Analysis of Combined Braking Torque on The Regenerative Anti-Lock Braking System in The Quarter Electric Vehicle Model

Corresponding email: katherin@ep.its.ac.id

Published at : 17 May 2024

Volume : IJtech

Vol 15, No 3 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i3.5265

Indriawati, K., Sudarmanta, B., Widjiantoro, B.L., Hafiizh, N.A., Said, A.H., 2024. Analysis of Combined Braking Torque on The Regenerative Anti-Lock Braking System in The Quarter Electric Vehicle Model. International Journal of Technology. Volume 15(3), pp. 628-640

| Katherin Indriawati | Department of Engineering Physics, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo–Surabaya, 60111, Indonesia |

| Bambang Sudarmanta | Department of Mechanical Engineering, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo–Surabaya, 60111, Indonesia |

| Bambang Lelono Widjiantoro | Department of Engineering Physics, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo–Surabaya, 60111, Indonesia |

| Nur Adlun Hafiizh | Department of Engineering Physics, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo–Surabaya, 60111, Indonesia |

| Ahmad Hazmi Said | Department of Engineering Physics, Institut Teknologi Sepuluh Nopember, Kampus ITS Sukolilo–Surabaya, 60111, Indonesia |

The

regenerative ABS is developed to avoid slip and to regenerate energy using two

types of braking: friction and motor. This paper discusses the experimental

results of combining the two types of braking which are applied to a

quarter-electric vehicle model. The control algorithm is developed using

sliding mode control (SMC), where continuous action is performed to produce

motor braking torque while discrete action is performed to produce hydraulic

braking torque (friction). Furthermore, the proposed control system also

implements control coordination to distribute braking torque, enhances the

occurrence of the non-slip process, and generates energy for vehicle batteries.

From the experimental results, it is concluded that the slip ratio value can be

used to obtain the optimum conditions for the braking process, where the

hydraulic torque as the cause of the slip, is limited through the braking

distribution algorithm. The proposed control system produces a response with a

brake speed of 2 m/s and a 3.39% increase in battery SOC.

Anti-lock braking system; Control coordination; Regenerative; Sliding mode control

One of

the efforts to reduce the negative impact of fossil fuel vehicles is the

development and use of electric vehicles. Generally, when braking occurs,

energy is wasted in the form of heat due to friction between the brake pads and

the wheels. Energy wastage is an important issue, especially for electric

vehicles. Therefore, this led to the design of a regenerative braking system

capable of converting kinetic energy into electricity when vehicles decelerate.

This energy is then stored in batteries for reuse, thereby increasing vehicle

efficiency (Usman et al., 2016; Benetti et al.,

2014; Faria and Delgado, 2014). The braking torque is generated by the

motor driving the vehicle. The results showed that the energy storage achieved

by this system is in the range of 8%-25% of the total energy used by the

vehicle, which is dependent on the regulatory cycle and control strategy, in

addition to manipulation of braking components such as the use of electric

brake boosters which can reduce electricity consumption (Nugraha et al., 2021; Shah et

al., 2018; Yu, Liu and Liu, 2016). Conversely, the braking torque

of the motor is often not capable of braking quickly, due to many influencing

factors,

such

as

motor speed, charging

status,

and battery temperature (Rajendran et al., 2018; Li, Du, and Li, 2016; Tehrani

et al., 2011; Zhang, Yin, and Zhang,

2010). Therefore, the process of braking with hydraulic torque is still

needed.

Generally, the

braking system plays an essential role in the safety of vehicles. The latest

technology commonly used to prevent the wheels of vehicles from being locked

during the sudden application of brakes is the anti-lock braking system (ABS).

According to preliminary studies, sudden braking leads to directional

instability such as understeer or oversteer. Braking force is influenced by several factors, such as road and

tire conditions, coefficient of friction, etc. Unlike the conventional braking

system, in the ABS, the wheels are kept from being locked with a certain slip

state where the coefficient of adhesion between the road and the tires is the

greatest. This makes the braking distance shorter, and the vehicle remains

stable or easy to control. Therefore, cars with ABS have the ability to reduce

the stopping distance and increase maneuverability compared to those without

this system (Fernandez et al., 2021; Aksjonov, Augsburg, and Vodovozov, 2016; Aly et al.,

2011).

