Modification of Horizontal Wind Turbine Blade: A Finite Element Analysis

Corresponding email: milad@gcet.edu.om

Published at : 18 Jan 2023

Volume : IJtech

Vol 14, No 1 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i1.5255

Hamza, S., Heidari, M., Ahmadizadeh, M., Dashtizadeh, M., Chitt, M., 2023. Modification of Horizontal Wind Turbine Blade: A Finite Element Analysis. International Journal of Technology. Volume 14(1), pp. 5-14

| Sahahd Hamza | Mechanical Engineering Department, Global College of Engineering and Technology, P.O. Box 2546,CPO Ruwi 112, Muscat, Sultanate of Oman |

| Milad Heidari | Mechanical Engineering Department, Global College of Engineering and Technology, P.O. Box 2546,CPO Ruwi 112, Muscat, Sultanate of Oman |

| Mohammad Ahmadizadeh | Department of Mechanical Engineering, Faculty of Engineering, Persian Gulf University, P.C. 7516913817, Bushehr, Iran |

| Mohammadreza Dashtizadeh | Department of Mechanical Engineering, Faculty of Engineering, Shiraz Branch, Islamic Azad University, Sadra, Shiraz, Iran |

| Mira Chitt | Mechanical Engineering Department, Global College of Engineering and Technology, P.O. Box 2546,CPO Ruwi 112, Muscat, Sultanate of Oman |

Turbines are efficient power generators.

Because wind energy is a clean fuel source, it is widely utilized in some

regions. One of the major factors affecting wind turbine performance is the

angle of attack of the blade. The aerodynamics and efficiency can be improved

by improvising the lift-to-drag ratio CL/CD to get the best design for wind

turbine blades. There are many factors affecting the efficiency of horizontal

wind turbine blades such as the angle of attack of the blade. Therefore, this

study investigated the effect of the angle of attack on coefficients and

forces, particularly on a blade with NACA 4412 airfoil in a horizontal axis

wind turbine. The length, thickness, and chord length of the blade were 3m,

0.36m, and 0.12 m

respectively. Computational Fluid Dynamics was used to develop to obtain lift

and drag coefficients in a horizontal wind turbine blade. In addition, the correlation between

different angles of attack, lift, and drag forces were studied and validated.

The results demonstrated that the lift and drag coefficients increase as the

angle of attack increases. Furthermore, the optimal angle of attack for this

study was 0° because it has the highest lift-to-drag ratio, resulting in the

greatest efficiency. The results demonstrated that it is possible to have a

different lift and drag coefficient for the same angles of attack at a similar

airfoil.

Angle of attack; Energy; Horizontal wind turbine; Lift-to-drag ratio

Globally, renewable energy is now more cost-effective

than fossil fuels (Sudarsono, Susastriawan, and Sugianto, 2019). Renewable energy is of great importance nowadays. It

provides reliable power supplies and fuel diversity, which leads to energy

security and lower fuel demand. There are various renewable energy sources. The

wind is one of the elements. Horizontal-axis turbines and vertical-axis

turbines are the two main types of wind turbines. The rotating axis of a wind

turbine is horizontal, or parallel to the ground if it has a horizontal axis.

The turbine's rotational axis is vertical or perpendicular to the ground in

vertical-axis wind turbines. In comparison to the

vertical design, the horizontal one is more common as it produces more power,

causing it the most common machine design in use today.

The blade is designed as an aerodynamic geometry with

nonlinear chord and twist angle distributions to convert wind energy into

mechanical power (Tang, 2012). Because numerous disciplines are involved, such as aerodynamics,

construction, materials, and economics, wind turbine blade design is a

multi-objective optimization process. The three main models that represent the

design process are an aerodynamic model, a structural model, and an economic

model (cost model). These three elements form the foundation of wind turbine

design. The aerodynamics model is crucial in the design of wind turbine rotor

blades and other components. Furthermore, the initial concern in the wind

turbine design process is an accurate aerodynamic model. The structural design

of a wind turbine blade includes defining the wind turbine loads, selecting an

appropriate material, building a structural model, and solving the model using

the finite element method. This process will be repeated several times until a

final design is achieved (Kasem, 2020). Cost of materials, labor and cycle durations, and

virtual factory are the three key processes that make up the cost model for

horizontal wind turbines.

