A New Multi-Component Solid of Atorvastatin Calcium with a Dipicolinic Acid Coformer for Improving the Water Solubility

Corresponding email: yudi.farmasi@unej.ac.id

Published at : 09 May 2023

Volume : IJtech

Vol 14, No 3 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i3.5088

Wicaksono, Y., Nugraha, A.S., Irawan, E.D., Nada, N., Nurhansyah, S.D., 2023. A New Multi-Component Solid of Atorvastatin Calcium with a Dipicolinic Acid Coformer for Improving the Water Solubility. International Journal of Technology. Volume 14(3), pp. 618-627

| Yudi Wicaksono | Drug Modification Research Group, Faculty of Pharmacy, University of Jember, Jl. Kalimantan No. 37, Jember 68121, Indonesia |

| Ari Satia Nugraha | Drug Utilisation and Discovery Research Group, Faculty of Pharmacy, University of Jember, Jl. Kalimantan No. 37, Jember 68121, Indonesia |

| Eka Deddy Irawan | Drug Delivery Research Group, Faculty of Pharmacy, University of Jember, Jl. Kalimantan No. 37, Jember 68121, Indonesia |

| Nadifa Nada | Drug Modification Research Group, Faculty of Pharmacy, University of Jember, Jl. Kalimantan No. 37, Jember 68121, Indonesia |

| Sofyan Dimas Nurhansyah | Drug Modification Research Group, Faculty of Pharmacy, University of Jember, Jl. Kalimantan No. 37, Jember 68121, Indonesia |

