A Configuration Approach to Reduce the Risk of COVID-19 Employees Infection in the Manufacturing Firms: The Role of Machine Automatization

Corresponding email: jherediap@icloud.com

Published at : 07 Oct 2022

Volume : IJtech

Vol 13, No 4 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i4.5287

Heredia, J., Geldes , C., Flores , A., Heredia, W., Gamarra, F.M.C., Miranda, L., 2022. A Configuration Approach to Reduce the Risk of COVID-19 Employees Infection in the Manufacturing Firms: The Role of Machine Automatization. International Journal of Technology. Volume 13(4), pp. 785-792

| Jorge Heredia | Department of Business Administration, Universidad del Pacífico, Calle Sanchez Cerro 2141, Jesús María, Lima 11, Perú |

| Cristian Geldes | Faculty of Economics and Business, Universidad Alberto Hurtado. Erasmo Escala 1835. Oficina 206, Santiago. Chile |

| Alejandro Flores | Department of Business Administration, Universidad del Pacífico, Calle Sanchez Cerro 2141, Jesús María, Lima 11, Perú |

| Walter Heredia | Facultad de Economía y Negocios, Universidad del Desarrollo, Santiago, Chile |

| Felix M Carbajal Gamarra | Energy Engineering, University of Brasilia, FGA-UnB, St. Leste Projeção A - Gama Leste, Brasilia 72444-240, DF, Brazil |

| Luisa Miranda | Pontificia Universidad Católica de Chile, CEO Nextmedicall, Jr. Domingo Ponte 1171, Lima, Perú |

Does automation adoption mitigate the COVID-19 infection rate

of employees? What resources and internal and external factors need to be

configured with automation to mitigate COVID-19 contagion from employees

successfully? According to the type of automation. What resources efficiently

complement to mitigate the contagion rate from employers? From a fuzzy-set

qualitative comparative analysis (fsQCA) approach, we analyzed 759

manufacturing firms in Finland, drawn from the World Bank 2020 Enterprise

Survey; this study addresses the multiple configurations that drive pandemic

risk mitigation and management. We find that configurations under automation

reduce the risk of employee infection. Our results show the critical role of

automation in employee safety. We argue that access to government support and

the development of technological innovation are necessary conditions for

implementing measures to prevent and mitigate the risk of contagion in the

employee. In addition, the first configuration states that manufacturing firms

employing soft automation can successfully mitigate employee exposure. The

second configuration states that high human resource flexibility successfully

complements firms with complex automation to achieve high mitigation. Finally,

the third configuration shows those manufacturing firms that employ low-tech

automation (manual processes); in this manner, digitization enables

successfully mitigating pandemic contagion. Moreover, it suggests recommendations

for policymakers and managers.

COVID-19; Digitalization; fsQCA; Industry 4.0; Machine Automatization

The death rate due to COVID-19 has increased already to three million people (Agus et al., 2021). Therefore, it is essential to know what strategies firms should implement to mitigate employee infection for welfare and safety in this "new normal." In such a manner, as resilient firms return to their activities, they must establish new safety and welfare measures for workers to mitigate the pandemic risk. Therefore, having better work conditions through high levels of safety and adequate worker health in a company plays a fundamental role (Levy et al., 2017; Berawi, 2021).

To achieve this purpose, Seale et al. (2020) state that

physical distancing, use of masks, and hand hygiene, persist in being

considered essential to deal with the pandemic. Therefore, firms present an

essential role in caring for the welfare of employees who face high exposure to

the virus they perform in essential activities (Rothan

& Byraredde, 2020).

Currently, in the era of Industry 4.0 (I4.0), technological

advances, such as Artificial Intelligence (A.I.) and automation, could play a

key role in mitigating the infection of employees by COVID-19. In such a

manner, automation processes generate greater interest in industries because it

offers an opportunity for jobs without much contact with other people,

drastically decreasing infections.

However, what conditions automation and digitization will

reduce employee contagion remains unclear. Thus, the present study attempts to

fill this gap by interacting with internal and external variables to understand

the complexity and explain risk mitigation in this "new normal." In

this sense, we address these challenges to develop an empirical model that

seeks to explain the best practice strategies that allow high-risk mitigation

in workers from a business perspective. So far, few studies seek to understand

the mechanisms that lead companies to adopt risk mitigation measures (De

Bruin et al., 2020; Koonin, 2020).

