Nanofiber Cellulose/Lignin from Oil Palm Empty Fruit Bunches and the Potential for Carbon Fiber Precursor Prepared by Wet-spinning

Published at : 18 Jan 2023

Volume : IJtech

Vol 14, No 1 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i1.5082

Harahap, M., Daulay, N., Zebua, D., Gea, S., 2023. Nanofiber Cellulose/Lignin from Oil Palm Empty Fruit Bunches and the Potential for Carbon Fiber Precursor Prepared by Wet-spinning. International Journal of Technology. Volume 14(1), pp. 152-161

| Mahyuni Harahap | 1. Department of Chemistry, Faculty of Science Technology and Information, Universitas Sari Mutiara Indonesia, Jalan Kapten Muslim, Medan 20124, Indonesia. 2. Cellulosic and Functional Materials Rese |

| Nurkholidah Daulay | Department of Chemistry, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Jalan Bioteknologi No.1, Medan 201555, Indonesia |

| Devi Zebua | Department of Chemistry, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Jalan Bioteknologi No.1, Medan 201555, Indonesia |

| Saharman Gea | 1. Cellulosic and Functional Materials Research Centre, Universitas Sumatera Utara, Jalan Bioteknologi No.1, Medan 20155, Indonesia. 2. Department of Chemistry, Faculty of Mathematics and Natural Sci |

This work isolated nanofiber cellulose (NFC) and Lignin from oil palm

empty fruit bunches (OPEFB). NFC/lignin-based carbon fiber was prepared by

using the wet-spinning technique and followed by pyrolysis at 500°C. Lignin isolated from OPEFB was

compared with commercial Lignin by using Fourier Transform Infrared (FTIR). The

nano dimension of NFC was observed by using Transmission Electron Microscope

(TEM). The NFC/lignin after pyrolysis was characterized by using SEM EDX and

Raman spectroscopy. NFC showed diameters between 5 nm and 60 nm. Both Lignin

commercial and isolated had aromatic benzene. Lignin was introduced to NFC,

where NFC/lignin composition of (100:0), (90:10), and (80:20) increased the

thermal stability of wet-spun fiber. Meanwhile, NFC/lignin (90:10) and (80:20)

had almost 50% residual mass. The result confirmed that the carbon material,

such as NFC/lignin (100:0), (90:10), and (80:20), had rod-like shape morphology

with diameters of 236.2 nm, 492.4 nm, and 653.2 nm, respectively. Furthermore,

the G band and D band of the carbonous material were observed at 1580 cm-1 and 1358 cm-1. The conversion of NFC/lignin

from OPEFB to carbon material was successful and potentially suitable for the

precursor of carbon fiber.

Carbon fiber; Lignin; Nanofiber cellulose; Oil palm empty fruit bunches

Carbon fiber is a

great research interest because of its large surface area, high porosity, low

density, sufficient electrical conductivity, and lightweight. Carbon fiber

demand was reported to increase by 10% annually (Wang et

al., 2019), as it

has become an important engineering material due to its unique and attractive

mechanical properties (stronger than steel and aluminum). Carbon fiber

reinforces polymer-matrix composites in advanced materials.

Polyacrylonitrile (PAN) is the most

suitable precursor for carbon-based material, accounting for high-performance

carbon fiber, high melting point, and rich carbon content. However, PAN is

petroleum-based with complex and costly manufacturing processes of the

functional materials, whose cost could be twice the carbon processing cost (Baker and Rials, 2013).

Furthermore, the increase in environmental awareness has sparked an interest in

materials produced from natural resources. Therefore, green carbon source as an

alternative to replacing petroleum-based polymers is more favored in

manufacturing carbon fiber.

Cellulose, the most abundant biomass resource,

originated from plants and microorganisms such as algae and tunicate. The

utilization of cellulose reduced the dependence on fossil resources and

protected the environment. Cellulose is environmentally friendly, abundantly

available, renewable, biodegradable, and biocompatible. However, the use of

cellulose as the precursor for carbon fiber has some limitations, such as

relatively low carbon content and aromatic absence in the biopolymers.

