Tobacco Extract for Inhibition of Carbon Steel Corrosion in H2S-contained NaCl Solution

Corresponding email: pramujo@che.itb.ac.id

Published at : 28 Jul 2023

Volume : IJtech

Vol 14, No 5 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i5.5272

Devianto, H., Nurdin, I., Widiatmoko, P., Silvia, D., Prakarsa, C., 2023. Tobacco Extract for Inhibition of Carbon Steel Corrosion in H2S-contained NaCl Solution. International Journal of Technology. Volume 14(5), pp. 1167-1176

| Hary Devianto | Chemical Engineering Program, Faculty of Industrial Technology, Institut Teknologi Bandung, Bandung 40132 Indonesia |

| Isdiriayani Nurdin | Chemical Engineering Program, Faculty of Industrial Technology, Institut Teknologi Bandung, Bandung 40132 Indonesia |

| Pramujo Widiatmoko | Chemical Engineering Program, Faculty of Industrial Technology, Institut Teknologi Bandung, Bandung 40132 Indonesia |

| Della Silvia | Chemical Engineering Program, Faculty of Industrial Technology, Institut Teknologi Bandung, Bandung 40132 Indonesia |

| Clarissa Prakarsa | Chemical Engineering Program, Faculty of Industrial Technology, Institut Teknologi Bandung, Bandung 40132 Indonesia |

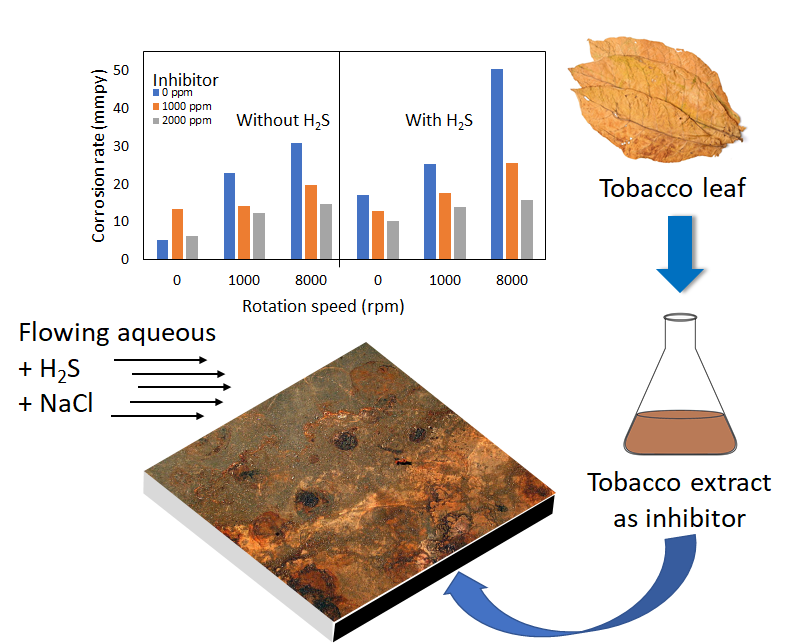

This study explored the effectiveness of tobacco

extract as a corrosion inhibitor for carbon steel in an H2S-containing

NaCl solution. The experiments were conducted at room temperature and

atmospheric pressure, with a variation in inhibitor concentration and rate of

fluid flow. Results showed that the tobacco extract decreases the corrosion

rate of carbon steel in the 3.5% NaCl solution. Increasing flow rate and

inhibitor concentration significantly affect the corrosion rate of carbon

steel. In the NaCl solution, crystalline corrosion product formation of

magnetite (Fe3O4) was mainly detected. Furthermore, the

presence of H2S leads to forming of a mackinawite (FeS) structure.

The inhibition efficiency of 1000 and 2000 ppm tobacco extract in NaCl solution

with the presence of H2S is in the range of 24 to 69%.

Carbon Steel; Corrosion; Flow rate; Hydrogen sulphide; Inhibitor; Tobacco extract

Chemical industries

produce daily necessities as a vital part of human life. The involvement of

corrosive fluid in chemical processing, both in static and dynamic flow, leads

to corrosion of the process equipment. Corrosion is a spontaneous metal deterioration

process due to environmental interaction (Roberge,

2008). In industries, carbon

steel is common material widely used for various purposes (Kurniawan, Mitha, and Fikri, 2018) because of its

satisfactory performance and attractive cost (Gandy,

2007). However, carbon steel is susceptible to corrosion (Dwivedi, Lepkova, and Becker, 2017).