This process

significantly increases a vehicle's safety in extreme conditions due to its

ability to maximize tire-road friction while maintaining a large lateral

(directional) force that ensures its control (Reif,

2014; Oleksowicz et al., 2013; Sergio

and Mara, 2010). According to Kim and Lee

(2013), an optimum slip ratio value maximizes the coefficient of

friction in all road conditions. Therefore, a suitable control strategy is to

maintain the slip ratio value to ensure the braking system's optimal and safe

working range.

Designing

an anti-lock braking system is a fairly complicated design process. Here, one

of the main obstacles is in determining the nonlinearity and uncertainty. Some advanced control

approaches have been proposed for ABS, such as fuzzy (Berouaken

and Boulahia, 2015; Yazicioglu and Unlusoy, 2008; Mirzaei et al., 2005), fuzzy-neural

(Lin and Le, 2017; Wang, Chen, and Su, 2012; Chen at al., 2006), sliding mode (Guo, Jian, and

Lin,

2014; Guo and Wang, 2012), model predictive control (He et al., 2021; Yuan et al., 2015), and other intelligent controls (Mirzaeinejad, 2018; Boopathi and Abudhahir, 2016; Topalov

et al., 2011).

The use of

regenerative braking as ABS was proposed by Tur, Ustun, and

Tuncay

(2007). Simulation comparisons between ABS with

motor and hydraulic braking torques were also carried out in this research.

Next, the analysis of the combination of the regenerative braking system and

ABS is carried out (Bera, Bhattacharyya, and Samantaray, 2011) using the sliding mode controller approach. This combination is

one of the innovative technological processes to improve vehicle performance.

The combined braking also serves to avoid overvoltage problems in electric

vehicles as discussed in Yusivar et al.

(2015). However, research on the combination of the two braking torques

is still small especially when it comes to ABS.

Regenerative ABS Plant

The Regenerative

Anti-lock Braking System (ABS) Plant in this research is applied to a single-wheel electric vehicle model, which only

uses one-wheel representation. The top represents the wheel speed

connected to a hydraulic braking system. Meanwhile, the bottom denotes the

vehicle's speed and is connected to a Brushless Direct

Current (BLDC) motor driver. The scheme of the regenerative ABS plant carried out in

this research is shown in Figure 1.

Figure 1

Schematic of the regenerative ABS plant (a) and the setup of the

plant (b)

This plant consists of a

battery that functions as a voltage source used by a motor driver to turn on

and regulate the vehicle. Therefore, electrical braking occurs when the driver

regulates the stator current, thereby producing attractive and repulsive forces

on the BLDC. Furthermore, this process is used to drive the bottom and top

wheels, usually zero at the point of contact. Generally, the braking system

with hydraulic torque occurs in vehicles by stopping the top wheels using brake

calipers, which decreases speed until they stop turning. In this case, a

hydraulic modulator is used to regulate the duration of braking. When a driver

applies the brake to a vehicle, the microcontroller receives speed data and

reacts to the braking module. The control algorithm used is a sliding mode

control (SMC) approach. The top and bottom wheel speed response graphs are

shown on the monitor screen.

The hydraulic modulator

consists of two on-off solenoid valves and one pump. The solenoid valve works

in reverse condition, depending on which operating position is needed as

described in Budiono et al. (2020).

However, during non-braking conditions, the input valve is closed while the

output is opened. This means that the system becomes dumped, thereby trapping

the brake fluid. Conversely, when braking is required, the output valve closes,

and the input valve opens enabling the flow of brake fluid into the calipers

and stopping the wheels. The pump is used to replace the function of the brake

pedal in every operating condition.

When brakes are applied, the BLDC changes its function from a motor to a generator. The specifications of the motor used in this research are shown in Table 1. This regenerative process reverses the current in the motor-battery circuit during deceleration and directs it to the battery. This condition is measured by the estimated state of charge (SOC) value. Therefore, it is necessary to measure Vuse, the value of the battery voltage when in use, using the equation (1):

where Vfull is the voltage when the battery is full.