Nanofiber cellulose (NFC), highly crystalline cellulose, has been used to

improve the properties of material cellulose-based, i.e., nanofiber

composite (Misran et

al., 2020), printed electronics (Hoeng, Denneulin, and Bras, 2016), biomedicine (Lin and Dufresne, 2014), nanocomposite (Helmiyati and

Anggraini, 2019), nanofiltration membrane (Rochardjo et

al., 2021), and filler for carbon fiber (Harahap et

al. 2019).

Lignin, the second most abundant biomass in the world, is a major

potential source of renewable aromatic resources (Ház et al.,

2019). It consists of three main phenylpropane

units, such as guaiacol (G), sryingyl (S), and p-hydroxyphenyl (H), at

different proportions depending on the sources and extraction process. In the

pulp industry, only 1%-2% of Lignin produced could be utilized, while the rest

was usually discharged directly to the sewage which could cause serious

environmental pollution (Baker and

Rials, 2013). A review of “global lignin supply overview

and kraft lignin potential as an alternative to petroleum-based polymer” stated

that kraft lignin production increased by 150% between 2014 and 2018, and

market pull for Lignin is projected between 2023 and 2028. Lignin has been a

proven alternative to petroleum energy, mainly due to its availability at

around one-third of the solid matter in woods (Dessbesell et

al., 2020). Preparing a high-value lignin-based

material remains a prominent issue in order to utilize this natural biopolymer

fully and reduce the contamination from pulp industry, considering low

mechanical properties of Lignin where tensile modulus, strength, and

strain-to-failure-values-were-accounted-for 52 ± 2 GPa, 1.04 ± 0.10 GPa, and

2.0 ± 0.2%, respectively (Zhang and Amod, 2014).

Several studies have reported the potential of lignin

application in advanced materials by combining Lignin with other polymers or

modifying it. Lignin-polyvinyl alcohol nanofiber was formulated for

microelectrode applications (Roman et

al., 2019). Other literature converted

lignin-polyacrylonitrile to carbon nanofiber (Ma, Li,, and

Chang, 2015). Lignin was also acetylated to ?enhance its functionality and exploit its application areas (Zhao et

al., 2017). Wang et al.

(2019) isolated nanocellulose from pulp hardwood and spun it with

commercial Lignin to produce conductive carbon microfibers. In addition, Geng et al. (2021) produced a highly strong

and conductive carbon fiber based-nanocellulose from jute fiber and sodium

lignosulfonate crosslinked by chitosan molecule.

In this study, we aim to prepare

biodegradable and green carbon fiber by using NFC and Lignin from oil palm

empty fruit bunches (OPEFB). Our previous study reported a simple method to

extract NFC and Lignin from OPEFB without producing by-product (Gea

et al., 2020). To the best of our

knowledge, there is no study yet reported carbon fiber-based NFC and Lignin

derived from OPEFB. ?We expect that blending NFC

and Lignin would increase the mechanical properties of lignin-based carbon

fiber. Furthermore, the production cost of NFC/lignin-based carbon fiber is

estimated to be lower than petroleum-based carbon fiber.

OPEFB was obtained

from PTPN IV Adolina, North Sumatra, Indonesia. The materials used in this

experimental were HNO3, NaNO2, NaOH pellets (>98%),

NaSO3, NaOCl (2.5%), H2O2 (30%), HCl (37%), H2SO4

(98%), DMSO (98%) purchased from Merck (Darmstadt, Germany). All materials were

used without further purification.

2.1. Isolation of Nanofiber Cellulose and Lignin

from Oil Palm Empty Fruit Bunches

OPEFB was cut into small

pieces with lengths around 1 cm. They were dried in a vacuum oven at 100![]() for six h. Next, 75 g of dried

OPEFB was put into a three-necked flask where 1 L HNO3 3.5% and 10

mg NaNO2 were added. The mixture was refluxed for two h at 90°C. The residue was collected and washed with

deionized water several times until pH was close to 7. After that, 375 mL NaOH

2% and 375 mL NaSO3 2% were added, and the reflux was continued for

one h at 50°C. Next, the

residue was collected and washed with deionized water until pH 7, while the

filtrate was collected for the lignin isolation process.

for six h. Next, 75 g of dried

OPEFB was put into a three-necked flask where 1 L HNO3 3.5% and 10

mg NaNO2 were added. The mixture was refluxed for two h at 90°C. The residue was collected and washed with

deionized water several times until pH was close to 7. After that, 375 mL NaOH

2% and 375 mL NaSO3 2% were added, and the reflux was continued for

one h at 50°C. Next, the

residue was collected and washed with deionized water until pH 7, while the

filtrate was collected for the lignin isolation process.

