Synthesis and Characterization of Cellulose Ethers from Screw Pine (Pandanus tectorius) Leaves Cellulose as Food Additives

Corresponding email: venty@mipa.uns.ac.id

Published at : 09 May 2023

Volume : IJtech

Vol 14, No 3 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i3.5288

Suryanti, V., Kusumaningsih, T., Safriyani, D., Cahyani, I.S., 2023. Synthesis and Characterization of Cellulose Ethers from Screw Pine (Pandanus tectorius) Leaves Cellulose as Food Additives. International Journal of Technology. Volume 14(3), pp. 659-668

| Venty Suryanti | 1. Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sebelas Maret, Jl. Ir. Sutami 36 A Surakarta 57126, Indonesia, 2. Center for Research and Development of Biotechn |

| Triana Kusumaningsih | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sebelas Maret, Jl. Ir. Sutami 36 A Surakarta 57126, Indonesia |

| Diah Safriyani | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sebelas Maret, Jl. Ir. Sutami 36 A Surakarta 57126, Indonesia |

| Indri Sri Cahyani | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sebelas Maret, Jl. Ir. Sutami 36 A Surakarta 57126, Indonesia |

Isolation

of

cellulose from Screw pine (Pandanus

tectorius) leaves and its transformation into cellulose ethers have been

successfully conducted. Crystalline cellulose was obtained as a white powder in

40.24% yield from dried Screw pine leaf powder through alkalization with sodium

hydroxide followed by bleaching with sodium hypochlorite. The crystalline

cellulose was converted to methyl cellulose (MC), carboxymethyl cellulose

(CMC), and hydroxypropyl cellulose (HPC) and

obtained 94.6%, 71.47%, and 81.54% yields, respectively. The

physicochemical properties of MC, CMC, and HPC, such as shape, color, pH,

Degree of Substitution (DS), and viscosity meet the standards for application

as a food additive. The pH and viscosity of the synthetic cellulose ethers were

7.53-7.60 and 61.98-62.41 cP, respectively. The DS value for MC,

CMC, and HPC were 1.680, 0.996, and 0.696, respectively. The study

revealed the potential of Screw pine cellulose to obtain food-grade cellulose

ethers since the properties of MC, CMC, and HPC agree with food additive

criteria.

Cellulose; Cellulose ethers; Food additive; Pandanus tectorius; Screw pine

Food additives are often added during food

processing to improve the taste, flavor, color, texture, and nutritional value.

Food additives are also used as preservatives for longer storage. The

consumption of food additives, especially synthetic additives, can cause

long-term negative health effects (Sahu, 2017).

Therefore, there is a great interest in the use of food additives from natural

sources to minimize the side effects. Demand for functional food has been

growing globally (Suryanti et al., 2021; 2020;

2016). Biopolymer-based materials from polysaccharide, especially

cellulose has great potential to be used as food additives (Li et al., 2018). In particular, cellulose

derivatives are widely used as food since they have low viscosity which adds

new properties to food products.

Cellulose can be obtained from

natural resources by acid-alkali treatment. The production of cellulose and its

derivatives from raw materials that are economically cheaper and locally

available is desirable. Cellulose is commonly converted into useful derivatives

by reactions typical of compounds containing hydroxyl groups. The hydroxyl

groups (-OH) of cellulose can be partially or fully reacted with

various reagents to obtain cellulose

ethers with useful properties (Tosh, 2014).

The isolation of cellulose ethers in living organisms, such as plants, animals,

bacteria, fungi, and yeast, is not reported yet. Therefore, synthetic cellulose

ether needs to be developed. Etherification of cellulose changes cellulose’s

solubility significantly, where cellulose ethers dissolve in water, dilute

acids, dilute alkalis, or act as organic solvents. Cellulose ethers, such

as methyl cellulose (MC), carboxymethyl

cellulose (CMC) and hydroxypropyl cellulose (HPC), have demonstrated useful

applications in various areas including food, personal care products, oil-field

chemicals, construction materials, the paper industry, as well as adhesives and

textile industries (Kimani et al., 2016;

Bhatt et al., 2011).