Table 1 Motor Specification

|

Item |

Value |

|

Model |

BM1418ZXF |

|

Rated Output Power |

750 W |

|

Rated Voltage |

48/60V DC |

|

Speed after Reduction |

480RPM |

|

Rated Speed |

2800RPM |

|

Full Load Current |

|

|

No Load Current |

|

|

Rated Torque/Full Torque |

2.56 N.m / 14.92 N.m |

|

Efficiency |

|

|

Gear Ratio |

1:6 |

The slip ratio value is calculated using the equation (2):

where

v is the lateral (vehicle) speed of the bottom wheel

ww is the angular speed of the top wheel

rw is the top

wheel radius at 0.275 m

The measurement module

components at this plant include a speed sensor that measures wheel and vehicle

speed, a current sensor used to determine the reverse current during regenerative

braking, and a voltage divider circuit for the battery voltage.

The speed sensor in this

system uses proximity, generating two signal conditions of high and low. The

signal is high when the sensor touches the ring, and low assuming it does not

detect the ring. Furthermore, the sensor outputs a value when the ring rotates

once. However, a signal conditioning circuit needs its rotation value to reach

a revolution per minute (rpm) before entering the microcontroller. The

proximity sensor works to read the angular speed value w (rpm) on the top and bottom wheels

(vehicle representation). At the bottom, the angular speed value is converted

to the lateral v (km/h) with the equation (3):

where D is the diameter of the bottom wheel at 0.32 m.

A voltage divider circuit

is used on the battery-microcontroller line to measure the battery voltage.

This is necessary because the total voltage on the battery is around 50 Volts,

while the microcontroller's analog input pin is only capable of reading a

maximum of 5 Volts. The voltage divider circuit used in this plant uses 2

resistors of 10K and 100K Ohms at 5% tolerance, respectively.

Current measurement is carried out using an integrated circuit (IC) which detects AC and DC. This sensor works according to the Hall Effect theory, where a conductor is positioned close to the IC to create a magnetic field, converted into a proportional voltage. This analog voltage is read by the microcontroller and converted to a current value in amperes.