Components such as sodium chloride and hydrogen sulfide in oil and gas

industries (Al-Janabi, 2020) increase the

corrosivity of process fluids to the carbon steel. The corroded carbon steel

leads to equipment failures, loss of containment, product contamination, and

work accident. Therefore, a study on carbon steel corrosion in NaCl and H2S

environments is crucial, especially in the petroleum industry, to reduce costly

social, economic, and even human losses (Zúñiga et

al., 2011; Sosa et al., 2003).

Adding corrosion inhibitors can reduce corrosion

risk. The inhibitors are a small quantity of a compound that controls, reduces

or prevents reactions between a metal and its surroundings (Fouda et al., 2014; Bentiss et al., 2002).

The inhibitor could be a synthetic organic corrosion inhibitor or a green

corrosion inhibitor extracted from natural Resources (Rani and Basu, 2012).

Organic inhibitors, such as thiourea derivatives, are effective in an acid

environment (Shetty and Shetty, 2017). In

seawater, sodium benzoate also has been used as an inhibitor (Nik et al., 2010). However, the

application of synthetic organic corrosion inhibitors is hindered by their

toxicity effect (Popoola, 2019), despite

their high effectivity. On the other side, green organic inhibitors have

recently become an attractive alternative in corrosion prevention research due

to their availability and relatively low cost (Kurniawan,

Mitha, and Fikri, 2018).

The green corrosion

inhibitors are biodegradable and do not contain heavy metals or other toxic

compounds. Extracts of a plant contain a wide variety of organic compounds.

Most of them contain heteroatoms such as P, N, S, and O (Shalabi et al., 2014; Bhawsar, Jain, and Jain, 2013). A

significant number of scientifical studies have been dedicated to the corrosion

inhibition of carbon steel in acidic media by natural products as corrosion

inhibitors (Shalabi et al., 2014; Bhawsar,

Jain, and Jain, 2013; Ramananda, 2013; Majidi et al., 2011; Eddy and Mamza, 2009; Prabhu et al., 2008).

In example, Nicotiana tabacum extract oil has been studied as a corrosion

inhibitor of mild steel in 2 M H2SO4 solution, with an

efficiency of 94.13% at 10 g/L, 303K. Atropa Belladonna extract has also

been investigated on the corrosion of carbon steel in 1 M HCl. It shows 96.6% at 500 ppm using the Tafel

polarization technique. Pradityana et al.

(2017) also used 300 mg/L Myrmecodia Pendans extract as a green

inhibitor of mild steel corrosion in 1 M H2SO4 media with

an efficiency of 64.68%.

Tobacco plants produce more

than 4,000 chemical compounds, including terpenes, alcohols, carboxylic acid,

nitrogen–containing compounds, and alkaloids (Loto

and Popoola, 2011). These components may inhibit electrochemical

activity by chemisorption of the extract components onto the steel surface. It

can reach up to 91.5% on inhibition efficiency, higher than black wattle

(66-87%) and orange peel (80% IE). the chemisorption of tobacco extract

components provides higher effective protection due to the reduction of the

reactivity of metal at the attached sites (Guo et

al., 2018; Shehata, Korshed,

and Attia, 2018). Kurniawan,

Mitha, and Fikri (2018) used tobacco extract as an inhibitor in a 3,5%

NaCl environment with CO2 with excellent results. In this work, we

also use tobacco due to its abundant availability in Indonesia. The H2S

is used as an impurity instead of CO2. The tobacco extract was

obtained from Virginia tobacco leaves using the maceration technique with

demineralized water as solvent. We evaluated the efficiency of tobacco extract

as a green corrosion inhibitor using electrochemical techniques.

2.1. Preparation of tobacco extract

The dried and ground Virginia

tobacco leaves (100 g) were soaked in 100 mL demineralized water for 72 hours

under a room temperature of 27°C. The extract solution was filtered through filter

paper and heated at 50 °C for 3 hours. The extract of tobacco leaf obtained

was used as an inhibitor.

