Engine Room Module Installation System Risk Analysis Based on Bayesian Network

Corresponding email: intan.baroroh@hangtuah.ac.id

Published at : 25 Jan 2024

Volume : IJtech

Vol 15, No 1 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i1.5136

Baroroh, I., Ma’ruf, B., Basuki, M., Hardianto, D., Kristiyono, T.A., 2024. Engine Room Module Installation System Risk Analysis Based on Bayesian Network. International Journal of Technology. Volume 15(1), pp. 75-86

| Intan Baroroh | Department of Naval Architecture and Ship Building, Marine Science and Technology, Hang Tuah University (UHT), Jalan Arief Rahman Hakim 150 Surabaya, East Java 60111, Indonesia |

| Buana Ma’ruf | The National Research and Innovation Agency (BRIN), Jalan Hidro Dinamika, Keputih, Sukolilo, Surabaya. East Java 60111, Indonesia |

| Minto Basuki | Department of Marine Engineering Institut Teknologi Adhi Tama Surabaya (ITATS), Jalan Arief Rahman Hakim 100 Surabaya, East Java 60117, Indonesia |

| Didik Hardianto | Department of Naval Architecture and Ship Building, Marine Science and Technology, Hang Tuah University (UHT), Jalan Arief Rahman Hakim 150 Surabaya, East Java 60111, Indonesia |

| Tri Agung Kristiyono | Department of Naval Architecture and Ship Building, Marine Science and Technology, Hang Tuah University (UHT), Jalan Arief Rahman Hakim 150 Surabaya, East Java 60111, Indonesia |

Implementation of system installation risk

on engine room module aims to anticipate ship production delays. However, in its implementation, there is the

problem of ship delivery delays in various shipbuilding companies. This research will analyze the risk analysis of the

installation of the engine room module system by identifying risk factors and

parameters that affect performance as a hazard identification that has the

potential to cause delivery delays.

The object of the research is the Indonesian Navy's

Auxiliary Hospital Ship, which has 6 zones with a pilot project developed in

zone 2. This includes an engine room that contains important constructions in

the form of a main motor foundation, auxiliary motor, and other machinery,

where the system was integrated.

Moreover, there are some works consisting of

construction, outfitting, and commissioning which are very complicated and

require high accuracy. The aim of the implementation of risk analysis of the installation

system in the engine room’s module is to assess potential risks, the

effect of risk on project delays, and project cost overruns. The research

method uses a Bayesian network because it is able to assess the most potential

risks and predict the possibility of delays at network nodes. The primary risk is associated with electrical

activities, specifically electrical

outfitting on wiring, clamping, and compound sub-components with a probability

of (0.0002560) in the Machinery Outfitting and Electrical Department. This risk stems from

inappropriate steps during drawing revisions, which have the potential to cause

delays in equipment installation, cable material procurement, and the

generation of cable cutting data. Therefore, early coordination with production

planning control, design, and the supply chain is crucial.

Bayesian network; Installation engine room module; Risk analysis

According to the Governing Council of the Indonesia National Ship Owner's Association (DPP INSA), the total ship class acceptance units, based on PT. BKI's report on new buildings from 2009 to 2018, show that the increase in class acceptance reached its peak in 2013. Furthermore, there was a decline from 2014 to 2017, and at the beginning of 2018, there was a growth of 829 units of ships compared to in 2016. This has a positive impact on the growth of national shipyards. Based on shipbuilding data at PT. PAL Indonesia, from 2011 to 2015, the development of shipyards in East Java experienced delays in two ships in the form of a 17.500 LTD tanker, two Tug ships of 2400 HP, and a SSV Philippines Navy ship."In the case of PT. Dumas Tanjung Perak shipyards, there were four shipbuilding delays from 2011 to 2020, including the 3500 DWT Hull No 109 tanker, 3500 DWT Hull No 111 tankers, 60 meters, and Fast Patrol Boat. Whilst PT. Dock and Shipping Surabaya was delayed in the production of Landing Craft Tank ships, Landing Craft Tank 100 TEUS, Tanker 6.500 DWT, and Self-Propelled Barge Cement Carrier.

