Volume 9(2), pp. 307–316

Baudys, M., Krysa, J., Zlamal, M., Mills, A.,

2015. Weathering tests of photocatalytic facade paints containing ZnO and TiO2.

Chemical Engineering Journal, Volume 261, pp. 83–87

Bhogaita, M., Devaprakasam, D., 2021. Hybrid photoanode of TiO2-ZnO synthesized by co-precipitation route for

dye-sensitized solar cell using phyllanthus reticulatas pigment sensitizer. Solar

Energy, Volume 214, pp. 517–530

Chen, M.C., Koh, P.W., Ponnusamy, V.K., Lee,

S.L., 2022. Titanium dioxide and other nanomaterials based antimicrobial

additives in functional paints and coatings: review. Progress in Organic

Coatings, Volume 163, p. 10666

Costa, J.R.C., Correia, C., Góis, J.R.,

Silva, S.M.C., Antunes, F.E., Moniz, J., Serra, A.C., Coelho, J.F.J., 2017.

Efficient dispersion

of TiO2 using tailor made poly(acrylic acid) -based block

copolymers, and its incorporation in water based paint formulation. Progress

in Organic Coatings, Volume 104, pp. 34–42

Daniyal, M., Akhtar, S., Azam, A., 2019.

Effect of nano-TiO2

on the properties of cementitious composites under different exposure

environments. Journal of Materials Research and Technology, Volume 8(6),

pp. 6158–6172

Daraee, M., Baniadam, M., Rashidi, A.,

Maghrebi, M., 2018. Synthesis of TiO2-CNT hybrid nanocatalyst and

its application in direct oxidation of H2S to S. Chemical Physics,

Volume 511, pp. 7–19

Dell’Edera, M., Lo Porto, C., De Pasquale,

I., Petronella, F., Curri, M.L., Agostiano, A., Comparelli, R., 2021.

Photocatalytic TiO2-Based coatings for environmental applications. Catalysis

Today, Volume 380, pp. 62–83

El-Kader, M.F.H.A., Elabbasy, M., Adeboye, A.A., Zeariya, M.G.M., Menazea, A.., 2021. Morphological, structural and

antibacterial behavior of eco-friendly of ZnO/TiO2 nanocomposite

synthesized via hibiscus rosa-sinensis extract. Journal of Materials

Research and Technology, Volume 15, pp. 2213–2220

Gao, H., Yang, S., Mao, D., Long, M., Qu, X.,

2022. Significant zinc release from widely-used commercial lithopone pigments

under solar irradiation. Environmental Pollution, Volume 292, p. 118352

George, J., Gopalakrishnan, C.C., Manikuttan,

P.K., Mukesh, K., Sreenish, S., 2021. Preparation of multi-purpose TiO2

pigment with improved properties for coating applications. Powder Technology,

Volume 377, pp. 269–273

Isfa, B., Jamarun, N., Emriadi, Ritonga,

A.H., Sisca, V., Faisal, H., Tanjung, D.A., 2022. Precipitated calcium

carbonate/lithopone nanoparticles as substitution of TiO2 pigment for

matte-type water-based paint. Rasayan Journal of Chemistry, Volume

15(4), pp. 2342–2349

Islam, M.T., Dominguez, A., Turley, R.S., Kim, H., Sultana, K.A., Shuvo, M., Alvarado-Tenorio, B., Montes, M.O., Lin, Y., Gardea-Torresdey, J., Noveron, J.C., 2020. Development of photocatalytic

paint based on TiO2 and photopolymer resin for the degradation of

organic pollutants in water. Science of The Total Environment, Volume

704, p. 135406

Jašková, V., Hochmannová, L., Vytrasová, J.,

2013. TiO2 and ZnO nanoparticles in photocatalytic and hygienic coatings.

International Journal of Photoenergy, Volume 2013. pp. 1–6

Karakas, F., Çelik, M.S., 2018. Stabilization

mechanism of main paint pigments. Progress in Organic Coatings. Elsevier

Volume 123, pp. 292–298

Li, Q., Liu, Y., Wan, Z., Cao, H., Zhang, S.,

Zhou, Y., Ye, X., Liu, X., Zhang, D., 2021. Microwave-assisted synthesis of

oxygen vacancy associated TiO2 for efficient photocatalytic nitrate

reduction. Chinese Chemical Letters, Volume 33(8), pp. 3835–3841

Lv, J., Yang, J., Li, X., Chai, Z., 2019. Size dependent radiation-stability

of ZnO and TiO2 particles. Dyes and Pigments, Volume 164, pp. 87–90

Mazabuel-Collazos, A., Gómez,

C.D., Rodríguez-Páez, J.E., 2019. ZnO-TiO2 nanocomposites synthesized by wet-chemical