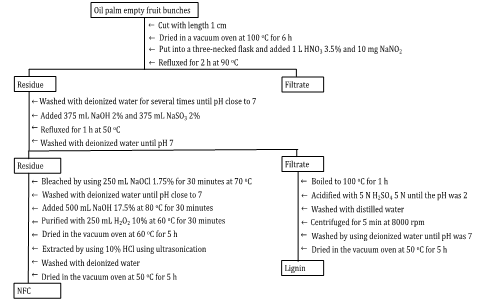

Next, the filtrate collected for lignin isolation was boiled at 100°C for one h. It was then acidified with 5 N H2SO4 5 N until the pH was 2. Next, it was washed with distilled water and centrifuged for 5 min at 8000 rpm at room temperature. Then, it was washed by using deionized water until pH was 7. The Lignin was dried in the vacuum oven at 50°C for five h. The scheme illustration for NFC and lignin isolation is shown in Figure 1.

Figure 1 A scheme

illustration for NFC and lignin isolation from OPEFB

2.2. Wet-spinning of Nanofiber

NFC was dissolved in DMSO under reflux

conditions at 60°C for 12 h with a 10% (w/v) concentration. The solution was

allowed to cool at room temperature. The same condition was also carried out

for the lignin solution. After that, three polymer solutions (NFC/lignin) with

the concentration of (100:0); (90:10); and (80:20) were dispersed by sonication

at 24 kHz, 20°C –30°C for 10 minutes. The solutions were spun in a coagulation

bath that contained a deionized water solution. The wet-spun condition was as

follows: needle diameter of 0.25 mm, feed rate of 0.004 g/minute, and wind

speed of 0.44 m/minute. The spun fiber was dried at room temperature and coded

as NFC/lignin (100:0); NFC/lignin (90:10); and NFC/lignin (80:20).

2.3.

Carbonization of Wet-spun Fiber

Carbonization of the wet-spun NFC/lignin

fibers was performed by using a tube furnace under a nitrogen atmosphere (200

mL/minute). First, 3 g of the sample was placed in a graphite sample holder and

placed inside the tube furnace. Then, pyrolysis with a heating rate of 5°C /minute

was done in two steps: pre-carbonization from 25°C to 100°C, held isothermally

for 30 minutes at 100°C, and carbonization between 100°C and 500°C, held

isothermally for 30 minutes at 500°C.

2.4.

Characterization

First, the NFC dimension was investigated

using JEOL/EO JEM-1400 (Tokyo, Japan) transmission electron microscope operated

at an accelerating voltage of 100 kV. A highly diluted NFC solution in

distilled water was prepared. The solution was dropped on carbon-coated

electron microscope grids and stained with uranyl acetate. Next, the morphology

of Lignin and NFC/lignin fiber was characterized by using Hitachi TM3030 (JEOL,

Ltd., Tokyo, Japan) scanning electron microscope (SEM). The sample was first

coated with a thin layer of gold to reduce charges during analysis. The

instrument was operated at an accelerating voltage of 10 kV. Third, the

solution's chemical compounds were studied using a Fourier-transform infrared

(FTIR) spectrometer (Nicolet 380, Thermo Scientific, Boston, USA), which used a

transmission mode with a resolution of 4 cm-1 and 100 scans. Fourth,

the crystallinity of NFC, Lignin, and NFC/lignin fibers was investigated by

using Bruker D8 advanced X-ray diffractometer (Bruker Optik GmbH, Ettlingen,

Germany). The instrument was operated at 35 kV and 25 mA. Next, the samples'

