Modeling of Coal Spontaneous Fire in A Large-Scale Stockpile

Corresponding email: yulianto.nugroho@ui.ac.id

Published at : 04 Apr 2023

Volume : IJtech

Vol 14, No 2 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i2.5367

Thabari, J.A., Auzani, A.S., Nirbito, W., Muharam, Y., Nugroho, Y.S., 2023. Modeling of Coal Spontaneous Fire in A Large-Scale Stockpile. International Journal of Technology. Volume 14(2), pp. 257-266

| Jeri At Thabari | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

| Ahmad Syihan Auzani | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

| Wahyu Nirbito | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

| Yuswan Muharam | Department of Chemical Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

| Yulianto Sulistyo Nugroho | Department of Mechanical Engineering, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

The increasing need for energy consumption has

resulted in the use of energy sources in coal continuing to increase. The

transportation and distribution activities of coal also cause the pile to be

exposed to heat when it is in a pile. Due to the kinetic characteristics of

low-rank coal, the pile is very susceptible to spontaneous fire processes. Of

course, this spontaneous fire phenomenon harms the safety and economic aspects

of the coal pile. This study aims to model finite elements using Multiphysics simulation

to determine the effect of the relative humidity of the pile on the temperature

distribution of large-scale coal piles. Thus, handling methods and things that

must be considered in storing and transporting coal piles can be formulated.

Thermal phenomena modelling in coal piles is modeled using COMSOL Multiphysics

software. The simulation is carried out by varying relative humidity of the

environmental conditions (ambient). The simulation results show that this

parameter can change the level of vulnerability of the pile to burn at an

earlier time.

Coal; COMSOL; Modeling; Relative Humidity; Spontaneous Combustion

Coal spontaneous fires have received a lot of attention, especially in terms of safety. There have been catastrophic events in the coal industry due to the susceptibility of coal piles to burn themselves (Kong et al., 2019). Although much of the spontaneous combustion of coal is related to laboratory scale, in reality, this problem often occurs in large-scale industries. Recently, studies on the tendency of coal piles to experience spontaneous fires continue to concern some researchers worldwide. Since 1924, testing methods have been introduced to determine the factors that play a role in the tendency of coal to burn on its own (Wang et al., 2018; Davis and Byrne, 1924). However, the problems faced in industrial conditions are very different from what occurred on a laboratory scale; namely, coal piles have a vast dimension. Therefore, the approach or method of testing used in the laboratory must reflect physical and chemical phenomena at large scales. This statement has been discussed alongside overviews regarding typical industrial spontaneous combustion characteristics in ref (Shi et al., 2022). Due to laboratory limitations in conducting large-scale testing, researchers continue to strive to study the phenomenon of spontaneous fires through numerical studies.

The development of numerical studies related to spontaneous coal fires has entered the domain of CFDs (Taraba et al., 2014) and multiphysics simulations (Thabari et al., 2021; Saleh et al., 2017). Large-scale simulations with stockpile conditions exposed to prolonged ambient thermal exposure have been done before (Zhang et al., 2016; Taraba et al., 2014). However, these studies ignore the influence of water content, both in the air in the form of relative humidity (RH) and the moisture concentration of coal in its simulation. In reality, RH is a vital parameter determining coal's susceptibility to spontaneous combustion phenomena. Another study (Wang et al., 2018) provides that RH is vital in initiating spontaneous fires in coal piles.

This study seeks to improve previous studies by involving the influence of RH from the air in a simulated process. The simulation was conducted using COMSOL Multiphysics which proved capable of modeling spontaneous coal fire simulations on a large scale (Li et al., 2021). The model is validated by comparing the simulation results with similar references, especially temperature and flow development.

2.1. Chemical Kinetics

The process of spontaneous combustion in coal is initiated by an oxidation reaction that is influenced by temperature and other factors. Despite its complexity, previous research conducted by Carras and Young (1994) and Yuan and Smith (2008) have determined that the rate of oxidation reactions in coal piles can be simplified to

2.2. Momentum Conservation

2.3. Energy Conservation

The heat transfer that occurs from forced convection in an environment with ambient temperature occurs with the following equations 12 and 13 as follows:

The heat generated from the oxidation reaction in a pile is modeled according to equation (1) and equation (3). However, equation (3) shall be modified by including porous fraction so that it becomes equation 14 as follows:

In the simulation with RH, the gas flow that enters the pile is

considered air with certain humidity.