The condition description of PT. PAL Indonesia, PT. Dumas

Tanjung Perak shipyards and PT. Dock and Shipping Surabaya has suffered

considerably due to a late penalty of delivery. Other losses are also in the

form of loss of trust from the ship owner and the bank as a lender. Besides, it

declines the company's performance. The latest developments in East Java

shipyards are accelerating production with the modular (Zone) system method on

hospital auxiliary ships whose construction plan was carried out on September

16, 2019. It planned handover of September 30, 2021, but there is a setback

until December 8, 2021, because of various obstacles during production,

especially the complex system in zone 2 of the engine room. The

loss of

shipbuilding delays can actually be reduced or anticipated if the risk

management process is implemented and executed properly at the beginning of the

project. The probability of risk can be calculated by various methods,

one of which is the Bayesian network (BN) approach. BN can be used in various

dynamic security and risk analyses due to its flexible structure on the cause of failure and

mutual conditional dependence by performing probability updates. Meanwhile,

quantitative risk analyses, such as Bow-tie, Barrier block diagram, and Petri net,

show an inability to consider conditional dependencies amongst underlying

events Zarei et al. (2017). The Bayesian method has also proven capable of being used

in complex model development Burova et al. (2021) by using a weighting method to evaluate

business economics risk Lyukevich et al. (2020). The advantages and flexibility of the Bayesian network

method are chosen in the risk analysis of the complex system installation of

the engine room zone 2.

Risk

measurement using the AHP (Analytic Hierarchy Process) is also carried out by (Zhong, Lv, and Zhang, 2019; Jia, Zhao, and Zhang,

2013). Moreover, Zhong collects the risk factors that

are potential from company T projects adapted to the Delphi method. After a few

rounds, it got 22 factors of level three from the factors of level 6 is

original. Then, filter 22 factors of level

three to identify TOP 10 factors using the Analytic Hierarchy Process (AHP).

Then, calculate the weights of all factors and get a list of the top 10 critical factors. Likewise, a

market risk mitigation strategy using the FUZZY FMEA method has been carried

out by Rahmatin et al. (2018) in food

companies by increasing promotion strategies,

promotion strategies are used as mitigation aspects. Risk for contractor expectations

versus insurance company policies by Hatmoko, Astuti, and Farania (2021), which causes the

head office to lose insurance claim benefits. Probabilistic Risk Assessment of COVID-19 Patients by Ting, Zakariah, and Yusri (2022) using the Logistic

Regression instrument.

Risk Control Failure of Iron Pipes by Suwandi, Zagloel, and Hidayatno (2021). However, the interactions are not clear and measurements

have not been carried out. While the impact of the risk variable cannot be

seen, its effect on the performance system.

Bayesian Risk Measurement in banking

institutions and the construction industry has been carried out by (Eschmann et al., 2019; Erango and Goshu, 2019; Zhou et al.

2018; Do and Yin, 2018; Fong et al., 2017; Kim et al. 2012;

Kumar, 2010). In addition, Zhou et al. (2018) did a risk assessment

and showed that the Bayesian network method performs risk assessment

effectively and works flexibly with offshore wind power

construction. The results inform risk mitigation measures by identifying risk sources using a Bayesian dynamic model. The measurement of the

risk of the shipbuilding industry with the Bayesian network with a

questionnaire approach has been carried out by Lee,

Park, and Shin (2009). The model developed for each network at its node has

not been analyzed until the risk value (VaR/Value at Risk) is obtained. The

activities carried out are limited n to n relationships, meaning that one

potential risk has an influence on one risk. Then, a risk analysis is carried

out on material components Basuki et al.

(2014). The subcomponents that

are most likely to cause project delays are the hull and engine equipment, so

they become the main priority in the installation of the engine room and its

equipment.

The duration of shipbuilding in the Indonesian Navy's Auxiliary Hospital

shipbuilding zone there are 6 zones. The construction time of the engine room

zone reaches the longest time, which is 76% of the total ship construction

time. The total blocks that make up the engine room zone reach 30% of the

weight of the 6 zones of ship arrangement. It contains complex systems

integrated into the form of main motor foundations, auxiliary motors, and other

machinery, as well as complex construction, outfitting, and commissioning that

require high accuracy. The engine room is the most urgent object of the

research on the W000302 shipbuilding process at PT PAL Indonesia's shipyard.

The

previous studies such as (Ting, Zakariah, and Yusri,

2022; Suwandi, Zagloel, and Hidayatno, 2021; Zhong, Lv, and Zhang, 2019; Basuki et al., 2014; Jia, Zhao, and Zhang, 2013), researchers are still in the stage of risk

identification, they have not thought about how to proceed with the research.

Many studies have shown that the implementation of the Bayesian Network leads

to better results. The purpose of this research is to identify and assess

engine room installation risks of the Navy Auxiliary Hospital shipbuilding by

using Bayesian Network. However, in this study a quantitative measurement of

the risk analysis has been carried out using the Bayesian method in relation to

the risk variable in each activity in each production workshop. This was due to

various constraints during production, especially complex systems in the zone 2

machine room.