thermal analysis was carried out using thermogravimetric analysis (TGA) and

DTA/TG Exstar SII 7300 (Hitachi medical system, Tokyo, Japan), where 10 mg

sample was placed in a platinum pan and tightly closed. The sample was analyzed

between 30°C and 600°C at a heating rate of 10°C/min. Finally, the morphology

of the carbonized NFC/lignin was observed by using SEM EDX, while the structure

was investigated by using Raman spectroscopy (Raman microscope enclosure,

RE-04, Renishaw, UK) using a 785 nm laser. The samples were analyzed without

any treatment. The analyzed region was visualized through a microscope with 50x

magnification. The range of wavelengths collected was typically from 150 to

3200 cm-1 over a time period of at least 30 seconds and multiple

accumulations for high sensitivity.

3.1. FTIR

Analysis

FTIR spectra for NFC and Lignin isolated from

OPEFB, commercial Lignin, wet-spun NFC/lignin are shown in Figure 2. Both

isolated and commercial Lignin had OH groups stretching in phenolic and

aliphatic structures at wavenumber 3430 cm-1. C-H stretching in

methyl and methylene groups and methoxy groups was shown at the absorption

bands of 2925 cm-1 and 2850 cm-1, respectively. Two

string vibrations were observed at 1515 cm-1 and 1637 cm-1

corresponding to the aromatic benzene ring. Syringyl units in Lignin were seen

at 1328 cm-1, 1228 cm-1, and 1125 cm-1 bands,

whereas guaiacyl structures appeared at 1272 cm-1 and 1032 cm-1

bands (Arun et al., 2020). The band at 1168 cm-1 corresponded to

the carbonyl stretching of conjugated ester groups. Similarly, the band from

1000 cm-1 to 800 cm-1 attributed to C-O, C-H, and C=O

aromatic out-of-the-plane deformation in Lignin (Arun

et al., 2020).

NFC/lignin spun-fiber showed absorption bands between 4000 and 3200 cm-1 corresponding to the hydroxyl groups (-OH) of water. This trend has become larger compared to isolated and commercial Lignin. In addition, C-O of the alcohol group in NFC could be clearly seen in NFC/lignin spun-fiber at the 1087 cm-1 to 1026 cm-1 band. For NFC, O-H and H-C-H stretching (alkyl, aliphatic) were seen at 3278 cm-1 and 2890 cm-1, respectively. The band at 1640 cm-1 corresponded to fiber-OH (absorbed water), 1429 cm-1 attributed to HCH and OCH bending vibrations (methylene group), and 1371 cm-1 referred to CH deformation vibration (CH3 or OH in plane). The band confirmed COC, CCO, and CCH deformation and stretching vibrations at 896-915 cm-1 (Xie et al., 2016).

Figure 2 FTIR spectra of NFC, isolated Lignin, commercial Lignin, NFC/lignin

(100:0), NFC/lignin (90:10), and NFC/lignin (80:20)

3.2. Morphological

Analysis

The dimension of NFC was

analyzed using TEM, while the morphological analysis of Lignin and wet-spun NFC/lignin

was carried out using SEM. TEM micrograph of NFC and SEM images of Lignin and

wet-spun NFC/lignin are shown in Figures 3 and 4, respectively.

Figure 3 TEM micrograph of NFC isolated from OPEFB with (a) 100 nm and (b) 200 nm

scale bars

Figure 4 SEM micrographs of: (a) lignin, (b) NFC/lignin

(100:0), (c) NFC/lignin (90:10), and (d) NFC/lignin (80:20) with 1.0 K

magnification

With reference to Figure 2,

NFC showed long fibers and web-like shapes with diameters between 5 nm and 60

nm. The same result was reported by another study claiming that NFC from

pineapple peels isolated by the steam explosion had a diameter in size range of

5–60 nm (Cherian et al., 2010). On the other hand, the dimension of NFC isolated

from Ushar (Calotropid Procea) was in size range of 10–20 nm (Oun and Rhim, 2016), whereas the NFC from cotton linter was in the size

of 12 nm (Morais et al., 2013). The shape and dimension of NFC were commonly

affected by the source of cellulose, isolation method, and reaction

condition.

