Proposing a Lean Manufacturing Framework Adapted to Very Small Businesses: Multiple Case Studies

Published at : 09 May 2023

Volume : IJtech

Vol 14, No 3 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i3.5417

Driouach, L., Zitouni, B., Khalid, Z., 2023. Proposing a Lean Manufacturing Framework Adapted to Very Small Businesses: Multiple Case Studies. International Journal of Technology. Volume 14(3), pp. 460-473

| Laila Driouach | National High School for Electricity and Mechanic Casablanca, BP 8118, Oasis, 20100, Morocco |

| Beidouri Zitouni | Higher School of Technology Casablanca, Km 7, Route El Jadida, B.P. 8012 Oasis, 20100, Morocco |

| Zarbane Khalid | Higher School of Technology Casablanca, Km 7, Route El Jadida, B.P. 8012 Oasis, 20100, Morocco |

Given the importance of

the Very Small Business category and the need to successfully implement Lean Manufacturing

in these companies, the objective of this paper is to propose a lean framework

adapted to implement Lean Manufacturing in Moroccan Manufacturing Very Small

Businesses. To achieve this objective, this paper spreads out a synthesis of

multiple case studies in five Manufacturing Very Small Businesses operating in

different sectors. The analysis of this case study leads to the development of

a Lean implementation framework suitable for the specific characteristics of

Moroccan Manufacturing Very Small Businesses. Thus, this paper's contribution

is the elaboration of an implementation Lean Manufacturing approach, including

steps, tools, methods, barriers to overcome, and critical success factors. The

characteristics of this approach are that it comes from the real and successful

experience of lean implementation in Moroccan Very Small Businesses, which

ensures its success in the Moroccan context.

Critical success factors; Framework; Lean tools; Lean manufacturing; Very small businesses

Lean Manufacturing (LM) or lean production

is the occidental version of the Toyota Production System (TPS) that appeared

in Japan since the 1950s (Farissi et al., 2021a; Driouach et al., 2019). The LM aims to

improve the company's overall performance by applying various tools,

techniques, and methods (Ribeiro et al., 2019; Roriz, Nunes,

and Sousa, 2017). Over the past few

years, Lean principles have been widely applied, both in small and medium-sized

companies (SMEs) (Farissi et al ., 2021b; Baby and Jebadurai, 2018), as well as in large companies all over

the world and also in Morocco (Arabi et al.,

2022; Bouazza, Lajjam, and Dkhissi, 2021; Bajjou and Chafi, 2018). Despite

the multitude of Lean implementation frameworks presented in the literature,

Very Small Businesses (VSBs) are still struggling to implement LM in their

organizations because of the difficulties faced by these organizations (Driouach et al., 2019; Antosz and Stadnicka,

2017; Zhou, 2016; Dora et al.,

2014; Rymaszewska, 2014; Matt and Rauch, 2013).

Very Small Businesses, VSBs, occupy a major

position in the economies of developed and developing countries (Alfonso-Orjuela, Cancino-Gómez,

and Perea- Sandoval, 2022; Harvie, 2019; Mbula et al.,

2019; Nomani and Sen, 2019). In Africa, firms with

five to nineteen employees create about half of all new jobs

(Page and Söderbom, 2015). In Morocco, more than 84% of firms generated annual revenues below 3 million

dirhams, according to the Moroccan Office of Industrial and Commercial Property

(OMPIC) barometer in 2017 (OMPIC, 2020). Most Moroccan companies are,

therefore, small in terms of turnover criterion. Consequently, these companies

must sustain themselves in the economic environment and continuously improve to survive and

grow. The LM is today one of the most powerful production systems in the world

that can ensure this. However, a review of the existing Lean implementation

frameworks revealed major gaps in the literature and highlighted the lack of an

appropriate framework for very small businesses (Driouach et al., 2019).

In order to develop a

new Lean approach that could be suitable for very small businesses (VSBs), we

propose in this paper to carry out multiple case studies in Moroccan VSBs. This

paper examines the Lean Manufacturing implementation process of a sample of

VSBs through the selected case studies. Then it develops a new lean

implementation framework appropriate to Moroccan VSBs' specificities. This

framework proposes a recommended set of implementation steps, tools, barriers,

and success factors that are derived from the successful experiences of five

Moroccan VSBs. The VSBs covered in these case studies are from different

business sectors and are diverse in terms of the number of employees and years

of experience.

In order to achieve

this paper's objectives, we start by explaining the methodology used to carry

out the case studies. We proceed with a review of the lean processes adopted by

the companies studied. Then we outline our survey results to propose an

effective implementation framework for Lean Manufacturing in Moroccan VSBs.

This study allows

professionals involved in Moroccan VSBs industries to dispose of a detailed

roadmap for implementing lean. In addition, this research paper represents a

platform for further contributions related to lean implementation in very small

manufacturing companies in Morocco.

