Hydroxylation Kinetics of Epoxidized Tung Oil Using Methanol as Nucleophilic Agent

Published at : 28 Jul 2023

Volume : IJtech

Vol 14, No 5 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i5.5376

Budiyati, E., Rochmadi, Budiman, A., Budhijanto, 2023. Hydroxylation Kinetics of Epoxidized Tung Oil Using Methanol as Nucleophilic Agent. International Journal of Technology. Volume 14(5), pp. 1060-1071

| Eni Budiyati | Department of Chemical Engineering, Faculty of Engineering, Universitas Muhammadiyah Surakarta, Jl. A. Yani No. 157, Pabelan Kartasura, Sukoharjo, Central Java, 57169, Indonesia |

| Rochmadi | Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Sinduadi, Sleman, Yogyakarta, 55284, Indonesia |

| Arief Budiman | Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Sinduadi, Sleman, Yogyakarta, 55284, Indonesia |

| Budhijanto | Department of Chemical Engineering, Faculty of Engineering, Universitas Gadjah Mada, Sinduadi, Sleman, Yogyakarta, 55284, Indonesia |

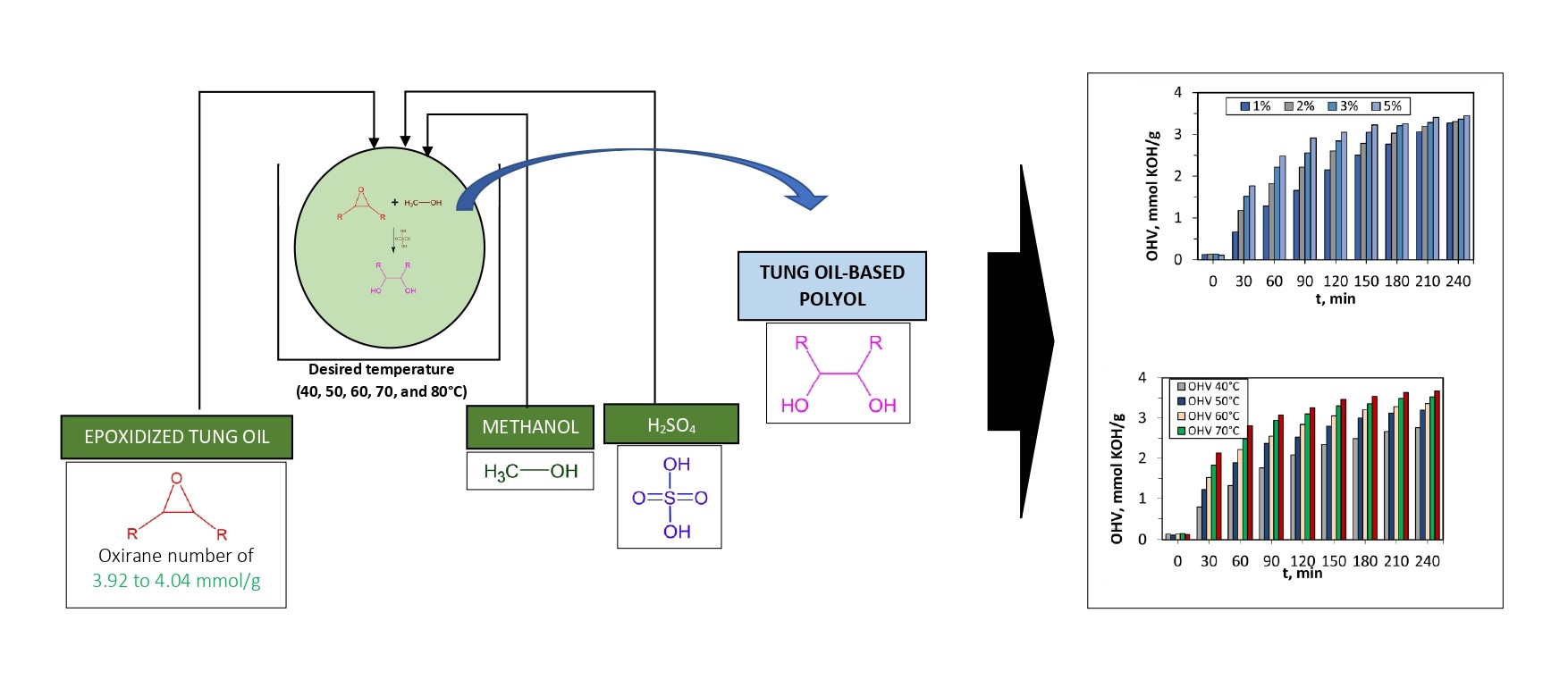

The synthesis of vegetable oil-based polyols has

been carried out through the epoxidation-hydroxylation process. However, Tung

oil has never been explored in the process, even though Tung oil has a high

double bond. Epoxidized

Tung Oil (ETO) with oxirane numbers of 3.92 to 4.04

mmol/g were hydroxylated with methanol and catalyzed by Sulfuric

Acid (H2SO4).

