A Two-dimensional Maintenance Service Contract Considering Availability and Maintenance Cost

Corresponding email: nurfaizatuss@gmail.com

Published at : 04 Apr 2023

Volume : IJtech

Vol 14, No 2 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i2.5105

Sa’idah, N.F., Cakravastia, A., Pasaribu, U.S., Iskandar, B.P., 2023. A Two-dimensional Maintenance Service Contract Considering Availability and Maintenance Cost. International Journal of Technology. Volume 14(2), pp. 363-373

| Nur Faizatus Sa’idah | Doctoral Program in Industrial Engineering and Management, Faculty of Industrial Engineering, Institut Teknologi Bandung, Jalan Ganesha 10, Bandung 40132, Indonesia |

| Andi Cakravastia | Industrial Engineering, Faculty of Industrial Engineering, Institut Teknologi Bandung, Jalan Ganesha 10, Bandung 40132, Indonesia |

| Udjianna Sekteria Pasaribu | Statistics Research Division, Faculty of Mathematics and Natural Sciences, Institut Teknologi Bandung, Jalan Ganesha 10, Bandung 40132, Indonesia |

| Bermawi Priyatna Iskandar | Industrial Engineering, Faculty of Industrial Engineering, Institut Teknologi Bandung, Jalan Ganesha 10, Bandung 40132, Indonesia |