Regenerative ABS Control System

3.1. Sliding

Mode Control Approach

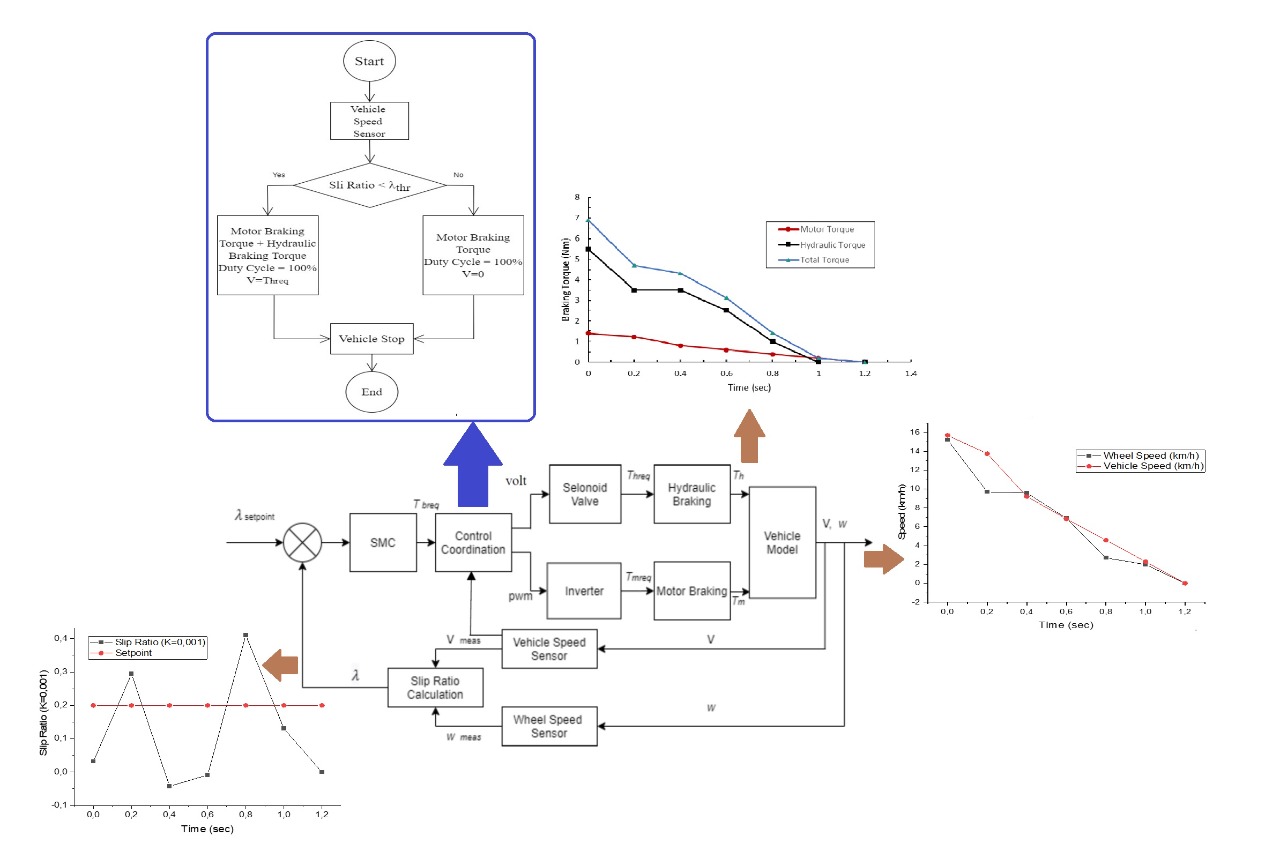

This research created a closed-loop

system for a regenerative ABS plant (Figure 2) using a sliding mode control

(SMC) suitable for plants with high nonlinearity characteristics such as ABS.

In this case, the controlled variable is the slip ratio l, which can be

calculated using the measured speed value of the vehicle (Vmeas)

or the wheel (wmeas). Therefore, it has the ability to

overcome the locked wheels when braking. The control

system is expected to set the slip ratio response around the setpoint value lsetpoint of 0.2,

which is the optimum value for dry and straight asphalt road conditions (Guo

and Wang, 2012).

The control signal with the SMC algorithm is generated using the nonlinear equation (4):

where:

Jw is the inertia moment of the wheel at 1 Nm

Kp is the proportional gain

K is controller gain

s = sliding surface = setpoint error (slip

ratio error)

The signum (sign) function is defined using (5):

The

SMC result is a control signal that represents the required braking torque, Tbreq.

The motor braking torque in this research is carried out

in full power from start to finish using a PWM signal with a duty

cycle of 100%. Therefore, continuous and discrete braking actions

are performed to produce motor and hydraulic (friction) braking torques.

The required motor braking torque Tmreq is computed using a linear function of sliding surface as (6):

Meanwhile, the hydraulic braking torque required Threq is the second-term part of (4), namely (7):

The

controller gain values Kp and K from the

SMC algorithm are determined by trial and error.

The control system adjusts the solenoid valve, which functions as an actuator to the control signal (volt). In its application, the hydraulic braking torque control signal is represented in the form of a delay. The ABS valve is controlled by 2 types of solenoids, which open and close the diaphragm to provide and relieve pressure on the brake chamber. As stated earlier, the first solenoid opens when braking and closes when the reverse is the case. Meanwhile, the second solenoid closes when braking and vice versa. Therefore, the required hydraulic braking torque is embodied in the form of braking duration or the microcontroller language using the term delay, namely (8):

where Thmax

is the hydraulic torque at maximum speed and Ts is

the sampling time.

The controller uses switching operations on the inverter. During the braking process, the inverter is tasked with increasing the back electromotive force (BEMF) voltage for current to flow into the battery. The braking energy is then stored in the battery, while the proportional control method is used to control the PWM signal on the inverter. Furthermore, the proposed system is very simple and efficient because it uses a switching operation on the inverter hence it does not require additional electronic components to perform regenerative braking.

