Analysis of Bittern Recovery Facility Using Mixed-Integer Nonlinear Programming: Centralized, Decentralized, and Hybrid Scenarios

Corresponding email: erwin@ie.its.ac.id

Published at : 09 May 2023

Volume : IJtech

Vol 14, No 3 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i3.5437

Widodo, E., Putra, F.S.U., Hartanto, D., Arvitrida, N.I., Bagastyo, A.Y., Warmadewanthi, I., Soehartanto, T., 2023. Analysis of Bittern Recovery Facility Using Mixed-Integer Nonlinear Programming: Centralized, Decentralized, and Hybrid Scenarios. International Journal of Technology. Volume 14(3), pp. 638-648

| Erwin Widodo | Industrial and Systems Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, 60111, East Java, Indonesia |

| Furqon Sandiva Utomo Putra | Industrial and Systems Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, 60111, East Java, Indonesia |

| Dody Hartanto | Industrial and Systems Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, 60111, East Java, Indonesia |

| Niniet Indah Arvitrida | Industrial and Systems Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, 60111, East Java, Indonesia |

| Arseto Yekti Bagastyo | Environmental Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, 60111, East Java, Indonesia |

| IDAA Warmadewanthi | Environmental Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, 60111, East Java, Indonesia |

| Totok Soehartanto | Instrumentation Engineering, Institut Teknologi Sepuluh Nopember, Surabaya, 60111, East Java, Indonesia |

The desalination process to produce salts leaves wastewater with a high concentration of minerals called bittern. Most salt producers dump bittern straight away. Such disposal is dangerous to the ecosystem since bittern may increase the environmental salinity. Furthermore, bittern still has potential as it contains minerals that can be extracted and offers value. Consequently, further bittern treatment is necessary to reduce the environmental impact and create a circular economy. However, some specific requirements are needed in determining how to carry out this recovery process. In that, recovery managers need to know the most suitable type and optimal operation variables. These are essential to meet cost-effectiveness and environmental benefits. This research proposes a mixed-integer nonlinear programming (MINLP) model for analyzing the supply and demand of the bittern recovery. This study offers a model to optimize the trade-off between cost and benefits of the recovery process. There are three scenarios to determine the best bittern recovery practices: centralized, decentralized, and hybrid scenarios. The proposed models are then tested and analyzed for their sensitivity due to essential parameters. The numerical analysis has shown that a centralized scenario is best suited for a region with a low bittern supply. Moreover, a hybrid scenario is best suited in an area with a higher bittern supply. In addition, a decentralized scenario is the most suitable option for a region where the number of salt farms is high, and the location is far from the recovery facility.

Bittern recovery; Circular economy; Mixed-integer nonlinear programming

Let us take a prominent example in a country with vast

salt consumption, Indonesia. Data have shown that Indonesia produced 2,349,629

metric tons of salt in 2018 (Ministry

of Maritime Affairs and Fisheries, 2019). In this

country, salts are produced through multilevel processing. The evaporation

process of seawater is carried out in the evaporator area. The crystallization

process is undertaken in a specific area

Commonly, bitterns are considered

waste and never used again. This waste is problematic because although bittern

water contains similar compounds to seawater, it is much more concentrated.

When bittern is directly dumped into the ecosystem, the increase in salinity

may harm the life in the area (Tewari,

2003). Furthermore, treating bittern solely as an unused

by-product of salt production is also a waste of potential since it still

contains minerals that can be extracted and have selling value. For every 10

million tons of salt produced, below is the composition of chemicals found in

the bittern:

Table 1 Chemical contained in bittern from 10 million tons of

salt produced (Abdel-Aal,

Zohdy, and Abdelkreem, 2017)

|

Chemical compound |

Tons |

|

NaCl |

1,500,000 |

|

MgCl2 |

1,200,000 |

|

MgSO4 |

700,000 |

|

KCl |

238,000 |

|

Bromine |

20,000 |

Those chemicals can still be utilized in other industries, such as

cosmetics, energy drinks, and salt industries, for the second time. This

estimation shows the potential that can be exploited by treating bittern. Thus,

bittern recovery in the salt industry can reduce the environmental impact of

salt production but also create a circular economy, which is a system that

focuses on reusing, recycling, and recovering to achieve sustainability (Sauvé,

Bernard, and Sloan, 2016).