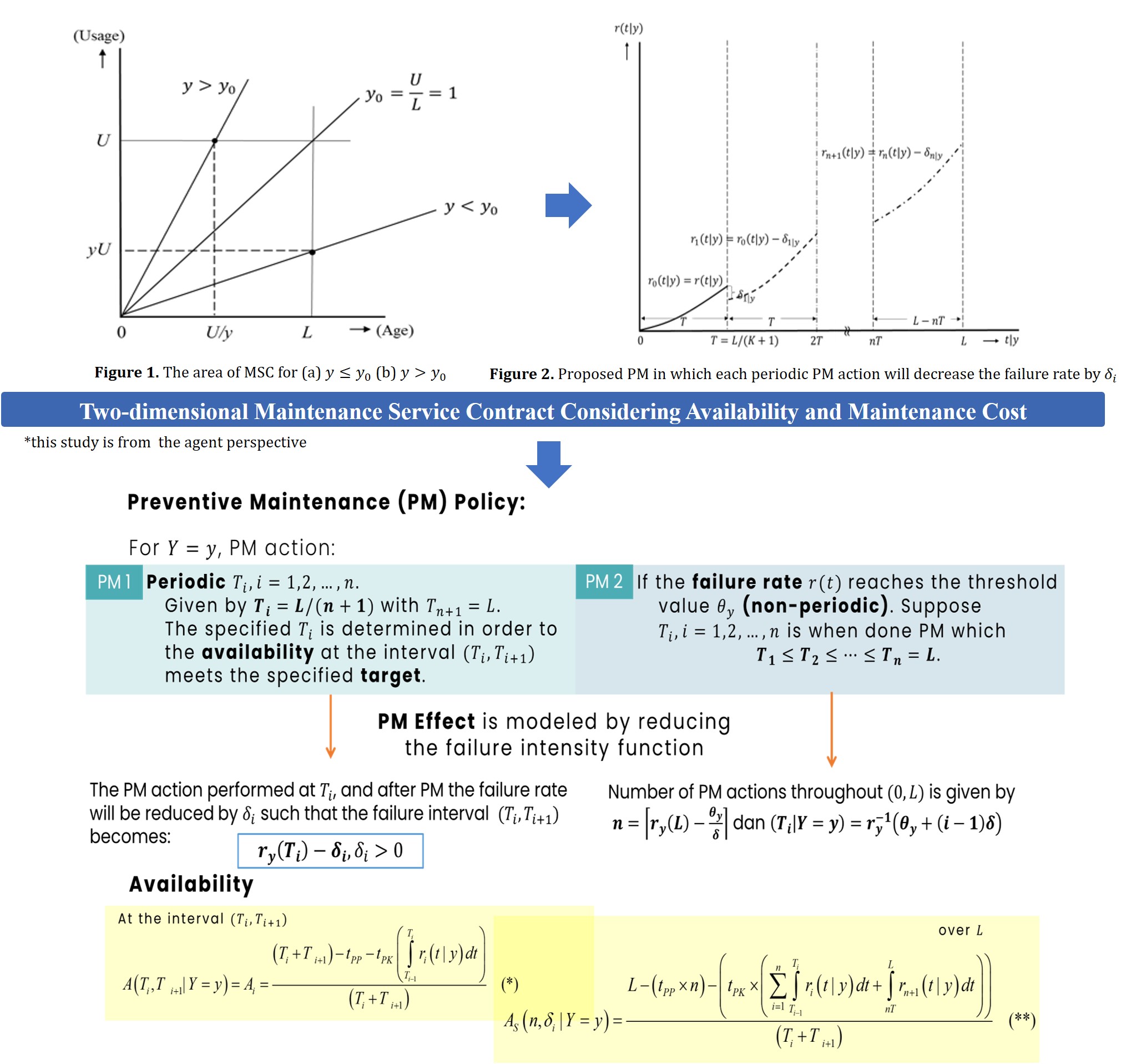

In this paper, we study a two- dimensional Maintenance

Service Contract (MSC) characterized by two limits (dimensions) of age and

usage. It is considered that an agent offers a two-dimensional MSC by

guaranteeing a certain level of equipment available to consumers. The agent

needs to reduce the total maintenance cost to offer competitive MSC prices.

Preventive maintenance actions (PM) are periodically carried out, and each PM

action is considered to improve reliability modeled by reducing the failure

rate function. Two decision variables (the PM interval (T) and the reduction in

the intensity function are obtained by considering two performance

measures that are relevant to agents and consumers (i.e., availability and

total maintenance cost). A numerical example is presented by considering three

types of equipment usage rates: low, medium, and high. The optimization of the

two performance measures can ensure availability targets and, at the same time,

minimize total maintenance costs.

Availability; Imperfect preventive maintenance; Maintenance service contract Total cost; Two-dimensional

Maintenance Service Contract (MSC) is defined as

an equipment maintenance contract that agents offer to

consumers within a certain period. Maintenance contracts, generally, are characterized

by a time limit (e.g., 1 year), called an MSC with one dimension. However, for

equipment such as dump trucks whose failure patterns are affected by age and

use, it is necessary to include a usage limit (e.g., 100,000 km) in

addition to the age limit. Different types of equipment may have different ways

of measuring usage. For example, a photocopier's usage can be measured by the

number of copies made, while a machine tool's usage can be measured by the

hours it is used. This MSC is referred to as an MSC with two dimensions. To

appeal to consumers, the MSC may include promised equipment performance (e.g.,

Target 94% equipment availability) in addition to the price charged. A

comprehensive review of MSC can be found in Murthy

and Jack (2014), and MSC is studied

From

the consumer side, equipment used to support business processes will

deteriorate with age and use, and eventually, failure will occur (Jiang and Murthy, 2008). Maintenance is an effective way to slow down

the deterioration of equipment so that failure can be minimized and

availability can be kept high (Pariaman et

al., 2017; Suthep and Kullawong, 2015; Jackson and Pascual, 2008). Consumers who own equipment,

generally need MSC because maintenance activities are not their main business

(core business), so they do not need to be done in-house.

Using an agent to maintain equipment through a

Maintenance Service Contract (MSC) is more cost-effective and reliable than

in-house maintenance, which requires expensive investments in human resources,

equipment and technology. MSC offers consumers the benefits of saving on

maintenance costs and improving equipment performance. Many studies have

explored MSC from the consumer's perspective, including research conducted by Huber and Spinler (2012) and Jensen and

Stonecash (2009). In general,

research from the consumer’s point of view always wants (i)

minimum cost or maximum profit, with additional considerations of other

performance measures such as (ii) service quality (eg. delivery time) (De-Almeida, 2007) (iii) product reliability (Laksana and

Hartman, 2010), or (iv) availability (Datta and Roy, 2010). Due to the important role of maintenance in

maintaining the condition of equipment, the agents respond proactively to the

consumers’ needs by offering MSCs that promise high availability. In addition to getting regular income, agents

can also build good relationships with consumers, which positively impacts the agent’s image (brand building).