2.1. Materials and Methods

The

Screw pine leaves were obtained from Gunung Kidul coastal area, Yogyakarta,

Indonesia. All chemicals were purchased from Sigma-Aldrich (Germany) and used

without any further purification. Fourier Transform Infrared (FT-IR) spectrum

was obtained by SHIMADZU FT-IR-prestige 21 using a KBr pellet in the range of

4000–400 cm-1. The powder was characterized by X-Ray diffraction

XPert MPD using Cu–K radiation (

= 1.5406 Å; 2

= 5–60°) at the voltage of 40

kV and current at 30 mA. Scanning Electron Microscope (SEM) data were collected

by SEM JSM-6510 with voltage at 10 kV and pressure at 70 Pa. Thermogravimetric

Analysis (TGA) of STA Linseis pt 1600 was used where the sample was heated to 600? at a heating rate of 10oC/min under atmospheric

pressure.

2.2.

Isolation of Cellulose from Screw Pine Leaves

The isolated cellulose was then analyzed by Fourier Transform Infra-Red (FTIR) spectroscopy, Scanning Electron Microscopy (SEM), Thermogravimetric Analysis (TGA), and X-ray Diffraction (XRD).

2.3.

Synthesis of Methyl Cellulose (MC)

MC was synthesized following Viera et al. (2007) method with some modifications. Screw pine leaf cellulose (1 g) was added to a mixture of 50% NaOH (5 mL) and isopropanol (30 mL). The mixture was stirred for 1 h at room temperature. The mixture was then filtered and the residue was mixed with acetone in a ratio of 1:20. The mixture was refluxed for 6 h at 50oC with dichloromethane being added dropwise in a ratio of 1:10. The mixture was neutralized with 10% acetic acid and then washed with 95% ethanol. The residue was dried at 50? to obtain pure MC.

2.4.

Synthesis of Methyl Cellulose (MC)

CMC was synthesized from Screw pine leaves cellulose according to Parid et al. (2018) method with some modifications. The CMC synthesis was performed in two steps: alkalization and etherification of cellulose. In the alkalization reaction, 1 g of cellulose was stirred in a mixture of 3 mL of 20% NaOH and 20 mL isopropanol for 1 h at room temperature. For the etherification reaction, the mixture was heated to 50oC and gradually added with a solution of trichloroacetic acid/isopropanol (1 g: 4 mL) and further stirred for 3 h. The resulting slurry was filtered and neutralized with 10% acetic acid. Then, the residue was rinsed with 95% ethanol to remove undesired by products. The residue was dried at 60oC for 6 h to obtain pure CMC.

2.5.

Synthesis of Hydroxypropyl cellulose (HPC)

HPC was synthesized according to Marseno et al. (2014) method with modifications. Screw pine cellulose (1 g) was added and mixed with 10% NaOH (4 mL) and isopropanol (25 mL). The mixture was stirred for 1 h at room temperature. The mixture was then refluxed for 3 h at 55oC where propylene oxide (1.4 mL) was added in a dropwise. The resulting mixture was filtered and the residue was neutralized with 10% acetic acid and then washed with 95% ethanol. The residue was dried at 60oC for 6 h to obtain pure HPC.

2.6.

Characterization of MC, CMC, and HPC

MC, CMC, and HPC were also measured for pH, degree of substitution

(DS), and viscosity. The cellulose ethers were analyzed by Fourier Transform Infra-Red

(FTIR) Spectroscopy and Scanning Electron Microscopy (SEM).

2.7. Instruments

The

functional groups of the cellulose and cellulose ethers were determined using a

Shimadzu FTIR Prestige 21 model 8201 PC. The surface morphologies of samples were examined by SEM

(JEOL JSM- 6510LA). The

thermal stability of cellulose was studied by thermogravimetric analysis using

an STA Linseis pt 1600 TGA analyzer. The degree of crystallinity of cellulose

was determined using an X-Ray diffractometer (XRD XPert MPD diffractometer).