Applying the economic concept would contribute to the environment and yield

society-wide benefits (Berawi,

2020). Furthermore, it will also follow the sustainable

development concept, a balance of economic growth and ecological regeneration (Berawi, 2019).

However, this requires a complex

process to maximize the efficiency and effectiveness of the bittern recovery.

One needs to know the optimal type and number of recovery stations, considering

the bittern supply chain availability and the demand for the extracted mineral.

It also needs to be cost-efficient and yield a beneficial result. An approach

that can meet this objective is mixed-integer nonlinear programming (MINLP).

MINLP is mathematical programming

that has continuous and discrete variables and nonlinearities within its

objective function and constraints (Bussieck and Pruessner,

2003). It has a wide range of use,

including in the process industry, chemical engineering, and manufacturing. We

used this model in a bittern recovery system because some values of variables,

such as the number of recovery facilities, need to be an integer, while others

(such as cost) do not. Furthermore, as the research objective maximizes circular

economy, the function has a non-convex element related to diminishing returns

and economies of scale, hence the need to include nonlinearity in the

programming.

In achieving a circular economy

in wastewater treatment, previous research has studied a circular economy and

cleaner production model. This research optimized product-machine allocation

using MILP (Rajput and Singh, 2020). Another research on wastewater treatment management that considers

both the economy and environment also implemented the MILP approach (Henriques et al., 2020; Zhou et al., 2020; Durkin, Millan-Agorio,

and Guo, 2020). In terms of using the MINLP

approach, a previous study has proposed a framework that considers the cost and

benefit of wastewater treatment (Padrón-Páez, Almaraz, and

Román-Martínez, 2020).

In the field of wastewater

treatment, several breakthroughs have been proposed. Cotton and carbon material

filter was implemented since they offer high sorption

capacities and simple preparation processes (Politaeva et al., 2020). In

addition, an anaerobic fixed bed reactor (AFBR) was proposed to reduce the odor

due to the high protein content in industrial wastewater (Purnomo, Mawaddah, and

Bayonita, 2021). Furthermore, Biofloc Technology and Effective Microorganism

S4 (EM4) have been attempted to be successful in reducing ammonia and nitrate

concentration in the shrimp agro-industry (Suwartha and Pujiastuti, 2017). Moreover, nanofiltration technology

was also observed and successfully proven to remove remazol red dye, indigosol

brown dye, and sodium sulfide (Na2S) in the batik textile industry (Istirokhatun et al.,

2021).

The present study aims to

implement the MINLP model for achieving a circular economy, specifically the

bittern recovery process. Furthermore, this research extends the scope by

comparing possible bittern recovery scenarios between centralized,

decentralized, or hybrid types of recovery stations to see which scenario would

be the best to apply to certain conditions. The other kind of recovery scenario

needs to be weighed in as it affects effectiveness and cost-efficiency. Both

profit maximization and the recovery process's environmental impact are

considered.

This research considered some

factors from the bittern's supply, demand structure, and recovery process

constraints. The model is used to maximize the profit by optimizing the

trade-off between the cost of waste transportation, recovery, and station

investment, benefiting from the selling value of the recovered minerals and the

environmental sustainability.

