Accident Tolerant Fuel Cladding Materials for Light Water Reactors: Analysis of Neutronic Characteristics

Corresponding email: ferhat.aziz@brin.go.id

Published at : 17 May 2024

Volume : IJtech

Vol 15, No 3 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i3.5345

Aziz, F., Rivai, A.K., Panitra, M., Dani, M., Suharno, B., 2024. Accident Tolerant Fuel Cladding Materials for Light Water Reactors: Analysis of Neutronic Characteristics. International Journal of Technology. Volume 15(3), pp. 608-617

| Ferhat Aziz | Research Organization of Nuclear Energy, National Research and Innovation Agency, B.J Habibie Science and Technology Complex, Serpong, Tangerang Selatan 15310, Indonesia |

| Abu Khalid Rivai | Research Organization of Nuclear Energy, National Research and Innovation Agency, B.J Habibie Science and Technology Complex, Serpong, Tangerang Selatan 15310, Indonesia |

| Mardiyanto Panitra | Research Organization of Nuclear Energy, National Research and Innovation Agency, B.J Habibie Science and Technology Complex, Serpong, Tangerang Selatan 15310, Indonesia |

| Mohammad Dani | Research Organization of Nuclear Energy, National Research and Innovation Agency, B.J Habibie Science and Technology Complex, Serpong, Tangerang Selatan 15310, Indonesia |

| Bambang Suharno | Department of Metallurgy and Materials, Faculty of Engineering, Universitas Indonesia, Depok 16424, Indonesia |

Nuclear reactor fuel is the basic component of all safety requirements

associated with nuclear energy production. The neutronic characteristics of light water

reactors with candidate accident-tolerant fuel cladding materials were

investigated in this work to improve nuclear safety. The materials were chosen

for their high-temperature strength, radiation resistance, and corrosion

resistance, which will contribute to nuclear safety. The research was conducted

using a deterministic neutronic code for reactor design and analysis. The

neutronic properties of a light water reactor system with candidate cladding

materials were analyzed and compared to those of the reference. The reference

cladding material was Zircaloy-4, and the candidate fuel cladding materials

examined were FeCrNi alloy, oxide dispersion strengthened steels of FeCrY2O3

and FeCrZrO2. The eigenvalues of the reactor were computed at

various fuel temperatures and burnup stages. The results of the study revealed

that employing candidate cladding materials led to a slightly hardened neutron

spectrum, reducing initial excess reactivity and resulting in lower fuel burnup. This can be compensated by adding fuel

enrichment up to 6%., which yields burnup value of 42000 MWd/T, which is higher

than the reference of 40000 MWd/T with a

reduced gap in initial excess reactivity from 28.4% to 25.4%.

The candidate fuel cladding materials also showed better than reference

reactivity loss properties in case of unwanted temperature increase. This

demonstrated that the examined improved tolerant materials have the ability to

increase the inherent safety of nuclear reactors.

ATF cladding; Doppler coefficient; Neutronic characteristics; Nuclear safety; Oxide dispersed strengthened

Nuclear energy is the most modern energy source, capable

of producing massive amounts of clean energy safely and reliably. This is

required to run modern industrial societies economically and sustainably, both

environmentally and in terms of the availability of resources. As a result, nuclear energy should play a

significant part in the necessary transformation of the 21st-century

energy-supply system. Moreover, modern technology can support the advancement

of a sustainable energy sector that is capable of efficient production,

management, and control. This can help strike a balance between economic

progress, effective ecosystem management, and environmental conservation (Berawi, 2021; Berawi et al., 2020; Brook et

al., 2014).

Following the core melt accident at the

Fukushima Daiichi nuclear power plant, there has been a growing interest in

novel approaches to improving nuclear safety. Existing knowledge must integrate

with modern, environmentally friendly innovation in safety technology (Yadav, Pal, and Karthikeyan, 2023; Rivai et al.,

2022). High-temperature water

vapor interaction with zirconium alloy cladding employed in

the light water reactor (LWR) exacerbated the accident, resulting in the

discharge of volatile hydrogen gas.

Researchers have since been studying ways to improve reactor safety in

the event of a loss of coolant, such as the feasibility of using accident-tolerant

nuclear fuel cladding options (Prianka and Prodhan,

2024; Takeda et al., 2016). Different potential cladding

materials for light water reactors have been investigated as alternatives to

the zirconium alloys widely used in LWRs.