The

gaps from previous research include: The use of Bayesian is still rare in the

field of ship production. Research from Basuki et al. (2014) has used Bayesian methods, but what is done is measuring the probability

of shipbuilding globally. However not all modules on the ship have the same

work, so it is less precise or less specific when applied to modules that are

complex in nature with work that requires a large volume of work. In the engine room zone, although it has a

small module form compared to other modules in the ship's body, it is a

specific zone that requires a high level of difficulty and a large volume of

work. This engine room zone absorbs the most cost and the longest time compared

to other parts of the zone on the ship's body. This is what requires a separate

study to measure the probability and impact of the risk evaluation. This is a gap from research studies regarding

engine room installations, so this research is very important to be carried out

in the construction of the Navy Auxiliary Hospital shipbuilding.

The risk measurement with conditional

probabilities in the engine room module installation model using a Bayesian

network. This model is expected to be able to analyze the magnitude of the

dominant factors that affect the delay in the installation of the engine room

zone in ship construction. The findings of risk

priorities at engine room installation points are used as a reference for

mitigation strategies for shipyards in overcoming delays. This research does not end

with Bayesian analysis but must be continued with quantitative impact

measurements. Not only with the solution of the shipyard management policy, but

there should be scientific results based on the calculation of the model formulation.

Daszynska-Zygadlo

(2012) advocates the use of scenario analysis in risk management studies in

future research. Risk evaluation using the scenario analysis approach allows

users to evaluate the impact of risks on the production process and develop strategies

for risk management in future studies.

As given in the

previous section, this study focuses on PT. PAL Indonesia on the

engine room installation of a new building code W000302. It focuses on

assessing the probability of risks that are affecting the engine room

installation activities. Risk identification is carried out on each production

component of the workshop related to engine room installation activities by

identifying all risks of project completion delays. Risk probabilities are

needed to build a Bayesian network that includes the investigation of hazard

correlation based on the number of nodes in the network using a probabilistic

approach Basuki et al. (2014). Bayesian Networks (BN) is a

powerful probabilistic approach often used for reasoning, diagnosis,

prediction, and decision-making under uncertainty. The engine room installation activity has an

impact on the occurrence of risks that are influenced by three kinds of factors

Ben-Asher (2008), namely:

a. Performance factor, which

is a factor that reflects a decrease in performance.

b. Cost factor, which is a

factor that reflects the additional cost.