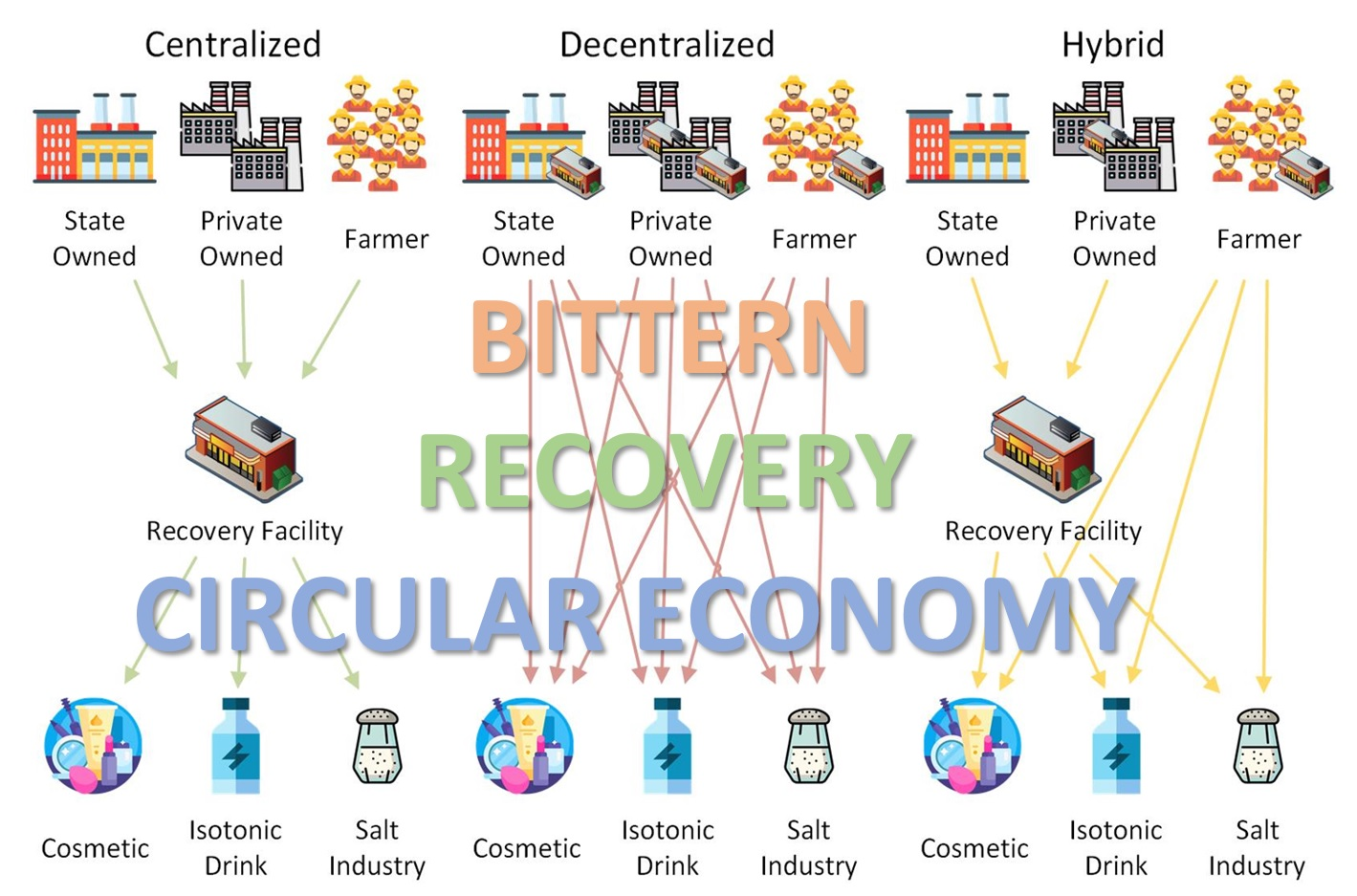

2.1. Conceptual Model

The

system discussed is a combination of the supply, demand, and bittern recovery

facility. The supplier of bittern, in this case, came from 3 types of salt

industries: state-owned industry, privately owned industry, and salt farmers.