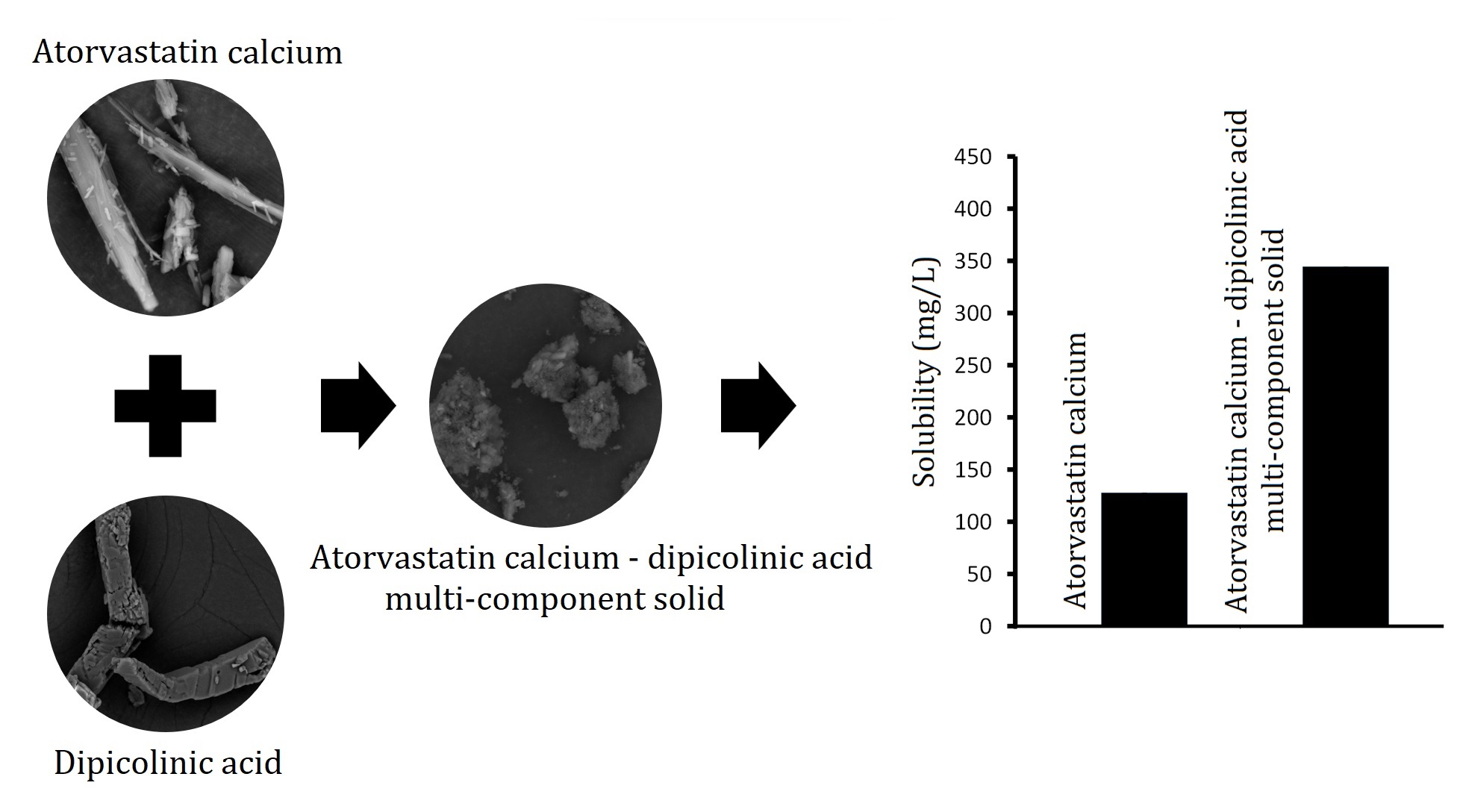

Atorvastatin

calcium is a potent active

pharmaceutical ingredient that reduces blood cholesterol

levels. However, oral bioavailability is low because it is difficult to

dissolve in water. Therefore, further research to increase the solubility of

the drug is needed to improve its bioavailability properties. This research aimed

to increase the solubility of atorvastatin calcium through the formation of a

multi-component solid. Furthermore, the drug was formed into a multi-component

solid with dipicolinic acid as a coformer using the solvent

evaporation-quenching method. A powder X-ray diffractometer (PXRD), Fourier

transform infrared (FTIR) spectrometer, differential scanning calorimeter

(DSC), and scanning electron microscope (SEM) was used to characterize the

solid. Also, the shake-flask method was used to analyze the solubility of the

solid in distilled water. The results showed that atorvastatin calcium and

dipicolinic acid formed a new multi-component solid of cocrystal type. The solubility of the atorvastatin calcium from the

multi-component solid was 344.31 ± 37.09 mg/L, which was a significant increase

of about 2.7-fold compared to the pure form.

Atorvastatin calcium; Dipicolinic acid; Multi-component solid; Solubility properties

The

rate of drug absorption in the gastrointestinal tract is determined by

solubility. Orally administered drugs must dissolve in the gastrointestinal

fluid for a passive diffusion process, the main absorption mechanism, to occur (Pindelska, Sokal, and Kolodziejski, 2017;

Maggi et al., 2015). The bioavailability of the absorbed drug fraction

produced the desired pharmacological effect (Williams et al., 2013). Therefore, drugs with low

solubility levels have oral bioavailability problems, posing challenges and

opportunities for their development (Javeer,

Patole, and Amin, 2013; Kawabata et al., 2011).

Atorvastatin calcium is a

potent statin drug that reduces blood cholesterol levels. It works by

inhibiting the enzyme HMG-CoA reductase in cholesterol biosynthesis (Anwar,

Warsi, and Mallick, 2011). According to the

biopharmaceutical classification system, it is categorized as a Class II drug with high

permeability but low solubility. The bioavailability of oral preparations is

about 12% due to their low solubility property (Anwar, Warsi, and Mallick, 2011). Therefore, research to increase the solubility of

this drug is needed.

The multi-component solid is one technique used to

improve the solubility of poorly soluble drugs (Zaini et

al., 2020; Chadha, Sharma, and Haneef, 2017; Haneef and Chadha, 2017). Cocrystal is a type of multi-component solid that

has gained attention for improving the solubility properties of poorly soluble

drugs. Furthermore, the

multi-component cocrystal is formed through noncovalent intermolecular

interactions between drug molecules and coformers to produce a single-phase

material with a new crystal lattice structure. Generally, the drugs that form cocrystals have new physical properties

that differ significantly from the starting materials (Shaikh

et al., 2018). The solubility of

the multi-component cocrystal

can be improved by

lowering the lattice energy and/or increasing the solvent affinity (Thakuria et al., 2013). Also,

the presence of a diverse coformer in the multi-component solid increases the

possibility of obtaining drug solids with better physical solubility properties

(Douroumis, Ross, and Nokhodchi, 2017; Gao et al., 2012; Tilborg et al., 2010). In addition, ketoprofen-nicotinamide, atorvastatin

calcium-succinic acid, and aripiprazole-succinic acid are examples of

multi-component cocrystals shown to increase solubility (Butreddy

et al., 2021; Wicaksono et al., 2019; Wicaksono et al.,

2018).