First, the bill cost of materials is estimated, then labor and cycle

time for a vacuum-assisted resin transfer molding process. This data is used to

create a virtual blade. It calculates the costs per blade for labor, utilities,

buildings, tools, equipment, maintenance, overhead, and capital. (Bortolotti et al., 2019).

Based on blade element momentum theory, Chaudhary and Roy (2015) reported on

the design and optimization of rotor blade performance for a 400-W compact wind

turbine at lower operating wind speeds (BEM). The main focus was the link

between solidity, pitch angle, tip speed ratio, and maximum power coefficient.

For a number of blades of 3, 5, and 7, the maximum power coefficient was found

for solidity in the range of 3% to 12% (Chaudhary and Roy, 2015). Yavuz et al. conducted an in-depth analysis of wind turbine

blades' design and performance evaluation and the outcome (Yavuz et al., 2015). Turbines are

efficient power generators. The turbine will not operate and produce power

efficiently if the speed is lower than the range. According to Yavuz et al.,

the greatest lift coefficient occurs when the attack angle is approximately 12

°, and the minimum velocity required to generate power is calculated to be 7

m/s (Yavuz

et al., 2015). Chang et al. devised a method that

incorporates design goals such as airfoil lift, drag coefficients, and

lift-drag ratio to produce an analytical expression that results in a highly

smooth airfoil for wind turbine applications. According to the study, airfoils

created using the proposed technology showed delayed flow separation and

excellent airfoil performance (Chang, et al., 2014).

Additionally,

Johansen et al. also developed a three-blade wind turbine rotor design

that maximizes the mechanical power coefficient (CP) in operating

circumstances. A free-wake lifting line approach and a three-dimensional

Navier-Stokes Solver were utilized to validate the model, which was created

using an actuator disc. The study found that CP = 0.51 and that it grows and

reduces as you get closer to the root and tip (Johansen et al., 2009).

One of the most challenging aspects in assessing the efficiency of a

wind turbine blade is the drag throughout its length, which attempts to stop

its movement. Drag is caused by the friction of air against the blade surface.

It runs parallel to the lift and in the same direction as the airflow across

the blade surface. Bending or twisting the blade, as well as tapering it

throughout its length, can reduce drag, resulting in the most efficient wind

turbine blade design. To enhance the efficiency of wind turbine blades, the

rotor blades require an aerodynamic profile to create lift and rotate the

turbine (Woofenden,

2013). The angle of

attack (AOA) of an airfoil is a 2D concept defined as the

angle between its chord and the undisturbed streamlines far upstream. Furthermore, it is the variation between lift and

drags with its direction of travel through a fluid. The determination of

the angle of attack is necessary in order to calculate lift and drag forces

over the blade, develop accurate aeroelastic models, or establish a control

tool (Soto-Valle

et al., 2020).

Various factors affect the efficiency of horizontal wind turbine blades

includingthe angle of attack of the blade. The angle of attack of the blade is

one of the most dominating parameters for wind turbine control and blade design

(Wen

et al., 2018). Ravi, Madhukeshwara, and Kumarappa (2015) presented a study on

NACA 4412 airfoil to compare wind tunnel test experimental results of lift and drag coefficients with two different modeling

approaches, namely the

k-? model and the Spalart-Allmaras model (Ravi, Madhukeshwara, and Kumarappa, 2015). These comparisons

revealed that the two models provided close predictions of the experimental

outcomes. It is concluded that the K-? SST turbulence model with transition

capabilities gives a close prediction of lift and drag coefficient both in the

pre-stall and post-stall region.

This study investigates the effect of the angle of attack on

coefficients and forces, specifically on a blade with NACA 4412 airfoil in a

horizontal axis wind turbine. The length, thickness, and chord length of the

blade were 3m, 0.36m, and 0.12m respectively. To accomplish these objectives, a

method was developed to model the horizontal wind turbine blade, generate

meshes, and perform Computational Fluid Dynamics (CFD) of horizontal axis wind

turbine blades to find lift and drag coefficients. CFD assists in determining

whether or not the turbine can operate because, if the turbine fails in CFD, it

will probably fail empirically. In addition, the correlation between different

angles of attack, lift, and drag forces have been investigated in this study.

Lastly, an attempt was made to compare the efficiency with other results by

modeling horizontal axis wind turbine blades in real dimensions. The real-size simulation, which is suitable

for the climate of the city, can be a significant reference for comparing data

between smaller and real sizes. Due to their high complexity, air-fluid and

aerodynamic calculations can generate strange and extraordinary results in

different dimensions. This type of analysis can be useful for improving wind

turbine blades in specific cities and may assist other researchers to achieve

more accurate results.