In addition, we seek to know the role of automation, so

our research aims to fill this gap, provide good practices to companies, and

work together with policymakers in this "new normality." We believe

the automation variable alone does not mitigate contagions for the safety of

workers. In this sense, we consider it essential to know which resources

successfully complement each type of automation to mitigate the contagions in

the workers of manufacturing companies. Thus, our objective is twofold.

Firstly, to identify which factors lead to high-risk mitigation to build

resilience that provides a better quality of life for workers and anticipate

problems in the short term. Secondly, we seek to know the interactions of the

factors that explain our objective. Third, analyze what type of automation is

complemented by resources that could reduce the rate of contagion in employees.

Therefore, this study addressed two questions: (i) How do

these factors interact, and under what context do they improve worker safety and

mitigate risk during the pandemic? (ii) What type of automation improves

worker's safety in developed manufacturing firms? According to the type of

automation (iii), What are resources that efficiently complement to mitigate

the contagion rate from employers? We employ an asymmetric

methodology such as fuzzy-set qualitative analysis (fsQCA) to achieve our

objective. It analyzes multiple causality and equifinality.

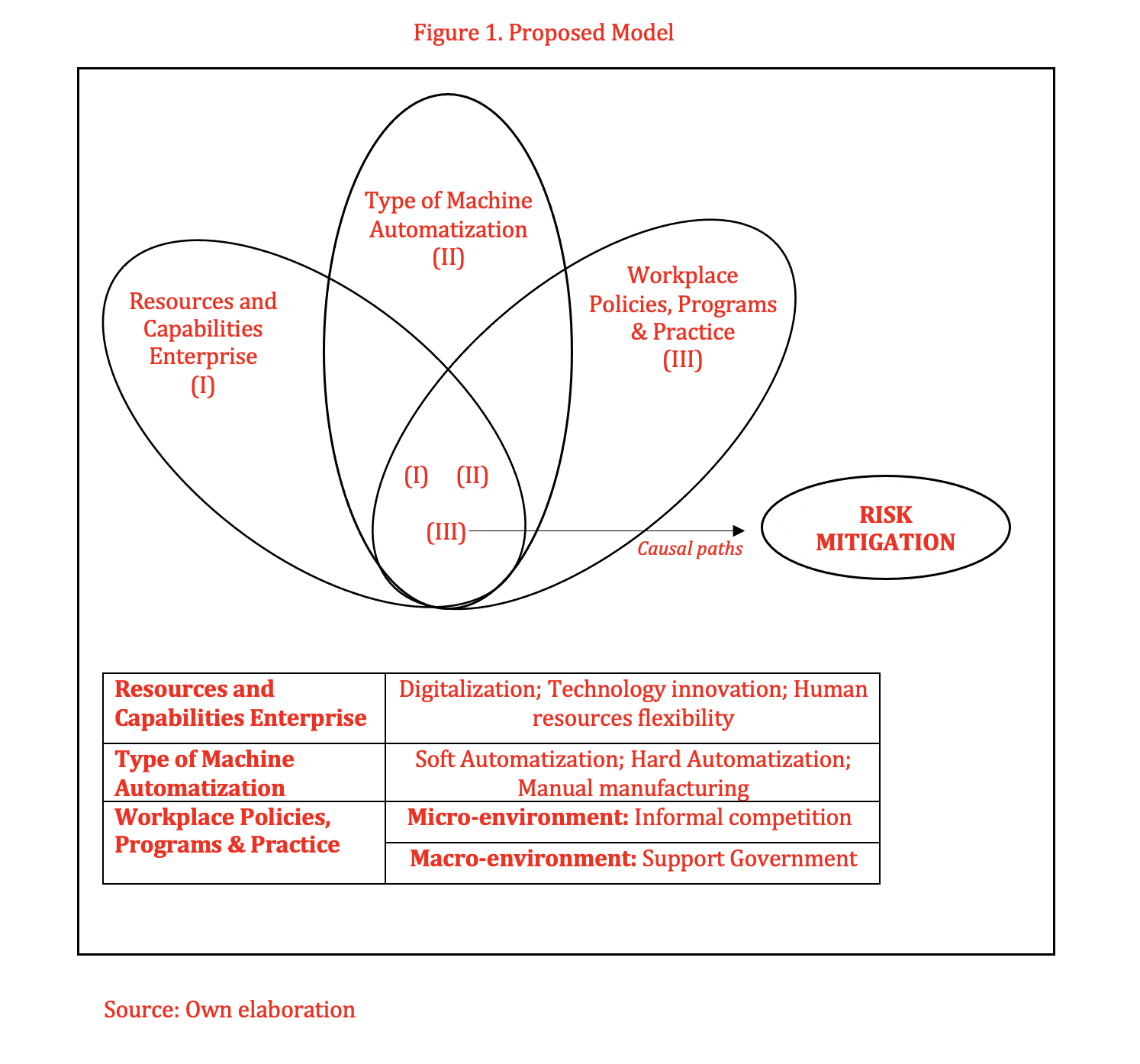

The

research is structured as follows: a theoretical framework addressing the

antecedents of firms with developed economies, the formulation of hypotheses,

and developing of a proposed model. In addition, the presentation of the method

and the results. Finally, we state the conclusions and give a discussion,

respectively.

The present study explores how to overcome employee

safety and risk mitigation during the COVID-19 pandemic. In such a manner, we

know that workers' safety, health, and welfare have become the focus of

attention to analyze during the pandemic. However, our study seeks to propose

the roles of automation and technology in manufacturing firms through new

strategies and tools to prevent and mitigate the risk of infections in

employees. In conclusion, automation is essential in strategies to prevent and

mitigate worker infections. In addition, our study contributes to knowing the

set of resources that successfully complement each other in manufacturing firms

according to each type of automation, thus exploring the companies'