3.1. Isolation of Cellulose

Cellulose was isolated from Screw

pine leaves by alkalization and bleaching processes. The white cellulose was

obtained in a 40.24% (w/w) yield. FTIR spectrum of isolated cellulose is

consistent with the results reported by Sheltami et

al. (2012). Obtained SEM image showed a typical shape of cellulose.

Cellulose fibers were individually dispersed which were separated and elongated

like ribbons with approximate diameters of 5.97 in the

range of 1.5–17

. The cellulose fibers' size is longer than

that of Screw pine leaf fibers. These results are consistent with research

conducted by Sheltami et al. (2012).

Thermogravimetric analysis of purified cellulose showed that thermal

degradation of cellulose occurred in the range 205-407oC with a significant

weight loss of 86.52%. The X-Ray diffractogram revealed that cellulose

structure was categorized as a crystal I type (Sheltami

et al., 2012). The crystallinity index of the isolated cellulose

was 83.03% which is higher than the value reported for the cellulose of rice

straw at 69.5% (Sheltami et al., 2012)

and bagasse cellulose at 58.77% (Nu et al., 2019). The data obtained from FT-IR, SEM, TGA, and X-Ray

Crystallography analyses confirmed that cellulose has been obtained from Screw

pine leaves.

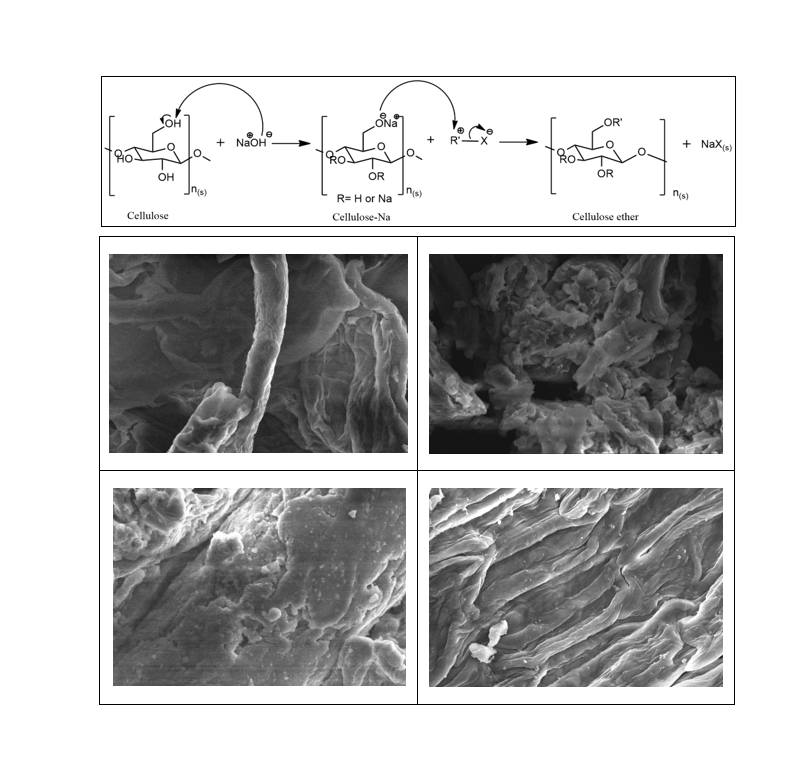

3.2. Synthesis of Cellulose Ethers from Cellulose

of Screw pine (Pandanus tectorius) Leaf

Williamson's etherification reaction was

used to synthesize the MC, CMC, and HPC. Williamson ether synthesis utilizes

deprotonated alcohol and an organohalide to form an ether. The alkoxide ion is a good

nucleophile and displaces halide ions from the alkyl halide to give a new

carbon oxygen bond. An alkoxide is produced by the treatment of alcohol with

either a base or an alkali metal. In this reaction, sodium hydroxide is reacted

with cellulose to obtain Na-cellulose.

The initial step of cellulose ether synthesis was performed by stirring screw

pine leaf cellulose and sodium hydroxide, forming a yellow-brown mass.