c. Schedule factor, which is a

factor that reflects the delay in the schedule

Based on the occurrence of the

engine room installation process, there are several potential risks, risk

events, and risk agents. The potential risk is assessed using the Bayes theorem

probability, where there is a partition relationship between the parts that

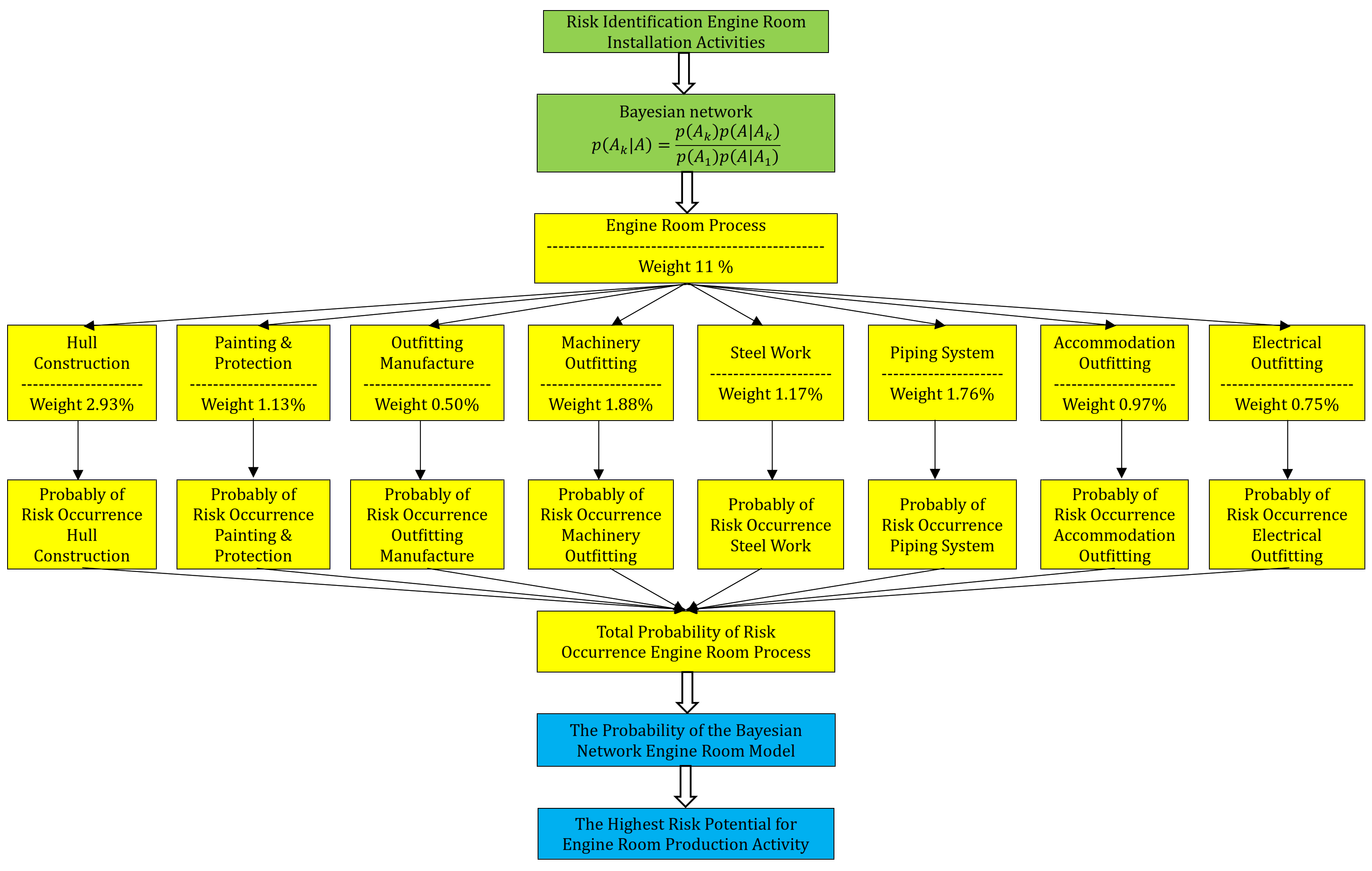

make up the entire sample space as shown in Figure 1.

Figure 1 Partitions concept for

engine room installation production process

According to Figure 1, A:

Production process of engine room installation; A1: Machinery Outfitting; A2: Electric, Electrical

Outfitting A3: Steel Work; A4: Piping System; A5: Fabrication; A6: Assembly; A7: Erection; A8: Painting and Protection; A9: Outfitting Manufacturing; A10: Accommodation Package in the Engine

Room Area. Ten workshops

associated with codes (A1 to A10) were analyzed by a Bayesian method.

According to Figure 1, it can

be formulated in equation 1-4 for Bayesian solutions as follows: if is the

partition space of the sample space S and if the partition

have probabilities not equal to zero, then the probability is:

Where j: 1,2……,n; is the name partition of the 1st to nth

Where k: 1,2….,n; is the number of partition

The Bayesian Network Model based on the Bayes theorem will be described

in more detail in accordance with the identification of risks in the work of

several workshops related to the production process of engine room

installation, according to Figure 1. Figure 1 explains the installation system

in the engine room has synergy and close interrelationships in it. This system

cannot function properly without mutual support between sub-models in the

engine room installation work. The successful execution of this work requires

full cooperation among these sub-models within the series of engine room

installation systems. The method consists of four stages, including:

· Risk identification on the sub-model in the engine room installation

system is done by collecting risk identification as

information or primary data to be taken in the field in the form of surveys,

interviews, and filling out questionnaires by the shipyard.

· Determine the weighting factor of each ship repair activity. The basis

for the preparation of weighting factors in work activities based on

"Proportional production progress" means that the balance in carrying

out production is divided into several stages of work. The weighting factor is

based on either the volume of block weight or the man-hour budget. The

estimation of man-hours for each activity is based on existing experience and

the level of difficulty. The difficulty factor is obtained from the experience

of the workshop or workers in carrying out the activity process. Essentially, the man-hour budget for each job or activity already takes

into account both the volume and the difficulty factor. The weighting factor

obtained varies depending on the workload in each process.

· After the weighting factors are given to the BN network model, the

calculation of the chances of each activity against the constraining factors

that affect these activities in each workshop begins. The risk opportunities

for each activity are summed up in total, so they become the total risk

opportunities for activities in each workshop. These delay factors will be used as the basis for creating a Bayesian

network involved in the engine room installation.