capabilities in managing strategies depending on the company's decisions.

According to our results, successfully digitalization complements companies

that use a low level of automation (manual processes) to jointly generate

preventive measures for workers' safety. Finally, we propose the need for a

relationship between business and government to mitigate the pandemic risk. In

addition, we provide practical implications for managers to look at the

internal factors (resources and capabilities) that mitigate employee infection.

The support at the Research Center of Universidad

del Pacífico (CIUP) is gratefully acknowledged. We also thank Jorge Peña

Contreras for his support of data processing.

Agus, A.A., Yudoko, G., Mulyono, N.,

Imaniya, T., 2021. E-Commerce Performance, Digital Marketing

Capability and Supply Chain Capability within E-Commerce Platform: Longitudinal

Study Before and After COVID-19. International Journal of Technology, Volume

12(2), p. 360

Andrews, D., Criscuolo, C., Gal, P.N.,

2016. The Best Versus the Rest: The Global Productivity Slowdown, Divergence

Across Firms and the Role of Public Policy

Berawi, M.A., 2021. Innovative Technology

for Post-Pandemic Economic Recovery. International

Journal of Technology. Volume 12(1), pp. 1–4

Chuah, S.H.W., Aw, E.C.X., Yee, D., 2021.

Unveiling the Complexity of Consumers' Intention to Use Service Robots: An FsQCA

Approach. Computers in Human Behavior, Volume 123, p. 106870

De Bruin, Y.B., Lequarre, A.S., McCourt,

J., Clevestig, P., Pigazzani, F., Jeddi, M.Z., Colosio, C. and Goulart, M.,

2020. Initial Impacts of Global Risk Mitigation Measures Taken During the

Combatting of the COVID-19 Pandemic. Safety

science, Volume 128, p. 104773

De Souza, A.F., Martins, J., Maiochi, H.,

Juliani, A.D.P., Jaskowiak, P.A., 2020. Development of a Mobile Application for

Monitoring and Controlling a CNC Machine Using Industry 4.0 Concepts. The

International Journal of Advanced Manufacturing Technology, Volume 111(9), pp. 2545–2552

Dennerlein, J.T., Burke, L., Sabbath, E.L.,

Williams, J.A., Peters, S.E., Wallace, L., Karapanos, M. and Sorensen, G., 2020.

An Integrative Total Worker Health Framework for Keeping Workers Safe and

Healthy During the COVID-19 Pandemic. Human factors, Volume 62(5), pp. 689–696

Fiss, P.C., 2011. Building Better Causal

Theories: A Fuzzy Set Approach to Typologies in Organization Research. Academy

of Management Journal, Volume 54(2),

pp. 393–420

Gonçalves, T., Gaio, C., Silva, M., 2018.