From the agent’s point of view, research was

carried out by Tarakci et al. (2006), where the agent offers specific incentives

based on the combination of target uptime and bonuses in the contract to

attract consumers. In addition, reliability improvement is also considered.

Generally, the agent looks for the optimal PM time interval to fulfill the

performance promise to the customer, which maximizes the profit. MSC can be

grouped into two categories: one-dimension MSC and two-dimension MSC.

One-dimensional MSC is characterized by a one-time limit (age). For example,

the MSC of a piece of equipment is for one year, while the two-dimension MSC is

characterized by an area of a two-dimensional plane where one dimension

describes a time limit and the other a usage limit (Iskandar et al., 2014). One-dimensional MSC research has considered several important

performance measures for agents (i.e., total cost and benefit) as well as

consumers (i.e., reliability and availability). First, many MSC studies

consider profit performance measures (Darghouth, Ait-kadi,

and Chelbi, 2017; Hamidi, Liao, and Szidarovszky, 2013; Chang and Lin, 2012). Second, the reliability performance measure is

considered in addition to the benefits (Laksana and

Hartman, 2010). Third, the

availability performance measure is also involved (Su and Cheng, 2018; Iskandar et al., 2014). The effect of PM's actions on increasing

reliability can be represented through a reduction in (i) failure rate or (ii)

virtual age. Some of them are researched by Darghouth, Ait-kadi, and Chelbi (2017) and Pasaribu, Husniah, and

Iskandar (2012), who specifically examined one-dimensional MSC with periodic PM

policies and the impact of PM reducing a virtual age. Other works are the

research of Husniah et al. (2019) and Yeh and

Chang (2007), which examine

one-dimensional MSC with a periodic PM policy model using an intensity

reduction function. There is also research by Iskandar

and Husniah (2017) and Yeh, Kao, and Chang (2009), who investigate one-dimensional contracts

using a PM policy that ensures equipment reliability.

Meanwhile, two-dimensional MSC

studies have not received much attention. As in one-dimensional MSC, the most

commonly used performance measure in two-dimensional MSC is profit (Huang, Gau, and Ho, 2015; Husniah et al., 2014). No studies have considered the availability

of two-dimensional MSCs. At the same time, consumers want high equipment

availability to be guaranteed. The motivation to prioritize availability is

because the losses (costs) due to equipment downtime are very large. For

example, the breakdown of equipment such as draglines (in the mining business)

and airplanes (in the transportation business) will result in huge losses for

the company operating the equipment. Performance in two-dimensional MSC can be

achieved by implementing various preventive maintenance (PM) policies, which

can be divided into two categories, namely periodic and non-periodic (Jiang and Murthy, 2008).

In this paper, we propose a

two-dimensional MSC that implements the imperfect PM policy carried out

periodically. The effect of the PM action on the two-dimensional MSC will be

developed by extending the formulation of the one-dimensional MSC. As in the

one-dimensional MSC studied by Yeh and Chang

(2007), It is assumed that the

effect of PM reduces the intensity function. Furthermore, this paper focuses on

two-dimensional MSC, The study is carried out from the agent's point of view,

considering two performance measures, namely: (i) equipment availability and

(ii) total maintenance costs, and involving two decision variables, i.e., the

PM time interval (T), and the failure rate reduction value for each PM. As

a result, the main contributions of this paper are (i) developing a PM policy

that ensures the equipment availability target with minimum costs and (ii)

obtaining optimal solutions of PM policies for a two-dimensional MSC with two

objective functions, namely maximizing availability and minimizing total cost.

This is in accordance with the goals desired by consumers for MSC, which are to

ensure high availability (for example, 94%) and simultaneously meet the

agency's goal of minimizing total maintenance costs. This paper is organized as

follows: The model formulation is given in Section 2, which includes a

discussion of the two-dimensional MSC formulation, failure modeling, and PM

impact modeling. Section 3 describes an optimization to find the optimal

solution that guarantees target availability with the minimum total cost.