The research aimed to improve the

water solubility properties of atorvastatin calcium through the formation of a

multi-component solid. Dipicolinic acid was used as a coformer due to its

solubility in water. The molecules have two donors and five acceptors of

hydrogen bonds, making it easy to form intermolecular interactions with other

molecules (Hiendrawan et al., 2016). In addition, the dipicolinic acid coformer is inert.

Hence it has no toxic effects. The atorvastatin calcium-dipicolinic acid

multi-component solid was prepared using the solvent evaporation-quenching

method. A powder X-ray diffractometer (PXRD), Fourier transform infrared (FTIR)

Spectrometer, differential scanning calorimeter (DSC), and scanning electron

microscope (SEM) were used to characterize the solid. The shake-flask method

was used to analyze the solubility of the samples in distilled water.

2.1. Materials

Atorvastatin

calcium (>98.0%) was provided by PT Dexa Medica (Palembang, Indonesia).

Dipicolinic acid (>98.5%), methanol (>99.8%), and distilled water were

purchased from Sigma-Aldrich (Saint Louis, USA), PT Smart Lab (Tangerang,

Indonesia) and CV Makmur Sejati (Jember, Indonesia) respectively.

2.2.

Preparation of Multi-component

Solid

The solvent evaporation-quenching method was used to

prepare the atorvastatin calcium-dipicolinic acid multi-component solid. The

preparation of the solid was carried out in a methanol solution with a molar

ratio of atorvastatin calcium-dipicolinic acid (1:1). The solution was

evaporated on a hotplate at 60 °C and stirred at 150 rpm until a dry solid was

obtained. Then the resulting solid was quenched at -80 °C for 12 hours, crushed

with the mortar, and passed through an 80-mesh sieve. The solid powder was stored

in a desiccator until it was tested for

solid-state and solubility properties. The scheme for the preparation of multi-component solids is shown in Figure

1.

2.3. Characterization

2.3.1.

PXRD

PXRD was a method used to analyze the phase types of solid materials. Furthermore, the analysis was conducted using a Philip Xpert diffractometer and a CuK?1 radiation source. The diffractogram was determined by filling the sample holder cavity of the X-ray diffractometer with sample powder and flattening it with a spatula. Also, the X-ray diffractometer was set at a voltage of 40 kV, a current of 30 mA, and a scan speed of 2? = 10°/minute with a range of 2? at 5-50°.

Figure 1 Scheme for

preparation of multi-component solids

2.3.2. DSC

Generally, the DSC test was used to determine the

solid-liquid or solid-solid transformation temperature of the sample. The

Thermo plus EVO DSC 8230 equipment was used, and about 2 mg of the powder

sample was placed into an aluminum container and tightly closed with a press device.

Then the sample was placed into the DSC, which was set to run at a temperature

range of 30-300 °C. The heating rate of DSC was 10 °C/minute under dry nitrogen

gas flow conditions at 50 mL/minute.

2.3.3.

FTIR

The FTIR testing was used to identify the functional

groups and intermolecular interactions of molecules in the solids. About 5 mg

of the sample powder was placed on the equipment’s board (Alpha Bruker), and

then the instrument was run at the wavenumber range of 4000-600 cm-1.

2.3.4. SEM

The SEM analysis aims to obtain the microscopic

properties, including surface topography and particle size of a sample. About 2

mg of the sample was placed on a stub specimen that had been given adhesive and

then coated with platinum for 20 seconds using the Hitachi E-1045 ion sputter.

Then the sample was inserted into the SEM base holder, and the voltage and

current were set at 15 kV and 12 mA, respectively. The observation of the

shape, size, and topography of the sample particles was carried out using the

appropriate magnification.

2.4. Solubility Testing

3.1. The Multi-component Solid

The solvent

evaporation-quenching method was used to prepare an atorvastatin

calcium-dipicolinic acid multi-component solid. Methanol was used as the

solvent because it easily dissolves atorvastatin calcium and dipicolinic acid.

The drug and coformer used in the preparation of the multi-component solid were

0.968 and 0.135 g, respectively, while the total solvent was 15 mL. Also, the

time required for the solvent evaporation process was 60 minutes. The solids

were quenched in a deep freezer at -80 ?C for 12 hours, then crushed with a

mortar and passed through an 80-mesh sieve.