Figure 2 Block diagram of the

slip ratio control system with SMC

3.2. Control Coordination

In an effort to obtain

regenerative energy in the motor braking section, it is necessary to regulate

the braking torque distribution. This distribution algorithm is expected to

make braking time faster with significant regenerative energy. In this

research, the distribution of braking (control coordination) is designed based

on the threshold value of the slip ratio, lthr. When it

is smaller than lthr, the

braking torque that works is hydraulic and motor. However, when the slip ratio

is greater than lthr, only

the motor works. The braking distribution then allows the torque to run from

start to finish but regulates the stopping time of the hydraulic because it

causes locked wheels. Furthermore, a controller is needed for the proper

functioning of the hydraulic braking torque to prevent slippage. In this case,

the controller algorithm used is SMC and the control coordination is able to

stop the vehicle quickly and without slipping. The braking distribution

algorithm is shown in Figure 3. lthr is

selected based on the open-loop test results of combined regenerative braking

(motor and hydraulic torque). The largest slip ratio value that occurs just

before the slip is used to determine the lthr value.

When electro-hydraulic braking is used, here the electric braking torque is

made to work at its maximum (PWM duty cycle is 100%), and the lack of braking

torque is overcome by hydraulic braking torque. So for high speed, braking can

still be done. A more detailed explanation is given in section 4 of this paper.

The regenerative performance of the ABS control system is evaluated by the SOC value and the integral of the time-multiplied absolute value of error (ITAE) which quantitatively characterizes the deviation from the actual wheel slip ratio value from the setpoint. Other performances include braking distance, brake speed, and average deceleration.

Figure 3 The proposed braking distribution algorithm

4.1. Analysis of the Effect of Braking Torque

A plant test is carried out

until the car stops in an open loop or without involving a controller. There

were 3 braking experiments, namely electric, hydraulic, and electric-hydraulic.

The open-loop test response

results for electric and hydraulic braking experiments are shown in Figures

4(a) and 4(b), i.e. slip ratio value and speed, respectively. The result

indicates that hydraulic braking with constant torque (5.5 Nm) produces a more

significant effect than the motor, as shown in Figure 5(a). Therefore, at 0.6 seconds, the system with hydraulic braking only

locks the wheels (zero speed) with a slip ratio value of 1 and the vehicle

stops at 1.2 seconds. Meanwhile, motor braking causes the vehicle to stop

at 1.6 seconds without slip events because the ratio is around ±0.2.

The regenerative energy

generated from the motor braking experiment increases the SOC value, as shown

in Figure 5(b). At the beginning of the braking process, the SOC value,

originally at 86.4%, increases until the wheel stops at 90.3%. Therefore, the

SOC value of the battery is increased by 3.9%.

Based on this experiment, it can be concluded that the slip event occurs due to the hydraulic braking torque, which needs to be adjusted without causing the wheels to lock.

Figure 4 Slip

ratio response (a) and speed response (b) during open-loop plant test with hydraulic

or motor braking

Figure 5 Braking

torque during individual tests (a) and SOC increase in the case of motor

braking torque (b)

The open-loop test response results for

the electric-hydraulic combined braking experiment are shown in Figures 6(a)

for slip ratio value and (b) for speed. The combined braking torque causes the

wheels to lock at 0.6 seconds, which is similar to the application of hydraulic

braking torque. However, the combined process causes the braking time to be

faster. In conclusion, the addition of motor braking torque accelerates the

braking time without changing the slip condition. Furthermore, the motor

braking needs to be carried out with the maximum motor braking torque to make

the maximum possible regenerative energy. Therefore, a braking distribution

algorithm is needed to regulate the regenerative energy storage without causing

slippage.

The threshold value for

distributing braking lthr is

determined based on the results of the slip ratio response in Figure 6(a). Its

value of 0.58 is obtained at 0.4 seconds just before the wheels are locked.

Therefore, the slip ratio threshold must be below this value. The braking

distribution algorithm applied in this research uses the lthr = 0.4.

Figure 6 Slip

ratio (a) and speed response (b) during the open-loop plant test

4.2. Control System Response Result

The required motor torque

value in Equation (6) is proportional to the setpoint error deviation value,

with a controller gain Kp of 13. However, this value cannot

be fulfilled entirely due to several factors influencing the motor torque. In

this case, the motor braking torque is proportional to the motor speed and the

hydraulic braking torque is equal to the required value, which is calculated by

equation (7). Based on the experimental results, it is found that the best

controller K gain value is 0.001.