Nuclear energy's viability as a clean and safe source of energy for many

developing countries will undoubtedly increase as technology advances and

delivers reliable and uninterrupted electrical energy systems to the consumers with appropriate technological

conditions for all parts of the electric networks (Gracheva et al., 2020, Antariksawan et

al., 2017, George et al., 2015, Soentono and Aziz, 2008).

Because of its low parasitic neutron absorption, zirconium alloy fuel cladding has been widely used since

the inception of commercial nuclear power plants (Thilagam

and Mohapatra, 2023). However, in a design-based accident

scenario, a condition may result in a reduction in safety margins. It is widely acknowledged that the outcome of a severe accident

scenario in a Light Water Reactor (LWR) is primarily influenced by the

operation and availability of safety systems. Given this feature, many

researchers are collaborating to investigate new fuel and cladding concepts

that provide better safety margins (Chen and Yuan,

2017; Dobuchi, Takeda, and Kitada, 2016; Barrett, Bragg-Sitton and Galicki,

2012;).

The accident tolerant fuel (ATF) cladding concept refers to

approaches to developing new types of fuel cladding materials with improved properties at

higher temperatures. In this concept,

zirconium alloy is modified or replaced with another high-performance oxidation-resistant

material to improve nuclear safety. The

potential cladding materials should also have high-temperature stress

resistance and low thermal neutron absorption cross-section for neutron economy

(Dani et al., 2023). Chromia,

alumina, and silica formers are recognized for their resistance to

high-temperature steam oxidation and low neutron capture cross-section.

Consequently, any new cladding material must incorporate at least one of the

elements Cr, Al, or Si (Sakamoto et al.,

2018; Terrani, 2018; Eiselt et al., 2016; Pouchon et al., 2005).

Among the many alternatives, FeCrNi alloy and ODS

(Oxide Dispersion Strengthened) stainless steels have been found to outperform

Zircaloy-4 in mechanical performance and are thus considered among the most promising candidates (Panitra, Rivai and Aziz, 2022). In the event of

an accident, the cladding materials can prevent a hydrogen explosion by

suppressing hydrogen generation caused by the oxidation of zirconium-based

alloys at high temperatures. They can also endure extremely corrosive

conditions at high temperatures. Furthermore, they are resistant to void

swelling and structural deformation. This study's use of FeCrY2O3

and FeCrZrO2 as cladding materials is of special relevance because

of the current effort to use local rare-earth elements such as yttrium, which

may be found in bauxite residue from the aluminum industry and zirconium, which

is abundant in Kalimantan (Kusrini et al.,

2020; Lu et al., 2017; Younker and Fratoni, 2016; Pint et al.,

2015; Li et al., 2013).

The neutronic behavior of

an LWR core was investigated using the SRAC (Standard Reactor Analysis Code)

system, a deterministic nuclear reactor analysis code. SRAC is a versatile and widely used tool for

different reactor core calculations. The

nuclear data used was JEFF (Joint Evaluated Fission and Fusion File) produced

through a collaboration of NEA Data Bank participating countries (NEA Data Bank, 2021; Okumura, Kugo and Tsuchihashi,

2007).