The objective of this study is to produce polyols from ETO and to evaluate the

influence of temperature and catalyst concentration on the hydroxylation process.

A second-order reaction kinetic study was also developed to represent the

reaction. The ETO hydroxylation was carried out in a batch reactor for four

hours. The reaction rate was determined based on the concentration of ETO

(oxirane number) and Hydroxyl Value (OHV). The result shows that temperature and

catalyst concentration have a directly proportional correlation to OHV and are

inversely proportional to the concentration of ETO (epoxy). For temperatures

above 40°C, the decreasing rate of the epoxy concentration at the beginning was

relatively much faster than at the end of the reaction. In the temperature

variation, the highest OHV obtained was 3.70 mmolKOH/g or 207.39 mgKOH/g at

80°C. The optimum catalyst concentration obtained in this study was 3%. The

evaluated kinetics model gave great results for all reaction temperatures, with

the highest total SSE for epoxy concentration and OHV data fitting of 0.156 and

0.045, respectively. The calculated activation energy (Ea) was 30.41 kJ/mol and

the pre-exponential factor (A) was 255.00 g.mmol-1.min-1.

Catalyst concentration; Epoxidized Tung Oil (ETO); Hydroxylation; Kinetics; Methanol

Polyol is an organic compound that has more than one hydroxyl (-OH) group. Bio-polyols that are synthesized from vegetable oils are a great alternative to replace petrochemical polyols. Oleochemical polyols have several characteristics, such as flexible, mechanical and chemical resistant, hard, and hydrophobic (Borowicz, Paciorek-Sadowska, and Isbrandt, 2020; Purnomo, Setyarini, and Anggono, 2020; Lavrenyuk, Parhomenko, and Mykhalichko, 2019). They are required in the manufacturing industries such as flooring, coatings, and foaming in the polymer industry, polyols are compounds that contain hydroxyl function groups that can be used for other chemical reactions. The main use of polyols is to be used as a reactant to make polymers. Polyols can also be used for other purposes, such as intermediate chemicals, lubricant formulations, and stabilizers (Bresolin et al., 2018; Gasni et al., 2017; Pavani, Pola-Rao, and Prasad, 2017; Kamalakar et al., 2015). Polyols are widely used in the manufacture of polyurethane. The synthesized polyol can be processed from renewable (e.g., vegetable oils) and unrenewable materials (e.g., petroleum). The hydroxyl group can be made from vegetable oils with a high content of unsaturated fatty acids through epoxidation followed by the hydroxylation process (Borowicz, Paciorek-Sadowska, and Isbrandt, 2020). Some vegetable oils have high unsaturated fatty acid content and some of them naturally contain other functional groups which cause various processes in synthesizing vegetable oil-based polyols. The four methods used to produce polyols are a) epoxidation followed by the ring-opening of the oxirane to form secondary hydroxyl groups; b) the enzymatic reaction; c) transesterification; and d) hydroformylation and reduction of aldehyde oil (Dong-Feng et al., 2019; Ionescu et al., 2016).

Hydroxylation

is the addition process of hydroxyl groups (-OH) to organic compounds.

Theoretically, vegetable oils can be converted to hydroxy in several ways, such

as catalytic hydrogenation, hydrochlorination or hydrobromination, and

ring-opening reactions with the addition of alcohol, amino alcohol, or acid (Coman et al., 2021; Borowicz,

Paciorek-Sadowska, and Isbrandt, 2020; Guo, Javni, and Petrovic, 2000). Hydroxylation reactions can be performed

in the absence of solvents with acidic catalysts. The catalysts used are

mineral acids, metal, and metal carbonyl. The ratio of molar hydroxyl and

epoxide groups ranges from 1:1 to 1:10 and the optimum temperature is around 50°C (Petrovic et al., 2010). In recent years, the ring-opening method of

epoxy has been widely investigated for the manufacturing process of vegetable

oil-based polyol compounds. This method involves two steps, i.e., epoxidation

of unsaturated fatty acids in vegetable oils and the ring-opening reaction of

epoxy using nucleophilic reagents such as amines, carboxylic acids/ halogenated

acids, or alcohol. The ring-opening reaction of epoxy with the addition of

alcohol produces alkoxy alcohol (Gallo, Teixeira, and Schuchardt, 2006; Williams, D Bradley, and Lawton, 2005). This reaction can be carried out using both

alkaline and acidic catalysts. Some of the catalysts that have been used in

these reactions include Lewis acid (Firouzabadi et al.,

2006), Bronsted acid (Gallo, Teixeira, and Schuchardt, 2006), and porphyrin complexes (Zakavi, Karimipour,

and Gharab, 2009).