Section 4 provides numerical examples and a discussion of the results. Finally,

we present conclusions and further research topics in Section 5.

Model

Formulation

This section will detail the two-dimensional MSC under study, failure

modeling, and PM effect modeling.

2.1. Two-dimensional

MSC

Consider

a two-dimensional MSC for equipment (e.g. dump trucks), which is characterized

by two parameters, L (time limit) and U (usage limit). For example, a

maintenance contract for a dump truck with a time limit of 1 year and a usage

limit of 100,000 km. Thus, these two contract limits form a rectangular area (Iskandar et al.,

2014). Suppose that the equipment with the rate of use is said to be moderate (normal) usage rate,

low usage rate, and high usage rate

. The contract will end at

2.2. Failure Modeling

Equipment failures that occur randomly during the

contract period are considered random points that fall in the maintenance

contract area (which is rectangular). There are three approaches to modeling

random points (equipment failure) on a two-dimensional plane (Murthy and Jack, 2014). In this paper, we shall use the formulation of a one-dimensional point process as has been done by

Iskandar, Murthy, and Jack (2005). Let

Equipment is repairable, and the

equipment failure over time is modeled with an intensity function (Iskandar and Murthy, 2003).

Suppose where

is a

non-decreasing function of t and y. Iskandar and Murthy (2003) provide a formulation of the intensity function

as a first-order polynomial function. Another formulation that can be used is

the Accelerated Failure Time (AFT) (Iskandar et al., 2014), and

this formulation will be used in this paper.

2.3. PM Policy

The agent requires a proper PM

policy to reduce failures and downtime, and this will increase availability. In

this paper, two PM policies are considered.

2.3.1. PM Policy 1

PM

actions are carried out periodically or at the time of Given by

, where L

is determined to ensure the availability at the interval

meets

the defined target and will be described in Section 2.5.

2.4.1. PM Policy 1

2.4.2. PM Policy 2

In this PM policy, whenever PM (if the failure rate reaches ), failure rate will be reduced by

. For a given Y = y, number of PM actions

throughout the period L

Note:

This approach extends Yeh and

Chang (2007) to a

two-dimensional case.

2.5. Availability and Total Maintenance Cost

2.5.1.

Availability

2.5.2. Total Maintenance Cost

PM Policy 1: Total maintenance costs include minimal repair costs (including expected downtime penalties) and PM action costs. The total expected cost of a two-dimensional MSC over the period is given by:

Optimal Decision

This section discusses the optimization scheme

(Optimization Schema) of the two-dimensional MSCs under consideration.

3.1. Two-dimensional MSC with PM 1 Policy

(Proposed)

Optimization

Scheme 3:

Find the

value of by

considering availability and total cost together. This is done using

optimization with two objective functions. Using the Weighted Sum method from

the study of Grodzevich and Romanko (2006), the structure of the

optimization function with two objectives is given below.

3.2. Two-dimensional MSC with PM Policy 2

Again, the three optimization schemes are also used to find the optimal solution.

Optimization

Scheme 1:

(i) First, using the algorithm proposed by Yeh and Chang (2007) finding the optimal value of which

minimizes the expected total cost. (ii) Second, based on the optimal

value of (i), then calculate the availability with the equation in (2).

Consider that is Weibull distribution

with

, where

is the scale parameter and

is the shape parameter. Suppose that each

failure incurs costs (including the minimal repair cost and possible penalty

cost) and the cost for performing a PM action with maintenance degree

. A similar form of maintenance cost is used by Supriatna et al.

(2020). These parameter values were used in Yeh and Chang (2007) and will be considered in this section given

in Table 1.

In this

section, we shall evaluate the performance of two-dimensional MSC with PM Policy 1

(proposed PM) and two-dimensional with PM Policy 2.

4.1. Discussion of MSC 2D results with PM 1

Tables 2 and 3 show the

results for low usage (y=0.9), comparing results with Schemes 1 and 2 and

then results with Schemes 2 and 3. From Tables 2 and 3, we have the following

findings. Increasing

the parameter value of gives

the same or increased availability for Schemes 1-3. This is expected because

larger

means

higher reliability (this agrees with the result of Yeh and Chang (2007) for a 1D MSC case). The

results with Scheme 2 always give higher availability values than Scheme 1.