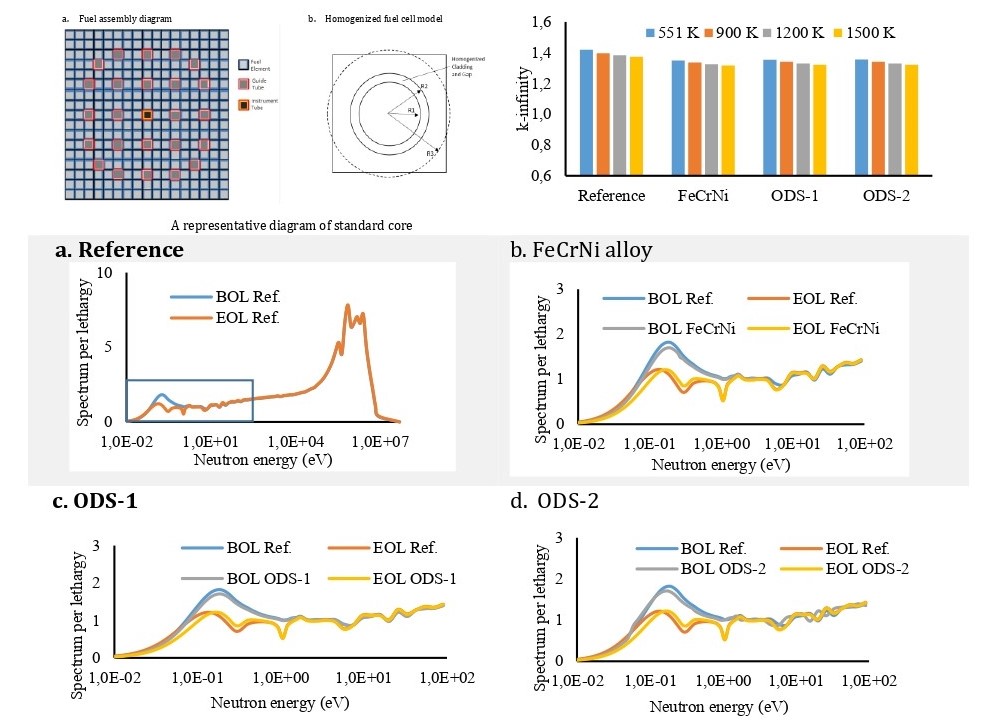

Figure 1 shows a representative diagram of a fuel assembly in a nuclear reactor. Geometric parameters and model description were based on the cylindrical model of a standard 17×17 fuel assembly of 1000 MW LWR, as shown in Figure 1a. In this investigation, control rods and instruments were assumed to be withdrawn from the reactor core. The simulation was based on a single unit of fuel assembly homogenized into a unit cell depicted in Figure 1b. The pitch-to-rod diameter was kept constant to maintain power transfer. The spacing between the pellet and the cladding was kept constant to maintain the thermal conductivity of the gap. The temperature in the fuel pellet, cladding, and moderator was varied in steps to investigate the effect of temperature on reactivity. The fuel pellet radius in this calculation was 4.12 mm, the homogeneous cladding plus gap thickness was 0.64 mm, the cladding outer radius was 4.76 mm, and the reference fuel enrichment was 4.12 percent. The 235U enrichments in the fuel with the ATF cladding were varied in this calculation at 4.12 percent, 5.35 percent, 5.60 percent, and 6.00 percent to investigate their effect on core neutronics. Under normal operating conditions, the fuel temperature is 900 K, the cladding temperature is 600 K, and the coolant temperature is 562 K.

Figure 1 A representative diagram

of standard 1000 MWe LWR 17x17 fuel assembly (a), and the model for the cell

homogenization where R1, R2, and R3 refer to fuel pellet radius, outer radius

of fuel cladding, and equivalent radius of coolant, respectively (b)

Table 1 The weight percentage of cladding materials used in this study

|

Zircaloy-4 |

Zr-Sn-Fe-Cr

(balance, 1.5, 0.3, 0.2) |

|

FeCrNi

alloy |

Fe-Cr-Ni

(balance, 20.0, 10.0) |

|

ODS-1 |

Fe-Cr-Y2O3

(balance, 10.0, 0.5) |

|

ODS-2 |

Fe-Cr-ZrO2

(balance, 25.0, 0.5) |

The cladding composition in

weight percent of Zircaloy-4, FeCrNi alloy, ODS-1, and ODS-2 is shown in Table 1.

Table 2 shows the main parameters of the reference LWR under consideration. When evaluating the Doppler coefficient,of the LWR design, we used the parameters given in Table 3.

Table

2 The LWR main parameters used in this neutronic

characteristics analysis

|

Thermal

Power |

3,000

MW |

|

Electric Power |

1,000 MWe |

|

Fuel enrichment of 235U |

4.12 % (reference), 5.35%, 5.60%, and 6.00%. |

|

Fuel type |

UO2 |

|

Fuel density |

10.28 g/cc |

|

Cladding Fuel Burnup |

Zircaloy-4, FeCrNi alloy, ODS-1,

ODS-2 40000 MWd/T |

|

Fuel cycle |

3 years |

|

Coolant/moderator |

water |

|

Core shape |

cylindrical |

Table 3 Parameters used in the Doppler coefficient

calculation

|

Parameter |

HZP |

HFP |

|

Fuel

temperature, (K) |

551.0 |

900.0 |

|

Cladding

temperature, (K) |

551.0 |

600.0 |

|

Moderator

(coolant) temperature, (K) |

551.0 |

562.0 |

|

Moderator

(coolant) density (kg/m3) |

766.0 |

748.0 |

The

reactivity, p, of the LWR core, can be calculated from Equation 1.

p=(k-1)/k (1)

where k is the neutron multiplication factor. If the value of k is larger than one, the reactivity is called excess reactivity (pex).