The SEM images of Lignin

isolated from OPEFB (Figure 3.a) had a uniform, flake-like, rough surface

morphology. However, SEM images of NFC/lignin 100:0, 90:10, and 80:20 (Figure

3.b, 3.c, and 3.d) showed non-uniform morphology. They looked like single

fibers but attached to each other. Pores were observed on those fibers, where

the higher the lignin content, the bigger the pore sizes were. NFC/lignin

(80:20) showed particles on the fiber surface that were not observed in

NFC/lignin (100:0) and (90:10). This appearance may be due to the sonication

time of NFC/lignin that was being too short. Higher lignin content should be

sonicated longer with more lignin particles dispersed into NFC.

3.3. Thermogravimetric

Analysis

The thermal stability of Lignin, NFC, and NFC/lignin (90:10, and 80:20) was analyzed using thermogravimetric analysis (TGA). The TGA traces for all samples are presented in Figure 5. All samples had a three-stage processing time function indicating sample weight loss.

Figure 5 TGA curve for Lignin, NFC, NFC/lignin (100:0), NFC/lignin (90:10), and

NFC/lignin (80:20)

3.4. XRD

Analysis

XRD analysis was carried out to confirm the crystallinity of NFC before and after blending with Lignin. Figure 6 shows the XRD pattern for Lignin, NFC, and wet-spun NFC/lignin (90:10). Lignin had an 18.30o-18.40o reflection attributed to the amorphous phase. At the same time, NFC had 22.3o reflection assigned to the crystallinity of NFC. This peak was high owing to NFC being a high crystalline material, with crystallinity >70% (Gea et al., 2020). From the pattern, NFC had the structure of cellulose I with two theta reflection at 14.5o – 15.3o, 15.7o–16.30o, and 21.90o–22.20o attributed to (1-10), (100), and (200) crystallographic plane respectively. The presence of Lignin in the NFC did not disturb the crystallinity.

Figure 6 XRD pattern of lignin, NFC, and NFC/lignin (90:10)

3.5. Characterization of Carbon

Fibers

3.5.1. SEM EDX Analysis

The morphology of wet-spun NFC/lignin after carbonization was investigated by using SEM EDX, as shown in Figure 7. Carbon fiber from NFC/lignin (100:0) Figure 7(a) shows the rod-like shape morphology. This sample had the smoothest surface morphology compared to the other fibers. The morphology of NFC/lignin (90:10) Figure 7(b) also shows a rod-like shape, but the fibers were stacked at each other. On the other hand, NFC/lignin (80:20) Figure 7(c) had rod-like and spherical morphology. The diameters were directly measured by using an SEM EDX machine, providing 236.2 nm, 492.4 nm, and 653.2 nm measurements for carbon fiber NFC/lignin (100:0), (90:10), and (80:20), respectively. All samples had approximately 50% oxygen and >25% sodium and carbon content. NFC/lignin (90:10) and NFC/lignin (80:20) contained 0.06% sulfur and 0.05% silicon. Another study reported that carbon fiber derived from Lignin and NFC pyrolyzed at 1000°C had >80% carbon content (Geng et al., 2020). Higher temperatures would increase the carbon content and decrease the oxygen content.

Figure 7 SEM images of wet-spun NFC/lignin (100:0), NFC/lignin (90:10), and

NFC/lignin (80:20) carbon fibers

3.5.2. Raman Analysis

Raman spectroscopy studied

the carbon structure of wet-spun NFC/lignin (100:0; 90:10; and 80:20). The

Raman spectra for the carbon fiber are presented in Figure 8. The crystalline

structure of carbon material in Raman spectroscopy showed four spectral regions

to indicate either amorphous or the crystalline parts in carbon as summarized

in the following: D (1350-1370 cm-1), G (1575-1582 cm-1),

D’ (~1620 cm-1) and G’ (2690-2730 cm-1). G-band was for

sp2 bonding of C=C bonds in the graphitic structures with E2g

vibration mode. It is normally presented in a single graphite crystal. Whereas,

D-band represented sp3 bonding in poorly graphitized fibers.

Therefore, according to the Tuinstra-Koenig equation, the ID/IG ratio could

determine the order level of carbon materials. The peak at ~1620 cm-1

appeared for non-graphitized fibers; whereas the band at 2690-2730 cm-1

presented graphitized fibers (Le et al. 2020).