In this study, we opted

to use case studies. It is a qualitative method that employs several data

collection techniques, such as questionnaires, interviews, site visits,

observations, and analyses of internal documentation. This choice is justified

by the fact that the case study methods are adapted to the exploratory nature

of the Moroccan VSBs sector, and they provide an in-depth analysis of the

selected cases. However, the case method has limitations, mainly because it

rarely allows for a statistical interpretation of data.

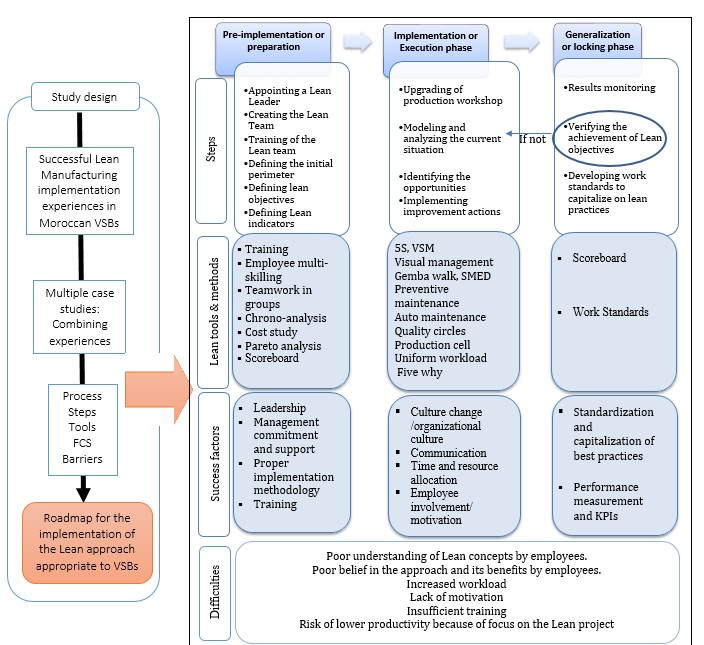

This study aims to develop a framework that integrates all the elements necessary for implementing Lean Manufacturing in very small businesses. Therefore, we draw on the experiences of Moroccan VSBs that have successfully implemented Lean Manufacturing. We juxtaposed their approaches in order to develop a practical and specific implementation approach for VSBs. The framework includes the implementation process, steps, tools, success factors, and barriers to implementation. Figure 1 illustrates all the steps in our methodology.

Figure 1 Methodology of the study

The multiple case studies in this paper are used to reproduce the lived experience and to illustrate different aspects of the cases studied by allowing the confirmation of the results obtained (Hancock et al., 2021). Figure 2 illustrates all the steps of the approach followed in this study.

Figure 2 Process followed in

conducting the case studies

The characteristics of

companies A, B, C, and D, in which the case studies are conducted, are

presented in Table 1.

Table 1 Main characteristics of

the studied companies

|

Activity sector

|

Number of employees |

Turnover

|

LM implementation

year |

Interviewee profile | |

|

A |

Food industry |

15 |

Less than 3 million

DH |

2015 |

Supply chain manager |

|

B |

Printing and

advertising |

9 |

Around 1 600 000 DH |

2014 |

Production manager |

|

C |

Textile manufacturing |

18 |

Less than 3 million

DH |

2018 |

Company manager |

|

D |

Manufacture of

refrigerating equipment |

10 |

Around 2,000,000 DH. |

2014 |

Quality manager |

|

E |

Production of

cosmetics and personal care products |

8 |

Less than 3 million

DH |

2013 |

Process manager |

Analysis of

the company characteristics in Table 1 reveals that although operating in

different sectors, the selected companies share common characteristics. We note

that all the targeted firms in our study have fewer than 20 employees, which

concludes that they are included in the industrial VSB category. Similarly, all

the studied companies have successfully implemented Lean programs for a recent

period of fewer than eight years.

Data collection through

interviews is an essential source of information used, especially in case studies

(Gagnon, 2005). This study's data

collection is based on semi-structured interviews, consulting the internal

documents company, visits, and observations.

The interviews are conducted through a face-to-face survey for 45 minutes to 1 hour each. The questionnaire has three sections. The first section of the survey concerns general information about the company (activities, turnover, and the number of employees). The second section describes the culture and organizational structure of the company, and the third section includes details about the entire lean manufacturing project of the company studied. The interviews are conducted with people directly involved in implementing the Lean program.

Review of Lean approaches adopted by the surveyed

enterprises

3.1. Overview of the studied companies

·

Case A: relates to a Moroccan VSB created in 2011 operating

in the food industry, specializing in producing fresh vegetables raw, washed,

peeled, cut, and packaged in specific packaging under ambient air or modified

atmosphere in adapted bags. The firm is organized into three production

workshops which carry out three types of operations: washing, preparing

vegetables (peeled and cut), packaging, and the last area is reserved for cold

refrigeration.

To satisfy the

customers' growing demand, the company decided in 2015 to launch a project to

increase its efficiency. Therefore, it was decided to start a lean

transformation in the organization.