The value of k, meaning the ratio of

the number of neutrons produced in one generation to the number of

neutrons absorbed in the preceding one, can be obtained from the core

eigenvalue or criticality calculation using SRAC. Hence, reactivity implies a deviation of a multiplication factor from one, and excess reactivity may be used as a measure of a reactor’s departure from criticality.

The safety performance of

accident-tolerant cladding materials can be expressed in terms of the temperature coefficient of reactivity, shown in Equation 2. The term

represents the change in reactivity per unit change

in fuel temperature (Kim and Jo, 2015).

The

where

The SRAC calculations in this work were performed in 16 energy coarse groups, condensed from the original 107 groups. The energy grouping was done to expedite macroscopic constant generation in cell calculation. The structure of neutron energy grouping was emphasized in the area around thermal energy group regions (0.025 eV-1.0 eV). Figure 2 displays the neutron energy spectrum of the considered reactor, acquired from the SRAC cell burnup calculation. This result aligns well with the calculations from the SCALE code (Detkina et al., 2020) and MCNPX calculation. Figure 2a shows the spectrum for the referenced LWR at the beginning of life (BOL) and end of life (EOL). Because the thermal to low-epithermal energy range is of importance in LWR, we compared and magnified the spectrum of the reference cladding with that of candidate cladding materials of FeCrNi alloy displayed in Figure 2b, ODS-1 in Figure 2c, and ODS-2 in Figure 2d.

Figure 2 Neutron energy spectrum at BOL and EOL of (a)

reactor core with reference fuel cladding, and the zoomed around thermal energy

spectrum of that with (b) FeCrNi alloy, (c) ODS-1 and (d) ODS-2

The result showed that the neutron spectra for the FeCrNi

alloy, ODS-1, and ODS-2 are slightly shifted to higher energy (hardened)

compared to the reference. The shift is

due to the increase in the energy

of some of the thermal neutrons by way of collision with the new ATF cladding materials,

which have much lower atomic mass than the reference. Accumulation of fission products and actinides towards EOL

further increases unwanted thermal neutron reactions. Hardened neutrons mean

the presence of fewer thermal neutrons needed for the fission reaction to occur

(Detkina et al., 2020; Chen and Yuan, 2017).

The effect of fuel burnup on the excess reactivity for ATF cladding under examination is shown in Figure 3, which is computed at hot full power. As a result of spectrum hardening, the excess reactivity was reduced relative to the reference. Figure 3a shows at the BOL, the excess reactivity of the reference 4.12% enrichment fuel is 28.4%dk/k, while the average values for ATF claddings under examination are around 20.6%dk/k and capable of only around 26000MWd/T burnup. Here, it is demonstrated that compared to the reference cladding, all three proposed cladding materials FeCrNi alloy, ODS-1, and ODS-2 - exhibited lower initial excess reactivity values. As a result, they would not supply sufficient excess reactivity to achieve the same final burnup level as the reference (40000 MWd/T).

To overcome this, one needs to increase the fuel

enrichment to a higher level. In this study, the excess reactivity was improved by raising the fuel

enrichment stepwise up to 6%, thereby improving the fuel burnup to approach the

reference case. A fuel enrichment of 5.35%, as shown in Figure 3b, improved the

fuel burnup to about 38000 MWd/T. A fuel enrichment of 5.60%, shown in Figure

3c, yielded an excess reactivity that was enough to maintain the reactor core

to match the burnup of the reference. However, further fuel enrichment up to

6.00%, as shown in Figure 3d exhibited a higher burnup capability of the

reactor core up to 42000 MWd/T with a reduced gap in initial excess reactivity

from 28.4% to 25.4%. This showed that in general, the new cladding materials

give lower initial excess reactivity than the reference material does to the

LWR. The lower initial reactivity can be caused by the spectrum hardening in

the thermal region, especially as fuel is consumed toward its end-of-life. The

deficiency in initial reactivity can be overcome by increasing the fuel

enrichment. As the fuel enrichment is increased, the rate of decrease in the

excess reactivity becomes less than that of the reference, such that it is

possible to have higher than reference fuel burnup at the EOL, as shown in

Figure 3d.