One of the most commonly used is NACA 4412

airfoil because it has a high cl/cd ratio. (Lololau et al., 2021). For instance, the NACA 4412 wing section has a 4%

camber at 0.4 chords from the leading edge and a 12% thickness. Teak is

utilized as the blade material because of its ease of production, availability,

and affordability (Sekhar, Kumar, and Reddy, 2014). Furthermore, the use of teak wood

blades were chosen due to their light weight and ability to withstand fatigue

testing (Maldhure and Kharde, 2013). It was agreed that SolidWorks software would be

utilized for the project's modeling work.

Figure 1 depicts the forces and angles of relative wind (p) and angle of attack (a) acting on blade sections, where TN and TQ are normal (thrust) and tangential (torque) forces, respectively, and both forces are generated by lift (L) and drag (D) forces.

Figure 1 Diagram of

the angles and forces on one of the sections of the HAWT blade

The Drag force

is a rearward, retarding force caused by disruption of airflow by the wing,

rotor, fuselage, and other protruding objects. The coefficient of drag is

defined by the equation (1) below:

Where: D is the drag force, ? density of the air (kg/m3), Vr relative velocity when air flowed through the airfoil (m/s), and l is the chord length (m). The Lift force

is a force that opposes the downward force of weight. It is produced by the

dynamic effect of the air acting on the airfoil and acts perpendicular to the

flightpath through the center of the lift. The

coefficient of lift is defined by following equation:

Where: L is the drag force, ? density of the air (kg/m3), Vr relative velocity when air flowed through the airfoil (m/s), and l is the chord length (m).

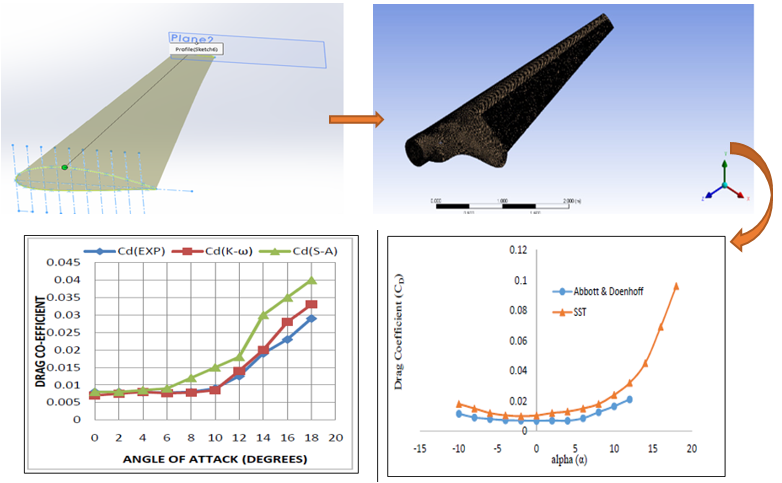

In this study,

the modeling process was initiated by creating the blade curve at the front

plane using (curves through xyz points) from the Curves menu from the Features

panel. As a reference for the blade length, the front plane was 3 m away from

the original curve and 0.36 m thick, while the chord length was 0.12 m. The

airfoil curves are then converted to a sketch on their respective reference

planes and twisted about their aerodynamic center. The new plane was used to

scale the original curve into a smaller entity with a ratio of 0.26 smaller

than the original curve. The scaled entity was given a 10-degree twist in the

direction denoted by the negative sign, which refers to the direction of the

twist. Additionally, a lofted base boss was made between the two planes which

consist of the original curve and the scaled entity, as depicted in Figure 2.

After lofting the two planes, a new sketch was created using the front plane to

draw a 250 mm-diameter circle and a construction line at the first quarter of

the chord length. Moreover, a new sketch was created at the front plane by

drawing a line connecting the blade and the circle. At the right side of the

blade, a spline was sketched to shape the blade.