Some researchers make polyols from

several vegetable oils, such as castor oil, flaxseed oil, sunflower seed oil,

soybean oil, peanut oil, and cotton seed oil through ozonolysis and

hydrogenation processes (Tran, Graiver, and Narayan, 2005) as well as epoxidation and

hydroxylation processes (Petrovic et al., 2010). Vegetable oils generally do not contain

hydroxyl groups but hold a relatively high content of unsaturated fatty acids (Helmiyati and Anggraini, 2019). The double bonding part of unsaturated

fatty acids can be converted into an epoxy group at atmospheric pressure

through epoxidation and further converted into a hydroxyl group with the

hydroxylation process. Petrovic et al.

(2010) patented epoxidized oil alcoholysis with different molecules such

as water, monoalcohol (methanol, ethanol, propanol, and butanol), and their

mixture using tetrafluoro boric acid as a catalyst (Petrovic et al., 2010; 2002). Polyol can be synthesized from several

epoxidized natural oils, such as epoxidized methyl oleate, epoxidized cocoa

butter, epoxidized palm olein, and epoxidized soybean. Polyols were produced

through a copolymerization reaction between the epoxidized oils and

tetrahydrofuran with a Lewis acid catalyst (Hoong et al., 2015). Mohammed et

al. (2013) synthesized polyols by reacting palm oil and soybean oil

with glycerol. The polyols were further processed in the manufacture of

polyurethane (Mohammed et al., 2013).

Tung oil is one of the types of

non-edible vegetable oil with a high content of unsaturated fatty acids. The

use of Tung oil as a raw material in the synthesis of polyols has several

advantages, such as: being renewable, relatively biodegradable, sustainable,

and not contradictory to food industry needs. Tung seeds kernel can result from

crude oil of 45-50% yield with a high content of unsaturated fatty acids, i.e.,

oleic acids, linoleic acids, and oleo stearate acids. The percentage of fatty

acid contained in Tung oil is about 66.17% of oleo stearic acid, 21.72% of

palmitic acid, 0.27 % of linoleic acid, 9.58% of oleic acid, and 2.26% of other

saturated fatty acids (Budiyati et al., 2020). Synthesis of bio-polyols can be carried out

by epoxidation of double bonds in unsaturated fatty acids and ring-opening of

epoxides with nucleophilic reagents. The advantages of chemical flow, such as

increased process safety and reliability, easy automation, and reproducibility

are leveraged to increase productivity and product quality in the ring-opening

epoxy. Pantone et al. (2017) investigated

the methanolysis reaction of Soy Oil Oxidized (ESO) in a continuous

flow system (Pantone et al., 2017). Various chemical modifications to Epoxidized Soybean Oil (ESBO) are performed through

the opening of epoxy rings. The ring-opening reaction with nucleophilic

compounds is one of the most commonly used processes. Several previous studies

examined the hydroxylation of epoxy rings with acids (acetic acid, formic acid,

and phosphoric acid) (Campanella and Baltanas, 2007; Guo et al., 2007). Alcoholysis using methanol, 1-decanol,

1-butanol, and 2-ethylhexanol was studied for the manufacture of lubricant

formulation (Hwang, Adhvaryu, and Erhan, 2003; Hwang and Erhan, 2001). The alkoxylate synthesis of triacylglycerol

from ESBO was developed using perchloric acid for the opening of epoxy rings (Adhvaryu, Liu, and Erhan, 2005).

Based on the literature review, the

hydroxylation process with Tung oil as raw material has never been carried out.

Evaluations of the hydroxylation kinetics and the process variables' effects

(such as temperature and catalyst concentration) also have not been discussed

specifically in the previous studies. Several previous studies evaluated the

reaction rate constants of the hydroxylation (epoxy and alcohol) as a part of

the side reaction in the epoxidation of vegetable oils (Kousaalya et al., 2018; De Haro et al.,

2016; Dai et al., 2009). Overall, this research has novelties in the

type of vegetable oil (i.e., Tung oil) and the proposed reaction kinetics.

Therefore, this study aims to evaluate the influence of temperature and

concentration of catalyst, as well as the second-order reaction kinetics in the

hydroxylation of ETO.

2.1. Materials

Epoxidized

Tung Oil (ETO) was

produced from the epoxidation process of Tung seed oil (Reutealis trisperma

(Blanco) Airy Shaw) (Budiyati et al., 2020). It has an initial concentration of epoxy

and hydroxy of 3.92 to 4.04 mmol/g and 0.11 to 0.16 mmol/g, respectively.

Pyridine, crystal violet indicator, hydrobromic acid (47 wt%), methanol,

sulfuric acid 98 wt%, glacial acetic acid (AR Grade), and potassium hydroxide

were purchased from CV. Zirconia Jaya, Yogyakarta, Indonesia. Acetic anhydride

and potassium hydrogen phthalate were purchased from CV. Multikimia,

Yogyakarta, Indonesia.

2.2.