In terms of reactivity loss resulting from a change in fuel temperature, Figure 4 illustrates the behavior of the LWR reactor. The figure demonstrates that, in all cases, excess reactivity is consistently lost with any increase in fuel temperature, underscoring the critical importance of this nuclear safety parameter. There are two main contributions to this situation. First, increasing fuel temperature increases resonance capture in 238U. As the temperature rises, the resonance peaks broaden over a wider range of neutron energies, allowing more neutrons to be captured. Second, the ratio of fission to absorption in the fuel changes with fuel temperature, depending on whether the fuel is fresh or in equilibrium fuelling. This ratio decreases as thermal neutrons speed up due to a temperature increase in fresh fuel where 235U is the only fissile nuclide at BOL. With a significant amount of 239Pu created via the transmutation of 238U, the ratio rises at EOL.

Figure 4 Reactivity loss due to fuel

temperature rise at 4.12% fuel enrichment, (a) the reference; (b) FeCrNi alloy

cladding; (c) ODS-1 cladding; and (d) ODS-2 cladding

At BOL, as the temperature of thermal neutrons

increases, less of the neutrons absorbed in the fuel generate fission. Atom 235U prefers thermal neutrons

as opposed to 239Pu, which prefers “hotter” neutrons. As a result, increasing the thermal neutron

temperature reduces the reactivity of fresh fuel. At EOL, due to the presence

of 239Pu, the reactivity increases with increasing thermal neutron

temperature.

The

results of a neutronic analysis of LWR using candidate tolerant fuel cladding

materials of FeCrNi alloy, ODS-1, and ODS-2 were compared to the reference

material of Zircaloy-4. The calculations

were carried out using the SRAC Code and the JEFF nuclear data file. It was

shown that neutron spectrum hardening occurred when the candidate cladding

materials were used. The hardening was responsible for the lower excess

reactivity value when compared to the reference. As a result, increasing fuel

enrichment to compensate for the reduction in initial reactivity is recommended

to match the reference reactor fuel cycle. The reactivity loss due to temperature

increase in BOL was slightly higher than in EOL, indicating that 239Pu

buildup reduced the reactivity loss in the hardened spectrum environment. The Doppler coefficients in the candidate

cladding materials were found to be comparable to the reference. Our study also

confirmed that the candidate accident-tolerant fuel cladding materials of

FeCrNi alloy, ODS-1, and ODS-2 demonstrate the negative temperature coefficient

of reactivity of the reactor core examined, which is an important feature in

the safety LWR.

The authors would like to extend their

gratitude to the management of BRIN for enabling this work. This research

received partial support from the Productive Innovative Research Program

(RISPRO) National Research Priority (PRN) on Commercial Nuclear Power Plant,

LPDP of the Ministry of Finance, under Contract No. 2/E1/III/PRN/2021.

Antariksawan, A.R., Umar, E., Widodo,

S., Juarsa, M., Kusuma, M.H., 2017. TRIGA-2000

Research Reactor Thermal-hydraulic Analysis using RELAP/SCDAPSIM/MOD3.4. International

Journal of Technology, Volume 8(4), pp. 698–708

Aziz, F., Panitra, M., Rivai, A.K., 2018. Synthesis and

Monte Carlo Simulation of Improved Concrete Composites for Enhanced X-Ray/Gamma

Ray Radiation Shielding. International Journal of Technology, Volume

9(4), pp. 695–706

Aziz, F., Panitra, M., Rivai, A.K., Silalahi, M., Sabrina, N.,

Dani, M., Setiawan, M.B., Setiadipura,

T., 2020. Investigation on Neutronic Properties of ZrC Coated Advanced TRISO

Fuel for High-Temperature Gas-Cooled Reactors. Journal of Physics:

Conference Series, Volume 1436, p. 12036

Barrett, K., Bragg-Sitton, S., Galicki, D., 2012. Advanced

LWR Nuclear Fuel Cladding System Development Trade-off Study. Idaho

National Lab (INL),

Idaho Falls

Berawi, M.A., 2021. Managing Cross-Sectoral Coordination in

Accelerating the Sustainable Development Agenda. International Journal of

Technology, Volume 12(2), pp. 228–231

Berawi, M.A., Suwartha, N., Surjandari, I., Zagloel, T.Y.M.,

Asvial, M., Harwahyu, R., Suryanegara, M., Setiawan, E.A., Maknun, I.J.,

Kusrini, E., Kartohardjono, S., Sofyan, N., Yuwono, A.H., Harjanto, S., Putra,

N., Budiyanto, M.A., Whulanza, Y., 2020. Accelerating Sustainable Energy

Development through Industry 4.0 Technologies. International Journal of

Technology, Volume 11(8), pp. 1463–1467

Brook, B.W., Alonso, A., Meneley, D.A., Misak, J., Blees,

T., van Erp, J.B., 2014. Why Nuclear Energy Is Sustainable and Has to Be Part

of The Energy Mix. Sustainable Materials and Technologies, Volume 1, pp.

8–16

Chen, S., Yuan, C., 2017. Neutronic Analysis on Potential

Accident Tolerant Fuel-Cladding Combination U3Si2-FeCrAl. Science and

Technology of Nuclear Installations, Volume 2017, p. 3146985

Dani, M., Aziz, F., Farihin, P.,Dimyati, A., Sukaryo, S.G.,

Lesmana, J.G., Insani, A.,Mustofa, S., Panitra, M., Huang, C.A., 2023.

Microstructures of Austenitic Stainless Steel 56Fe25Ni16.6Cr0.9Si0.5Mn

Solid-Treated with Different Cooling Rates. Philippine Journal of Science

Volume 152 (3): pp. 989–998

Detkina, A., Peakman, A., Litskevich, D., Liang, J., Merk,

B., 2020. Evaluation of BWR Burnup Calculations Using Deterministic Lattice

Codes SCALE-6.2, WIMS-10A and CASMO5. Energies, Volume 13(10), p. 2573

Dobuchi, N., Takeda, S., Kitada, T., 2016. Study on the

relation between Doppler reactivity coefficient and resonance integrals of

Thorium and Uranium in PWR fuels. Annals of Nuclear Energy, Volume 90,

pp. 191–194

Eiselt, C.C., Schendzielorz, H., Seubert, A., Hary, B., de

Carlan, Y., Diano, P., Perrin, B., Cedat, D., 2016. ODS-Materials for High

Temperature Applications In Advanced Nuclear Systems. Nuclear Materials and

Energy, Volume 9, pp. 22–28

George, N.M., Terrani, K., Powers, J., Worrall, A.,

Maldonado, I., 2015. Neutronic Analysis of Candidate Accident-Tolerant Cladding

Concepts in Pressurized Water Reactors. Annals of Nuclear Energy, Volume

75, pp. 703–712

Gracheva, E., Toshkhodzhaeva, M., Rahimov, O., Dadabaev, S.,

Mirkhalikova, D., Ilyashenko, S., Frolov, V., 2020. Modeling the Reliability of

High-Voltage Power Transmission Lines Taking into Account the Influence of the

Parameters of a Sharply Continental Climate. International Journal of

Technology, Volume 11(8), pp. 1557–1569

Kim, K.O., Jo, D., 2015. Analysis of Doppler coefficients

for typical PWR UO2 and MTR U3Si2-Al fuels using ENDF/B-VI and VII. Annals

of Nuclear Energy, Volume 85, pp. 1024–1028

Kusrini, E., Zulys, A., Yogaswara, A., Prihandini, W.W.,

Wulandari, D.A., Usman, A., 2020. Extraction and Enrichment of Lanthanide From

Indonesian Low-Grade Bauxite Using Sulfuric Acid Heap Leaching and Phytic Acid.

Engineering Journal, Volume 24(4), pp. 305–314

Li, S., Zhou, Z., Wang, M., Hu, H., Zou, L., Zhang, G.,

Zhang, L., 2013. Microstructure and Mechanical Properties of 16 Cr-ODS Ferritic

Steel for Advanced Nuclear Energy System. Journal of Physics: Conference

Series, Volume 419(1), p. 012036

Lu, C., Lu, Z., Wang, X., Xie, R., Li, Z., Higgins, M., Liu,

C., Gao, F. and Wang, L., 2017. Enhanced Radiation-tolerant Oxide Dispersion

Strengthened Steel and its Microstructure Evolution under Helium-implantation

and Heavy-ion Irradiation. Scientific Reports, Volume 7(1), p. 40343

NEA Data Bank, 2021. Nuclear Data Service. OECD NEA.