3.2. PXRD Diffractogram

The PXRD characterization

was conducted to analyze the solid-state phase of the atorvastatin

calcium-dipicolinic acid multi-component solid. Although the diffractogram of

crystalline solids is characterized by the presence of sharp diffraction peaks,

that of amorphous solids is characterized by the absence of diffraction peaks.

The formation of new crystalline solids from the starting material mixture was

indicated by a diffractogram with new diffraction peaks different from each

starting material (Karagianni,

Malamatari, and Kachrimanis, 2018).

Figure 2

shows the diffractograms of atorvastatin calcium, dipicolinic acid, and

atorvastatin calcium-dipicolinic acid multi-component solid. The diffractogram

of atorvastatin calcium has diffraction peaks of 2? at 9.4; 10.2; 11.8; 17.0;

19.4; 21.6; and 23.7°, while the dipicolinic acid has diffraction peaks of 2?

at 11.1; 16.9; 19.4; 24.4; 27.9; 32.6; and 37.1°. Also, the physical mixture of

atorvastatin calcium and dipicolinic acid powder showed a diffractogram with

diffraction peaks of 2?, which are a combination or overlay of the respective

diffraction peaks. However, the atorvastatin calcium and dipicolinic acid

multi-component solid showed the new diffraction peaks of 2? at 13.2; 17.9;

18.7; 23.5; and 26.3°, in contrast to the individual peaks.

Figure 2

Diffractogram of (a) atorvastatin calcium, (b) dipicolinic acid, (c) physical

mixture of atorvastatin calcium and dipicolinic acid, and (d) atorvastatin

calcium - dipicolinic acid multi-component solid

The results

of PXRD characterization showed that the solid-state of atorvastatin

calcium-dipicolinic acid multi-component solid has a diffractogram different

from each starting material, indicating the formation of a solid with a new

crystalline phase. Also, the dipicolinic acid molecules acted as a coformer in

the atorvastatin calcium-dipicolinic acid multi-component solid, forming a new

crystal lattice with the atorvastatin calcium molecules (Karagianni, Malamatari, and Kachrimanis, 2018). This lattice has different energy from the starting

material, resulting in new physicochemical properties (Thakuria

et al., 2013).

3.3. DSC Thermogram

DSC

characterization was used to observe the solid-state phase transformation of

the sample due to heating (Wicaksono et al.,

2020). The melting point data,

enthalpy of fusion, and phase transformation profile were obtained from this

characterization (Pindelska, Sokal, and

Kolodziejski, 2017; Karagianni et al., 2018; Qiao et al., 2011). Figure 3 showed the DSC thermograms of atorvastatin

calcium, dipicolinic acid, and atorvastatin calcium-dipicolinic acid

multicomponent solid. The atorvastatin calcium DSC thermogram showed two sharp

endothermic peaks at 155.0 °C (?H = 69.04 J/g) and 236.2 °C (?H = 23.56 J/g),

indicating the melting point and decomposition temperature, respectively (Shete et al., 2010). In

addition, the dipicolinic acid DSC thermogram showed one sharp endothermic peak

at 260.4 °C (?H = 496.76 J/g), indicating the melting point and no

decomposition up to 300 °C which is in line with the literature (Hiendrawan et al., 2016).

The DSC thermogram of atorvastatin

calcium and dipicolinic acid multi-component solid showed two sharp endothermic

peaks at 98.0 °C (?H = 26.62 J/g) and 192.9 °C (?H = 35.21 J/g). The sharp

endothermic peak at 98.0 °C indicated the melting point of the solid, while the

peak at 192.9 °C depicted the decomposition temperature. Therefore, the results of DSC

characterization showed that the solid has a thermogram profile that differs

from the starting material in terms of melting point and decomposition temperatures. The changes in the thermogram profile indicated the

presence of intermolecular interactions in the multi-component solid between

molecules of the drug and the coformer. Also, the multi-component solid of

atorvastatin calcium and dipicolinic acid showed a lower melting point and

enthalpy of melting than the individual material. The decrease in melting point

and enthalpy of melting indicated lower lattice energy, making it easy to

convert the solid into liquid when

heated (Thakuria et al., 2013; Qiao et al.,

2011).