·

Case B: concerns a

small company founded in 2009, manufacturing products for sales promotion such

as Displays, Distributor Displays, and POS Displays. The company has four

production cells: printing, cutting, assembly, and distribution.

In order to

differentiate itself from its competitors and manage large-scale projects,

management recognized the need for an integral improvement project. It,

therefore, initiated a Lean Manufacturing program.

·

Case

C: located in Agadir and has

specialized since 1996 in clothing and textiles. It deals with the production

of personalized clothing and the professional marking of textiles. The garment

manufacturing process takes place in 5 workshops:

-

Textile

graphics Workshop

-

Pattern-making

and garment-cutting Workshop

-

Preparation

and control of fabrics/choice of marking workshop

-

Textile

confection or manufacture workshop

-

Packaging

workshop

In 2018, in order to be more competitive, the

company opted for the implementation of a Lean project.

·

Case D: located in Casablanca and founded in 1994. It aims

to manufacture refrigerating and electrical equipment, refrigerating doors, and

insulating panels. The factory is composed of a design office and four

workshops in particular sheet metal working, aluminum joinery, thermal

insulation injection, and assembly to obtain a product ready for installation.

The production in this company is done in a piece or small series. The

workshops are handcrafted but equipped with technical and industrial means. The

workshops are also separated, which creates the problem of transport and

wasting of raw material in aluminum carpentry.

Since its

inception, the company has been looking to earn significant market shares. In

this view, it is committed to reducing production costs further, meeting

delivery deadlines, and eliminating waste. Thus, management decided to

implement the Lean program in 2014.

·

Case E: located in Marrakech, specialized in the design,

manufacture, and supply of cosmetic and personal care products. The company has

three production lines.

To be more competitive,

improve the work conditions, and increase its annual profit, the company's

manager opted for a Lean transformation applied first to adequate product

families.

Table 2 gives more

information about the lean projects that unfolded in the studied companies.

Table 2 Duration and

contributions of lean projects in studied businesses.

|

|

Lean project duration |

Project contributions |

|

A |

6 months |

Increasing the

production capacity by 30% (20 kg/day), reducing the waiting and movement

time of the operators by 20%, reducing the changeover time by about 25 min,

and reducing the customer complaints by 20%. |

|

B |

1 year |

Increasing profit

margin from 40% to 60%, 40% in production capacity, reducing customer

complaints due to increased product quality, and the achievement of 0 delays. |

|

C |

6 months |

Increasing production capacity by

15%, reducing waiting time by 20%, and customer complaints by 20%. |

|

D |

1 year |

Increasing annual

gain by 20%. |

|

E |

1 year |

Increasing annual

profit by 16%. |

3.2. Lean project in studied

Cases

3.2.1 Lean project implementation in case A

Lean transformation

within the company is generalized to all workshops. Its insertion was

progressive, starting with the workshop: preparation of vegetables. The project

consists of three main phases: the pre-implementation phase, the implementation

phase, and the generalization phase.

-

During the "pre-implementation phase", the

management designated the supply chain manager as a lean leader. He received

appropriate training led by a lean expert for three days. In turn, he trained

the "lean team". The Lean team first concerned themselves with the

selection of the initial scope of implementation. Based on

"timekeeping", the team chose the "vegetable preparation"

workshop because it has the longest execution time. This phase ends with the

project objectives definition, such as increasing the production capacity by

20%, reducing the number of customer complaints by 60%, and reducing the

execution time.

-

The "implementation phase" consists of four

steps. First, the Lean team committed to improving the workshop by launching

the 5S program. Next, modeling and analysis of the current situation in the

workshop are generated using the VSM tool. Finally, opportunities for

improvement are identified, and improvement actions are implemented.

-

The "generalization phase" consists of

extending the previous phase's objectives to the whole production process. It

starts after the first results of the Lean manufacturing approach were

obtained. In this phase, the Lean approach is taken up again for the two other

workshops: the washing and packaging workshops. A work standard is elaborated

to capitalize, and a tool monitoring the results is established.

3.2.2 Lean project

implementation in case B

The general framework

for the implementation of Lean Manufacturing in this second project includes

three main phases: preparation phase, execution phase, and lock-in phase.

-

The initial phase begins with the designation of the

Lean Leader (Production Manager) and the creation of the Lean team. This step

is followed by the precise definition of the project objectives, then carrying

out a 3-day training program led by an expert consultant for the "Lean

team" throughout the project. The first mission of this team is to proceed

to a qualitative diagnosis of the level of maturity of the lean culture within

the company to establish a master plan for implementing the lean. The

preparation phase ends with the definition of lean indicators and the creation

of a feedback mechanism in order to better evaluate the actions of the

execution phase.

-

For the execution phase, as in the first case C1, the

first step is to upgrade the production floor by launching a 5S-Housekeeping

program. The second step is modeling the current situation of the company. The

analysis of the obtained mapping allows for redesigning the future situation,

identifying improvement opportunities, and defining an action plan. In this

phase, the company decided to eliminate waste throughout the value chain and

minimize downtime using a set of tools: Preventive Maintenance Plan, SMED, and

auto-maintenance.