Figure 2 Left: Lofted Boss Base; Right: The CAD model

after meshing

A horizontal-axis wind turbine blade with a Naca 4412 airfoil was

modeled and analyzed in this study. The blade measured 3 meters in length, 0.36

meters in thickness, and 0.12 meters in chord length. The blade was analyzed in

the simulated wind tunnel using Ansys software. The blade was placed horizontally

and connected to the left wall from the root in the direction of the X-axis in

the mentioned wind tunnel; it was located at the end of the first third of the

wind tunnel. The entrance surface of the tunnel had a curved projection. Hence,

the wind entering the tunnel would be proportional to its speed, Reynolds

number, and disturbances. The X-axis or transverse axis of the wind tunnel

should be used when adjusting the angle of attack. This angular change was done

without displacement in the depth of the wind tunnel. The depth of the wind

tunnel was three times the length of the blade. Air entered the blade from the

front of the wind tunnel at a speed of 6.9 m/s. In this study, the Reynolds

number was determined based on the kinematic viscosity value which is

The mesh

generating process was conducted using ANSYS Workbench Project Schematic and double-click on the Mesh cell in the elbow fluid flows analysis

system as shown in Figure 2. Generating a mesh manually can be

time-consuming and error-prone. Mesh size is a key factor in an effective

simulation. Mesh refining techniques should be used to optimize mesh

sensitivity to produce a mesh of excellent quality. Mesh convergence was done

in this study. A blade was modeled and meshed with eight different sizes

ranging from 0.5 mm to 5.5 mm. Both lift and drag were obtained. It was

observed that the outcomes are approximately the same with a 2-mm mesh size.

Hence, convergence was reached when there was no qualitative change in the

result of less than 1% in the blade. Therefore, a mesh size of 2 mm was chosen

for the whole study.

Despite the fact that ANSYS CFD is an industry-standard modeling software, it is important to ensure that the results produced are logical and valid. The results produced from the blade using ANSYS were compared with XFLR5 software. XFLR5 is a user-friendly design and analysis program for airfoils and bodies. The program analyzes the aerodynamic performance of two-dimensional airfoils using XFOIL codes. The program is capable of calculating lift, drag, pitching moment, and pressure coefficients of airfoils in two-dimension by using a fully coupled viscous/non viscous interaction method with a high-order panel method (GÜZELBEY, Eraslan and Dogru, 2018). The results obtained from ANSYS Fluent were compared with XFLR5 software to guarantee the accuracy of the results.

Several parameters influence

the efficiency of horizontal wind turbine blades, including the blade's angle

of attack. One of the most important criteria for wind turbine control and

blade design is the angle of attack of the blade (Wen et al.,

2018). The effect of the angle of attack on lift and drag

coefficients and forces of NACA 4412 is studied insufficiently. This research

will investigate this correlation to increase the efficiency of horizontal

wind turbines. Therefore,, the focus of this research is on the alteration of

horizontal wind turbine blades. To accomplish these goals, a methodology for

modeling a horizontal wind turbine blade, creating meshes, and performing

computations were created.

Figure 3 compares the outcomes of previous studies

conducted to determine the lift coefficient for NACA 4412 with the outcomes of

the current study. Figures 3.1, 3.2, and 3.3 are the results of the previous

studies conducted on the relation between the angle of attack and lift

coefficient, while Figure 3.4 is the result of the current study. In all

the studies, the lift coefficient is observed to increases as the angle of

attack increases. Also observed in the previous study is that after 16°, the

lift coefficient starts to decrease as the blade stalls, and the lift decreases

once more. Nevertheless, the results of the present study indicated that the

lift coefficient continued to increase until it reached 20°.

Figure

3 Comparison between different graphs to obtain Cl;

(a): Ravi, Madhukeshwara, and Kumarappa, (b): Petinrin and Onoja, (c): Khaled,

(d): current study.

The results

obtained from this study were relatively similar to the results of previous

studies conducted to find the drag coefficient. Table 1 displays the results of

a study conducted by Ravi utilizing the book “theory of wing sections” by

Abbott with two different modeling approaches, namely the k-? model and

Spalart-Allmaras, and the results of the current study from 0°-18°.

This indicates that the Spalart-Allmaras has the highest matching with the current

study results of Cd.

Figure 4 shows a comparison between the results from the previous

studies conducted to find the drag coefficient for NACA 4412 in addition to the

results obtained from this study. It is observed that in all the studies the

drag coefficient increases with the increase in the angle of attack. Also, the

drag coefficient starts to decrease after 16°. However, the

results obtained from this study indicated that the lift coefficient kept

increasing until 20°.