Figure 3 DSC thermogram of (a) atorvastatin calcium, (b)

dipicolinic acid, and (c) atorvastatin calcium - dipicolinic acid

multi-component solid

3.4. FTIR Spectra

The FTIR characterization

aimed to analyze the functional groups in atorvastatin calcium, dipicolinic

acid, and atorvastatin calcium-dipicolinic acid multi-component solids. In

addition, the FTIR spectra were used to analyze the presence of intermolecular

interactions between the drug and the coformer in the multi-component solids (Bekbayeva et al., 2022; Karagianni, Malamatari, and Kachrimanis, 2018; Pindelska Sokal, and

Kolodziejski, 2017). Figure 4 showed the FTIR spectra of atorvastatin calcium, dipicolinic

acid, and atorvastatin calcium-dipicolinic acid multicomponent solid. The drug

showed FTIR spectra with specific absorption peaks at 3364 cm-1

(NH-free stretching), 3096 cm-1 (OH- stretching), 1650 cm-1

(C=O stretching), and 1216 cm-1 (CN stretching), indicating

suitability as stated in the literature (Wicaksono et al.,

2019). According to the literature, the FTIR spectrum of

the coformer showed a wide and strong absorption peak at 3300-2400 cm-1

(OH stretching of the carboxylic acid group) and 1692 cm-1 (C=O

stretching of carboxylic the acid group), respectively (Hiendrawan et al.,

2016).

Figure 4 FTIR

spectra of (a) atorvastatin calcium, (b) dipicolinic acid, and (c) atorvastatin calcium-dipicolinic acid

multi-component solid

The FTIR

spectra of atorvastatin calcium-dipicolinic acid multi-component solid showed

absorption peaks that were the combination of the components. However, the

absorption peaks changed in intensity and wave number. The FTIR spectra showed that the absorption peaks of atorvastatin

calcium in the multi-component solids shifted, with free NH stretching from

3364 to 3381 cm-1, OH from 3096 to 3032 cm-1, C=O from

1650 to 1700 cm-1, and CN from 1216 to 1224 cm-1. Meanwhile, the absorption peaks of dipicolinic acid in

the multi-component solid spectra changed, with a decrease in the intensity of

the O-H absorption peak of the carboxylic acid group and a shift in the C=O

stretching from 1692 to 1648 cm-1. According to the FTIR analysis,

the solid spectra showed shifts in the absorption peaks of the acceptor and

donor groups of hydrogen bonds of atorvastatin calcium and dipicolinic acid

molecules. This indicated the presence of intermolecular hydrogen bonds between

molecules of the drug and coformer in the solid (Karagianni, Malamatari, and Kachrimanis, 2018).

The PXRD analysis showed

that atorvastatin calcium-dipicolinic acid formed a new crystalline solid with

a different diffraction pattern and crystal lattice from the starting

materials. Furthermore, the DSC analysis results showed that the component’s

solid state has a new single solid phase with different thermal properties

(melting point and enthalpy of fusion) from the starting material. The FTIR analysis showed that intermolecular hydrogen

bonds were formed between the acceptor and donor groups of hydrogen bonds of

atorvastatin calcium and dipicolinic acid molecules. According to the analysis of the PXRD diffractogram, DSC thermogram, and

FTIR spectra, the solid-state of the atorvastatin calcium-dipicolinic acid is a

new multi-component cocrystal (Karagianni, Malamatari, and Kachrimanis, 2018; Pindelska Sokal, and

Kolodziejski, 2017;

Qiao et al., 2011).

3.5. Morphology

The SEM examination aimed to analyze microscopic properties,

including the sample’s surface topography and particle size (Sukeksi et al., 2021; Ali et al.,

2020; Qiao et al., 2011). Figure 5 shows the micrographs of atorvastatin

calcium, dipicolinic acid, and atorvastatin calcium-dipicolinic acid multi-component solid. The atorvastatin calcium powder particles

were rod-shaped, with lengths ranging from 30-100 mm. Also, the surface

topography of drug particles showed surface properties, as stated by the

literature (Wicaksono et al.,

2019). The

dipicolinic acid particles were shaped as a plate light measuring 20-200 mm in length and a flat

surface, as stated in the literature (Hiendrawan

et al., 2016). In addition, the preparation of atorvastatin calcium-dipicolinic acid multi-component solid produced irregularly shaped particles with a

diameter of 15-40 mm and a rough surface. The multi-component

solid showed

microscopic differences with each starting material because the morphological

identity of these materials was not observed in the atorvastatin

calcium-dipicolinic acid multi-component

solid.