In the synthesis of MC, the

etherification step was carried out by the addition of dichloromethane to

Na-cellulose. The MC was obtained as white powders in 94.61% yield. The synthesis of CMC was

accomplished by reacting Na-cellulose and trichloroacetic acid (TCA). CMC is

commonly prepared by the reaction of cellulose with monochloroacetic acid

(MCA). In this work, TCA was used instead of MCA. The CMC was obtained as a white

powder with a 71.47% yield. This yield is double compared to that reported by Bono et al. (2009) (33.15%) for CMC from

palm kernel cake; and Huang et al. (2017) (64.40%)

for CMC from spent tea leaf. The difference in yield could be attributed to the

temperature of the reaction, and the concentration of NaOH and

carboxymethylating agent. The synthesis of HPC was conducted by mixing

Na-cellulose and propylene oxide at 55°C. The HPC was obtained as white powders

in 81.54% yield. The highest yield was obtained for the synthesis of MC may due

to the steric reason where the methyl group caused the least steric bulk.

3.3. FT-IR Spectral Analysis of Cellulose Ethers

FT-IR spectra of the cellulose ethers

confirm the successful synthesis of MC, CMC, and HPC from Screw pine cellulose

(Figure 2 and Table 1). There are typical absorption peaks of MC at 1500-800 cm-1

(Ibrahim et al., 2015; Viera et al.,

2007). An absorption of -CH alkane appears at 1414 cm-1

indicating the presence of methyl compounds of MC. Additionally, the presence

of a peak at 1158 cm-1 for C-O ether and a peak at 1574 cm-1 peak

for C-C confirmed that MC was obtained. The typical cellulose peaks are also

found at 3389-3445 cm-1 for -OH groups, at 2902 cm-1

for -CH (stretching) groups, at 1339 cm-1 for -CH (bending) groups,

at 1022 and 1062 cm-1 for carbonyl (C=O) group (stretching) and at

895-927 cm-1 for -CH uptake (rocking) deformation of the

1,4-glycosidic bond.

Figure 2 FTIR spectra of cellulose (a), MC (b), CMC (c), and HPC (d)

Table 1 FTIR spectra analysis of

cellulose, MC, CMC, and HPC

|

Absorption band (cm-1) |

Functional Groups | |||

|

Cellulose |

MC |

CMC |

HPC | |

|

3384 |

3389-3445 |

3445 |

3445 |

-OH

stretching |

|

2902 |

2902 |

2899 |

2899 |

-CH

stretching of methyl and methylene |

|

- |

- |

- |

1650 |

OH bending (water) |

|

- |

- |

1570-1638 |

- |

-C=O

stretching |

|

1431 |

- |

1416 |

1416 |

-CH2

and -CH3 bending |

|

- |

1317-1414 |

- |

- |

-CH2,

-CH3 scissoring |

|

1321 |

- |

1330 |

- |

C-O

stretching ether group |

|

1112-1163 |

1158 |

1159 |

1159 |

C-O-C

stretching asymmetric |

|

1031-1058 |

1022-1062 |

1024-1066 |

1063 |

O-C-O

stretching of ether |

|

898 |

896 |

895 |

896 |

C-H

bending ( |

The FTIR spectra of

HPC reveal the presence of functional groups of HPC (Joshi

et al., 2019; Marseno et al., 2014; Bhatt et al., 2011;

Sharma et al., 2009). Absorption at 2899 cm-1 and 1416

cm-1 shows C-H and methylene groups of hydroxypropyl cellulose,

respectively. In addition, there is also absorption at 1063 and 1159 cm-1 for

C-O ether (stretching). The typical absorption of cellulose was found at 3445

cm-1 for absorption of the -OH group (stretching), 1323 cm-1

for the -CH group (bending), and 896 cm-1 for absorption of -CH

(stretching) deformation of the 1,4-glycosidic bond. This indicates that

cellulose was successfully modified into HPC.