· Measuring delay factors using Bayesian theory with the latest

measurements, conclusions are drawn from the results of risk analysis in engine

room installation. The analysis of high-risk constraints in delay values serves

as a reference for developing further mitigation strategies.

Results

Based on the occurrence of

the engine room installation process and the results observed during the study

on the production code W000302, the researcher analyzed the results and developed the following model under the

Machinery Outfitting (MO) and Electrical Outfitting (EO) Departments, including

the piping workshop, machinery outfitting, steel work, electrical, electrical

outfitting. Meanwhile, activities under the Hull Outfitting and Accommodation

Outfitting Department include Outfitting Manufacturing workshops, Package

Accommodations in the Engine Room area, and Painting and Protection. In

contrast, the activities are under the Department of Hull Construction. It includes fabrication, assembly, and erection. All of these workshops

had a role in the construction of the W000302 ship engine room system

installation, PT. PAL Indonesia was found to have several potential risks. Researcher apply the concept of

probability and the Bayesian method with the weight of each factor obtained

from historical data records of PT. PAL Indonesia, as shown in Figure 2. The basis for the preparation of weighting

factors in work activities is based on Proportional production progress. The value of the weight of each process is obtained from data collected

by the shipbuilding company. The weight values ??will differ for different

shipbuilding processes and shipbuilding companies. It depends on the ship base

owned by the shipbuilding company. The factor is the target value carried out

by each activity workshop.

Ten related workshops that make up the engine room

installation can be analyzed by using a Bayesian network to get the delay

probability value for each factor. The probability value for each factor is the

multiplication result of 1/10 (since there are ten factors) and the weight of

each factor (derived from historical data, as described earlier). Probability

on Bayesian networks is needed to assess any possible delays in the production

process as the focus of this study.

Figure 2 The weighting of the Bayesian main network model

in the engine room

The risk approach for each activity of the Bayesian network new building

engine room model was calculated using the following formula: Risk =

probability of risk occurrence x consequence of risk occurrence. The delay of

the engine room installation process is obtained from the conditions in the

shipyard. The results of this probability of risk occurrence are the basis for

the variable values of the factors that cause delays in each workshop. The

value of this variable causes the performance value of the workshop to decrease

from the initial planning. The decline in the performance of each workshop

affects production delays that cause delays in production time, financial

losses, and even the most severe contract cancellation. For this reason, it is very

necessary to apply risk evaluation in every shipbuilding project to anticipate

losses early. Bayesian probability in each activity of the Bayesian network new

building engine room model is shown in Table 1.

The

network model under the Department of Machinery Outfitting and Electrical

Outfitting includes the Bayesian network model of Machinery Outfitting, shown

in Figures 3(a), (b), (c), and (d).

Table 1 The probability of the Bayesian network engine room model

|

Activity |

Factor Weight |

Probability |

|

Machinery Outfitting (MO) |

0.0188 |

0.0003760 |

|

Electrical Outfitting (EO) |

0.0075 |

0.0004650 |

|

Steel Work |

0.0117 |

0.0003900 |

|

Piping System |

0.0176 |

0.0001340 |

|

Fabrication |

0.0082 |

0.00020377 |

|

Assembly |

0,0141 |

0.00035252 |

|

Erection |

0.0071 |

0.00017721 |

|

Outfitting Manufacturing |

0.0050 |

0.0000830 |

|

Accommodation Outfitting |

0.0097 |

0.0001940 |

|

Painting & Protection |

0.0113 |

0.0003770 |

|

Total |

0.1100 |

0.0027790 |

Figure 3

Bayesian networks: (a) Machinery outfitting; (b) Electric outfitting; and (c)

Steel Work

Figure 4 Bayesian network Piping system

In Figure 3(a), the Bayesian Machinery

Outfitting (MO) network comprises 5 activities with the weight assigned to each

factor. In Figure 3(b), the electrical outfitting network has 4 activities with

the weight of each factor. Figure 3(c) represents the full outfitting block

system and steelwork with 3 activities and the weight of each factor.

Additionally, Figure 4 illustrates the piping system with 13 activities and the

weight assigned to each factor. This also applies to the network model under

the Hull Outfitting & Accommodation Outfitting Department and the network

model under the Hull Construction Department. Bayesian

probabilities for each point in the machinery outfitting (MO) workshop, steel

work, electrical, electrical outfitting, and piping workshop based on the

material network model can be found in Table 2.