The braking distribution algorithm works based on the slip ratio value, which uses the value of lthr = 0.4 as described in the previous section. The braking distribution graph shown in Figure 7 indicates that the hydraulic braking torque is no longer constant and reduces with a decrease in speed. The vehicle stops at 1.2 seconds (Figure 8(a)). At the time of 1 second, only the braking torque of the motor works because the slip ratio in the 0.8 seconds has already passed lthr, as shown in Figure 8(b). In total, the braking torque initially reached 7 N.m, however, it decreased until at 0.6 seconds to reach 3.1 N.m, therefore causing the wheels to unlock as in the case of braking with constant hydraulic torque (without controller). In this case, no more slip events occur, and the ratio value is maintained around 0.2 as shown in Figure 8(b).

Figure 7

Distribution of braking torque of the regenerative ABS control system

Figure 8 Speed response (a) and slip ratio response (b) of the regenerative ABS control system

Figure 9 SOC

value (a) and current value (b) of regenerative ABS control system

Figure 9(a) shows the changes in SOC

values due to regenerative energy conversion. Overall, there was a 3.4%

increase in SOC from 89.61% to 93%. Therefore, the regenerative energy

generated from the regenerative ABS control system is smaller than in the case

of motor braking alone at 4.7%, as shown in Figure 5(b). This is due to the

distribution of braking torque between the motor and hydraulic torque, hence

the brake speed is increased without causing the slip.

Figure 9(b) shows the

response of the motor current during braking at 3.26 A. Furthermore, when the

motor brakes, the current value changes to -0.08 A, thereby indicating that the

current direction is no longer to the motor but to the battery. This indicates

the conversion of mechanical energy with a torque value of 1.38 N.m into the

electrical current of 3.34 A, at the beginning of the braking process. The

regenerative energy generated is then significantly reduced as the speed

decreases, with a current below 0.25 A.

The regenerative ABS

control system is expected to make non-slip braking run quickly with the

maximum possible generation of regenerative energy. When the lthr value

used is less than 0.4, the braking time becomes longer, and the regenerative

energy is greater. Meanwhile, when the lthr value is

greater, the braking time becomes faster with smaller regenerative energy.

Therefore, it can be concluded that there is a trade-off between braking speed

and energy recovered. This led to the process of optimizing problems associated

with the lthr variable,

which is interesting to be used as a topic for further research.

The ABS regenerative

control system using the SMC approach is compared to its performance with the

proportional gain scheduling approach which is also conducted in this research. The

results of the performance comparison are shown in Table 2. It shows that the

SMC approach is slightly superior in all aspects, including ITAE. Thus, it can

be concluded that the type of nonlinear control algorithm is not the main

determinant for the performance of the combined braking system, but it is the

coordination control that determines the performance of the regenerative ABS.

Table 2

Comparison of Control Scheme Performance

|

No |

Scheme |

Average Deceleration (m/s2) |

Braking Distance (m) |

ITAE |

SOC (%) |

Brake Speed (m/s) |

|

1 |

SMC |

0.726 |

2.473 |

0.719 |

3.39 % |

2.025 |

|

2 |

Proportional

Gain Scheduling |

0.63 |

2.38 |

0.71 |

2.43 % |

1.983 |

In

conclusion, the regenerative ABS control system equipped with a braking

distribution feature has the ability to produce fast non-slip braking action

and increase the battery SOC by almost 4%. The continuous action of the motor

braking torque plays a role in accelerating the braking time in addition to

generating regenerative energy. Meanwhile, the discrete action of hydraulic

braking torque plays a role in accelerating braking time and needs to be

limited to avoid slipping through coordinated control based on the threshold

value of the slip ratio. Therefore, the process of determining this threshold

value can be used as a topic for future research to achieve optimum

regenerative braking conditions.

The authors are grateful to the Institut Teknologi Sepuluh Nopember for

their financial support under the Collaboration Research Centre project scheme

(reference

1159/PKS/ITS/2021).

Aly, A.A., Zeidan,

E.S., Hamed, A., Salem, F., 2011. An Antilock-Braking Systems (ABS) Control: A Technical

Review. Intelligent control and Automation. Volume 2(03), pp. 186

Aksjonov, A., Augsburg,

K., Vodovozov, V., 2016. Design and Simulation of The Robust ABS and ESP Fuzzy

Logic Controller on The Complex Braking Maneuvers. Applied Sciences, Volume 6(12), p. 382

Bera, T.K.,

Bhattacharyya, K., Samantaray, A.K., 2011. Bond Graph Model-Based Evaluation of

a Sliding Mode Controller for Combined Regenerative and Antilock Braking System.