Hydroxylation Process

Epoxidized Tung Oil (ETO) was produced from Tung seed oil

epoxidation. Peracetic acid was used as an oxidator (in-situ generated) and

sulfuric acid as the catalyst. The epoxidation process was carried out for 4

hours at a temperature of 60°C and the stirring speed was maintained constant

at 600 rpm (Budiyati

et al., 2021). ETO was

hydroxylated with 6 g of methanol and 3% (of the total solution) sulfuric acid

in an Erlenmeyer flask. As much as 75 g of epoxidized Tung oil and a mixture of

methanol and sulfuric acid were fed into the reactor. The process was carried

out isothermally (at a temperature of 40°, 50°, 60°, 70°, and 80°C) with a stirring

velocity of 700 rpm. Then, the catalyst concentration was varied at 1%, 2%, 3%,

and 5%. The Hydroxylation process ran for 4 hours with a sampling time interval

of 30 minutes. The samples were purified in the separation funnel using warm

distilled water. The obtained samples were analyzed to determine their oxirane

number and hydroxyl value. A schematic illustration of this experiment is shown

in Figure 1.

2.3

Determination of Concentration of ETO and Hydroxyl Value

The concentration of ETO was represented

by the oxirane number. It was analyzed by hydrobromic acid solution with

glacial acetic acid method (Budiyati et al., 2020). The Hydroxylation

Value

(OHV) of polyols was determined according to the ASTM method D1957-86 with the

mixture of pyridine and acetic anhydride as a hydroxyl number reagent.

Potassium hydroxide was used as a titrant in the titration process.

Figure 1 Schematic illustration of this experiment

3.1. Effect of Temperature on

Hydroxylation

Temperature significantly affects chemical

reactions, including ETO hydroxylation. In this study, the optimum temperature

evaluation was conducted. ETO as a reactant or raw material is naturally highly

reactive. Before the raw materials were used in experiments, they were stored

in the freezer with limited storage time (maximum about 2 days) at a

temperature of 4°C. After the freezing pre-treatment, the raw materials were

ready to be fed into the reactor which has varied temperatures of 40°, 50°,

60°, 70°, and 80°C. Figure 2(a) presents a correlation between epoxy/ETO

concentration and reaction time at various temperatures of hydroxylation. From

Figure 2(a), it is seen that the concentration of ETO decreased with the

increase in reaction time and this condition occurred at all observed reaction

temperatures. It is obvious because the longer the reaction time, the more ETO

moles (as reactants) reacted. As a consequence, there are more epoxy molecules

converted in the process. The temperature has a similar effect as the reaction

time to the hydroxylation of ETO. The rising temperature decreases the ETO

concentration. This phenomenon happens because the increase in temperature

enlarged the kinetic energy and reactiveness of the reactant molecules. The

decreasing rate of epoxy concentration at the lowest temperature, 40°C, was

relatively slow from the beginning to the end of the reaction. At higher

temperatures, 50° to 80°C, the decreasing rate of the epoxy concentration at

the beginning was relatively fast and began to stable after 120 minutes. As

mentioned previously, at a higher temperature the molecular kinetics of the

reactants will increase, thus increasing the collision factor and accelerating

the reaction rate (Yang et al.,

2010).

Methanol was a primary alcohol that can

be a powerful nucleophile in the hydroxylation of ETO. It is seen from the

final conversions (of about 84%) with a reaction time of 4 hours. This result

supports previous research which states that the hydroxylation conversion of

epoxide compounds with primary alcohol was higher compared to secondary and

tertiary alcohols (Mirza-Aghayan et al., 2014). Mirza-Aghayan,

et al. (2014) stated that a long reaction time is required for

the opening of epoxide rings with secondary alcohol. However, the generated

conversions in this study were lower than in previous studies. Hydroxylation of

styrene epoxide with methanol-catalyzed Graphite Oxide (GO)

resulted in a conversion of about 94%. This significant difference was due to

the use of different raw materials and catalysts (Mirza-Aghayan et

al., 2014).

Figure 2(b) shows OHV at various

reaction times and temperatures. The observed concentration of polyols or OHV

increased with reaction time, for all temperatures. This phenomenon occurs

because a longer reaction time increased particle contact. At the same reaction

time, the samples treated with higher temperatures have more OHV produced. The

molecular kinetics of the reactant molecules rose with the increase in

temperature and this condition triggered the collision molecules. The highest

OHV obtained in this study (from the optimum temperature variation) was

approximately 3.70 mmol KOH/g or 207.39 mg KOH/g. This result was in accordance

with the previous studies, which are 180.34 mg KOH/g (Dai et al., 2009) and 191±15 mg KOH/g (Pantone et al.,

2017). Dai et al. (2009) also

conducted similar research with different types of alcohol, namely

1,2-ethanediol, and 1,2-propanediol. The obtained OHV values are 253.33 mg

KOH/g (for 1,2-ethanediol) and 289.31 mg KOH/g (1,2-propanediol). The vegetable

oil used in the two aforementioned studies was soybean oil, while this research

also used vegetable oil. Based on these results, it can be concluded that the

type of vegetable oil and operating conditions are parameters that have a

significant effect on the results of the hydroxylation reaction.