Table 2 Probability of Bayesian network model in Machinery Outfitting

|

Activity |

Probability |

Weight Factor |

|

Machinery

Outfitting |

|

|

|

Fabrication & install instrument Tank |

0.0000188 |

0.05 |

|

Install & loading

equipment |

0.0001015 |

0.27 |

|

Function Test Equipment E/R |

0.0000564 |

0.15 |

|

Main Engine & propulsion

equipment |

0.0001692 |

0.45 |

|

Flushing & Other |

0.0000300 |

0.08 |

|

Sub Total |

0.0003760 |

1.00 |

|

Electric, Electrical Outfitting |

|

|

|

Steelwork (EO) |

0.0001390 |

0.30 |

|

Wiring, Clamping &

Compound |

0.0002560 |

0.55 |

|

Installation Equipment |

0.0000230 |

0.05 |

|

Connecting Cable |

0.0000460 |

0.10 |

|

Sub Total |

0.0004650 |

1.00 |

|

Steel Work |

|

|

|

Install ducting/ ventilator |

0.0001800 |

0.45 |

|

Install grating/realing/ floor/leader |

0.0001400 |

0.35 |

|

Install pondasi / machinery |

0.0000800 |

0.20 |

|

Sub Total |

0.0003900 |

1.00 |

|

Piping System |

|

|

|

Main Engine Lubricating Oil

service and Hydraulic Power pack Unit piping system (ME & LO) |

0.0000110 |

0,08 |

Table 2 (Continue on) Probability of Bayesian network model in Machinery Outfitting

|

Activity |

Probability |

Weight Factor |

|

Piping System |

|

|

|

Diesel Generator Lubricating Oil service

and Lubricating Oil transfer piping system (DG & LO) |

0.0000130 |

0.10 |

|

Main Engine fuel Oil service transfer

piping system |

0.0000050 |

0.04 |

|

HPU piping system propulsion system (HPU PSP) |

0.0000100 |

0.07 |

|

Lubricating Oil purifying & fuel oil

purifying piping system (LOP & FOP) |

0.0000059 |

0.04 |

|

Fuel Oil transfers and overflow piping

system (FO&OP) |

0.0000240 |

0.18 |

|

Fresh Water Cooling piping system (FWCP) |

0.0000140 |

0.10 |

|

Sea

water cooling piping system (SWCP) |

0.0000220 |

0.16 |

|

Main Engine Fuel Oil service piping system (MEFOBS) |

0.0000050 |

0.04 |

|

Diesel Generator Fuel Oil Service (DGFOBS) |

0.0000070 |

0.05 |

|

Starting air piping system (STAPS) |

0.0000050 |

0.04 |

|

Service

air piping system. (SAPS) |

0.0000065 |

0.05 |

|

Exhaust gas piping system (EGPS) |

0.0000060 |

0.05 |

|

Sub Total |

0.0001340 |

1.00 |

Bayesian probabilities for each point in the

fabrication workshops, assembly and erection based on the material network

model in Hull Construction Department be found in Table 3.