Therefore, it can be concluded that the drug and coformer formed a new

multi-component solid system with new physical characteristics and solid-state

properties.

Figure 5 Micrographs

of a) atorvastatin calcium, (b) dipicolinic acid, and (c) atorvastatin calcium-dipicolinic acid

multi-component solid

3.6. Solubility

Solubility is

a parameter that directly affects the bioavailability and pharmacological

effect of an active pharmaceutical ingredient. However, atorvastatin calcium is

an active pharmaceutical ingredient with low solubility. Therefore, developing

the solubility properties of the drug is necessary to prevent the problem of

low bioavailability and lack of pharmacological response when formulated into

pharmaceutical preparations (Anwar,

Warsi, and Mallick, 2011). Table 1 shows the solubility test of pure atorvastatin

calcium and atorvastatin calcium-dipicolinic acid multi-component solid.

The test showed that the

solubility of atorvastatin calcium was 127.63 ± 7.52 mg/L. This result

indicated that 31.91 mg of atorvastatin calcium would dissolve in 250 water

media. Conversely, atorvastatin calcium is formulated into tablets with doses

of 40 and 80 mg. Therefore, atorvastatin calcium is categorized as a Class II

drug in the biopharmaceutical classification system, indicating low solubility,

and often has bioavailability when formulated into pharmaceutical preparations (Pobudkowska et al., 2015). The solubility of the drug in the multi-component solid was 344.31 ±

37.09 mg/L, which was significantly higher than the pure form (p<0.05).

Therefore, the formation of atorvastatin calcium-dipicolinic acid

multi-component solid can be used to solve the solubility problem of the drug.

Table 1 The solubility of pure

atorvastatin calcium and atorvastatin calcium - dipicolinic acid

multi-component solid in distilled water

|

Replication |

Solubility (mg/L) | |

|

Atorvastatin calcium |

Atorvastatin calcium-dipicolinic acid

multi-component solid | |

|

1 |

121.46 |

385.51 |

|

2 |

136.01 |

333.82 |

|

3 |

125.43 |

313.59 |

|

Mean ± SD |

127.63 ± 7.52 |

344.31 ± 37.09 |

The

solubility of a crystalline solid is influenced by the lattice energies of the

crystal (Elder, Holm, and Diego, 2013). Generally, crystalline solids with lower lattice

energies are more soluble because the constituent molecules are bound in a

lattice with weaker energies (Kuleshova et al., 2013; Thakuria et al., 2013). The

PXRD test showed that the atorvastatin calcium-dipicolinic acid multi-component

cocrystal had a different diffractogram pattern from each constituent

component. Also, the FTIR analysis results showed that the multi-component

solid formation resulted in a new crystalline structure through intermolecular hydrogen

bonds (Khadka et al., 2014). Therefore, atorvastatin calcium-dipicolinic acid

multi-component solid has a higher solubility than the pure form of the drug

due to the decrease in lattice energies of the crystal. This phenomenon caused

the molecules of the drug and coformer to interact more easily with solvent

molecules during the dissolution process (Kuleshova et al.,

2013; Thakuria et al., 2013).

The solvent evaporation-quenching

method was used to convert atorvastatin calcium to a new multi-component solid

with a dipicolinic acid coformer. Furthermore, the PXRD, DSC, FTIR, and SEM

analyses indicated that the solid state of atorvastatin calcium-dipicolinic

acid was a multi-component cocrystal. The solubility testing of the

multi-component solid in distilled water showed a significant improvement of

about 2.7-fold in atorvastatin calcium solubility compared to the pure form.

Therefore, the formation of the multi-component solid can be used to solve the

atorvastatin calcium bioavailability problem due to its low solubility.

Atorvastatin calcium-dipicolinic acid multi-component solid still needs to be

further tested for its in vivo bioavailability so that the multi-component

solid can be formulated into pharmaceutical preparations with better

performance. ?

The authors would like to thank the Rector of the

University of Jember for the research funding through the “Penelitian Pasca Doktor”

(PPD) grant 2020 decree number 15732/UN25/LT/2020 under contract number

3454/UN25.3.1/LT/2020.