3.2. Effect of The Catalyst

Concentration on Hydroxylation

The

evaluation of the catalyst's influence on ETO hydroxylation was conducted at

the temperature of 60°C and a constant stirring velocity of 600 rpm. The

catalyst used in this study was sulfuric acid (H2SO4). The catalyst activated methanol

as a nucleophilic agent, then activated methanol reacted with ETO. Catalyst

concentration is an important parameter in reaction kinetics. Catalysts can

accelerate reactions, but on the other hand, can produce burnt or dark brown

polyols. In this study, the catalyst concentrations were varied at 1%, 2%, 3%,

and 5% to obtain the optimum value.

Figure

3(a) describes the correlation between the concentration of epoxy/ETO against

the time and catalyst concentration. As explained in the previous discussion, a

longer reaction time resulted in a lower concentration of epoxy. Generally, the

concentration of catalysts had an inverse correlation to the ETO concentration.

Higher catalyst concentration promotes more epoxy molecules to react. Catalysts

reduce the activation energy; therefore, reactions can run faster. However, the

addition of a catalyst has its limit. The addition of catalyst concentrations

from 1% to 3% had a significant effect on the reaction kinetics while the

addition of catalysts from 3% to 5% produced a less significant effect.

The initial

concentration of ETO was around 3.99 – 4.00 mmol/g. The initial concentration

of ETO was not fixed at a single value due to the highly reactive properties of

epoxy compounds. In practice, ETO was prepared in a time adjacent to its

hydroxylation process. At the end of the reaction, the ETO converted were

approximately 75.58%, 77.46%, 80.34%, and 81.00% for catalyst concentrations of

1%, 2%, 3%, and 5%, respectively. In addition, the use of an H2SO4

catalyst at relatively high concentrations caused the discoloration of

polyols, i.e., dark brown. This can lead to denaturation of the product,

resulting in decreased quality of polyols. From these data, a catalyst

concentration of 3% can be recommended as the optimum value in this reaction.

These results differ slightly from those reported by Yadav

and Singh (2014), optimum catalyst concentration was 5% (Yadav and Singh, 2014). This was due to the different

types of catalysts and epoxy used. The types of catalysts used in the previous

study and this research are ferrocenium tetrafluoroborate and sulfuric acid,

respectively. Then, the previous study used non-vegetable oil-based epoxies,

such as 1,2-epoxydodecane and 1,2-epoxyhexane.

3.3. Hydroxylation Kinetics

The second-order reaction

model was evaluated on the hydroxylation kinetics. Two assumptions were taken

in this research: (1) the hydroxylation was a pseudo-homogeneous reaction and

(2) there is no side reaction occurred. The reason for taking the assumption

(1) is that methanol and ETO are organic compounds that can dissolve well with

each other. Then, sulfuric acid is an inorganic compound that has limited

solubility in these organic compounds. The amount of sulfuric acid is

inconsiderable (i.e., 3%). So, overall, the reaction can be considered a

pseudo-homogeneous. While, the reason for assumption (2) is that based on the

experimental results, the concentration of the oxirane (which reacts) is

proportional to the concentration of the formed polyol. The molar ratio of

epoxy (ETO) to methanol was 1:1 (equimolar). The concentration of the H2SO4

catalyst was 3% of the total weight of the reactants. The used catalyst

concentration was based on the discussion in the previous section (i.e.,

section 3.2.), which concluded that the optimum catalyst concentration was 3%.

The process was carried out in a batch reactor for four hours. The reaction

took place isothermally and at a constant stirring speed (700 rpm). The

mechanism of the ETO hydroxylation is shown in Equation (1).

The elementary reaction law states that the rate of a reaction is

proportional to the concentration of each reactant.

Then, the rate of reaction can be represented

by Equation (2).

Because of equimolar ([R3OH]0 = [ETO]0)

and coefficient of R3OH = coefficient of epoxy (ETO), so [R3OH]

= [ETO]. Then Equation (2) changed into Equation (3).

The reaction rate equation followed Equation (3), where the

hydroxylation had a reaction order of 2 or could be called a second-order

reaction.

The sum of the square of errors (SSE) of this

kinetics model was determined by Equation (4).

The experimental data used in this model were the ETO concentration and OHV for each temperature. The kinetic parameter (k) was obtained by minimizing the sum of the square of error (SSE) as the objective function. The algorithm for determining the reaction rate constant is shown in Figure 4.