This differentiation creates the assumption that each industry type has a

different amount of output and amount of entity. In that, state-owned and

private-owned industries will have larger salt output but fewer entities than

salt farmers. The consumer who demands the chemical gained from the bittern

recovery process comes from the cosmetic, isotonic, and salt industries, and

each requires a different chemical extracted. The bittern recovery facility

scenario that would be considered in this research is as follows:

A centralized system has a

single location that handles the bulk of the demand for bittern recovery. While

decentralized means the organization will have multiple treatment hubs as close

as possible to the source of bittern, working simultaneously to cover a broader

range (Libralato, Volpi, and Avezzu,

2012).

Figure 1 The supply chain flow between the salt industry, bittern recovery

facility, and consumers in different scenarios

The

above sub-system, later on, will be expressed in cost and benefits variables.

The cost variables are facility investment, the bittern recovery process,

material handling, and transportation costs. At the same time, the benefit

variables came from the revenue from selling the extracted chemical to the

consumers and the economic valuation of the environmental benefit from

recovering the bittern. The model is also subjected to the amount of bittern

supplied, the chemical demanded, and the facility's capacity.

2.2. Mathematical Model

The model is based on

MINLP, mathematical modeling involving discrete variables and nonlinear

constraint functions (Leyffer et al.,

2009). For each scenario described, a

model is developed as follows:

2.2.1. Centralized

Scenario

Objective function:

Constraint:

3. Demand is assumed to be equal to the mass of chemicals supplied due to implementing a pull system.

2.2.2. Decentralized

Scenario

Objective function:

As each salt producer has its bittern recovery

facility, inbound transportation cost and material handling are assumed to be

zero. Constraints (10) to (16) were then applied.

2.2.3. Hybrid

Scenario

Objective function:

Max profit (Z) = Max profit Centralized + Max profit

decentralized

A new index (l) is introduced to differentiate the

centralized and decentralized equation to solve this. The centralized max profit

is as follows:

While the

decentralized max profit is as follows:

The mathematical models are then run into LINGO, a

tool to build and solve linear, nonlinear, quadratic, stochastic, and integer

optimization programming (LINDO, n.d.). The data of environmental benefits is approximated

from the literature review, while transportation cost and material handling

costs are approximated using the local gas price and labor cost.

3.1. Model

Running Results

Below are the results of the model

running test:

Table 1 Model running results (in a million rupiah)

|

Centralized |

Decentralized |

Hybrid | |

|

Total Revenue |

563,169.6 |

606,015.7 |

395,461.6 |

|

Environmental Benefit |

117,659.3 |

114,279.2 |

43,136.38 |

|

Investment Cost |

1,000 |

500 |

1,350 |

|

Inbound transportation cost |

58.226340 |

- |

56,895 |

|

Inbound material handling |

85,315.53 |

- |

11,671.07 |

|

Outbound transportation cost |

117,355.4 |

201,851.3 |

111,487.65 |

|

Outbound material handling |

14,444.12 |

14,444.12 |

9,388.676 |

|

Recovery cost |

61,880 |

309,400 |

114,478 |

Our calculation assumes that the environmental benefit was

gained through economic valuation by performing wastewater treatment (Hernández-Sancho,

Molinos-Senante, and Sala-Garrido, 2010). Our numerical

experiment shows that the centralized scenario yields the highest profit at the

value of Rp 400,833.9 million, followed by the decentralized with Rp 193,599.5

million and the hybrid scenario with Rp190,222.5 million. When we compare the

revenues under centralized and decentralized scenarios, the latter is slightly

higher than the former. Nonetheless, the decentralized scenario yields lower

overall profit than that under centralized. The reason is the total processing

cost of a decentralized scenario is way higher than the centralized one.

Another reason is centralized scenario experience benefits from an economic

scale. This situation makes its corresponding investment considerably cheaper (Mourtzis and

Doukas, 2012). When we proceed to the following comparison

between decentralized and hybrid scenarios, the former yields higher profit

than the latter. This is due to higher facility investment costs under the

hybrid scenario. In addition, both scenarios still incur considerably high

inbound transportation and material handling costs.