Available online at

https://www.oecd-nea.org/jcms/pl_27360/nuclear-data-services, Accessed on

August 25, 2021

Okumura, K., Kugo, T., Tsuchihashi, K.,

2007. SRAC 2006: A Comprehensive Neutronic

Calculation Code System. JAEA

Data/Code 2007-004, Japan Atomic Energy Agency, Tokai, Ibaraki, Japan

Panitra, M., Rivai, A.K., Aziz, F., 2022. Simulation Study on the Effect of ODS

Cladding Material on the Criticality of Nuclear Reactors Using MCNP5. In:

AIP Conference Proceedings, Volume 2501 (1), p. 040010

Pint, B.A., Terrani, K.A., Yamamoto, Y., Snead, L.L., 2015.

Material Selection for Accident Tolerant Fuel Cladding. Metallurgical and

Materials Transactions E, Volume 2(3), pp. 190–196

Pouchon, M. A., Dobeli, M., Schelldorfer, R., Chen, J.,

Hoffelner, W., Degueldre, C., 2005. ODS steel as structural material for High

Temperature Nuclear Reactors. ??????? ??????? ????? ? ???????, Volume

2005, pp. 105–108

Prianka, S.E.A, Prodhan, M.M.H., 2024. Evaluation of

neutronic characteristics of accident tolerant fuel concepts in SMART reactor

fuel assemblies using DRAGON. Nuclear Engineering and Design, Volume 421,

p.113100

Rivai, A.K., Aziz, F., Panitra, M.,

Insani, A., 2022. Neutronic

Investigation of a Light Water Reactor with SiC Ceramic As Accident-Tolerant

Fuel Cladding (ATFC) Material. In: AIP Conference Proceedings Volume

2663 (1), p. 070004

Sakamoto, K., Miura, Y., Ukai, S.,

Kimura, A., Yamaji, A., Kusagaya, K., Kondo, T., Yamashita, S., 2018. Progress on Japanese Development of Accident Tolerant

FeCrAl-ODS Fuel Claddings for BWRs. In: Conference Proceedings of

TOPFUEL 2018, pp. 2015–2016

Silalahi, M., Wicaksana, H., Aziz,

F., Ahda, S., Iskandar, M., 2020. A

New Synthesized Microalloys Steel ODS of High Amplitude Ultrasonically

Irradiation. Makara Journal of Technology, Volume 23(3), pp. 111–118

Soentono, S., Aziz, F., 2008. Expected Role of Nuclear

Science and Technology to Support The Sustainable Supply of Energy In Indonesia.

Progress in Nuclear Energy, Volume 50(2–6), pp. 75–81

Takeda, S., Ono, M., Wada, K., Kitada, T., 2016. Study on

the Doppler reactivity worth considering thermal agitation in epithermal range

for various types of nuclear fuels. Annals of Nuclear Energy, Volume 96, pp.

264–269

Terrani, K.A., 2018. Accident Tolerant Fuel Cladding

Development: Promise, Status, And Challenges. Journal of Nuclear Materials,

Volume 501, pp. 13–30

Thilagam, L., Mohapatra, D.K., 2023. Preliminary neutronics

analysis for generation III+ VVER design - VVER-1200. Nuclear and Particle

Physics Proceedings, Volume 341, pp.98-103

Whulanza, Y., 2023. Cohering Existing Technology with

Greener and Modern Innovation. International Journal of Technology,

Volume 14(2), pp. 232–235

Wootan, D., Burns, K., Gates, R., Longoni, G., Schmitt, B.,

2015. A Concept for A Flexible Neutron Source. Transactions of the American

Nuclear Society, Volume 112, pp. 340–343

Yadav K.K., Pal, U., Karthikeyan, R., 2023. Concept of accident tolerant fuel in nuclear reactors. Nuclear and Particle Physics Proceedings. Volume 341, pp.62-66

Younker, I., Fratoni, M., 2016. Neutronic Evaluation of Coating and Cladding Materials for Accident Tolerant Fuels. Progress in Nuclear Energy, Volume 88, pp. 10–18