Ali, N.H.S.O., Rahman, S.N.S.A., Adol, H.A., Hamid,

M.H.S.A., Taha, H., Rosli, M.Y.H., Kumara, N.T.R.N., Mahadi, A.H., Usman, A.,

2020. Fabrication and Characterization of S-Benzyldithiocarbazate Schiff Base

Microcrystals by a Reprecipitation Method for Enhanced Antibacterial Activity. International

Journal of Technology. Volume 11(7), pp. 1319–1328

Anwar, M., Warsi, M.H., Mallick,

N., 2011. Enhanced Bioavailability of Nano-Sized Chitosan-Atorvastatin

Conjugate after Oral Administration to Rats. European

Journal of Pharmaceutical Sciences, Volume 44, pp.

241–249

Bekbayeva,

L., Negim, E., Niyazbekova , R., Kaliyeva, Z., Yeligbayeva, G., Khatib, J.,

2022. The Effects of Modified Chitosan on the Physicomechanical Properties of

Mortar. International Journal of Technology, Volume 13(1), pp. 125–135

Multicomponent

Crystalline Solid Forms of Aripiprazole Produced via Hot Melt Extrusion

Techniques: An Exploratory Study. Journal of

Drug Delivery Science and Technology, Volume

63, p. 102529

Chadha, R., Sharma, M., Haneef, J., 2017.

Multicomponent Solid Forms of Felodipine: Preparation, Characterisation,

Physicochemical and In-Vivo Studies. Journal

of Pharmacy and Pharmacology, Volume 69, pp. 254–264

Douroumis, D., Ross, S.A., Nokhodchi, A., 2017.

Advanced Methodologies for Cocrystal Synthesis. Advanced Drug Delivery Reviews, Volume 117, pp.

178–195

Elder,

D.P., Holm, R., de Diego, H.L., 2013. Use of Pharmaceutical Salts and Cocrystals to Address the Issue of Poor Solubility. International Journal of Pharmaceutics,

Volume

453, pp. 88–100

Gao,

Y., Gao, J., Liu, Z., Kan, H., Zu, H., Sun, W., Zhang, J., Qian, S., 2012.

Coformer Selection Based on Degradation Pathway of Drugs: A Case Study of

Adefovir Dipivoxil–Saccharin and Adefovir Dipivoxil–Nicotinamide Cocrystals. International Journal of Pharmaceutics.

Volume 438, pp. 327–335

Haneef, J., Chadha, R., 2017. Drug-Drug

Multicomponent Solid Forms: Cocrystal, Coamorphous and Eutectic of Three Poorly

Soluble Antihypertensive Drugs Using Mechanochemical Approach. AAPS PharmSciTech, Volume 18(6), pp.

2279–2290

Hiendrawan, S., Veriansyah, B.,

Widjojokusumo, E., Soewandhi, S.N., Wikarsa, S., Tjandrawinata, R.R., 2016.

Simultaneous Cocrystallization and Micronization of Paracetamol-Dipicolinic

Acid Cocrystal by Supercritical Antisolvent (SAS). International Journal of

Pharmacy and Pharmaceutical Sciences, Volume 8(2), pp.

89–98

Javeer,

S.D., Patole, R., Amin, P., 2013. Enhanced Solubility and Dissolution of

Simvastatin by HPMC-Based Solid Dispersions Prepared by Hot Melt Extrusion and

Spray-Drying Method. Journal of

Pharmaceutical Investigation, Volume 43, pp. 471–480

Karagianni, A., Malamatari, M.,

Kachrimanis, K.,

2018. Pharmaceutical Cocrystals: New Solid Phase

Modification Approaches for the Formulation of APIs. Pharmaceutics,

Volume

10(18), pp. 1–30

Kawabata, Y., Wada, K., Nakatani, M., Yamada, S., Onoue, S., 2011. Formulation

Design for Poorly Water-Soluble Drugs Based on Biopharmaceutics Classification

System: Basic Approaches and Practical Applications. International Journal of Pharmaceutics, Volume 420, pp. 1–10