2.2.

Preparation of metal specimens

The material tested was AISI 1018 carbon

steel. Two types of specimens were prepared, i.e. specimens to measure the

corrosion rate (in the form of a solid cylinder with a diameter of 3 mm and a

length of 20 mm) and specimens to determine the inhibition mechanism (in the

form of a 10 mm x 10 mm plate). The carbon steel cylinder is coated with

Teflon®, which acts as an insulator so that only one side of the surface is in

contact with the fluid. The plate specimens are connected by cables and covered

with resin so that only one side is exposed. Before testing, the electrode was

polished using different abrasive papers (up to 2000 grit) and cleaned with

demineralized water and alcohol.

2.3.

Preparation of test media

All chemicals were obtained from Merck,

Germany, without prior treatment. The electrolyte solution is NaCl solution at

a concentration of 35,000 ppm. The solution volume is 50 mL, with and without

adding 600 ppm H2S. Concentrations of tobacco extract are varied at

0, 1000 and 2000 ppm. As in previous research, the H2S gas is made

by reacting Na2S solid with 3 M of HCl solution using Kipp's

apparatus (Rachmawati et al., 2011).

The formed H2S gas is flowed into the NaCl solution for a specific

time to obtain the determined H2S concentration.

2.4.

Corrosion test

Corrosion rate was measured using the

potentiodynamic method and determining the corrosion inhibition mechanism by

using Cyclic Voltammetry (CV), Electrochemical Impedance Spectroscopy (EIS),

X-Ray Diffraction (XRD), and Scanning Electron Microscope (SEM) analyses. The

conventional three-electrode cell is used for the polarization curve, CV and

EIS experiments. Pt-Ir electrode was used as the auxiliary electrode, a

saturated calomel electrode (SCE) was used as the reference electrode, and the

sample was used as the working electrode. All polarization curve tests were

conducted at a scan rate of 5 mV/s. The Gamry Framework and Echem® Analyst

software analyzed the polarization curves. The EIS measurements were performed

with frequencies ranging from 50,000 Hz to 1 Hz, and EIS results were analyzed

using the Gamry Echem® Analyst software. After the corrosion test, the surface

morphologies were observed using SEM. Corrosion phases were detected using XRD

and identified by matching peak positions automatically with Match! Software.

Corrosion rate measurement experiments

were carried out by varying the flow rate, the presence of H2S, and

the concentration of tobacco extracts under room temperature. Then, experiments

to determine the corrosion inhibition mechanism were carried out by varying the

immersion time. The studied carbon steel samples were immersed in 3.5% NaCl

solution with the addition of tobacco extract as an inhibitor for an hour and a

week. The corrosion mechanism was analyzed based on CV and EIS analyses.

3.1. Corrosion Rate of Carbon Steel in 3.5% NaCl

Solution

The corrosion rate of carbon

steel was determined using the potentiodynamic polarization method against

variations in the flow rate of the solution, the presence of dissolved H2S,

and the concentration of tobacco extract in the electrolyte solution. The

result is shown in Figure 1.

Effect

of H2S - The polarization curve of carbon steel in

NaCl solution with the presence of H2S can be seen in Figure 2a. The

presence of H2S in the 3.5% NaCl solution increased the corrosion

rate. This is due to the dissociation of dissolved H2S into H+

and HS-. The increased concentration of H+ ions in the

solution increases the corrosion rate because the H+ ions can

oxidize carbon steel (Rachmawati et al.,

2011).

Effect

of flow rate - In general, increasing the

flow rate (related to the rotational speed of the electrode) of the solution

will increase the corrosion rate of the carbon steel. The polarization curve in Figure 2b indicates increased dissolved

oxygen as the fluid flow rate increases (Roberge,

2008). The cathodic curve moves to a

higher current with increasing rotational speed.

Effect of tobacco extract - The polarization curve of carbon steel in NaCl solution with the presence of tobacco extract is presented in Figure 3a. The addition of tobacco extract decreased the corrosion rate of the steel in the NaCl solution containing H2S. Adsorption of C-O, N-H, and O-H functional groups from the compounds in the tobacco extract onto the metal surface forms metal protective layers. The presence of these groups in the extract is detected in the Fourier-Transform Infrared Spectroscopy (FTIR) spectrum, as shown in Figure 3b.