route: study of their structural and optical properties. Materials Chemistry

and Physics, Volume 222, pp. 230–245

Ma, J., An, W., Xu, Q., Fan, Q., Wang, Y.,

2019. Antibacterial casein-based ZnO nanocomposite coatings with improved water

resistance crafted via double in situ route. Progress in Organic Coatings,

Volume 134, pp. 40–47

Mamaghani, A.H., Haghighat, F., Lee, C.-S.,

2019. hydrothermal/solvothermal synthesis and treatment of TiO2 for photocatalytic

degradation of air pollutants: preparation, characterization, properties, and

performance. Chemosphere, Volume 219, pp. 804–825

Miklecic, J., Blagojevic, S.L., Petri?, M.,

Jirous-Rajkovic, V., 2015. Influence of TiO2 and ZnO nanoparticles

on properties of waterborne polyacrylate coating exposed to outdoor conditions.

Progress in Organic Coatings, Volume 89, pp. 67–74

Papp, I.Z., Alegría, A., Kónya, Z., Kukovecz,

Á., 2022. Investigation into the effect of ZnO nanorod coating on the thermal-mechanical and dielectric

properties of ITO coated PET. Materials Research Bulletin, Volume 149, p. 111701

Peruchi, R., Bartosiak, A., Zuchinali, F.F.,

Bernardin, A.M., 2021. Development of a water-based acrylic paint with

resistance to efflorescence and test method to determine the appearance of stains.

Journal of Building Engineering, Volume 35, p. 102005

Razali, M.N. Bin, Alkaf, A.A., Zuhan,

M.K.N.B.M., 2022. formulation of water-based white colour paint from waste

titanium dioxide. Materials Today: Proceedings, Volume 48(6), pp.

1905–1909

Rosales, A., Ortiz-Frade, L., Medina-Ramirez,

I.E., Godínez, L.A., Esquivel, K., 2021. Self-cleaning of SiO2-TiO2 coating: effect of sonochemical

synthetic parameters on the morphological, mechanical, and photocatalytic

properties of the films. Ultrasonics Sonochemistry, Volume 73, p. 105483

Sisca, V., Deska, A., Syukri, S., Zilfa, Z.,

Jamarun, N., 2021. Synthesis and characterization of CaO limestone from lintau buo supported by TiO2

as a heterogeneous catalyst in the production of biodiesel. Indonesian

Journal of Chemistry, Volume 21(4), pp. 979–989

Sofyan, N., Ridhova, A., Wu, J., Yuwono,

A.H., 2018. Characteristics of nano rosette TiO2 hydrothermally

grown on a glass substrate at different reaction time and acid concentration. International

Journal of Technology, Volume 9(6), pp. 291–319

Sofyan, N., Ridhova, A., Yuwono, A.H.,

Sianturi, M.C., 2019. Effect of NaCl addition on nano rosette TiO2 crystal

growth during hydrothermal deposition. International Journal of Technology,

Volume 10(6), pp. 291–319

Solanki, K., Parmar, D., Savaliya, C., Kumar,

S., Jethva, S., 2021. Surface morphology and optical properties of sol-gel

synthesized TiO2 nanoparticles: Effect of Co, Pd and Ni-doping. Materials Today: Proceedings, Volume 50(part 6), pp.

2576–2580

Somturk, S.M., Emek, ?.Y., Senler, S., Eren,

M., Kurt, S.Z., Orbay, M., 2016. Effect of wollastonite extender on the

properties of exterior acrylic paints. Progress in organic coatings,.

Elsevier Volume 93, pp. 34–40

Song, S. Song, H., Li, L., Wang, S., Chu, W., Peng, K., Meng, X., Wang, Q., Deng, B., Liu, Q., Wang, Q., Weng, Y., Hu, H., Lin, H., Kako, T., Ye, J., 2021. A selective Au-ZnO/TiO2 hybrid

photocatalyst for oxidative coupling of methane to ethane with dioxygen. Nature

Catalysis, Volume 4(12), pp. 1032–1042

Yuwono, A.H., Zhang, Y., Wang, J., 2014. Investigating the nanostructural

evolution of TiO2 nanoparticles in the sol-gel derived TiO2-polymethyl methacrylate

nanocomposites. International Journal of Technology, Volume 1(1), pp.

291–319