Khadka, P., Ro, J., Kim, H., Kim,

L. Kim, J.T., Kim, H., Cho, J.M., Yun, G., Lee, J., 2014. Pharmaceutical

Particle Technologies: An Approach to Improve Drug Solubility, Dissolution, and

Biavailibility. Asian Journal of Pharmacy and Pharmaceutical Sciences, Volume

9(6), pp. 304–316

Kuleshova, L.N., Hofmann, D.W.M.,

Boese, R., 2013. Lattice Energy Calculation- A Quick Tool for Screening of

Cocrystal and Estimation of Relative Solubility. Case of Flavonoids. Chemical

Physics Letters, Volume 564,

pp. 26–32

Maggi,

L., Canobbio, A., Bruni, G. Musitelli, G., Conte, U., 2015. Improvement of the

Dissolution Behavior of Gliclazide, a Slightly Soluble Drug, Using Solid

Dispersions. Journal of Drug Delivery

Science and Technology, Volume 26, pp. 17–23

Pindelska, E., Sokal, A., Kolodziejski, W.,

2017. Pharmaceutical Cocrystals, Salts and Polymorphs: Advanced

Characterization Techniques. Advanced

Drug Delivery Reviews, Volume 117, pp. 111–146

Pobudkowska,

A., Domanska, U., Jurkowska, B.A., Dymczuk, K., 2015. Solubility of

Pharmaceuticals in Water and Alcohols. Fluid

Phase Equilibria, Volume 392, pp. 56–64

Qiao, N., Li, M., Schlindwein, W., Malek, N.,

Davies, A., Trappitt, G., 2011. Pharmaceutical Cocrystals: An Overview. International Journal of Pharmaceutics,

Volume 419, pp. 1– 11

Shaikh, R., Singh, R., Walker,

G.M., Croker, D.M., 2018. Pharmaceutical Cocrystal Drug Products: An Outlook on

Product Development. Trends in

Pharmacological Sciences, Volume 39(12), pp.

1033–1048

Shete, G., Puri, V., Kumar, L., Bansal,

A.K., 2010. Solid State Characterization of Commercial Crystalline and

Amorphous Atorvastatin Calcium Samples. AAPS PharmSciTech, Volume

11(2), pp. 598–609

Sukeksi, L.,

Iriany, Grace, M., Diana, V., 2021. Characterization of the Chemical and Physical

Properties of Bar Soap Made with Different Concentrations of Bentonite as a

Filler. International

Journal of Technology, Volume 12(2), pp. 263–274

Thakuria, R., Delori, A., Jones, W., Lipert,

M.P., Roy, L., Hornedo, N.R., 2013. Pharmaceutical Cocrystals and Poorly

Soluble Drugs. International Journal of

Pharmaceutics, Volume 453, pp. 101–125

Tilborg, A., Michaux, C.,

Norberg, B., Wouters, J., 2010. Advantages of Cocrystallization in the Field of

Solid-State Pharmaceutical Chemistry: L-Proline and MnCl2. European Journal of Medicinal Chemistry,

Volume

45, pp. 3511–3517

Wicaksono, Y., Rosidi, V.A., Saragih, S.Y., Fauziah,

L.S., Setyawan, D., 2020. Preparation

of Spray Dried Coamorphous Solids to Improve the Solubility and Dissolution

Rate of Atorvastatin Calcium. Jurnal

Teknologi, Volume 83(2),

pp. 77–83

Wicaksono, Y., Setyawan, D.,

Siswandono, S., 2018. Multicomponent

Crystallization of Ketoprofen-Nicotinamide for Improving the Solubility and

Dissolution Rate. Chemistry Journal of Moldova, Volume 13(2), pp. 74–81

Wicaksono, Y., Setyawan, D.,

Siswandono, S., Siswoyo, T.A. 2019. Preparation and

Characterization of a Novel Cocrystal of Atorvastatin Calcium with Succinic

Acid Coformer. Indonesian Journal

of Chemistry, Volume 19(3), pp.

660 – 667

Williams, H.D., Trevaskis, N.L., Charman, S.A., Shanker,

R.M., Charman, W.N., Pouton, C.W., Porter, C.J.H., 2013. Strategies to Address

Low Drug Solubility in Discovery and Development. Pharmacological Reviews, Volume 65, pp. 315–499

Zaini, E., Afriyani, A., Fitriani, L., Ismed, F.,

Horikawa, A., Uekusa, H., 2020. Improved Solubility and Dissolution Rates in

Novel Multicomponent Crystals of Piperine with Succinic Acid. Scientia Pharmaceutica, Volume

88(21), pp. 1–12