Figure 3 (a) Polarization curve of carbon steel in NaCl solution with H2S

and various concentrations of tobacco extract (b) FTIR spectra of tobacco

extract sample

To be noted, the addition of

tobacco extract into NaCl solution in the absence of H2S and under

static conditions increases the corrosion rate. This condition is caused by the

acidity of tobacco extract, which increases the corrosivity of the solution.

The NaCl solution with 1000 and 2000 ppm tobacco extract has pH of 6.4 and 5.9,

consecutively. Formation of a stable, protective layer due to the acid

environment, however, is hindered due to the slow diffusion and adsorption of

tobacco extract's protective compounds onto the steel surface. The addition of

disturbances in the form of flow rate and the presence of H2S

resulted in tobacco extract forming a better protective layer. It inhibits

steel corrosion with an efficiency of 24% to 69% at tobacco extract

concentrations of 1000 ppm and 2000 ppm, respectively.

3.2.

Corrosion Inhibition Mechanism of The Tobacco Extract

Based on the voltammogram in Figure 4,

the corrosion product is unstable since the current ratio at the cathodic peak

to the current at the anodic peak is not equal to 1. The reaction is also

considered irreversible because the potential difference at the anodic and

cathodic peaks exceeds 59 mV. Two cathodic peaks in the voltammogram of samples

in the NaCl solution with H2S and inhibitor solution indicate the

reduction occurred through two reaction stages. Meanwhile, one anodic peak on

the voltammogram indicates that the oxidation reaction occurs in a single

stage.

Figure 4a shows that within the same

potential window and 1-hour immersion, the carbon steels show low corrosion

current, both in a solution of NaCl with 600 ppm of H2S and NaCl with

an inhibitor. The low current indicates a slow corrosion rate of carbon steel.

In Figure 4b, it appears that the anodic current of carbon steel immersed in a

solution of NaCl with 600 ppm of H2S and 2000 ppm of inhibitor for a

week (40 mA) is smaller than the anodic current of steel after immersion for 1

hour (160 mA). This indicates that the tobacco extract, together with the

presence of H2S, can function as an inhibitor. Figure 4b also shows

that within a long exposure time, the corrosivity of H2S is higher

than in tobacco extract.

Testing using EIS is carried out to

determine the electrical circuit equivalent of the ongoing corrosion process.

Three equivalent electrical circuits are generated depending on the type of

electrolyte solution used. The Nyquist plot is shown in Figure 5. Meanwhile,

the equivalent circuit and correlated electrical double layers on the

electrode's surface are presented in Figure 6. Table 1 lists the fitting of the

electrochemical impedance parameters of each configuration.

Figure 6 Equivalent circuit of

steel corrosion in 3.5% NaCl solution and correlated electrical double layers:

(a) in the absence of tobacco extract as an inhibitor, both with and without H2S;

(b) with inhibitor; and (c) with inhibitor and H2S

Electrolyte resistance increased by adding the non-conductive tobacco extract concentration to the electrolyte solution, decreasing electric current and corrosion rate. The addition of tobacco extract and H2S also resulted in increasing in Rct value. The Rct relates to the protective formation layer on the steel surface (Pradityana et al., 2017). A thicker and evenly distributed protective layer inhibits the charge transfer of corrosion reaction (Fouda et al., 2014). The corrosion products of carbon steel in NaCl solution containing H2S and tobacco extract after immersion for one week were analyzed using XRD and can be seen in Figure 7a. Magnetite (Fe3O4) is always present as a corrosion product for the three types of electrolyte solutions used. Immersed in an electrolyte solution of H2S, the steel forms an iron sulfide compound, namely mackinawite (FeS).

Figure 7 (a) X-ray Diffraction

spectra of the corroded carbon steel after one-week immersion in 3.5% NaCl

contains H2S and tobacco extract and morphology of (b) mackinawite

after one-week immersion in 3.5% NaCl solution contains H2S and 2000

ppm of tobacco extract, and (c) magnetite after one-week immersion in 3.5% NaCl

solution contains 2000 ppm of tobacco extract

The existence of mackinawite and magnetite was confirmed by SEM

observations and compared the XRD to the literature, as shown in Figures 7b and

7c.