Figure 4 Algorithm for determining the

reaction rate constant (k)

The experimental data

and resulting model concentrations of ETO and OHV are shown in Figure 5. From

Figure 5, it is clear that at all evaluated reaction temperatures, experimental

data on epoxy and polyol concentrations were fit to the modeling results. This

indicates that in the reaction system, there was no side reaction and the

reaction rate has an order of 2 (two). At 40°C, the deviation between the

experimental data and the model (especially for epoxy concentrations) was

relatively greater than at higher temperatures. For example, at a reaction time

of 30 minutes, the ETO concentrations were about 3.52 mmol/g (experiment) and

3.18 mmol/g (model). This was due to the high viscosity property of epoxidized

Tung oil. At the beginning of the reaction, this high viscosity causes poor

homogeneity in the reaction system and a low reaction rate. This high viscosity

was not considered in the model, as there is no viscosity parameter from

Equation (2) to (3). The deviation between the ETO concentration of

experimental data and the model was getting smaller by the time t > 30

minutes because homogeneity was achieved.

The

reaction rate constant and the Sum of the Square of Errors (SSE) for each temperature

are shown in Table 1. The reaction rate constant had a reaction order of 10-3

g.mmol-1.min-1. This result is in agreement with the

previous study (De Haro et al., 2016). The reaction rate constant was

directly proportional to the reaction temperature. The k values for the range

temperatures of 40 – 80°C were 1.98 x10-3 to 7.83 x10-3

g.mmol-1.min-1. The smallest SSE for epoxy and polyol

concentrations were obtained at 60°C and 70°C. In addition, the sample treated

at 40°C resulted in the highest SSE, with an average SSE of 0.100. From Table

1, it is seen that in the temperature range of 40°C to 70°C, the average SSE

value decreased with the increase in temperature. However, at a temperature of

80°C the SSE average rose again. It indicates that it was possible that the

side reactions began to occur at such a temperature. The observed SSE for

polyol concentrations/OHV was around 0.004 to 0.045 while the SSE of epoxy was

0.013 to 0.156. This suggests that experimental data from epoxy and polyol

concentrations were fit to the results of the model. Overall, the evaluated

kinetics model provided satisfactory results.

Figure 5 The experimental and model concentrations of

ETO and polyol (OHV) as a function of reaction time at various temperatures:

(a) 40°C, (b) 50°C, (c) 60°C, (d) 70°C, and (d) 80°C

Table 1 Reaction rate

constant (k) and SSE values for hydroxylation kinetics model

The reaction rate constants obtained from each temperature can be

further used as the input data to determine the Activation Energy (Ea)

and Pre-exponential

Factor (A) using the Arrhenius

equation. The relative error value of the curve was low and the r-square

parameter shows a satisfactory value of 0.98. The curve slope is the value of

(-Ea/R), where R is the ideal gas constant. Meanwhile, the intercept curve is

the ln (A) value. The calculated energy (Ea) is 30.41 kJ/mol and the Pre-exponential Factor (A) is 255.00 g.mmol-1.min-1.

The Ea values in this study were a bit different from the previous studies,

which were 29.56 and 39.99 kJ/mol (Dai et al., 2009) and 43.11 kJ/mol (Kousaalya et al., 2018). The vegetable oils used in the

previous study were soybean oil and Perilla oil, respectively. Overall, the

type of vegetable oil directly affects the value of the resulting Ea of

hydroxylation.

Polyols were successfully synthesized from epoxidized Tung oil

through hydroxylation using methanol as a nucleophilic agent. Sulfuric acid (H2SO4)

was added as a catalyst. From this study, it can be concluded that the

resulting polyol concentrations (OHV) were directly proportional to the

temperature, time of reaction, and catalyst concentration. On the other hand,

the concentration of ETO is inversely proportional to the mentioned parameters.

The highest OHV obtained from the temperature variation was 207.39 mg KOH/g at

80°C. A catalyst concentration of 3% can be recommended as the optimum

condition in this reaction. A proposed second-order reaction kinetics model can

represent hydroxylation kinetics. A good agreement between experimental data

and calculated concentration was achieved. The k values for the range

temperatures of 40°C – 80°C were about 1.98 x10-3 to 7.83 x10-3

g.mmol-1.min-1. Future research shall focus on the

characterization and application of Tung oil-based polyol products.

The authors are thankful to the

“Direktorat Riset dan Pengabdian Masyarakat, Direktorat Jenderal Penguatan

Riset dan Pengembangan, Kementerian Riset, Teknologi dan Pendidikan Tinggi”

Indonesia for the research grant of Penelitian Disertasi Doktor (PDD). Number

3079/UN1.DITLIT/DIT-LIT/PT/2020.

| Filename | Description |

|---|---|

| R1-CE-5376-20220306013407.docx | Graphical Abstract in DOC |

Adhvaryu,

A., Liu, Z., Erhan, S.Z., 2005. Synthesis of Novel

Alkoxylated Triacylglycerols

and Their Lubricant

Base Oil

Properties. Industrial Crops and Products, Volume 21(1), pp. 113–119

Borowicz,

M., Paciorek-Sadowska, J., Isbrandt, M., 2020. Synthesis and Application of New

Bio-polyols Based

on Mustard Oil

for the Production of Selected

Polyurethane Materials.