3.4. SEM Analysis of MC, CMC, and HPC

Figure 3 SEM micrograph of

cellulose (a), MC (b), CMC (c), and HPC (d) at magnification

3000X

3.5. Physical Properties of Cellulose Ethers

The physical properties of cellulose

ethers are presented in Table 2. DS is one of the important parameters in

determining the quality of cellulose ethers. DS is the average number of hydroxyl groups

substituted in every anhydroglucose unit in the chain. The higher the DS value of the product obtained, the better the

cellulose ether quality. DS of cellulose ethers was found to be

dependent upon the source of cellulose, therefore cellulose ethers prepared

from various cellulose sources may have various DS values.

The DS of the MC product was 1.68 which

is in the range of 1.3-2.6 for the DS value of MC as a food additive. The commercial DS of CMC is

0.5-1.5 (Karatas and Arslan, 2016). CMC

having DS below 0.4 is swellable but insoluble in water. CMC having DS above

0.4 is soluble in water, because the hydro-affinity of CMC is enhanced with

increasing DS value (Varshney et al., 2006).

The DS value of synthesized CMC was 0.996, indicating it is soluble in water.

The result is higher than the DS of CMC from palm kernel cake (0.31) and oil

palm fiber (0.29) (Huang et al., 2017).

DS values of CMC from Miscanthus sinensis,

Eichhornia crassipes, and Cyperus papyrus are 0.35, 0.80, and

0.76, respectively (Kimani et al. 2016).

The DS of synthesized HPC was 0.696. This result is in accordance with the

characteristics of HPC as a food additive where the DS value of HPC should be

above 0.12.

The pH of the 1%

solution of MC, CMC, and HPC in distilled water were 7.53, 7.60, and 7.56, respectively. The

pH of food grade MC, CMC, and HPC according to FAO standards are 5-8, 6-8.5, and 5-8.5, respectively.

These results suggest that the pH of the synthesized MC, CMC, and HPC meet the

standards as food additives.

The viscosity value of 1% MC, CMC, and

HPC solution in distilled water was 62.39; 62.41, and 61.98 cP, respectively. These results are in accordance with the MC,

CMC, and HPC standards as food additives. The viscosity of CMC is correlated

with DS value: a higher DS results in higher cation exchangeability and

viscosity. The low DS value indicates fewer hydrophilic groups, which implies

the reduction of the bonding of polymer with water molecules. Higher viscosity

(66.6 cP) was reported for CMC from Palm Kernel Cake (PKC) (Bono et al., 2009) while lower viscosity

(14.0 cP) was reported for CMC from orange mesocarp. The variation in

properties of the different CMC could be a result of the source of cellulose

used, plant species, age, and source which affect the cellulose content

compositions (Carere et al., 2008).

Table 2 Physicochemical properties of MC, CMC, and HPC

|

Properties |

Cellulose Ethers | ||

|

MC |

CMC |

HPC | |

|

Physical

state and Appearance |

white

powder |

white

powder |

white

powder |

|

pH |

7.53 |

7.60 |

7.56 |

|

Viscosity

|

62.39

cP |

62.41

cP |

61.98

cP |

|

DS |

1.680 |

0.996 |

0.696 |

Cellulose was isolated from Screw pine (Pandanus tectorius) leaves in 40.24 % yield employing alkali

treatment followed by bleaching with sodium hypochlorite. The structure of the

obtained cellulose was confirmed by FTIR, SEM, and TGA analysis. Cellulose ethers

have been successfully synthesized from Screw pine leaves cellulose through

Williamson ether synthesis. Cellulose ethers MC, CMC, and HPC were obtained in

94.6%, 71.47%, and 81.54% yields, respectively. The products have been

confirmed by FTIR spectra and SEM images. The physicochemical properties, such

as shape, color, pH, viscosity, and DS suggest that synthesized MC, CMC, and

HPC meet the criteria as food additives.

The grant research with contract number 452/UN27.21/PN/2020 from Sebelas

Maret University, Indonesia is greatly appreciated.