Tobacco extract can

reduce the corrosion rate of AISI 1018 steel in a flowing NaCl solution containing

H2S, with an inhibition efficiency of 24 – 69% for a concentration

of 1000 – 2000 ppm. The corrosion mechanism of carbon steel in NaCl solution

with and without H2S or tobacco extract starts from the oxidation of

Fe to Fe2+ to form an iron oxide compound in the form of magnetite

(Fe3O4). The presence of H2S causes the

formation of an iron-sulfide compound, namely mackinawite (FeS), as a corrosion

product. Future work will be conducted to study the

operating temperature's effect on tobacco extract inhibitors' stability and

performance.

Al-Janabi, Y.T.,

2020. An Overview of Corrosion in Oil and Gas Industry. In: Corrosion Inhibitors in the Oil and Gas

Industry, Saji V.S., Umoren, S.A., (ed.),

pp. 1–39

Bentiss, F.,

Bouanis, M.M., Marwari, B., Traisnel, M., Lagrenee, M.M., 2002. Effect of

Iodide Ions on Corrosion Inhibition of Mild Steel by

3,5-Bis(4-methylthiophenyl)-4H–1,2,4-Triazole in Sulfuric Acid Solution. Journal

of Applied Electrochemistry, Volume 32,

pp. 671–678

Bhawsar, J.,

Jain, P.K., Jain, P., 2015. Experimental and Computational Studies of Nicotiana

Tabacum Leaves Extract as Green Corrosion Inhibitor for Mild Steel in Acidic

Medium. Alexandria Engineering Journal, Volume 54, pp. 769–775

Dwivedi, D.,

Lepkova, K., Becker, T., 2017. Carbon Steel Corrosion: A Review of Key Surface

Properties and Characterization Methods. RSC Advances, Volume 7, p. 4580

Eddy, N.O.,

Mamza, P.A.P., 2009. Inhibitive and Adsorption Properties of Ethanol Extract of

Seeds and Leaves of Azadirachta Indica on the Corrosion of Mild Steel in H2SO4.

Portugaliae Electrochim. Acta, Volume 27, pp. 443–456

Fouda, A.S.,

Elewady, G.Y., Shalabi, K., Habouba, S., 2014. Tobacco Plant Extracts as Save

Corrosion Inhibitor for Carbon Steel in Hydrochloric Acid Solutions. International

Journal of Advanced Research, Volume 2, pp. 817–832

Gandy, D., 2007.

Carbon Steel Handbook. Electric Power Research Institute, California

Guo, Y., Gao,

M., Wang, H., Liu, Z., 2017. Tobacco Rob Extract as Green Corrosion Inhibitor

for N80 Steel in HCl Solution. International Journal of Electrochemical

Science, Volume 12, pp. 1401–1420

Kahyarian, A.,

Srdjan, N., 2019. H2S Corrosion of Mild Steel: A Quantitative

Analysis of the Mechanism of the Cathodic Reaction. Electrochimica Acta, Volume

297, pp. 676–684

Kim, Y.S., Kim,

J.G., 2017. Corrosion Behavior of Pipeline Carbon Steel under Different Iron

Oxide Deposits in the District Heating System. Metals, Volume 7(5), p.