Industrial Crops and Products, Volume 155,

p. 112831

Bresolin,

D., Mazurek, V., Valério, A., Sayer, C., de Araújo, P.H.H., de Oliveira, D.,

2018. Poly (Urea-urethane)

Nanoparticles using Mono- and Diacylglycerol

from Glycerolysis of Castor

Oil as Biopolyol

and Stabilizer. European

Polymer Journal, Volume 108, pp. 529–535

Budiyati,

E., Rochmadi, Budiman, A., Budhijanto, 2021. Synthesis of Vegetable Oil-Based

Polymers from Tung Oil (Reutealis Trisperma(Blanco) AiryShaw). Universitas

Gadjah Mada

Budiyati,

E., Rochmadi, R., Budiman, A., Budhijanto, B., 2020. Studies on Epoxidation of Tung

Oil with Hydrogen

Peroxide Catalyzed

by Sulfuric Acid.

Bulletin of Chemical Reaction Engineering and Catalysis, Volume 15(3), pp. 674–686

Campanella,

A., Baltanás, M.A., 2007. Degradation of the Oxirane

Ring of Epoxidized

Vegetable Oils

in a Liquid-liquid-solid Heterogeneous Reaction

System. Chemical

Engineering and Processing, Volume

46(3), pp. 210–221

Coman,

A.E., Peyrton, J., Hubca, G., Sarbu, A., Gabor, A.R., Nicolae, C.A., Iordache,

T.V., Averous, L., 2021. Synthesis and Characterization

of Renewable Polyurethane

Foams using Different

Biobased Polyols

from Olive Oil.

European Polymer Journal, Volume 149, p.

110363

Dai,

H., Yang, L., Lin, B., Wang, C., Shi, G., 2009. Synthesis and Characterization of the Different Soy-based

Polyols by Ring

Opening of Epoxidized

Soybean Oil

with Methanol, 1,2-ethanediol and 1,2-propanediol. Journal

of the American Oil Chemists' Society, Volume 86, pp. 261–267

De-Haro,

J.C., Izarra, I., Rodríguez, J.F., Perez, A., Carmona, M., 2016. Modelling the Epoxidation Reaction

of Grape Seed

Oil by Peracetic

Acid. Journal of Cleaner Production, Volume 138, pp. 70–76

Dong-Feng, G., Ma, Y., Zhang, M., You-Jia, P., Hong-Hu, Li., Guo-Liu, C., Hong-Zhou, Y., 2019. Polyurethane-coated Urea using Fully

Vegetable Oil-based

Polyols: Design, Nutrient

Release and Degradation.

Progress in Organic Coatings, Volume 133,

pp. 267–275

Firouzabadi,

H., Iranpoor, N., Jafari, A.A., Makarem, S., 2006.

Aluminumdodecatungstophosphate (AlPW12O40) as a Reusable

Lewis Acid Catalyst: Facile Regioselective

Ring Opening

of Epoxides with Alcohols,

Acetic Acid

and Thiols. Journal of Molecular Catalysis A:

Chemical, Volume 250(1-2),

pp. 237–242

Gallo,

J.M.R., Teixeira, S., Schuchardt, U., 2006. Synthesis and Characterization of Niobium Modified

Montmorillonite and its use in the Acid-catalyzed Synthesis

of hydroxyethers. Applied Catalysis A: General, Volume 311, pp. 199–203

Gasni,

D., Mulyadi, I.H., Affi, J., Miswar, A.Y., 2017. Investigation of Wear

Mechanism in Ball Bearings Lubricated by A Bio-lubricant.

International Journal of Technology, Volume 7,

pp. 1248–1257.

Guo,

A., Javni, I., Petrovic, Z., 2000. Rigid Polyurethane

Foams Based

on Soybean Oil.

Journal of Applied Polymer Science, Volume 77(2), pp. 467–473

Guo,

Y., Hardesty, J.H., Mannari, V.M., Massingill, J.L., 2007. Hydrolysis of Epoxidized Soybean

Oil in the Presence

of Phosphoric Acid.

Journal of the American Oil Chemists' Society, Volume 84, pp. 929–935

Helmiyati, Y.A., Anggraini, Y., 2019. Nanocomposites Comprising Cellulose

and Nanomagnetite as Heterogeneous

Catalysts for the Synthesis

of Biodiesel from Oleic

Acid. International Journal of Technology, Volume 10(4), pp. 798–807

Hoong,

S.S., Yeong, S.K., Hassan, H.A., Din, A.K., Choo, Y.M., 2015. Synthesis and Characterization of Polyurethanes Made

from Copolymers of Epoxidized

Natural Oil

and Tetrahydrofuran. Journal of Oleo Science,

Volume 64(1),

pp. 101–115

Hwang,

H.S., Adhvaryu, A., Erhan, S.Z., 2003. Preparation and Properties of Lubricant

Basestocks from Epoxidized

Soybean Oil

and 2-ethylhexanol. Journal of the American Oil Chemists' Society, Volume 80(8),

pp. 811–815

Hwang,

H.S., Erhan, S.Z., 2001. Modification of Epoxidized

Soybean Oil

for Lubricant Formulations

with Improved Oxidative

Stability and Low

Pour Point.