-

In the final phase, the team develops all the

necessary work standards in order to capitalize on the best practices achieved

and ensure the sustainability of the results.

3.2.3 Lean project implementation in case C

-

In the pre-implementation phase, a multidisciplinary

Lean team is formed. After being trained by an external expert, the team starts

its first mission by selecting the first workshop in which the Lean project will

start. The Workshop "textile confection and manufacture" is selected

for its higher production cost. The Lean team then performs a qualitative

diagnosis of the maturity level of the Lean culture within the company. Then,

it establishes the master plan for Lean implementation. Finally, the team

defines the Lean indicators that will allow the monitoring of the results.

-

As in cases A and B, the Lean team begin the

implementation phase by upgrading the "textile confection or manufacture"

workshop with a 5S program. Then, an analysis of the company's current

situation is carried out in order to design the future situation and identify

improvement opportunities and finally to implement actions such as implementing

a quality control process throughout the manufacturing process and visual

management tools and standardizing the work process.

-

In the generalization phase, the lean program is

extended to other workshops. Also, work standard is developed to capitalize on

the results. By implementing a tool for monitoring results (dashboard), the

company has estimated that a saving of more than 60% of the total cost of waste

has been achieved since the Lean program was set up.

3.2.4 Lean project

implementation in case D

The company relied on a

three-phase Lean Manufacturing implementation approach: preparation phase,

execution phase, and locking phase.

-

During the preparation phase: The management clearly

expressed its commitment by defining the Lean project's objectives. Then,

management appointed the "Quality Manager" as the "Lean

Manager", who formed a multi-functional team including two technicians and

two operators. This team received five days of initial training from a Lean

expert consultant. Afterward, the team identified Lean indicators that will be

used to evaluate actions to be undertaken.

-

In the execution phase, a 5S upgrade program is

initiated to reorganize the space and create an environment conducive to

culture change. Afterward, the team addressed the analysis of the current

situation using the "VSM". All production times are monitored and

analyzed to highlight non-value-added activities in the process. Then,

improvement actions are developed as pilot projects of work standardization to

reduce raw material wastage, preventive maintenance projects, production

stoppage costs, quality control projects, and non-conformity costs.

- The locking phase consists in elaborating working standards to capitalize on the best practices achieved. An IT tool is created to monitor results. In the end, the company estimated that over 30% of the total cost of waste (time and raw material) had been saved since the implementation of the Lean program.

3.2.5 Lean project implementation in case E

The Lean approach, in this case, unfolds in three phases:

pre-implementation, implementation, and generalization.

-

Initially, a team of three persons was nominated as

the Lean team. It received a 5-day training by an external firm. Then, it

carried out a "Pareto analysis" in order to select the initial Lean

perimeter. The choice is made according to the product families with the

greatest sales volume. Ten product families are retained to apply for the Lean

program. Then, Lean objectives are set. The first phase ended with establishing

key performance indicators (KPIs).

-

In order to improve the working conditions, the Lean

team started by organizing the workstations according to the 5S method. It then

carried out a diagnosis of the current situation, and then improvement actions

were drawn up to achieve the Lean objectives. The actions consisted of ensuring

the standardization of manufacturing methods for the selected families and the

training of all operators to enable them to perform auto-maintenance of equipment

and reducing the changeover time by using the SMED method.

-

In the generalization phase, the best practices were

extended to all product families.

Implementing lean: Results from VBS case

studies

This section presents

the results of the case study through the analyses of different lean approaches

in the Moroccan VSBs studied.

4.1. Lean implementation process

The lean implementation

processes within the five studied VBS are all unfolding in 3 phases either pre-implementation,

implementation, generalization or preparation phase, execution, and locking

phases.

The companies that

opted for preparation, execution and lock-in phases opted to implement lean to

the whole process at once without selecting an initial perimeter. Contrary to

those that opted for pre-implementation, implementation and generalization

phases, they selected an initial perimeter and then generalized the lean

approach to the whole process. The perimeter selection is made according to the

following criteria:

·

Production line or product family characterized by the

highest production cost.

·

Production line or product family with the highest

annual production volume.

·

Production line or product family with the longest

production time.

·

Production line or product family with the highest

number of customer complaints.

Each phase is characterized by a series of steps

summarized in Table 3.

We

can resume from Table 3 that:

-

In the first phase:

all companies created a lean team, but only three appointed a team

leader. They all trained the team, and the majority of them defined the project

objectives and the Lean indicators.

-

In the second phase: all companies started by

implementing the 5S method since it is considered easy to deploy and less costly (Gupta, 2022; Rose et al., 2017; 2011). They all performed the modeling of the current

situation in order to identify opportunities, and then they implemented

improvement actions.