2.4. Species Conservation

2.5. Boundary Condition

On

each side, there is heat transfer due to convection by external ambient

conditions with a convective heat transfer coefficient of 7.5 W/m2.K

(Krishnaswamy

et al., 1996). The moving wind flow is assumed to be the air

containing only O2 in a 21% mass fraction. Table 1 contains all set

parameters for the boundary conditions.

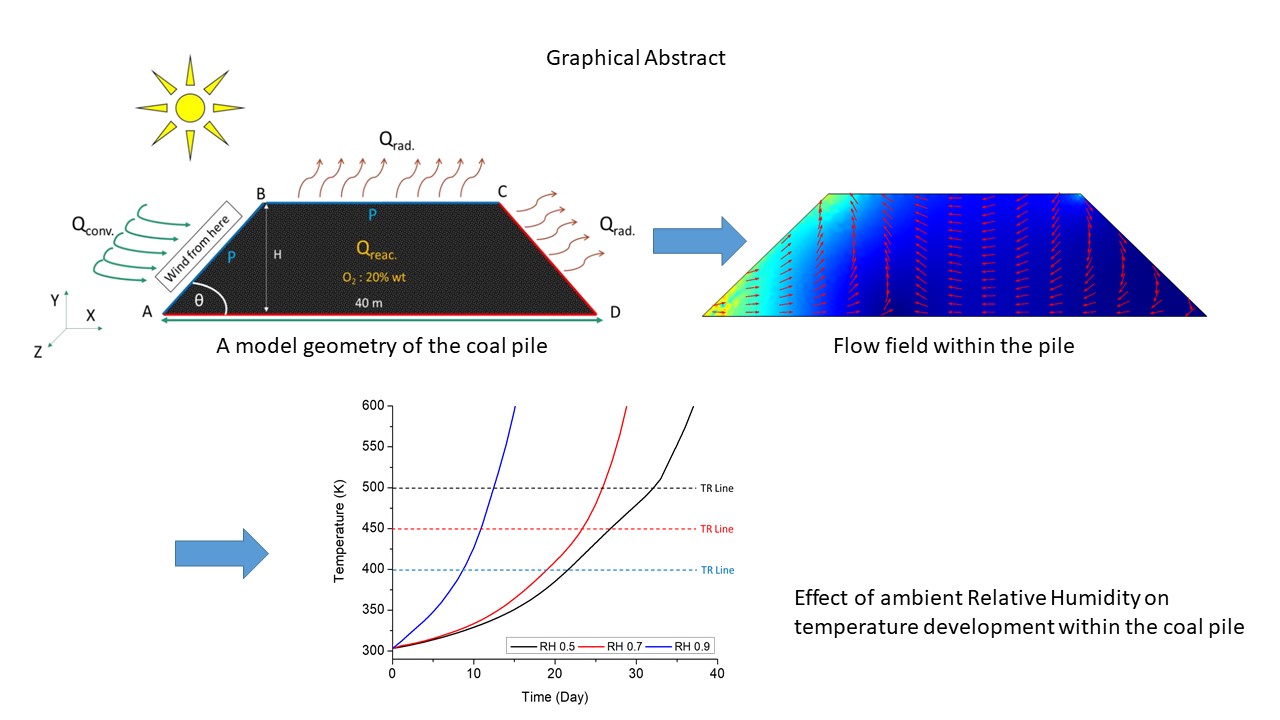

2.6. Model Geometry

Two coal pile geometries are depicted in two dimensions in this study. The geometry of the first pile refers to the following sources (Zhu et al., 2013) to validate the species transport equation (can be seen in Figure 2). The coal pile is depicted as a trapezoid with a base length of 12 m and a height of 6 m. The angle of the inclined part of the pile is 56.3°. As seen from Figure 1, the second pile geometry is chosen to facilitate the change (variation) of some test parameters. The second pile also has a similar shape, namely a trapezoid with a height of 10 m, an angle value of 45°, and the length maintained at 40 m.