Journal of the American Oil Chemists' Society, Volume 78, pp. 1179–1184

Ionescu,

M., Radojcic, D., Wan, X., Shrestha, M.L., Petrovic, Z.S., Upshaw, T.A., 2016.

Highly functional polyols from castor oil for rigid polyurethanes. European

Polymer Journal, Volume 84, pp. 736–749.

Kamalakar,

K., Mahesh, G., Prasad, R.B.N., Karuna, M.S.L., 2015. A Novel Methodology

for the Synthesis of Acyloxy

Castor Polyol

Esters: Low Pour

Point Lubricant

Base Stocks.

Journal of oleo science, Volume 64(12), pp. 1283–1295

Kousaalya,

A.B., Beyene, S.D., Gopal, V., Ayalew, B., Pilla, S., 2018. Green Epoxy Synthesized

from Perilla Frutescens: A Study

on Epoxidation and Oxirane

Cleavage Kinetics

of High-linolenic Oil.

Industrial Crops and Products, Volume 123,

pp. 25–34

Lavrenyuk,

H., Parhomenko, V.P., Mykhalichko, B., 2019. The Effect of Preparation

Technology and the Complexing on the Service

Properties of Self-extinguishing

Copper(II) Coordinated

Epoxy-amine Composites

for Pouring Polymer

Floors. International Journal of Technology, Volume 10(2),

pp. 290–299

Mirza-Aghayan,

M., Alizadeh, M., Tavana,

M.M., Boukherroub, R., 2014. Graphite Oxide: A Simple

and Efficient Solid

Acid Catalyst

for the Ring-opening of Epoxides

by Alcohols. Tetrahedron Letters, Volume 55(49),

pp. 6694–6697

Mohammed,

I.A., Al-Mulla, E.A.J., Kadar, N.K.A., Ibrahim, M., 2013. Structure-property Studies of Thermoplastic

and Thermosetting Polyurethanes

using Palm and Soya

Oils-based Polyols.

Journal of Oleo Science, Volume 62(12), pp. 1059–1072

Pantone,

V., Laurenza, A.G., Annese, C., Fracassi, F., Fusco, C., Nacci, A., Russo, A.,

D’Accolti, L., 2017. Methanolysis of Epoxidized

Soybean Oil

in Continuous Flow

Conditions. Industrial Crops and Products, Volume 109, pp. 1–7

Pavani,

P.N.L., Pola-Rao, R., Prasad, C.L.V.R.S.V., 2017. Synthesis and Experimental Investigation

of Tribological Performance

of a Blended (Palm

and Mahua) Bio-lubricant

using the Taguchi Design

of Experiment (DOE).

International Journal of Technology, Volume 8(3), pp. 418–427

Petrovic,

Z., Javni, I., Guo, A., Zhang, W., 2002. Method of Making Natural

Oil-based Polyols

and Polyuretahanes Therefrom.

United States Patent,

US 6,433,121 B1

Petrovic,

Z.S., Javni, I., Zlatanic, A., Guo, A., 2010. Modified Vegetable Oil-based

Polyol. United States Patent, US 7,786,239 B2

Purnomo,

P., Setyarini, P.H., Anggono, A.D., 2020. Fiber Orientation Effect on Fracture

Toughness of Silk Fiber-Reinforced Zeolite/HDPE Composites. Faculty of

Mechanical Engineering (FME) Transactions, Volume 49(1),

pp. 128–134

Tran,

P., Graiver, D., Narayan, R., 2005. Ozone-mediated polyol synthesis from

soybean oil. Journal of the American Oil Chemists Society, Volume 82(9),

pp. 653–659

Williams, D Bradley G., Lawton, M., 2005. Aluminium Triflate: A Remarkable

Lewis Acid Catalyst

for the Ring Opening

of Epoxides by Alcohols. Organic and Biomolecular Chemistry, Volume

3(18), pp. 3269–3272

Yadav,

G.D., Singh, S., 2014. Ring Opening of Epoxides With Alcohols Using Fe(Cp)2BF 4

as Catalyst. Tetrahedron Letters, Volume 55(29), pp. 3979–3983

Yang,

Z., Peng, H., Wang, W., Liu, T., 2010. Crystallization behavior of

poly caprolactone)/layered double hydroxide nanocomposites. Journal of

Applied Polymer Science, Volume

116(5), pp. 2658–2667

Zakavi,

S., Karimipour, G.R., Gharab, N.G., 2009. Meso-tetraarylporphyrin Catalyzed Highly

Regioselective Ring

Opening of Epoxides

with Acetic Acid.

Catalysis Communications, Volume 10(4), pp. 388–390