In addition, Scheme 2 also provides a lower total cost of up to 71.70% (see

Table 2, for the parameter

) than

the results of Scheme 1. The total cost is smaller because the PM Policy 1

improves reliability by optimizing

(is not constant). Furthermore, Scheme 3 also

provides an availability value that is as large as the results of Scheme 2. The

advantage of Scheme 3 is that the total cost obtained is lower than the total

cost with Schemes 1 and 2. Total maintenance costs can be reduced by up to

71.70% (see Table 2 on parameters

). Thus, the best optimization

scheme for PM 1 policy is Scheme 3, and this pattern also holds for medium and

high usage rates (Note: the results cannot be included due to the number of

page limitations of a paper).

In this paper, a two-dimensional

Maintenance Service Contract (MSC) study is conducted with (1) periodic and (2)

non-periodic PM policies by considering availability performance measures and

total maintenance costs. The two-dimensional MSC with periodic PM policy

provides the best performance – in terms of availability (can guarantee an

availability target) and low total costs at any rate of usage considered. Here, a two-dimensional MSC study was

conducted from the agent's point of view. One of the further research topics is

a two-dimensional MSC study that takes into account the two parties- i.e., the

agent and the consumer, who are very concerned about the price of MSC. This

topic can be modeled by a game theory formulation and provides optimal results for

both parties. In addition, from an equipment maintenance perspective, MSC can

also consider condition-based preventive maintenance options so equipment

performance can be even better. Furthermore, as the maintenance services can be

provided by the Original Equipment Manufacturer (OEM) or the agent, another

interesting topic is to study a 2D MSC involving three parties– i.e., the

Original Equipment Manufacturer (OEM), the agent, and the consumer. The

integration of three-party decision problems is an interesting topic because it

can mathematically describe the relationship of competition or cooperation

between agents. The formulation can be done using two-level game theory and it

is expected to choose the optimal option for consumers as well as the optimal three-party

coordinated option. The findings will be very beneficial for the parties

involved with the following details: (i) the agent can achieve the availability

target with minimum total maintenance costs, and (ii) the consumer benefits

from the optimal target of equipment availability and MSC price to maximize

profit. Research on these topics is on the way.

The research and study were supported by the

Ministry of Research, Technology, and Higher Education (Kementrian Ristek-Dikti)

Indonesia through the Program Magister menuju Doktor untuk Sarjana Unggul (PMDSU).

Chang, Wen

Liang, and Lin, Jyh-Horng, 2012. Optimal maintenance policy and length of

extended warranty within the life cycle of products. Computers and Mathematics

with Applications, Volume 63, pp. 144–150

Darghouth,

M.N., Ait-kadi, D., Chelbi, A., 2017. Joint optimization of design,

warranty and price for products sold with maintenance service contracts. Reliability

Engineering and System Safety, Volume 165, pp. 197–208

Datta, P.P., Roy, R., 2010. Cost modelling

techniques for availability type service support contracts: a literature review

and empirical study. CIRP Journal of Manufacturing Science and Technology, Volume

3, pp. 142–157

De-Almeida, A.T., 2007. Multicriteria

decision model for outsourcing contracts selection based on utility function

and ELECTRE method. Computers & Operations Research, Volume 34, pp.

3569–3574

Grodzevich, O., Romanko, O., 2006.

Normalization and other topics in multi-objective optimization. In:

Proceedings of the Fields-MITACS Industrial Problems Workshop, pp. 89–101

Hamidi, M., Liao, H., Szidarovszky, F., 2013. A game-theoretic model for

establishing maintenance service contracts. In: IIE Annual Conference

and Expo, pp. 3178–3187

Huang, Y.-S., Gau, W.-Y., Ho, J.-W., 2015. Cost analysis of two-dimensional

warranty for products with periodic preventive maintenance. Reliability Engineering and System Safety, Volume 134, pp. 51–58