Part I Journal System Control Engineering, Volume 225, pp. 918–934

Benetti, G., Delfanti,

M., Facchinetti, T., Falabretti, D., Merlo, M., 2014. Real-Time Modeling and

Control Of Electric Vehicles Charging Processes. IEEE Transactions on Smart Grid, 6(3), pp. 1375–1385

Berouaken, A., Boulahia,

R., 2015. Fuzzy Control of Anti-Lock Braking System And Active Suspension In A

Vehicle. Sciences & Technologie.

B, Sciences de l'ingénieur, Volume 2015, pp. 41–45

Boopathi, A.M.,

Abudhahir, A., 2016. Adaptive Fuzzy Sliding Mode Controller for Wheel Slip

Control in Antilock Braking System. Journal

of Engineering Research, Volume 4, pp. 1–19

Budiono, H.D.S.,

Sumarsono, D.A., Adhitya, M., Baskoro, A.S., Saragih, A.S., Prasetya, S.,

Zainuri, F., Nazaruddin, Heryana, G., Siregar, R., 2020. Development of Smart

Magnetic Braking Actuator Control for A Heavy Electric Vehicle. International

Journal of Technology, Volume 11(7), pp. 1337–1347

Chen, G.M., Wang, W.Y.,

Lee, T.T., Tao, C.W., 2006. Observer-Based Direct Adaptive Fuzzy-Neural Control

for Anti-lock Braking Systems. International

Journal of Fuzzy Systems, 8(4).

Faria, M., Delgado,

2014. Managing The Charging of Electrical Vehicle: Impacts on The Electrical

Grid and on The Environmental. Intelligent Transportation Systems Magazine

IEEE, Volume 6(3), pp. 54–65

Fernández, J.P.,

Vargas, M.A., García, J.M.V., Carrillo, J.A.C., Aguilar, J.J.C., 2021.

Coevolutionary Optimization of A Fuzzy Logic Controller For Antilock Braking

Systems Under Changing Road Conditions. IEEE

Transactions on Vehicular Technology, Volume 70(2), pp. 1255–1268

Guo, J., Jian, X., Lin,

G., 2014. Performance Evaluation of an Anti-Lock Braking System for Electric

Vehicles with a Fuzzy Sliding Mode Controller. Energies, Volume 7(10),

pp. 6459–6476

Guo, J., Wang, J.,

2012. Application of Sliding Mode Control for Electric Vehicle Antilock Braking

Systems. Advanced

Materials Research, Volume 505, pp. 440–446

He, Z., Shi, Q., Wei,

Y., Gao, B., Zhu, B., He, L., 2021. A Model Predictive Control Approach with

Slip Ratio Estimation for Electric Motor Anti-Lock Braking of Battery Electric

Vehicle. IEEE Transactions on Industrial

Electronics, Volume 69(9), pp. 9225–9234

Kim, J., Lee, J., 2013.

Real-Time Estimation of Maximum Friction and Optimal Slip Ratio Based on

Material Identification for a Mobile Robot on Rough Terrain. In: 13th International

Conference on Control, Automation and Systems (ICCAS 2013), pp. 1708–1713

Li, W., Du, H., Li, W.,

2016. A New Torque Distribution Strategy for Blended Anti-Lock Braking Systems

of Electric Vehicles Based On Road Conditions And Driver's Intentions. SAE International Journal of Passenger

Cars-Mechanical Systems, Volume 9, pp. 107–115

Lin, C.M., Le, T.L.,

2017. PSO-Self-Organizing Interval Type-2 Fuzzy Neural Network for Antilock

Braking Systems. International Journal of

Fuzzy Systems, Volume 19, pp. 1362–1374

Mirzaei, A., Moallem, M., Mirzaeian, B.,

Fahimi, B., 2005, September. Design of an Optimal Fuzzy Controller For Antilock

Braking Systems. In 2005 IEEE Vehicle

Power and Propulsion Conference, pp. 823–828

Mirzaeinejad, H., 2018. Robust Predictive

Control of Wheel Slip in Antilock Braking Systems Based On Radial Basis

Function Neural Network. Applied Soft

Computing, Volume 70, pp. 318–329

Nugraha, A.A., Sumarsono, D.A., Adhitya, M.,

Prasetya, S., 2021. Development of Brake Booster Design for Electric City Cars. International