Target Costing and Innovation-Exploratory Configurations: A Comparison of FsQCA,

Multivariate Regression, and Variable Cluster Analysis. Journal of Business Research, Volume

89, pp. 378–384

Heredia, J., Castillo-Vergara, M., Geldes,

C., Gamarra, F.M.C., Flores, A., Heredia, W., 2022. How Do Digital Capabilities

Affect Firm Performance? The Mediating Role of Technological Capabilities in the

“New Normal”. Journal of Innovation &

Knowledge, Volume 7(2), p. 100171

Hurtado, L.A., Mocanu, E., Nguyen, P.H.,

Gibescu, M., Kling, W.L., 2015. Comfort-constrained Demand Flexibility

Management for Building Aggregations Using a Decentralized Approach. In 2015

International Conference on Smart Cities and Green ICT Systems, pp. 1–10

Kavitha, B.C., Vallikannu, R., 2022. IoT

Assisted Predictive Maintenance and Worker Safety: An Initiative. In Information and Communication Technology for

Competitive Strategies (ICTCS 2020). Springer,

Singapore, pp. 719–727

Koonin, L.M., 2020. Novel Coronavirus Disease

(COVID-19) Outbreak: Now is the Time to Refresh Pandemic Plans. Journal

of business continuity & emergency planning, Volume 13(4), pp. 298–312

Levy, B.S., Wegman, D.H., Baron, S.L.,

Sokas, R.K., 2017. Occupational and Environmental

Health: Recognizing and Preventing Disease and Injury (7th ed.).

Oxford University Press

Liao, Y., Deschamps, F., Loures, E.D.F.R.,

Ramos, L.F.P., 2017. Past, Present and Future of Industry 4.0-a Systematic

Literature Review and Research Agenda Proposal. International journal

of production research, Volume 55(12),

pp. 3609–3629

Manzo, M.A., Rodríguez, J.C., 2022.

Ensuring the High Performance of Design and Engineering Firms in Mexico's

Aerospace Industry: A Qualitative Comparative Analysis. International Journal of Technology. Volume 13(1), pp. 5–15

Mithani, M.A., 2020.

Adaptation in the Face of the New Normal. Academy of Management Perspectives, 34(4), 508–530

Naruetharadhol, P., Srisathan, W.A.,

Gebsombut, N., Wongthahan, P., Ketkaew, C., 2022. Industry 4.0 for Thai SMEs: Implementing

Open Innovation as Innovation Capability Management. International Journal of Technology. Volume 13(1), pp. 48–57

Ragin, C.C., 2000. Fuzzy-set Social

Science. University of Chicago Press

Rihoux, B., Ragin, C.C., Yamasaki, S., Bol,

D., 2009. Conclusions-The Way (s) Ahead. Configurational comparative

methods: Qualitative comparative analysis (QCA) and related techniques, pp.

167–178

Rothan, H.A., & Byrareddy, S.N., 2020.

The Epidemiology and Pathogenesis of Coronavirus Disease (COVID-19) Outbreak. Journal

of autoimmunity, Volume 109,

p. 102433

Schneider, C.Q., Wagemann, C., 2012. Set-theoretic

Methods for the Social Sciences: A Guide to Qualitative Comparative Analysis. Cambridge University Press

Seale, H., Heywood, A.E., Leask, J., Sheel,

M., Thomas, S., Durrheim, D.N., Bolsewicz, K. and Kaur, R., 2020. COVID-19 is Rapidly

Changing: Examining Public Perceptions and Behaviors in Response to This

Evolving Pandemic. PloS one, Volume 15(6), p. e0235112

Stroe, S., Sirén, C., Parida, V., Wincent,

J., 2022. Framing Ideas for New Venture Resources Acquisition in Crises: An

fsQCA Analysis. Journal of Business

Venturing Insights, Volume 17, p. e00307

Szajna, A., & Kostrzewski, M. (2022).

AR-AI Tools as a Response to High Employee Turnover and Shortages in

Manufacturing during Regular, Pandemic, and War Times. Sustainability, 14(11), 6729.

Volume 14(11), pp. 6729

Tiirinki, H., Tynkkynen, L.K., Sovala, M., Atkins, S., Koivusalo, M., Rautiainen, P., Jormanainen, V. and Keskimäki, I., 2020. COVID-19 Pandemic in Finland–Preliminary Analysis on Health System Response and Economic Consequences. Health policy and technology, Volume 9(4), pp. 649–662

Zheng, P., Sang, Z., Zhong, R.Y., Liu, Y., Liu, C., Mubarok, K., Yu, S. and Xu, X., 2018. Smart Manufacturing Systems for Industry 4.0: Conceptual Framework, Scenarios, and Future Perspectives. Frontiers of Mechanical Engineering, Volume 13(2), pp. 137–150