Huber, S., and Spinler, 2012. Pricing of

full-service contracts. Eur J Oper Res, Volume 222, pp. 113–131

Husniah, H., Maulana, H.A., Pasaribu, U.S.,

and Iskandar, B.P., 2019. Two-dimensional lease contract with preventive

maintenance using bivariate Weibull. International Journal of Industrial

Engineering: Theory Applications and Practice, Volume 26(1), pp. 48–58

Husniah, H., Pasaribu, U.S., Cakravastia, A.,

Iskandar, B.P., 2014. Two dimensional maintenance contracts for a fleet of dump

trucks used in mining industry. Applied Mechanics and Materials, Volume

660, pp. 1026–1031

Iskandar, B.P., Husniah, H., 2017. Optimal preventive maintenance

for a two dimensional lease contract. Computers and Industrial Engineering, Volume 113, pp. 693–703

Iskandar, B.P., Murthy, D.N.P., 2003. Repair-replace strategies for

two-dimensional warranty policies. Mathematical

and Computer Modelling, Volume 38, pp. 1233–1241

Iskandar, B.P., Murthy,

D.N.P., Jack, N., 2005. A new repair-replace strategy

for items sold with a two-dimensional warranty. Computers

and Operations Research, Volume 32(3), pp. 669–682

Iskandar, B.P., Pasaribu, U.S., Cakravastia, A., Husniah, H., 2014. Maintenance

service contracts for a fleet of dump trucks used in mining industry. In: CIE

2014 - 44th International Conference on Computers and Industrial Engineering

and IMSS 2014 - 9th International Symposium, pp. 2480–2491

Jackson, C., Pascual,

R., 2008. Optimal maintenance service contract negotiation with aging

equipment. European Journal of Operational Research, Volume 189, pp. 387–398

Jensen, P.H., Stonecash, R.E., 2009. Contract

type and the cost of provision: evidence from maintenance service contract. Fiscal

Studies, Volume 30, pp. 279–296

Jiang, R., Murthy D.N.P., 2008. Maintenance:

decision models for management. Beijing, China: Science Press

Laksana, K., Hartman, J.C., 2010.

Planning product design refreshes with service contract and competition

considerations. International Journal of Production Economics, Volume

126(2), pp. 189–203

Murthy, D.N.P., Jack, P., 2014. Extended

warranties, maintenance service and lease contracts: modeling and analysis for

decision-making. London: Springer-Verlag

Pariaman, H.,

Garniwa, I., Surjandari, I., Sugiarto, B., 2017. Availability analysis of the

integrated maintenance technique based on reliability, risk, and condition in

power plants. International Journal of Technology, Volume 3, pp. 497–507

Pasaribu, U.S., Husniah, H., Iskandar, B.P., 2012.

Stochastic system in discrete preventive maintenance and service contract. In:

Proceedings of 2012 IEEE Conference on Control, Systems and Industrial

Informatics, ICCSII 2012, pp. 250–254

Su, C., Cheng, L., 2018. Design

of maintenance service contract upon the expiration of availability-based

warranty. In: Proceedings of International Conference on Computers and

Industrial Engineering, CIE, Volume 2018

Supriatna, A., Singgih, M.L., Widodo, E., and

Kurniati, N., 2020. Overall equipment

effectiveness evaluation of maintenance strategies for rented equipment. International

Journal of Technology, Volume 11(3), pp. 619–630

Suthep, B.,

Kullawong, T., 2015. Combining reliability-centered maintenance with planning

methodology and applications in hard chrome plating plants. International

Journal of Technology, Volume 3, pp. 442–451

Tarakci, H., Tang, K., Moskowitz, H., Plante,

R., 2006. Incentive maintenance contracts for channel coordination. IIE

Transactions, Volume 38, pp. 671–684

Yeh, R.H., Chang, W.L., 2007. Optimal threshold value of

failure-rate for leased products with preventive maintenance actions. Mathematical and Computer Modelling, Volume 46(5-6), pp. 730–737

Yeh, R.H., Kao, K.-C., Chang, W.L., 2009. Optimal preventive maintenance

policy for leased equipment using failure rate reduction. Computers and Industrial Engineering, Volume 57(1), pp. 304–309