- As for the third phase: three steps are capitalized by the majority of companies. These are "Capitalization and standardization of lean practices", "Generalization of actions by extending the lean perimeter" and "Monitoring results".

Table 3 Lean implementation

process in the studied companies

|

Phase |

Steps |

A |

B |

C |

D |

E |

|

Pre-implementation

or preparation phase |

Appointing a Lean

Leader |

× |

× |

|

× |

|

|

Creating the Lean

Team |

× |

× |

× |

× |

× | |

|

Training of the Lean

team |

× |

× |

× |

× |

× | |

|

Defining the initial

perimeter |

× |

|

× |

|

× | |

|

Defining lean

objectives |

× |

× |

|

× |

× | |

|

Qualitative diagnosis

of the lean culture maturity level |

|

× |

× |

|

| |

|

Establishing the

master plan |

|

× |

× |

|

| |

|

Defining Lean indicators |

|

× |

× |

× |

× | |

|

Creating

a feedback mechanism |

|

× |

|

|

| |

|

Implementation

or Execution phase |

Upgrading the

production workshop by launching a 5S-Housekeeping program |

× |

× |

× |

× |

× |

|

Modeling and

analyzing the current situation |

× |

× |

× |

× |

× | |

|

Design the future

situation and deduce the necessary "Kaizen Project". |

|

× |

|

|

| |

|

Identifying the

opportunities |

× |

× |

× |

|

| |

|

Implementing

improvement actions |

× |

× |

× |

|

× | |

|

Implementing

pilot projects |

|

|

|

× |

| |

|

Generalization

or locking phase |

Results monitoring

(to evaluate the contribution of lean) |

× |

|

× |

× |

|

|

Developing work

standards to capitalize on lean practices |

× |

× |

× |

× |

× | |

|

Extending the

approach to other lines and other product families |

× |

|

× |

|

× | |

|

Ensuring the

sustainability of the results and best practices achieved |

|

× |

× |

|

|

4.2. Lean

tools and methods implemented in the surveyed companies

This

section presents the set of lean tools and methods implemented by the companies

in which the case studies are conducted. Table 4 summarizes the lean

tools implemented during all phases of the lean process.

In the first phase, all

the studied firms employed the same tools. The only difference is in defining

the initial perimeter. Company A uses the timekeeping of production operations,

company B uses cost analysis, and company C uses "Pareto analysis".

Frequently

used Lean tools are:

·

VSM: is considered a privileged way to support the

Lean implementation approach (Kholil et al., 2021).

·

Visual management: is considered among the practices

requiring the least financial investment

(Rose et al., 2011).

·

Gemba walks: practiced by all the companies studied,

where the manager is often in contact with the factory floor to identify waste

and opportunities for improvement (Micieta et al., 2022).

·

TPM: is not applied, but their pillars of

"preventive maintenance" and "self-maintenance" are

implemented (Driouach et al., 2020).

·

The dashboard and the standardization of work methods

are implemented in the last phase.

In addition, each company employs a different set of specific tools according to the objectives outlined.

Table 4 Lean tools and methods implemented in very small

businesses

|

|

Tools |

A |

B |

C |

D |

E |

|

Phase 1 |

Training |

× |

× |

× |

× |

× |

|

Employee

multi-skilling |

× |

× |

× |

× |

× | |

|

Teamwork in groups |

× |

× |

× |

× |

× | |

|

Chrono-analysis |

× |

|

|

|

| |

|

Cost study |

|

|

× |

|

| |

|

Pareto analysis |

|

|

|

|

× | |

|

Phase 2 |

5S |

× |

× |

× |

× |

× |

|

VSM |

× |

× |

× |

× |

× | |

|

Visual management |

× |

× |

× |

× |

× | |

|

Gemba |

× |

× |

× |

× |

× | |

|

SMED |

|

× |

× |

|

× | |

|

TPM |

|

|

|

|

| |

|

Preventive

maintenance |

× |

× |

× |

× |

× | |

|

Auto maintenance |

× |

× |

× |

× |

× | |

|

Production cell |

|

× |

|

× |

| |

|

Kanban |

|

|

|

× |

| |

|

Uniform workload |

|

× |

× |

|

| |

|

Production smoothing |

|

|

× |

|

| |

|

5 why |

|

|

× |

× |

| |

|

Statistical process

control |

|

|

× |

|

| |

|

Kaizen |

|

× |

|

|

| |

|

PDCA |

× |

|

|

|

| |

|

Quality circles |

|

× |

× |

|

| |

|

Small batch

production |

|

|

|

|

× | |

|

Supplier management |

|

|

|

× |

| |

|

Phase 3 |

Work standards |

× |

× |

× |

× |

× |

|

Scoreboard (performance

management) |

× |

× |

× |

× |

× |

4.3. Critical success factors for lean

implementation in VSBs

In order to develop a

comprehensive approach to implementing the Lean approach, identifying critical

success factors (CSFs) is also an essential step that will make managers'

decision-making easier. These factors are summarized in Table 5.