Figure 1 Model

Geometry

It is

worth mentioning that the angle of pile correlates to the capacity of the

coal-handling facility. Even though it is not discussed further in this study,

this angle characteristic might be impactful because it correlates with the

drag force of the wind. The model is assumed to have an infinite size in the

z-axis direction. The simulation is carried out by taking a slice from the pile's

center. With a very long geometry in the z-axis direction, the effect of the

phenomenon in the z-direction is assumed to have no significant impact.

2.7. Model Assumption

The model in this study was developed by making assumptions in several

parts. It is done to reduce the computational load but still provide

representative results for the experiment. The assumptions are 1. The particle

size of the pile is assumed to be uniform; 2. The porosity of the pile is

assumed to be uniform for each point; 3. The spread of molecules in the stack

occurs by diffusion; 4. The heat source involved in the heat transfer process

is the convection process from the environment and the heat from the oxidation

process; 5. The phenomenon of movement of water particles (moisture) from coal

is not modeled; 6. Coal is considered a dry pile; 7. The intrinsic effect of

coal is neglected; 8. The characteristics of the simulated coal samples are

taken from (Chen et al., 2018) unless explicitly mentioned; 9. All simulations were transient

simulations with the time step of 1 day; 10. All simulations were assigned with

303 K ambient temperature.

The model is validated

using the following reference (Zhu

et al., 2013), including the input

physical and chemical parameters. This study selected a wind speed value of 0.05 m/s

and 1 m/s to match the results with the reference. This study attempts to apply

the transport of concentrated species interface to case studies. The Transport

of Concentrated Species (TCS) interface is selected based on COMSOL usage

guidelines that state that transport of diluted species is suitable for use

when the number of solvents reaches 90% (COMSOL,

2019). In Zhu's study, the

only species modelled was O2. In general, the composition of air is

21% O2 and 79% N2 by mass fractions Assuming that N2

is solvent, the interface is less precise to use. N2 is also

considered inert and only used as a mass train (Wu et al., 2016). It is known that the nitrogen content is still relatively stable to a

temperature of 600°C (Pels et al., 1995) and requires a temperature that can be reached up to 1200°C

to be able to react to the process of pyrolysis coal (Jiao et al., 2021) so the selection of N2 as inert in this study is still

entirely appropriate. In terms of validation, the isothermal contour

distribution of the study results is comparable to the exact parameters of

reference (Zhu et al., 2013) through Figure 2.

It is seen that the models that apply the

TCS interface can describe similar results with the reference. However, there

is a slight difference from the maximum temperature value achieved. In the

study with wind speeds of 0.05 m/s, the maximum temperature reached was 396 K.

Meanwhile, the maximum temperature recorded by this study on the same day and

conditions was 367 K. The same thing was also seen in the simulation results

with wind speed conditions of 1 m / s. The maximum temperature value recorded

from this study is 367 K. At the same time, the reference shows a value of 410

K. This difference is obtained due to the effort to use dynamic parameters in

the simulation model. The dynamic parameters used are the air's thermal

characteristics and the magnitude of the O2 flux that goes into the

pile. Thermal characteristics of air are obtained from the COMSOL Material

Library, while flux O2 is described through equation 27.

Although

discrepancies exist, it is worth noting that this study also reached a

temperature (80 – 90°C) where coal pile spontaneous combustion has occurred,

similarly like what was done in (Zhang et al., 2016).

Figure 4 Temperature distribution

(Top-Left); O2 consumption rate (Top-Right); CO2

production rate (Bottom-Left); CO-Production rate (Bottom-Right); on the 30th

day with the following configurations (1 cm particle size, 0.3 porosity, 1 m/s

velocity, 0.7 RH)

There

are two studies described the flow patterns in large-scale coal piles when they

are affected by wind (Taraba et al., 2014, Zhang et al., 2016). In both

studies, the computing domain was determined as very large to minimize the

outlet's influence of wind flow on coal piles. Based on Figure 3, the

simulation results from this study showed a flow pattern in a good resemblance

as reported in (Taraba et al., 2014, Zhang et al., 2016). Simulation

results show that the flow is experiencing circulation where air enters from

the side of the pile and goes towards the top end of the pile. In ref (Zhang

et al., 2016), this was described as

the chimney effect. From the study, it can also be observed that although a

stream of wind flows down the other side of the pile, the temperature

development on that side is not very significant. It can happen because the

flow does not provide the power to penetrate the cracks of the pile which

allows oxygen to enter and initiate the dominant oxidation process.

