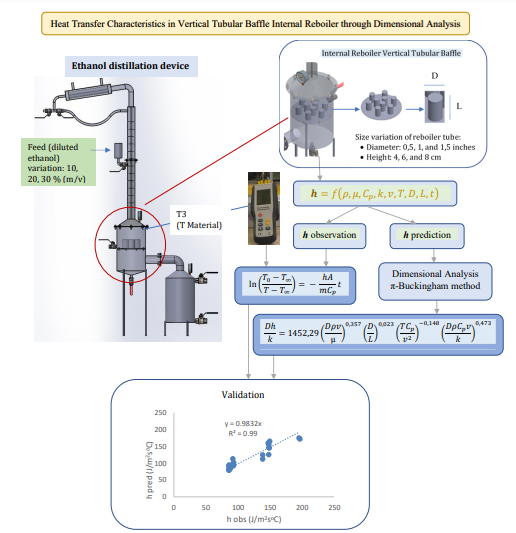

Heat Transfer Characteristics in Vertical Tubular Baffle Internal Reboiler through Dimensional Analysis

Corresponding email: bambang_pw@ugm.ac.id

Published at : 01 Jul 2022

Volume : IJtech

Vol 13, No 3 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i3.5170

Susmiati, Y., Purwantana, B., Bintoro, N., Rahayoe, S., 2022. Heat Transfer Characteristics in Vertical Tubular Baffle Internal Reboiler through Dimensional Analysis. International Journal of Technology. Volume 13(3), pp. 508-517

| Yuana Susmiati | 1. Doctoral student of Agricultural Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada, Jl. Flora 1, Bulaksumur, Yogyakarta, 55281, Indonesia 2. Departemen of Renewable Energy |

| Bambang Purwantana | Departement of Agricultural and Biosystem Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada, Jl. Flora 1, Bulaksumur, Yogyakarta, 55281, Indonesia |

| Nursigit Bintoro | Departement of Agricultural and Biosystem Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada, Jl. Flora 1, Bulaksumur, Yogyakarta, 55281, Indonesia |

| Sri Rahayoe | Departement of Agricultural and Biosystem Engineering, Faculty of Agricultural Technology, Universitas Gadjah Mada, Jl. Flora 1, Bulaksumur, Yogyakarta, 55281, Indonesia |

Heat transfer in shell

and tube heat exchangers is in general described in terms of the relationships

of Nuselt, Prandtl, and Reynold dimensionless numbers. One of the parameters of

heat exchanger performance is convective heat transfer coefficient (h),

and mathematical model can predict it. This study aimed to find out the

relationship of the parameters that affected the performance of vertical

tubular baffle internal reboiler during ethanol distillation. The

mathematical model was developed by a dimensional analysis with the ?-Buckingham method. Several influencing

parameters during the distillation process were identified to develop a

mathematical model. The study was carried out on the distillation process of

low-concentration ethanol, i.e., 10%, 20%, 30% using internal reboilers with

different tube sizes, i.e., diameters of 1.27 cm, 2.54 cm, 3.81 cm and height

of 4 cm, 6 cm, 8 cm, to obtain the value of h observation. Based on the

results of the study, a heat transfer model was obtained, i.e.,, where Nu, Re, D, L, T, Cp, v, ?, and k, are respectively Nuselt, Reynold, tube diameter, tube height,

temperature, heat capacity, velocity, mass density, and thermal conductivity of

the fluid (material). This model can be used to determine h prediction,

and the result is following h observation with equation y = 0.98x and R² = 0.99. Based on the results of

the study, it is known that differences in material concentration, diameter,

and height of the reboiler tube affect the value of h.

Dimensional analysis; Internal reboiler; ?-Buckingham method

A distillation

process is determined by the type of heat exchanger (reboiler) that serves to

heat and evaporate the distilled solution. The temperature in the reboiler is

determined by the types of the reboiler and it affects the distillation

productivity (Bhanvase

et al., 2007 and Foletto,

2015). In general,

small-scale distillation uses an internal reboiler, i.e., a heat exchanger

located in the bottom column of the distillation equipment and submerged in the

distilled solution (Bell

et al., 2011).

The types of heat

exchangers used as internal reboilers include stub in U-tube bundle reboiler (Voigt & Nj, 2013), calandria (Bhanvase et al., 2007), and vertical helical coil (Ghorbani et al., 2010). A design and test of another type of heat

exchanger with different shapes and directions of fluid flow were developed by (Susmiati et al., 2019) named vertical tubular baffle. This study showed

that the geometry (diameter, height, and the number of tubes) in this type of

heat exchanger affects the heat transfer coefficient. As explained by (Abd & Naji, 2017) the heat transfer coefficient in a heat

exchanger can be increased by increasing the tube length. (Lei et al., 2017) also stated that different baffle shapes

in a shell and tube heat exchanger produce different heat transfer

coefficients, i.e., louver baffle is higher than segmental baffle.