Table 5 CSFs for lean

implementation in MSEs

|

|

Critical success

factors |

A |

B |

C |

D |

E |

|

Phase 1 |

Leadership

|

× |

× |

|

× |

|

|

Management

commitment and support |

× |

× |

× |

× |

× | |

|

Alignment

with overall company strategy |

|

× |

|

|

| |

|

Long-term

vision |

× |

|

|

× |

| |

|

Proper

implementation methodology |

× |

|

× |

× |

× | |

|

Training |

× |

× |

× |

× |

× | |

|

Competence

and expertise |

× |

|

|

× |

| |

|

Appropriate

selection of the Lean perimeter |

|

|

× |

|

| |

|

Planning

before implementation |

× |

|

|

× |

| |

|

Phase 2 |

Culture

change/organizational culture |

× |

× |

× |

× |

× |

|

Financial

support |

× |

|

|

|

× | |

|

Communication

|

× |

|

× |

× |

| |

|

Improvements

with small pilot projects |

|

|

|

× |

| |

|

Time

and resource allocation |

× |

× |

× |

× |

× | |

|

Employee

involvement/motivation |

× |

× |

× |

× |

× | |

|

Phase 3 |

Standardization

and capitalization of best practices |

× |

× |

× |

× |

× |

|

Performance

measurement and KPIs |

× |

× |

× |

× |

× | |

|

Continuous

improvement |

|

|

× |

× |

|

Table 5 shows that in

the first phase, all companies recognize that "management commitment and

support" and "training" are the most critical factors for

implementing Lean successfully. In addition, some emphasize the importance of "proper

implementation methodology", "leadership", and

"communication", which is one of the approaches by which companies

can seek to increase their competitive advantage (Qosasi et

al., 2019).

The CSFs considered primary by all VBSs in the second

phase are "Cultural change/organizational culture", "Time and

resource allocation", and "Employee involvement/motivation".

Finally,

"standardization and capitalization of best practices" and

"performance measurement and KPIs" are perceived by all companies as

CSFs for the third phase.

4.4.

Difficulties in

implementing lean in VSBs

In

order to inform VSBs about the obstacles that can affect Lean Manufacturing

implementation, the following section focuses on the difficulties encountered

by the studied companies during the Lean implementation process. Table 6 lists

the various obstacles experienced.

Table 6 Obstacles to implementing lean in VSBs

|

|

A |

B |

C |

D |

E |

|

Lack of management commitment |

|

|

|

× |

|

|

Lack of knowledge/understanding of Lean

Manufacturing by management. |

|

|

|

|

× |

|

Poor belief in the approach and its benefits by

management |

× |

|

|

|

|

|

Short-term commitment from management |

|

|

× |

|

× |

|

Employee's reluctance to change |

|

|

|

|

× |

|

Poor understanding of Lean concepts by employees. |

× |

|

× |

× |

× |

|

Poor belief in the approach and its benefits by

employees. |

× |

|

× |

× |

× |

|

Increased workload |

× |

× |

|

× |

× |

|

Lack of motivation |

|

× |

× |

× |

|

|

Insufficient training |

× |

|

× |

|

× |

|

Difficulty in

quantifying Lean benefits |

|

|

|

|

× |

|

Risk of lower productivity

because of focus on the Lean project |

× |

× |

× |

× |

× |

From table 6, we

conclude that the barriers related to "Risk of lower productivity because

of focus on the Lean project" and "Increased workload" are the

most cited by all interviewees. This can be explained by the small number of

employees in VSBs. In addition, productivity is a puzzle, a complicated function where

several factors act, and it needs to be solved (Woodhead

and Berawi, 2020). This result aligns with those who state that Lean

Manufacturing tends to increase workload and put more pressure on the staff (Baglin and Capraro, 1999; Landsbergis, Cahill,

and Schnall, 1999).

Proposing an effective implementation framework for

Lean Manufacturing in Moroccan VSBs

The previous section's findings are capitalized on as an integral

implementation framework, including all the necessary elements to implement

Lean Manufacturing in Moroccan VBS in the particular implementation process,

tools, success factors and barriers. Contrary to existing models, this

framework is directly derived from the VSBs' own experiences and thus considers

their characteristics and specificities. Figure 3 presents our proposed

framework.

The lean implementation process within the five

studied VSBs unfolds in 3 phases either pre-implementation, implementation,

generalization or preparation phase, execution, and locking.

Figure 3 Proposed

lean implementation framework in Moroccan VSBs

The first

phase defines how Lean transformation will initially be integrated within the

company. Top management begins this phase by expressing its leadership and

commitment to the Lean project by appointing a Lean leader and creating a "Lean team". As a

very small business, the Lean team can contain few individuals, but it must be

multi-skilled and adhere to the principles of teamwork. Training is provided by

a Lean expert to ensure an initial impetus to introduce the Lean culture within

the team, to avoid misunderstanding of the Lean concept by the employees and to

reinforce the belief in the Lean approach and its benefits.