To compare our results to those with

similar works of centralized versus decentralized and hybrid concepts for water

waste treatment, we reviewed some related articles. By using specially

constructed wetlands in China, decentralized and sometimes hybrid wastewater

systems may overcome the efficiency of the centralized system (Ying et al., 2021). This

fact is contrary to our initial numerical experiment results. In addition, a

study of non-targeted analysis with gas chromatography-spectrometry

was conducted to evaluate the performance of centralized versus decentralized

water waste systems in the USA and South Africa (Mladenov

et al., 2022). Surprisingly, the

decentralized system was found to perform better than the centralized one.

Moreover, a study to assess

the efficiency of rural sewage treatment (RuST) was conducted by using

centralized and decentralized scenarios (Yuansheng

et al., 2021). An interesting

result was revealed when it was found that the centralized scenario does not

always provide the best result. By proposing rural residents' spatial pattern

(RESP) and the optimal pattern of RuST, a decentralized scenario offers a

better outcome for water waste treatment.

We decided to proceed with our numerical

experiment further based on those aforementioned exciting facts. As the primary

purpose of this research is to create a model that can be used in

decision-making, it is not enough to have a single result, as shown in Table 1.

Thus, sensitivity analysis is applied to two important parameters in our

proposed model: annual bittern supplied and the proportion of salt produced by

each industry type.

3.2. Profit

sensitivity on annual bittern supply

Figure 2 Profit sensitivity on the changes in annual bittern supply

Predictably, the total profit would

exponentially increase with more supply of bittern. However, each scenario

would eventually reach its infeasible point, meaning it can no longer fulfill

the constraints due to the cost incurred becoming too high. The centralized

scenario is the first to do so. The reason is that with the highest material

handling and transportation cost that linearly increases with the rise of

bittern supply, it reaches a point where it is no longer economically feasible.

This situation happens when the bittern supply reaches 1.25 million tons per

year.

Moreover, the decentralized scenario

became infeasible when the bittern supply reached 1.5 million tons per year.

The reason is the processing cost became too overwhelming, and the revenue

could not keep up. The outbound transportation cost also became too expensive

as it needed to transport the resulting chemicals to each buyer from each of

the respective salt farms. Additionally, while applying the decentralized

scenario to the 1.25 million tons supply mark is still feasible, the hybrid scenario

has become more profitable. The reason is that it has a much lower recovery

cost than the decentralized scenario. The scenario would remain feasible until

the bittern supply reaches 2 million tons annually.

Thus, if the decision-maker intends to utilize

the full extent of bittern available in their region, it is more recommended to

use the hybrid scenario to accommodate a larger volume.

3.3. Profit

sensitivity on the proportion of salt produced from industry type

Figure 3 Profit sensitivity on the changes in the proportion of salt

produced in each industry type

The analysis shows that

both decentralized and hybrid scenarios would increase profit as salt farmers'

proportion of salt increases. The reason is that inbound transportation and

material handling costs will reduce if more bitterns are processed in-house.

Increasing the bittern percentage supplied by salt farmers would eventually

make the decentralized scenario more profitable than the centralized one.

However, when looking at

how the proportion of state-owned and private-owned industries is divided, it

shows different tendencies. While the hybrid scenario would exponentially

increase profit, the decentralized scenario would be flatter. Although not by a

large margin. The reason is that private-owned and state-owned industries have

fewer plan quantities than salt farmers, benefiting from the economy of scale

of a centralized recovery facility than a decentralized one. This decentralized

scenario would eventually be less profitable than a hybrid scenario when the

salt farm proportion is not overwhelmingly dominating compared to the other two

industry types.

As an interesting note, even

though it is considered a "salt farmer" in this research, the same

principle is also applied in the condition where the salt farms in a region are

a lot and far in between, regardless of the owner of said factory. Thus, a

decentralized scenario would be preferable if a decision-maker wants to apply a

bittern recovery scenario in a region where that situation is prominent.