The heat

transfer in the vertical tubular baffle internal reboiler during the ethanol

distillation process can be described in the form of a relationship of various

influencing parameters and

was obtained,

where Nu, Re, D, L, T, Cp, v, ?, and k, are respectively Nuselt, Reynold, tube diameter, tube height,

temperature, heat capacity, velocity, mass density, and thermal conductivity of

the fluid (material). The mathematical model can be used to

determine the convective heat transfer coefficient (h) and its validity

reaches 99%. The highest convective heat transfer coefficient was obtained

in the experiment with a reboiler that was 1.27 cm in diameter and 8 cm in

height, and a 10% material concentration, i.e., 196.19 J/m2soC.

The author would like

to express her gratitude for the research funding through the program of Final

Project Recognition (RTA) of Universitas Gadjah Mada in 2019. The author would

also like to thank the technicians and managers of the Laboratory of Energy and

Agricultural Machinery, Faculty of Agricultural Technology, Universitas Gadjah

Mada, for the completion of this research.

Abd,

A.A., Naji, S.Z., 2017. Case Studies in Thermal Engineering Analysis Study of

Shell and Tube Heat Exchanger for Clough Company with Reselect Different

Parameters to Improve the Design. Case Studies in Thermal Engineering, Volume

10, pp. 455–467

Alimoradi,

A., 2017. Case Studies in Thermal Engineering Study of Thermal Effectiveness

and its Relation with NTU in Shell and Helically Coiled Tube Heat Exchangers. Case

Studies in Thermal Engineering, Volume 9, pp. 100–107

Badi,

D., Al Helal, A., Lagat, C., Phan, C., Barifcani, A., 2021. Evaluation of Reboiler

Temperature Retention Time in MEG Degradation Products at Varying MEG Concentrations.

Journal of Petroleum Science and Engineering, Volume 196, p. 107735

Bell,

J.A., Bouck, D., Farone, J.P., Flowers, J., Grave, E., Kister, H.Z., Marut, T.,

Morehead, P., Olsson, R., Parker, J., Summers, D.R., De Villiers, W.E., Wilder,

L., Xu, S., Yeoman, N., 2011. Reboiler Circuits for Trayed Columns. Chemical

Engineering, Volume 118(1)

Bhanvase,

B.A., Deosarkar, M.P., Shirsath, S.R., Gaikwad, R.W., 2007. Internal Reboiler

in the Distillation Column. Chemical Engineering World, Volume 42(6), pp. 86–88

Choi, K., Oh, J., 2011. Two-Phase Flow Boiling Heat

Transfer of R-410A and R-134A in Horizontal Small Tubes. International

Journal of Technology, Volume 2(2), pp. 139–146

Demedeiros,

A., Ferguson, R., Powers, B., 2009. Transient

Response Characteristics and Lumped System Analysis of Geometrically Similar

Objects. Available online at

https://studylib.net/doc/18343208/transient-response-characteristics-and-lumped-system-anal

Foletto,

E.L., 2015. Operation Parameters of a Small-Scale Batch Distillation Column for

Hydrous Ethanol Fuel (HEF) Production. Ingeniería e Investigación, Volume

35(1), pp. 31–35

Fouda,

A., Nada, S.A., Elattar, H.F., Refaey, H.A., Bin-mahfouz, A.S., 2018.

International Journal of Mechanical Sciences Thermal Performance Modeling of

Turbulent Flow in Multi-Tube in Tube Helically Coiled Heat Exchangers. International

Journal of Mechanical Sciences, Volume 135, pp. 621–638

Ghorbani,

N., Taherian, H., Gorji, M., Mirgolbabaei, H., 2010. Experimental Study of Mixed

Convection Heat Transfer in Vertical Helically Coiled Tube Heat Exchangers. Experimental

Thermal and Fluid Science, Volume 34(7),

pp. 900–905

Kim,

D., Joshua, E., Pialago, T., Shin, J., Kyung, O., Kim, M., Woo, C., 2017. Performance

Characteristics of Heat Exchanger with Internal Turbulence Generators under

Various Blade Configurations and Operating Conditions. Applied Thermal

Engineering, Volume 123, pp.

562–572

Lei,

Y., Li, Y., Jing, S., Song, C., Lyu, Y., Wang, F., 2017. Design and Performance

Analysis of the Novel Shell-and-Tube Heat Exchangers with Louver Baffles. Applied

Thermal Engineering, Voluem 125,

pp. 870–879

Liaw,

K.L., Kurnia, J.C., Sasmito, A.P., 2021. Turbulent Convective Heat Transfer in

the Helical Tube with Twisted Tape Insert. International Journal of Heat and

Mass Transfer, Volume 169, p.