The second phase is the most time-consuming; to

promote its success, we must allocate sufficient time and resources and involve

all employees in the proper implementation of Lean projects (Arabi et al., 2022; Elboq, Hlyal, and El Alami, 2020). The

objective is to motivate them to increase their responsibilities and ownership

of actions. Indeed, insufficient training, increased workload and lack of

motivation are possible barriers that may appear and end up materializing into

real problems.

In the third stage, it

is important to monitor the results of the Lean project through dashboards to

measure and compare the performance achieved regularly. If the initial set of

Lean goals is not achieved, a return to mapping the current situation is necessary

(see Figure 3). If not, best practices should be capitalized, standardized and

shared. This is to ensure the sustainability of the Lean culture in the

company.

This research work is

one of the first analyses that relate Lean Manufacturing to VSBs. The case

studies carried out are capitalized upon in a roadmap derived directly from

VSBs' experiences. The proposed framework includes all the elements necessary

to implement Lean Manufacturing in VSBs, including the implementation process,

the tools, the success factors and the barriers to success. The framework developed

in this work can be useful to stakeholders in very small industries, such as

contractors, consultants and owners, and especially government agencies. It

could be applied to very small industries to validate it and identify areas for

improvement. While the study meets

its objectives, it has some limitations, as with any research study, such as

the reluctance of the companies to welcome us to answer the questions of the

surveys and especially to visit the workplaces and verify the results of the

Lean transformation. We certainly tried to have as many case studies as

possible. But the survey could contain a larger number of companies and

therefore be more representative.

The authors acknowledge the Laboratory of Mechanics,

Production and Industrial Engineering, Higher National School of Electricity

and Mechanics and High School of Technology Casablanca-Morocco, for the

provision of research facilities. The authors would also like to thank the

editor and anonymous reviewers for their useful suggestions.

Alfonso-Orjuela, L.C., Cancino-Gómez, Y.A.,

Perea- Sandoval, J.A. 2022. Classification of SMEs According to Their

ICT Implementation. International Journal of Technology. Volume

13(2), pp. 229–239

Antosz,

K., Stadnicka, D., 2017. Lean Philosophy Implementation in

SMEs – Study Results. Procedia Engineering, Volume 182, pp. 25–32

Arabi, S., Bajjou, M.S., Chafi, A., El

Hammoumi, M., 2022. Evaluation of Critical Success Factors (CSFs) to Lean Implementation

in Moroccan SMEs: A Survey Study. In: 2022 2nd International

Conference on Innovative Research in Applied Science, Engineering and

Technology (IRASET) IEEE, pp. 1–10

Baby, B.N.P.,

Jebadurai, D.S., 2018. Implementation of Lean Principles to

Improve the Operations of a Sales Warehouse in the Manufacturing Industry. International

Journal of Technology, Volume 9(1), pp. 46–54

Baglin, G., Capraro, M.,1999. L’Entreprise Lean Production ou

la PME compétitive par l’action collective. PU LYON, French

Bajjou, M.S., Chafi, A., 2018.

Towards Implementing Lean Construction in the Moroccan Construction Industry:

Survey Study. In: 2018 4th International Conference on Optimization and Applications

(ICOA) IEEE, pp. 1–5

Bouazza, Y., Lajjam, A., Dkhissi, B. 2021.

The Impact of Lean Manufacturing on Enviromental Performance in Moroccan Automotive

Industry. Management Systems in Production Engineering, Volume 29(3), pp. 184–192

Dora, M., Van Goubergen, D., Kumar, M.,

Molnar, A., Gellynck, X., 2014. Application of Lean Practices in Small and

Medium-Sized Food Enterprises. British Food Journal, Volume 116(1), pp.

125–141

Rymaszewska, A.D, 2014. The Challenges of Lean Manufacturing Implementation

in SMEs. Benchmarking: An International Journal, Volume 21(6), pp. 987–1002

Driouach, L., Oumami, M.E., Beidouri, Z.,

Zarbane, K., 2020. Towards Implementing Lean Manufacturing in Very Small

Businesses in Morocco: Qualitative Exploratory Study. International Journal

of Supply Chain Management, Volume 9(6), pp 34–48

Driouach, L., Zarbane, K., Beidouri, Z.,

2019. Literature Review of Lean Manufacturing in Small and Medium-sized

Enterprises. International Journal of Technology, Volume 10(5), pp. 930–941

Elboq, R., Hlyal, M., El Alami, J. 2020.

Empirical Assessment of Critical Success Factor of Lean and Six Sigma in the

Moroccan Automotive Industry. IOP Conference Series: Materials Science and

Engineering, Volume 827(1), pp. 012043

Farissi, A., Driouach, L., Zarbane, K., El Oumami, M., &

Beidouri, Z. 2021a. COVID-19 impact on moroccan small and medium-sized

enterprises: can lean practices be an effective solution for getting out of

crisis?. Management Systems in Production Engineering,Volume 29(2), pp.