The research has proposed three

different scenarios of the bittern recovery process. Each scenario could be

profitable when applied to certain conditions. Our numerical experiment has

successfully shown some model behavior as evidence on which scenario is more

financially preferable to use. However, the implementation of such scenarios

would depend on several different circumstances. Our proposed model set works

based on profit optimization. Such mathematical representation can provide some

optima in a numerical result of decision variables that maximizes circular

economy benefit. This process is done by maximizing the revenue items

consisting of the cost of extracted chemicals and environmental benefits and

minimizing the associated cost, including transportation, material handling,

investment, and recovery cost. Some insights derived from our analysis can

assist decision-makers of bittern recovery processes in selecting which bittern

recovery scenario is the best-suited option. The centralized scenario is best

suited when in a region with a low bittern supply. The hybrid scenario is best

suited in a region with a higher bittern supply. The decentralized scenario is

best for a region where the salt farms are a lot and far in between. Nonetheless,

there are some limitations and drawbacks to this research. Hence, some

betterment is interesting as future works are done by transforming the model

into a dynamic model instead of a deterministic one, allowing for more accurate

results. Future works can also expand the model for other scenarios.

The

authors gratefully acknowledge the two (2) financial support for this work from

the Indonesian Ministry of Education, Culture, Research, and Technology in

Institut Teknologi Sepuluh Nopember, ITS, Surabaya. First is Collaboration

Research Scheme in Direktorat Riset dan Pengabdian Masyarakat in 2021 (Research

and Community Service Directorate) with grant number D72021 – Dana ITS

(Consortium). Second is Program Kompetisi Kampus Merdeka 2021 (Independent

Campus Competition Program), organized by the Industrial and Systems

Engineering Department.

Abdel-Aal, H., Zohdy, K., Abdelkreem, M., 2017. Seawater Bittern a

Precursor for Magnesium Chloride Separation: Discussion and Assessment of Case

Studies. International Journal of Waste Resources, Volume 7(1), pp. 1–6

Berawi, M.A., 2019. The Role of

Industry 4.0 in Achieving Sustainable Development Goals. International

Journal of Technology, Volume 10(4), pp. 644–647

Berawi, M.A., 2020. Managing

Nature 5.0: The Role of Digital Technologies in the Circular. International

Journal of Technology, Volume 11(4), pp. 652–655

Bussieck, M.R., Pruessner, A.,

2003. Mixed-Integer Nonlinear Programming. Washington: GAMS Development

Corporation

Durkin, A., Millan-Agorio, M.,

Guo, M., 2020. Process Systems Design Framework for Resource Recovery from

Wastewater. Computer Aided Chemical Engineering, Volume 48, pp. 1039–1044

Henriques, A.A., Fontes, M., Camanho,

A., Silva, J.G., Amorim, P., 2020. Leveraging Logistics Flows to Improve the

Sludge Management Process of Wastewater Treatment Plants. Journal of Cleaner

Production, Volume 276(2), p. 122720

Hernández-Sancho, F.,

Molinos-Senante, M., Sala-Garrido, R., 2010. Economic Valuation of

Environmental Bene?ts from Wastewater Treatment Processes: an Empirical

Approach for Spain. Science of the Total Environment, Volume 408(4), pp.

953–957

Istirokhatun, T., Susanto, H.,

Budihardjo, M.A., Septiyani E., Wibowo, A.R., Karamah E.F., 2021. Treatment of

Batik Industry Wastewater Plant Effluent using Nanofiltration. International

Journal of Technology, 12(4), pp. 770–780

Leyffer, S., Linderoth, J.,

Luedtke, J., Miller, A., Munson, T., 2009. Applications and Algorithms for

Mixed Integer Nonlinear Programming. Journal of Physics: Conference Series,

Volume 180, p. 012014

Libralato, G., Volpi, A., Avezzù, G. F., 2012. To centralise or to

decentralise: An Overview of The Most Recent Trends in Wastewater Treatment

Management. Journal of Environmental Management, Volume 94(1), pp. 61–68

LINDO, n.d. LINGO 19.0 -

Optimization Modeling Software for Linear, Nonlinear, and Integer Programming.