Afolabi, L.O., Megat-Yusoff, P.S.M., Ariff, Z.M., Hamizol, M.S.,

2019. Fabrication of Pandanus Tectorius

(Screw-Pine) Natural Fiber Using Vacuum Resin Infusion for Polymer Composite

Application. Journal of Materials Research and Technology, Volume 8(3), pp. 3102–3113

Alabi, F.M., Lajide, L., Ajayi, O.O.,

Adebayo, A.O., Emmanuel, S., Fadeyi, A.E., 2020. Synthesis And Characterization

of Carboxymethyl Cellulose from Musa Paradisiaca

And Tithonia Diversifolia. African

Journal of Pure and Applied Chemistry, Volume 14(1), pp. 9–23

Bhatt, N., Gupta, P.K., Naithani, S.,

2011. Hydroxypropyl Cellulose From A-Cellulose Isolated from Lantana Camara

with Respect To DS And Rheological Behaviour. Carbohydrate Polymers,

Volume 86, pp. 1519–1524

Bono, A., Ying, P.H., Yan, F.Y., Muei,

C.L., Sarbatly, R, Krishnaiah, D., 2009. Synthesis and Characterization of

Carboxymethyl Cellulose From Palm Kernel Cake. Advances in Natural and Applied

Sciences, Volume 3(1),

pp. 5–12

Carere, C.R., Sparling, R., Cicek, N.,

Levin, D.B., 2008. Third Generation Biofuels Via Direct Cellulose Fermentation.

International Journal of Molecular Sciences, Volume 9(7), pp. 1342–1360

Haleem, N., Arshad, M., Shahid, M., Tahir, M.A. 2014. Synthesis of Carboxymethyl

Cellulose from Waste Of Cotton Ginning Industry. Carbohydrate Polymers,

Volume 113, pp. 249–255

Huang, C.M., Chia, P., Lim, C.S., Nai, J., Ding, D.Y., Seow, P.,

Chan, E.W., 2017. Synthesis and Characterisation of Carboxymethyl Cellulose

From Various Agricultural Wastes. Cellulose Chemistry and Technology,

Volume 51, pp. 665–672

Ibrahim, M.M., Fahmy, T.Y., Salaheldin, E.I.,

Mobarak, F., Youssef, M.A., Mabrook, M.R., 2015. Synthesis of

Tosylated and

Trimethylsilylated Methyl Cellulose As Ph-Sensitive Carrier Matrix. Life

Science Journal, Volume 1(12), pp. 29–37

Joshi, G., Rana, V., Naithani, S.,

Varshney, V.K., Sharma, A., Rawat, J.S., 2019. Chemical Modification of Waste Paper: An

Optimization Towards Hydroxypropyl Cellulose Synthesis. Carbohydrate Polymers, Volume 223, pp. 1–12

Karatas, M., Arslan, N., 2016. Flow Behaviours of Cellulose And

Carboxymethyl Cellulose From Grapefruit Peel. Food Hydrocolloids,

Volume 58, pp. 235–245

Kimani, P.K., Kareru, P.G., Madivoli, S.E.,

Kairigo, P.K., Maina, E.G., Rechab, O.S., 2016. Comparative Study of

Carboxymethyl Cellulose Synthesis From Selected Kenyan Biomass. Chemical

Science International Journal, Volume 17(4), pp. 1–8

Li, Y.Y., Wang, B., Ma, M.G., Wang, A., 2018. Review of Recent

Development On Preparation, Properties, And Application Of Cellulose-Based

Functional Materials. International Journal of Polymer Science, Volume

2018, pp. 1–18

Li, W., Cai, G., Zhang, P., 2019. A Simple and Rapid Fourier

Transform Infrared Method For The Determination Of The Degree Of Acetyl

Substitution Of Cellulose Nanocrystals. Journal of Materials Science,

Volume 54(10), pp. 8047–8056

Nasatto, P.L., Pignon, F., Silveira, J.L.M., Duart, M.E.R., Noseda,

M.D., Rinaudo, M., 2015, Methylcellulose, a cellulose derivative with original

physical properties and extended applications, Polymers, Volume 7, pp.