83-90

Farissi, A., El Oumami, M., Beidouri, Z., 2021b. Assessing

Lean Adoption in Food Companies: The Case of Morocco. International Journal

of Technology, Volume 12(1), pp. 5–14

Gagnon, Y.C., 2005. L’Étude A de Cas Comme Méthode de Recherche:

Guide de Réalisation (The Case Study as a Research Method: Guide to

Realization)

Gupta, K. 2022. A Review on Implementation

of 5S for Workplace Management. Journal of Applied Research on

Industrial Engineering, Volume 9(3), pp. 323–330

Hancock, D.R., Algozzine, B., Lim, J.H.

2021. Doing Case Study Research: A Practical Guide for Beginning Researchers

Harvie, C., 2019. Micro-Small- and

Medium-Sized Enterprises (MSMEs): Challenges, Opportunities and Sustainability

in East Asia. In K. Jayanthakumaran, N. Shukla, C. Harvie, O. Erdenetsogt

(Éds.), Trade Logistics in Landlocked and Resource Cursed Asian Countries,

pp. 155–174). Springer Link

Kholil, M., Haekal, J., Suparno, A.,

Savira, D., Widodo, T., 2021. Lean Six sigma Integration to Reduce Waste in

Tablet coating Production with DMAIC and VSM Approach in Production Lines of

Manufacturing Companies. International Journal of Scientific Advances, Volume 2(5), pp. 719–726

Landsbergis, P.A., Cahill, J., Schnall,

P., 1999. The Impact of Lean Production and Related New Systems of Work

Organization on Worker Health. Journal of Occupational Health Psychology,

Volume 4(2), pp. 108–130

Matt, D.T., Rauch, E., 2013.

Implementation of Lean Production in Small Sized Enterprises. Procedia CIRP,

Volume 12, pp. 420–425

Mbula, E.K., Lorenz, E., Greenish, L.T.,

Jegede, O.O., Garba, T., Mutambala, M., Esemu, T., 2019. Are African Micro- and

Small Enterprises Misunderstood Unpacking the Relationship Between Work Organisation,

Capability Development and Innovation. International Journal of Technological Learning,

Innovation and Development, Volume 11(1), pp. 1–30

Mi?ieta, B., Howaniec, H., Bi?asová, V.,

Kasajová, M., Fusko, M. 2022. Increasing Work Efficiency in a Manufacturing

Setting Using Gemba Walk. European Research

Studies Journal, European Research Studies Journal, Volume 4, pp. 601–620

Nomani, R.F., Sen, A., 2019. Efficiency and Its

Determinants: Firm-level Evidences from Micro Enterprises in Dibrugarh District

of Assam. SEDME (Small Enterprises Development, Management Extension Journal), Volume 46(2), pp. 82–99

OMPIC., 2020. Office Marocain de la

Propriété Industrielle et Commerciale (Moroccan Office of Industrial and

Commercial Property). Available online at: http://barometre.directinfo.ma,

Accessed on December

2020

Page, J., Söderbom, M., 2015. Is Small

Beautiful? Small Enterprise, Aid and Employment in Africa: Is Small Beautiful? African

Development Review, Volume 27(S1), pp. 44–55

Qosasi, A., Maulina, E., Purnomo, M.,

Muftiadi, A., Permana, E., Febrian, F., 2019. The Impact of Information and

Communication Technology Capability on the Competitive Advantage of Small

Businesses. International Journal of Technology, Volume 10(1), pp.

167–177

Ribeiro, P., Sá, J. C., Ferreira, L.P.,

Silva, F.J.G., Pereira, M.T., Santos, G., 2019. The Impact of the Application

of Lean Tools for Improvement of Process in a Plastic Company: A case study. Procedia

Manufacturing, Volume 38, pp. 765–775

Roriz, C., Nunes, E., Sousa, S., 2017.

Application of Lean Production Principles and Tools for Quality Improvement of

Production Processes in a Carton Company. Procedia Manufacturing, Volume

11, pp. 1069–1076

Rose, A.M.N., Deros, B.M., Rahman, M.N.A.,

Nordin, N., 2011. Lean Manufacturing Best Practices in SMEs. In: Conference

on Industrial Engineering and Operations Management

Rose, Ab Rashid, M.F.F., Mohamed, N.N.,

Ahmad, H., 2017. Similarities of lean Manufacturing Approaches Implementation

in SMEs Towards the Success: Case study in the Automotive Component Industry. MATEC Web of

Conferences, Volume 87, p. 02024

Woodhead, R., Berawi, M.A. 2020. Value

Creation and the Pursuit of Multi Factor Productivity Improvement. International

Journal of Technology, Volume 11(1), pp. 111–122

Zhou, B., 2016. Lean Principles,

Practices, and Impacts: A Study on Small and Medium-Sized Enterprises (SMEs). Annals

of Operations Research, Volume 241(1?2), pp. 457–474