Available at: https://www.lindo.com/index.php/products/lingo-and-optimization-modeling,

Accessed on May 20, 2022

Ministry of Maritime Affairs and

Fisheries, 2019. Produksi Garam (Salt Production). Kementerian Kelautan

dan Perikanan Republik Indonesia

Mladenov, N., Dodder, N.G.,

Steinberg, L., Richardot, W., Johnson, J., Martincigh, B.S., Buckley, C.,

Lawrence, T., Hoh, E., 2022. Persistence and Removal of Trace Organic Compounds

in Centralized and Decentralized Wastewater Treatment Systems. Chemosphere,

Volume 286(1), p. 13162

Mourtzis, D., Doukas, M., 2012.

Decentralized Manufacturing Systems Review: Challenges and Outlook. Logistic

Research, Volume 5, pp. 113–121

Padrón-Páez, J.I., Almaraz,

S.D.-L., Román-Martínez, A., 2020. Sustainable Wastewater Treatment Plants

Design Through Multiobjective Optimization. Computers & Chemical

Engineering, Volume 140(2), p. 106850

Politaeva, N., Taranovskaya, E.,

Mukhametova, L., Ilyashenko, S., Atamanyuk, I., Afif, R.A., Pfeifer, C., 2020.

Cotton Fiber and Carbon Materials Filters for Efficient Wastewater

Purification. International Journal of Technology, Volume 11(8), pp.

1608–1617

PT Garam, 2018. Profil Perusahaan

(Company Profile). Available at: https://www.ptgaram.com/profilperusahaan, Accessed

on June 12, 2020.

Purnomo, C., Mawaddah, M.E., Bayonita, S., 2021. The Simulation and

Experimental Study of COD Removal from Rubber Industrial Wastewater using

Anaerobic Fixed Bed Reactors. International Journal of Technology,

Volume 12(2), pp. 320–328

Rajput, S., Singh, S.P., 2020.

Industry 4.0 Model for Circular Economy and Cleaner Production. Journal of

Cleaner Production, Volume 277, p. 123853

Sauvé, S., Bernard, S., Sloan,

P., 2016. Environmental Sciences, Sustainable Development and Circular Economy:

Alternative Concepts for Trans-Disciplinary Research. Environmental

Development, Volume 17, pp. 48–56

Suwartha, N., Pujiastuti, D.R.,

2017. Enhancing Removal Efficiency of Ammonia and Nitrate in Shrimp Farm

Wastewater Using Biofloc Technology and Effective Microorganism S4 (EM4). International

Journal of Technology, Volume 8(6), pp. 1021–1030

Tewari, A., 2003. The effect of

sea brine and bittern on survival and growth of mangrove Avicennia marina

(Dicotyledones: Avicenniaceae). Indian Journal of Geo-Marine Sciences, Volume

32(1), pp. 52–56

Ying, F., Wu, X., Shao, L., Han,

M., Chen, B., Meng, J., Wang, P., Chen, G., 2021. Can Constructed Wetlands Be

More Land Efficient Than Centralized Wastewater Treatment Systems? A Case Study

Based on Direct and Indirect Land Use. Science of The Total Environment,

Volume 770, p. 144841

Yuansheng, H., Li, P., Li, H.,

Zhang, B., He, Y., 2021. To Centralize or To Decentralize? A Systematic

Framework for Optimizing Rural Wastewater Treatment Planning. Journal of

Environmental Management, Volume 300, p. 11367

Zhou, X., Zhang, H., Long, Y.,

Song, M., Qiu, R., Yan, Y., Liang, Y., 2020. Sustainable And Clean Oilfield

Development: Optimal Operation of Wastewater Treatment And Recycling System. Journal

of Cleaner Production, Volume 252, p. 119819