Table 3 Probability

of Bayesian network model in hull construction

|

Activities |

Probability |

Weight Factor |

|

Fabrication |

|

|

|

Marking |

0.0000101883 |

0.05 |

|

Cutting |

0.0001426360 |

0.70 |

|

Bending |

0.0000407000 |

0.20 |

|

Handling |

0.0000101883 |

0.05 |

|

Sub Total |

0.0002037660 |

1.00 |

|

Assembly |

|

|

|

Preparation/Handling |

0.000035252 |

0.10 |

|

Fitting |

0.000211512 |

0.60 |

|

Welding |

0.000070504 |

0.20 |

|

line heating |

0.000035252 |

0.10 |

|

Sub Total |

0.000352520 |

1.00 |

|

Erection |

|

|

|

Transporter process, block transferring |

0.000044303 |

0.25 |

|

Back process, lift/loading block |

0.000026582 |

0.15 |

|

Adjusting |

0.000044303 |

0.25 |

|

Fitting & welding |

0.000062024 |

0.35 |

|

Sub Total |

0.000177214 |

1.00 |

Table 4 Probability

of Bayesian network model in painting and protection

|

Activities |

Probability |

Weight Factor |

|

Painting

and Protection |

|

|

|

Power tool |

0.0001500 |

0.40 |

|

Final painting |

0.0001300 |

0.35 |

|

Base painting |

0.0000900 |

0.25 |

|

Sub Total |

0.0003700 |

1.00 |

|

Outfitting Manufacturing |

|

|

|

Steelwork independent tank |

0.0000170 |

0.20 |

|

Seat pump |

0.0000250 |

0.30 |

|

Seat auxiliary engine |

0.0000250 |

0.30 |

|

Seat Diesel Generator |

0.0000080 |

0.10 |

|

Seat bearing |

0.0000040 |

0.05 |

|

Overhead crane |

0.0000040 |

0.05 |

|

Sub Total |

0.0000830 |

1.00 |

|

Accommodation

Package in the Engine Room Area | ||

|

Insulation |

0.0000485 |

0.25 |

|

Lining |

0.0000388 |

0.20 |

|

Ceiling |

0.0000388 |

0.20 |

|

Cementing (deck Covering) |

0.0000388 |

0.20 |

|

Vinyl |

0.0000291 |

0.15 |

|

Sub Total |

0.0001940 |

1.00 |

Discussion

The impact of risk

occurrence is based on three factors, the scheduling factor for ship delivery,

late or not. The cost factor is a manifestation of costs that must be incurred

by the shipyard due to delays in the ship delivery schedule and company performance

factors that will determine public confidence in the shipyard's performance and

capabilities (this factor is difficult to determine to measure it). So that

only scheduling and cost factors can be measured. Scheduling factors that cause

engine room installation delays in anticipation of production delays require a

risk analysis of the inhibiting factors during the production process, as

follows: In the Machinery Outfitting (MO) and Electrical Outfitting (EO)

Departments, the highest risk potential for wiring production activity,

clamping and compound reaches a delay probability of (0.000256). This is due to the potential for revisions to delays in

equipment installation, cable material, and cable cutting data lately, so it is

necessary to coordinate with Production Control Planning, Design, and Supply

Chain early.

The Hull Construction Department has the highest

potential risk of fitting activities reaching a delay probability of

(0.000211512). The equipment installation was

delayed because of the consists of one side welding machine being damaged, the

Import Profile lately, and the block dimension accuracy nonappropriate, so

initial coordination with the project, procurement division, accuracy and

design team. The Hull Outfitting & Accommodation Outfitting

Department has the highest potential risk of power tool activities reaching a

delay probability of (0.00015). Repainting is

necessary due to burn-age (welding and fairing), dust, worker dirt, and the

difficulty of painting caused by the complex position of the area. To enhance

the work method during the erection stage, it is essential to focus on

maintaining, protecting the surface, and ensuring a high-quality paint finish. The

delay in the installation of the engine room has an effect on the cost factor incurred

by the shipyard. The delay in the schedule described in the shipping contract reached

IDR 764,552,010,000 based on the contract agreement. Every 1-day delay will be

fined 1 per mill with a maximum fine of 5% of the contract value. The

calculation of the amount of the fine is by multiplying the number of days of

delay multiplied by the value of the shipbuilding contract.

The method shown in this study is applicable to

Zone 2 engine room installations of new buildings. However, there are some

adjustments required for different types of shipbuilding projects. The risk

identification and probability assessment is based on the engine room

installation of project W000302. Therefore, little or no bias is introduced.

The Bayesian network produced has provided a visual interpretation, cause and

effect, which is very helpful in analyzing the risk potential of each activity.

From the engine room installation activity, the highest potential probability

is in the wiring production activity, clamping, and compound that reach a delay

probability of (0.000256). This is due to the revision of drawings, which have

the potential to delay the installation of equipment, late cable material, and

late cable cutting data, so it is necessary to coordinate early with Production

Control Planning, Design, and Supply Chain. This variable value causes a

decrease in the performance of each workshop, which affects production delays

in terms of production time, financial losses, and even the most severe

contract cancellation.

Acknowledgments

Thank you to the Division of Trading Ships PT. PAL Indonesia, Department

of Electrical Outfitting and Machinery Outfitting, Department of Hull

Outfitting & Accommodation Outfitting, and Department of Hull Construction

along with The National

Research and Innovation Agency (BRIN) for the realization of the preparation of this paper. Department of Naval Architecture

and shipbuilding, Faculty of Marine Science and Technology, Hang

Tuah University for this publication.

Authors Contributions

Intan Baroroh and Buana Ma’ruf contributed equally as the main

contributors to this article. All authors have accepted responsibility for the

entire content of this manuscript and approve the final article.

Basuki, M., Manfaat, D., Nugroho, S., Dinariyana, A,. 2014. Probabilistic risk Assasment of The

Shipyard Industry using The Bayesian Method. International Journal of

Technology, Volume 5(1), pp. 88-97

Ben-Asher, J.Z., 2008. Development Program Risk Assessment based on

Utility Theory, Risk

Management, Volume 10, pp. 285-299

Burova,

E., Grishunin, S., Suloeva, S., Stepanchuk, A., 2021. The Cost management of

Innovative Products in an Industrial Enterprise Given the Risks in the Digital

Economy, International Journal of

Technology, Volume 12(7), pp. 1339-1348

Daszynska-Zygadlo,

K., 2012. Scenario Planning and Real Options Analysis In Integrated Risk

Management Process. Universitatis Mariae Curie-Sklodowska. Sectio H.