Table 1 Comparison

between Ravi, Madhukeshwara, and Kumarappa’s study to obtain Cd

|

AOA |

Current Cd

Results |

Spalart-Allmaras Cd results |

K-? model Cd

results |

Wind Tunnel

Test Cd results |

|

0 |

0.005 |

0.008 |

0.007 |

0.008 |

|

2 |

0.01 |

0.008 |

0.0075 |

0.008 |

|

4 |

0.017 |

0.0085 |

0.008 |

0.0079 |

|

6 |

0.026 |

0.009 |

0.0076 |

0.0078 |

|

8 |

0.037 |

0.012 |

0.0078 |

0.008 |

|

10 |

0.049 |

0.015 |

0.0085 |

0.009 |

|

12 |

0.062 |

0.018 |

0.014 |

0.0125 |

|

14 |

0.077 |

0.03 |

0.02 |

0.019 |

|

16 |

0.092 |

0.035 |

0.028 |

0.023 |

|

18 |

0.109 |

0.04 |

0.033 |

0.029 |

Figure 4 Comparison between different graphs to obtain Cd; (a): Ravi, Madhukeshwara, and Kumarappa, (b): Petinrin and Onoja, (c): Khaled study, (d): the current study

Figure 5 shows a comparison between the results from the previous studies conducted to find a lift-to-drag ratio for NACA 4412 in addition to the results obtained from this study. Khaled's previous research demonstrated that the efficient attack angle for an airfoil is 6 °, after which the efficiency of the airfoil decreases. The current study indicated that the most efficient attack angle is 0°. This experiment was conducted at angles ranging from -14° to 20°. The expectations for angles above 20° are likely to have an increment in lift force and drag force. Consequently, both the lift and drag coefficients will rise.

Figure 5 Comparison

between different graphs to obtain

Cl/Cd; (a): Khaled study, (b): the current study

This

project is modifying the horizontal wind turbine blade design by studying the

effect of blade angle of attack on efficiency. In 2019, lift and drag are the

key factors affecting wind turbine efficiency. The project was conducted by

selecting an appropriate airfoil, selecting appropriate software, modeling a

horizontal wind turbine blade using SolidWorks, transferring CAD files into

Ansys, running models and investigating CFD results, and validating the

obtained results. CFD investigation was conducted on an attack angle ranging

from -14° to 20°.

The

negative lift coefficient only occurs at small angles of attack, which

corresponds to laminar separation without flow transition and reattachment. It

also implies that the lift is acting in the opposite direction of the body (Pranesh, et al, 2019). It was

determined that the lift coefficient increased as the angle of attack increased

because the angle between the chord line and relative wind increased.

Furthermore, it is also observed that the drag coefficient decreased until it

reached to 0°, then it increased as the lift coefficient increased. As

the angle of attack increases, the lift coefficient increases which affects in

the amount of the induced drag. This effect is known as “induced drag” or “drag

due to lift.” Induced drag increases as the angle of attack of the blade

increase. As a result of increasing the drag coefficient, the drag force

increased too. Positive drag force indicates that the airfoil is decelerating;

thus, the values obtained experimentally indicate that the drag is causing the wind

turbine blade to slow. Furthermore, the lift-to-drag ratio is used to express

the relation between lift and drag and is determined by dividing the lift

coefficient by the drag coefficient. This ratio indicates the airfoil’s

efficiency; the higher the ratio the more efficient is the airfoil.

The

findings of this research were close to the previous studies conducted to find

lift coefficients. In the literature, it has been demonstrated that a higher

Reynolds number results in a higher lift coefficient; thus, the difference in

lift coefficient results can be attributed to the use of various Reynolds

numbers. The current study used a Reynolds number of 563,500, whereas the

previous study used a Reynolds number of 3 million.

The angle of

attack is a significant factor that affects the efficiency of the blade.

Furthermore, it is very important to determine the ideal attack angle for the

airfoil selected to guarantee the best performance and efficiency. This project

aimed to investigate the impact of the relationship between angle attack and

efficiency by determining the optimal angle of attack to increase the

efficiency of the horizontal axis wind turbine blade. Therefore, an analysis

was conducted on the blade to find the lift coefficient, drag coefficient, and

lift and lift-to-drag coefficient ratio. Furthermore, the lift and drag force

affecting the blade was determined and calculated. This study concluded that

the most efficient attack angle for NACA 4412 is 0° and the

highest lift and drag coefficient occurred at 20°. The results

demonstrated that an identical airfoil have different lift and drag

coefficients at the same angle of attack. This study was conducted by modeling

a full blade and performing dynamic analysis on the blade to produce results,

which may cause a source of errors due to modeling errors. However, this

problem can be overcome by using an airfoil curve instead of the entire blade

for the analysis.