182

Kurniawan, B.A.,

Mitha, V., Fikri, N., 2018. Effect of Fluid Flow, Ph and Tobacco Extracts

Concentration as Organic Inhibitors to Corrosion Characteristics of AISI 1045

Steel in 3.5% NaCl Environment Containing CO2 Gas. American

Institute of Physics, Volume 1945

Loto, C.A.,

Popoola, A.P.I., 2011. Synergistic Effect of Tobacco and Kola Tree Extracts on

the Corrosion Inhibition of Mild Steel in Acid Chloride. International

Journal of Electrochemical Science, Volume 6, pp. 3264–3276

Majidi, L.,

Znini, M., Cristofari, G., Ansari, A., Bouyanzer, A., Paolini, J., Costa, J.,

Hammouti, B., 2012. Green Approach to Corrosion Inhibition of Mild Steel by

Essential Oil Leaves of Asteriscus Graveolens (Forssk.) in Sulphuric

Acid Medium. International Journal of Electrochemical Science, Volume 7,

pp. 3959–3981

Nik, W.W., Sulaiman, O., Giap, S.E., Rosliza, R.,

2010. Evaluation of Inhibitive Action of Sodium Benzoate on Corrosion Behaviour

of AA6063 in Seawater. International

Journal of Technology, Volume

1(1), pp. 20–28

Popoola, L.T.,

2019. Organic Green Corrosion Inhibitors (OGCIs): A Critical Review. De

Gruyter, Volume 37(2), pp. 71–102

Prabhu, R.A.,

Venkatesha, T.V., Shanbhag, A.V., Kulkarni, G.M., Kalkhamhkar, R.G., 2008.

Inhibition Effects of Some Schiff’s Bases on The Corrosion of Mild Steel in

Hydrochloric Acid Solution. Journal of Corrosion Science, Volume 50, pp. 3356–3362

Pradityana, A.,

Sulistijono, Shahab, A., Noerochim, L., 2017. Sarang Semut (Myrmecodia Pendans)

Extract as a Green Corrosion Inhibitor for Mild Steel in Acid Solution. International Journal of Technology, Volume 1, pp. 48–57

Rachmawati,

I.D., Nurdin, I., Widiatmoko, P., Devianto, H., Irmayanti, F., Saptohadi, S.,

2020. The Effect of Flow Rate and NaCl Concentration on the Corrosion Behavior

of Carbon Steel in NaCl Solutions Containing H2S. IOP Conference Series.: Material Science

and Engineering, Volume 778, p. 012137

Ramananda, M.,

2013. A Green Approach: Corrosion of Mild Steel by Adhatoda Vasica Plant

Extract in 0.5 M H2SO4. Journal of Materials and

Environmental Science, Volume 4, pp. 119–126

Rani, B.E.,

Basu, B.B.J., 2012. Green Inhibitors for Corrosion Protection of Metals and

Alloys: An Overview. International Journal of Corrosion, Volume 2012,

pp. 1–15

Roberge, P.R.,

2008. Corrosion Engineering: Principles and Practice. McGraw-Hill, New

Jersey

Saji, V.S.,

2019a. Research Advancements in Sulfide Scavengers for Oil and Gas Sectors. Reviews

in Chemical Engineering, Volume 37(6),

pp. 663–686

Saji, V.S.,

2019b. Progress in rust converters. Progress in Organic Coating, Volume

127, pp. 88–99

Shalabi, K.,

Abdallah, Y.M., Hassan, H.M., Fouda, A.S., 2014. Adsorption and Corrosion

Inhibition of Atropa Belladonna Extract on Carbon Steel in 1 M HCl Solution. International

Journal of Electrochemical Science, Volume 9, pp. 1468–1487

Shehata, O.S.,

Korshed, L.A., Attia, A., 2018. Green Corrosion Inhibitors, Past, Present,

and Future. Corrosion Inhibitors, principles and Recent

Applications, Volume 6, pp.

121–142

Shetty, S.D.,

Shetty N., 2017. Inhibition of Mild Steel Corrosion in Acid Medium. International Journal of Technology, Volume 5, pp. 909–919

Sosa, E.,

Cabrera, R., Oropeza, M.T., Hernandez, F., Casillas, N., Tremont, R., Cabrera,

C., 2003. Electrochemically Grown Passive Films on Carbon Steel (SAE 1018) in

Alkaline Sour Medium. Electrochim Acta, Volume 48, p. 1665

Wallaert, E.,

Tom, D., Iris, D.G., Verbeken K., 2018. FeS Corrosion Products Formation and

Hydrogen Uptake in a Sour Environment for Quenched & Tempered Steel. Metals,

Volume 8(1), p. 62

Zúñiga, E.M.,

Veloz, M.A., Uruchurtu, J., Reyes, V.E., 2011. Corrosion of Carbon Steel in

Sour Water from the Oil Industry: The Effect of Temperature. International

Journal of Electrochemical Science, Volume 6, pp. 5016–5030