The flow rate tends upwards because the pressure recorded at

the top end of the pile is lower when compared to the pressure within the pile.

Therefore, O2 coming through the sides also experiences a tendency

to move towards the flow. Nevertheless, the reactivity of coal makes oxygen

consumed on its way to a low-pressure point. It is seen that the hot spot of

the pile is centered around the area where the rate of O2

consumption is very dominant. It gives the idea that the oxidation process

continues to occur in the lower third of the pile where the pressure is more

dominant, allowing O2 to enter and penetrate the cracks of the pile

and react before the oxygen makes it to the top of the pile. The region where

the highest temperatures are observed is also where the CO and CO2

production rate is seen highest.

3.3. Relative Humidity

Figure 5 Left: T-t graph on RH variation.

Right: T-t graph on velocity variation

The

simulation results

(Figure 5) show that with RH conditions of 0.5, the time required for the pile to

reach the thermal runaway (TR) phenomenon

is 33 days. Increasing the value to RH 0.7 shortens the time required for the

pile to reach thermal runaway to 25 days. The pile becomes increasingly

critical to experience thermal runaway when the RH value is at the highest

value, which is 0.9. Temperature development results were similar{Wang, 2018 #3} (Wang et

al., 2018). The

mentioned study observed that coal piles would experience an earlier

temperature increase when irrigated with air with a higher RH value. It was also explained that the heat of

rewetting occurs when extra heat is produced due to the

condensation and wetting process of the bulk material. Similar to (Wang et

al., 2018), this model

does not incorporate the

competition between

the evaporation of the pile’s moisture content and heat from the condensation process

because the pile is simulated as a dry pile. The heat (heat of rewetting) is caused by the

condensation of the water content carried by air at the pile's bottom. Alongside

the RH graph, the Temperature – time graph of the velocity effect shows that

the coal pile’s susceptibility toward spontaneous combustion increases as the

velocity (wind) increases. Future

developments can be made to simulate the competition process between moisture

evaporation and heat of rewetting in order to better analyze phenomena that may

occur in real-world conditions.

This study was done to observe how relative humidity could influence

the susceptibility of coal piles to undergo spontaneous combustion. Two coal

pile geometry were simulated, where one was done for model validation purposes

only. This study's result strengthens the fact that a higher relative humidity

value could make the coal pile more prone to spontaneous combustion. Given the result that ambient

condition is influential toward spontaneous coal combustion, adjustments to the

geographical conditions of the storage area or shipping lane to be traversed

can provide knowledge for managers in preparing appropriate plans/scenarios in

the storage or transportation process. Hence, it can increase the safety factor of the pile for the mentioned scenarios. Nevertheless, this study was done

in two-dimensional (2D) shape, where the assumption of very long geometry

toward one direction (here, it is z-axis direction). This assumption might fall

through for cases with intermediate sizes and might require three-dimensional

(3D) simulations. Therefore, future study with 3D simulations might help to

provide more understanding for coal spontaneous combustion in wider range of

large pile in storage transportation.

The authors would like to thank the financial support provided by

the Ministry of Education, Culture, Research, and Technology of the Republic of

Indonesia through Penelitian Dasar Unggulan Perguruan Tinggi (PDUPT) 2021

funding scheme under Grant No. 8/E1/KP.PTNBH/2021 dan

NKB-218/UN2.RST/HKP.05.00/2021 managed by the Directorate for Research and

Public Services (DRPM) Universitas Indonesia.

Chen, X., Li, H., Wang, Q., Zhang, Y., 2018.

Experimental investigation on the macroscopic characteristic parameters of coal

spontaneous combustion under adiabatic oxidation conditions with a mini

combustion furnace. Combustion Science

and Technology, Volume 190(6), pp. 1075–1095

COMSOL, 2019. Chemical reaction

engineering module user’s guide. In COMSOL, p. 122

Davis, J.D.,

Byrne, J.F., 1924. An adiabatic method for studying spontaneous heating

of coal1. Journal of the American

Ceramic Society, Volume 7(11), pp.