This research

was funded by Oman's Global College of Engineering and Technology.

Bortolotti, P., D. Berry, R. Murray, E.

Gaertner, D. Jenne, R. Damiani, G. Barter, K. Dykes. 2019. A detailed wind

turbine blade cost model. Report Golden National Renewable Energy

Laboratory, NREL/TP-5000-73585, USA

Chang, J., Zhu,W., Fischer, A., Garcla, N.R.,

Madsen, J., Chen, J., Shen,W.Z. 2014. Design and validation of the high

performance and low noise CQU-DTU-LN1 airfoils. Wind Energy, Volume 17, pp. 1817–1833

Chaudhary, M., Roy A., 2015. Design & optimization of a small wind turbine blade for operation at low wind speed, International Journal on Recent Technologies in Mechanical and Electrical Engineering, Volume 2(3), pp. 83–94

GÜZELBEY, I.H., Eraslan Y., Dogru, M.H., 2018. Numerical Investigation of Different Airfoils at Low Reynolds Number in terms of Aerodynamic Performance of Sailplanes by using XFLR5. Karadeniz Fen Bilimleri Dergisi, Volume 8(1), pp. 47–65

Johansen, J., Madsen, H.A., Gaunaa, M., Bak,

C., Srensen, N.N. 2009. Design of a wind turbine rotor for maximum aerodynamic

efficiency. Wind Energy, Volume12, pp.

261–273

Kasem, M.A.M., 2020. Aerodynamic, structural,

and aeroelastic design of wind turbine blades. In: Design

Optimization of Wind Energy Conversion Systems with Applications. IntechOpen, pp. 109–125

Lololau, A., Soemardi, T.P., Purnama, H.,

Polit, O., 2021. Composite multiaxial mechanics: laminate design optimization

of taper-less wind turbine blades with ramie fiber-reinforced polylactic acid. International

Journal of Technology, Volume 12(6), pp. 1273–1287

Maldhure, S., Kharde, D., 2013. Fatigue

failure analysis of small wooden wind turbine blade. International Journal

of Computational Engineering Research, Volume 3(2), pp. 2250–3005

Pranesh, C., Sivapragasam M., Deshpande M.D.,

Narahari H.K. 2018. Negative lift characteristics of NACA 0012 aerofoil at low

Reynolds numbers. Sådhanå, p. 44:21

Ravi, H.C., Madhukeshwara, N., Kumarappa, S.,

2013. Numerical investigation of flow transition for NACA-4412 airfoil

using computational fluid dynamics, International Journal of Innovative

Research in Science, Engineering and Technology, Volume 2(7), pp. 2778–2785

Sekhar, ?.C.K., Kumar ?.N.G., Reddy, ?.?.B.G., 2014. Design of blade for a wooden small scale

wind turbine for domestic purposes. International Journal of Current

Engineering and Technology, Volume 44(33), pp. 1309–1313

Soto-Valle, R., Bartholomay, S., Alber, J., Manolesos,

M., Nayeri, C.N., Paschereit, C.O., 2020. Determination of the angle of

attack on a research wind turbine rotor blade using surface pressure

measurements, Wind Energy Science Discussions, Volume 2020, p. 35

Sudarsono, Susastriawan, A.A., Sugianto.,

2019. Three-dimensional cfd analysis of performance of small-scale hawt based

on modified NACA-4415 airfoil. International Journal of Technology, Volume

10(1), pp. 212–221

Tang, X., 2012. Aerodynamic design

and analysis of small horizontal axis wind turbine blades. Thesis,

University of Central Lancashire, United Kingdom

Yavuz, T., Koç, E., K?lk??, B., Erol, Ö.,

Balas, C., Aydemir, T., 2015. Performance analysis of the airfoil-slat arrangements

for hydro and wind turbine applications. Renewable

Energy, Volume 74(C), pp 414-421

Wen, B., Tian, X., Dong, X., Peng, Z., Zhang,

W., Wei, K., 2019. A numerical study on the angle of attack to the

blade of a horizontal-axis offshore floating wind turbine under static and

yawed conditions. Energy, Volume 168, pp. 1138–1156

Woofenden, I.,

2013. Wind Power for Dummies, Wiley Publishing Inc