Journal of Technology. Volume 12(4), pp. 802–812

Oleksowicz, S.A.,

Burnham, K.J., Southgate, A., McCoy, C., Waite, G., Hardwick, G., Harrington, C., McMurran, R., 2013. Regenerative Braking

Strategies, Vehicle Safety and Stability Control Systems: Critical Use-Case

Proposals. Vehicle System Dynamics, Volume

51(5), pp. 684–699

Rajendran, S.,

Spurgeon, S., Tsampardoukas, G., Hampson, R., 2018. Intelligent Sliding Mode

Scheme For Regenerative Braking Control. IFAC-PapersOnLine,

Volume 51(25), pp. 334–339

Reif, K., 2014. Brakes, Brake Control and Driver Assistance

Systems. Weisbaden, Germany, Springer Vieweg

Sergio, M.S., Mara, T.,

2010. Active Braking Control Systems Design for Vehicles. London, UK:

Springer.

Shah, D.A., Yu, L.,

Liu, X., Zheng, S., 2018. A New Design Of Main Cylinder Electric Booster For

Brake-By-Wire System. In: International Design Engineering Technical

Conferences and Computers and Information in Engineering Conference, Volume

2018, p. 85570

Tehrani, M.M.,

Hairi-Yazdi, R., Haghpanah-Jahromi, B., Esfahanian, V., Amiri, M., Jafari, R.

2011. Design of an Anti-Lock Regenerative Braking System for A Series Hybrid

Electric Vehicle. International Journal

of Automotive Engineering, Volume 1(2), pp. 16-20.

Topalov, A., Oniz, Y.,

Kayacan, E., Kaynak, O., 2011. Neuro-fuzzy Control of Antilock Braking System

Using Sliding Mode Incremental Learning Algorithm. Neurocomputing, Volume

74(11), pp. 1883–1893

Tur, O., Ustun, O., Tuncay, R.N., 2007.

An Introduction to Regenerative Braking of Electric Vehicles as ABS. In: IEEE Intelligent Vehicles Symposium, Volume

2017, pp. 944–948

Usman, M., Knapen, L., Vanrompay, Y.,

Bellemans, T., Janssens, D., Wets, G., 2016. A Coordinated Framework for

Optimized Charging of EV Fleet in Smart Grid. Procedia Computer Science, Volume 94, pp. 332–339

Wang, W.Y., Chen, M.C., Su, S.F., 2012.

Hierarchical T–S Fuzzy-Neural Control of Anti-Lock Braking System and Active

Suspension in a Vehicle. Automatica, Volume 48(8), pp. 1698–1706

Yazicioglu, Y.,

Unlusoy, Y.S., 2008. A Fuzzy Logic Controlled Anti-Lock Braking System (ABS)

For Improved Braking Performance and Directional Stability. International Journal of Vehicle Design,

Volume 48(3-4), pp. 299–315

Yuan, L., Chen, H.,

Ren, B., Zhao, H., 2015. Model Predictive Slip Control for Electric Vehicle

With Four In-Wheel Motors. In: 34th Chinese Control

Conference (CCC), Volume 2015, pp. 7895-7900

Yusivar, F., Haslim,

H.S., Farabi, Y., Nuryadi, K., 2015. New Control Scheme for Combined

Regenerative and Mechanical Brakes in Electric Vehicles. International

Journal of Technology, Volume 6(1), pp. 44–52

Yu,

L., Liu, X., Liu, X., 2016. Analysis of Energy Consumption on Typical

Main Cylinder Booster Based Brake-by-Wire System (No. 2016-01-1955). SAE Technical Paper, Volume 2016

Zhang, J.L., Yin,

C.L., Zhang, J.W., 2010. Improvement Of Drivability and Fuel Economy With A Hybrid

Antiskid Braking System In Hybrid Electric Vehicles. International Journal

Of Automotive Technology, Volume 11(2), pp. 205–213