809–816

Jiao, T., Fan, H., Liu, S., Yang, S., Du, W.,

Shi, P., Yang, C., Wang, Y., Shangguan, J., 2021. A Review on nitrogen

transformation and conversion during coal pyrolysis and combustion based on

quantum chemical calculation and experimental study. Chinese Journal of Chemical Engineering, Volume 35, pp. 107–123

Kong, B., Wang, E., Lu, W., Li, Z., 2019.

Application of electromagnetic radiation detection in high-temperature

anomalous areas experiencing coalfield fires. Energy, Volume 189, p. 116144

Krishnaswamy, S., Agarwal, P.K., Gunn, R.D., 1996.

Low-temperature oxidation of coal 3. modelling spontaneous combustion in coal

stockpiles. Fuel, Volume 75(3), pp. 353–362

Li, Y., Shi, X., Zhang, Y., Xue, J., Chen, X.,

Zhang, Y., Ma, T., 2021. Numerical investigation on the gas and temperature

evolutions during the spontaneous combustion of coal in a large-scale furnace. Fuel,

Volume 287, p. 119557

Nugroho, Y.S., Rustam, R.R., Saleh, I., Saleh,

M., 2008. Effect of humidity on self-heating of a sub-bituminous coal under

adiabatic conditions. Fire Safety Science,

Volume 9, pp. 179–189

Pels, J.R., Kapteijn, F., Moulijn, J.A., Zhu,

Q.,Thomas, K.M., 1995. Evolution of nitrogen functionalities in carbonaceous

materials during pyrolysis. Carbon, Volume

33(11), pp. 1641–1653

Saleh, M., Muharam, Y., Nugroho, Y., 2017. modeling

of the crossing point temperature phenomenon in the low-temperature oxidation

of coal. International Journal of

Technology, Volume 8, pp. 104–113

Shi, X., Chen, X., Zhang, Y., Zhang, Y., Guo,

R., Zhao, T., Liu, R., 2022. Numerical simulation of coal dust self–ignition

and combustion under inclination conditions. Energy, Volume 239, p. 122227

Taraba, B., Michalec, Z., Michalcová, V.,

Blejcha?, T., Bojko, M., Kozubková, M., 2014. CFD simulations of the effect of

wind on the spontaneous heating of coal stockpiles. Fuel, Volume 118, pp. 107–112

Thabari, J.A., Supit, S., Nirbito, W.,

Muharam, Y., Nugroho, Y.S., 2021. Modeling on the effect of heat exchanger

submersion on controlling spontaneous combustion in a coal pile. Journal of Advanced Research in Fluid

Mechanics and Thermal Sciences, Volume 81(1), pp. 158–164

Wang, X., Luo, Y., Vieira, B., 2018.

Experimental technique and modeling for evaluating heat of rewetting effect on

coals' propensity of spontaneous combustion based on adiabatic oxidation

method. International Journal of Coal

Geology, Volume 187, pp. 1–10

Wen, H., Yu, Z., Deng, J., Zhai, X., 2017.

Spontaneous ignition characteristics of coal in a large-scale furnace: an

experimental and numerical investigation. Applied

Thermal Engineering, Volume 114, pp. 583–592

Wu, D., Vanierschot, M., Verplaetsen, F.,

Berghmans, J., Van den Bulck, E., 2016. Numerical study on the ignition

behavior of coal dust layers in air and O2/CO2 atmospheres. Applied Thermal Engineering, Volume

109, pp. 709–717

Yuan, L., Smith, A.C., 2008. Numerical study

on effects of coal properties on spontaneous heating in longwall gob areas. Fuel,

Volume 87(15), pp. 3409–3419

Zhang, J., Liang, Y., Ren, T., Wang, Z., Wang,

G., 2016. Transient CFD modelling of low-temperature spontaneous heating

behaviour in multiple coal stockpiles with wind forced convection. Fuel Processing Technology, Volume

149, pp. 55–74

Zhu, H.Q., Song, Z.Y., Tan, B., Hao, Y.Z., 2013. Numerical investigation

and theoretical prediction of self-ignition characteristics of coarse coal

stockpiles. Journal of Loss Prevention in

the Process Industries, Volume 26(1), pp. 236–244