Oeconomia, Volume 46(4), pp. 75-84

Do, H.M.,

Yin, K.L., 2018. Rainfall

Threshold Analysis and Bayesian Probability Method for Landslide Initiation

Based on Landslides and Rainfall Events in the Past. Open Journal of Geology, Volume 8(7),

pp. 674-696

Erango, M.A., Goshu, A.T.,

2019. Bayesian

Joint Modelling of Survival Time and Longitudinal CD4 Cell Counts Using

Accelerated Failure Time and Generalized Error Distributions. Open Journal

of Modelling and Simulation, Volume 7(01), pp. 79–95

Eschmann, M., Stamey, J. D., Young, P.D., Young,

D.M., 2019. Bayesian Approach to

Ranking and Selection for a Binary Measurement System. Open

Journal of Statistics, Volume 9, pp. 436-444

Fong, D.K.H., Chen, Q., Chen, Z., Wang, R., 2017. An Application of Heterogeneous Bayesian Regression Models with Time

Varying Coefficients to Explore the Relationship between Customer Satisfaction

and Shareholder. Open Journal of Statistics, Volume 7(1), pp. 36-53

Hatmoko,

J.U.D., Astuti, P.K., Farania, S.N., 2021. Insuring Project Risks: Contractor

Expectations versus Insurance Company Policies. International Journal of Technology,

Volume 12(1), pp. 90–100

Jia, K., Zhao, X.,

Zhang, L., 2013. Assessing

Money Laundering Risk of Financial Institutions with AHP?: Supervisory

Perspective. Journal of Financial

Risk Management, Volume 2(1), pp.

29-31

Kim, G., Sangsung, P., Jun, S., Kim, Y., Kang, D.,

Jang, D., 2012. A Study on Forecasting System of Patent Registration Based on

Bayesian Network. Intelligent Information Management, Volume 4, pp. 284-290

Kumar, D., 2010. Bayesian and

Hierarchical Bayesian Analysis of Response Time Data With Concomitant

Variables. Journal Biomedical Science

and Engineering, Volume 3, pp. 711-718

Lee, E., Park, Y., Shin, J.G., 2009. Large

Engineering Project Risk Management Using A Bayesian Belief Network. International

Journal of Expert Systems With Applications, Volume 36(3),

pp. 5880–5887

Lyukevich, I., Agranov, A., Elvova, N, Guzikova., L, 2020. Digital Experience: How to Find a Tool for Evaluating Business Economic

Risk. International Journal of Technology, Volume 11(6), pp. 1244–1254

Rahmatin, N., Santoso, I.,

Indriani, C., Rahayu, S., Widyaningtyas, S., 2018. Integration of the Fuzzy Failure Mode

and Effect Analysis (Fuzzy FMEA) and the Analytical Network Process (ANP) in

Marketing Risk Analysis and Mitigation. International Journal of Technology,

Volume 9(4), pp. 809–818

Suwandi,

A., Zagloel, T.Y., Hidayatno, A. 2021. Risk Control Failure of Iron Pipes in

Finished Goods Warehouses using Dynamic Systems. International Journal of Technology, Volume 12(1), pp. 15–21

Ting,

C., Zakariah, H., Yusri, Y.Z.M., 2022. Probabilistic Risk Assessment of

COVID-19 Patients at COVID-19 Assessment Centre. International Journal of Technology,

Volume 13(6), pp. 1193–1201

Zarei, E., Azadeh, A., Aliabadi, M., Mohammadfam,

I., 2017. Dynamic Safety Risk Modeling of Process Systems Using Bayesian

Network. Process Safety Progress, Volume 36(4), pp. 399–407

Zhong, J., Lv, J., Zhang, Y.,2019. Customized Production Project Risk Management with Analytic Hierarchy

Process. Journal of Social

Sciences, Volume

7, pp. 85–95

Zhou, C., Liu, X., Gan, L., Zheng, Y., Zhong, Q.,

Ge, K., Zhang, L., 2018. Assessment

and Countermeasures for Offshore Wind Farm Risks Based on a Dynamic Bayesian

Network. Journal of Environmental

Protection, Volume 9, pp. 368–384