120918

Lin,

J.H., Huang, C.Y., Su, C.C., 2007. Dimensional

Analysis for the Heat Transfer Characteristics in the Corrugated Channels of

Plate Heat Exchangers. International Communications in Heat and Mass

Transfer, Voluem 34(3), pp.

304–312

Loubière,

C., Delafosse, A., Guedon, E., Chevalot, I., Toye, D., Olmos, E., 2019.

Dimensional Analysis and CFD Simulations of Microcarrier Just Suspended State In

Mesenchymal Stromal Cells Bioreactors. Chemical Engineering Science,

Volume 203, pp. 464–474

Nakla,

M. El. 2011. International Journal of Multiphase Flow on Fluid-To-Fluid

Modeling of Film Boiling Heat Transfer using Dimensional Analysis. International

Journal of Multiphase Flow, Volume 37(2),

pp. 229–234

Padmanabhan,

S., Reddy, O.Y., Yadav, K.V.A.K., Raja, V.K.B., Palanikumar, K., 2021. Heat Transfer

Analysis of Double Tube Heat Exchanger with Helical Inserts. Materials

Today: Proceedings, Volume 46(part 9), pp. 3588–3595

Parhi,

S.S., Rangaiah, G.P., Jana, A.K., 2019. Optimizing Reboiler Duty and Reflux

Ratio Profiles of Vapor Recompressed Batch Distillation. Separation and

Purification Technology, Volume 213,

pp. 553–570

Perry,

R.H., Green, D.W., Maloney, J.O., 1997. Chemical Engineers’ Handbook Seventh.

McGraw-Hill, USA

Pexton,

M., 2014. How Dimensional Analysis Can Explain. Synthese, Volume 191(10), pp. 2333–2351

Putra, N., Septiadi, W.N., Julian, G., Maulana, A., Irwansyah,

R., 2013. An Experimental Study on Thermal Performance of Nanofluids in

Microchannel Heat Exchangers. International Journal of Technology, Volume

4(2), pp. 167–177

Rosa,

S., Elena, M., Taqueda, S., Luis, J., Paiva, D., Silva, M., Moraes, D., 2017.

Nusselt’s Correlations in Agitated Tanks using the Spiral Coil with Rushton Turbine

and PBT 45° Impeller. Comparison With Tanks Containing Vertical Tube Baffles. Applied

Thermal Engineering, Volume 110,

pp. 1331–1342

Siswantoro,

Rahardjo, B., Bintoro, N., Hastuti, P., 2012. Mathematical Modeling of Heat and

Mass Transfer on Frying by using Sand as a Medium for Transferring Heat. Agritech,

Volume 32(1), pp. 87–97

Susmiati,

Y., Purwantana, B., Bintoro, N., Rahayoe, S., 2019. Design and Testing of the

Vertical Tubular Baffle Heat Exchanger as an Internal Reboiler in the

Distillation Device. IOP Conference Series: Earth and Environmental Science,

Volume 355(1), 012001

Susmiati,

Y., Purwantana, B., Bintoro, N., Rahayoe, S., 2021. Kinerja Internal Reboiler

Tipe Vertical Tubular Baffle pada Proses Distilasi Etanol secara Batch (Internal Performance of Vertical Tubular

Baffle Reboiler in Batch Ethanol Distillation Process). Jurnal Rekayasa

Proses, Volume 15(1), p. 59

Tuncer,

A.D., Sözen, A., Khanlari, A., Gürbüz, E.Y., Variyenli, H.?., 2021. Upgrading the

Performance of a New Shell and Helically Coiled Heat Exchanger by using

Longitudinal Fins. Applied Thermal Engineering, Volume 191, p. 116876

Voigt,

I., Nj, D.U.P., 2013. Modular

Evaporators. International Sugar

Journal, Volume 116(1382), pp. 119–123

Wicaksono, R.P.S., Fathia, S.H., Kolang, I.F., Riadi, A.,

Nirbito, W., Muharam, Y., Nugroho, Y.S., 2019. Effect of the Heat Transfer Surface

on Prevention of Spontaneous Combustion of Coal. International Journal of

Technology, Volume 10(6), pp.

1220–1227

Witdarko,

Y., Bintoro, N., Suratmo, B., Rahardjo, B., 2016. Pemodelan pada Pengeringan

Pneumatik Mekanis Tepung Kasava: Hubungan Koefisien Pindah Panas dengan

Variabel Pengeringan (Modelling on

Mechanical Cassava Flour Pneumatic Drying: Correlation of Heat Transfer

Coefficient and Drying Variables). Agritech, Volume 36(3), pp. 362–368

Zhang, T., Hu, J., Tang, S., 2018. Densities and

Surface Tensions of Ionic Liquids/Sulfuric Acid Binary Mixtures. Chinese

Journal of Chemical Engineering, Volume 26(7), pp. 1513–1521