777–803

Marseno, D.W., Haryanti, P., Adiseno, B.,

Haryadi, 2014, Synthesis and Characterization Of Hydroxypropylcellulose From

Oil Palm Empty Fruit Bunches (Elaeis Guineensis Jacq), Indonesian

Food and Nutrition Progress, Volume 13(1), pp. 24–30

Parid, D.M., Abd Rahman, N.A., Baharuddin,

A.S., Mohammed, M.A.P., Johari, A.M., Razak, S.Z.A., 2018. Synthesis and

Characterization of Carboxymethyl Cellulose from Oil Palm Empty Fruit Bunch

Stalk Fibres. BioResources, Volume 13(1), pp. 535–554

Sahu, S.C., 2017. Food additives. Food and Chemical Toxicology, Volume

107, pp. 529-529

Sharma, R., Varshney, V.K., Chauhan,

G.S., Naithani, S., Soni, P.L., 2009, Hydroxypropylation of Cellulose Isolated

from Bamboo (Dendrocalamus Strictus) With Respect To Hydroxypropoxyl

Content And Rheological Behavior Of The Hydroxypropyl Cellulose. Journal of

Applied Polymer Science, Volume 113, pp. 2450–2455

Sheltami, R.M., Abdullah, I., Ahmad, I.,

Dufresne, A., Kargarzadeh, H., 2012. Extraction of Cellulose Nanocrystals from

Mengkuang Leaves (Pandanus Tectorius). Carbohydrate

Polymers, Volume 88(2), pp.

772–779

Sun, J.X., Sun, X.F., Zhao, H., Sun, R.C.,

2004. Isolation and Characterization Of Cellulose From Sugarcane Bagasse. Polymer

Degradation and Stability, Volume 84(2),

pp. 331–339

Suriyatem, R.,

Noikang, N., Kankam, T., Jantanasakulwong, K., Leksawasdi, N., Phimolsiripol,

Y., Sommano, S.R., 2020. Physical Properties of Carboxymethyl Cellulose From

Palm Bunch And Bagasse Agricultural Wastes: Effect Of Delignification With

Hydrogen Peroxide. Polymers, Volume 12(7), p. 1505

Suryanti, V., Marliyana, S.D., Putri, H.E., 2016. Effect

of Germination On Antioxidant Activity, Total Phenolics, ?-carotene, Ascorbic

Acid And ?-Tocopherol Contents Of Lead Tree Sprouts (Leucaena Leucocephala

(lmk.) de Wit). International Food Research Journal, Volume 23(1),

pp. 167–172

Suryanti, V., Riyatun, Suharyana, Sutarno, Saputra,

O.A., 2020. Antioxidant activity and compound constituents of gamma-irradiated

black rice (Oryza sativa l.) var. cempo ireng indigenous of Indonesia. Biodiversitas, 2020,

Volume 21(9), pp. 4205–4212

Suryanti, V., Marliyana, S.D., Rohana, G.L., Trisnawati,

E.W., Widiyanti, 2021. Bioactive Compound Contents and Antioxidant

Activity of Fermented Lead Tree (Leucaena Leucocephala (lmk.) de Wit)

Seeds. Molekul, Volume 16(3), pp. 192–199

Nu, D.T.T., Hung, N.P., Hoang, V.C.,

Bruggen, B.V.D., 2019. Preparation of an Asymmetric Membrane from Sugarcane

Bagasse Using DMSO as Green Solvent. Applied Sciences. Volume 9(16),

p. 3347

Tosh, B., 2014. Synthesis And Sustainable

Applications Of Cellulose Esters And Ethers:

A Review. International Journal of Energy, Sustainability and

Environmental Engineering, Volume 1(2), pp. 56–78

Viera, R.G.P., Filho, G.R., Assuncao,

R.M.N., Meirele, C.S., Vieira, J.G., Oliveira, G.S., 2007. Synthesis and Characterization

Of Methylcellulose From Sugar Cane Bagasse Cellulose. Carbohydrate Polymers,

Volume 67, pp. 182–185

Varshney, V.K., Gupta, P.K., Naithani, S., Khullar, R., Bhatt, A.,

Soni, P.L., 2006. Carboxymethylation of -cellulose Isolated from Lantana Camara With Respect To Degree Of

Substitution And Rheological Behaviour. Carbohydrate Polymers,

Volume 63(1), pp. 40–45