From Figure 7, the peaks for G band and D band were at 1580 cm-1 and 1358 cm-1, indicating the presence of carbon material in the wet-spun fiber NFC/lignin (100:0; 90:10; and 80:20) with ID/IG values of 0.84, 0.86, and 0.84 respectively. The results provided information that the carbonization process for all wet-spun fiber was successful, and the fiber had a potential use for carbon fiber precursor. However, in the next study, the pyrolysis temperature could be increased to 1000°C in order to obtain higher G band. Table 1 summarises several applications of carbon fiber derived from biomass.

Figure 8 Raman spectra of NFC/lignin (100:0), NFC/lignin (90:10), and NFC/lignin

(80:20) carbon fibers

Table 1 Carbon fiber derived from biomass

|

Raw material |

Method |

Application |

References |

|

Bamboo |

Lay-up method |

Composite |

(Pramono,

Rebet, and Zulfa, 2017) |

|

Nanocellulose from jute fibre/sodium lignosulfonate |

Wet-spinning

|

Conductive carbon fibre |

(Geng et al., 2021) |

|

Nanocellulose/lignin |

Wet-spinning |

Conductive carbon fibre |

(Wang et al., 2019) |

NFC-isolated OPEFB have diameters between

5 nm and 60 nm with long fibers and web-like shapes, whereas Lignin has

uniform, flake-like, and rough surface morphology. The introduction of Lignin

into NFC nanofiber increases the thermal stability and residual mass and maintains the

crystallinity. Carbon fiber from wet-spun NFC/lignin carbonized at 500°C has

rod-like shape morphology. NFC/lignin (100:0) has the smoothest surface

morphology compared to other carbon fibers. The diameter of the carbon fiber

increases with the presence of Lignin into NFC, where diameters of 236.2 nm,

492.4 nm, to 653.2 nm have resulted in NFC/lignin (100:0), (90:10), (80:20)

samples respectively. The carbon content of all samples is >25%. Raman

spectroscopy confirms the G band (1580 cm-1) and D band (1358 cm-1)

for all carbonous NFC/lignin indicating the presence of carbon material in the

samples. The carbonization process for all wet-spun NFC/lignin fiber is

successful, and the fiber can be used as a carbon fiber precursor.

This research received no specific grant from any

funding agencies in the public, commercial, or not-for-profit sectors.

Arun, V., Perumal, E.M., Prakash, K.A.,

Rajesh, M., Tamilarasan, K., 2020. Sequential fractionation and characterization

of lignin and cellulose fiber from waste rice bran. Journal of Environmental

Chemical Engineering, Volume 8(5), pp. 1–19

Baker, D.A., Rials, T.G., 2013. Recent advances

in low-cost carbon fiber manufacture from lignin. Journal of Applied Polymer

Science, Voulme 130(2), pp. 713–28

Cherian, B.M., Leao, A.L., Souza, S.F.d.,

Thomas, S., Pothan, L.A., Kottaisamy, M., 2010. Isolation of nanocellulose from

pineapple leaf fibres by steam explosion. Carbohydrate Polymers, Volume

81(3), pp. 720–25

Dessbesell, L., Paleologou, M., Leitch, M.,

Pulkki, R., Xu, C.C., 2020. Global lignin supply overview and kraft lignin

potential as an alternative for petroleum-based polymers. Renewable and

Sustainable Energy Reviews, Volumer 123, pp. 109768

Gea, S., Siregar, A.H., Zaidar, E.,

Harahap, M., Indrawan, D.P., Perangin-angin, Y.A., 2020. Isolation and characterisation

of cellulose nanofibre and lignin from oil palm empty fruit bunches. Materials,

Volume 13(10), pp. 2290

Geng, L., Cai, Y., Lu, L., Zhang, Y., Li,

Y., Chen, B., Peng, X., 2021. Highly strong and conductive carbon fibers

origanted from bioinspired lignin/nanocellulose precursor obtained by

flow-assited alignmnet and in situ interfacial complexation. ACS Sustainable

Chemistry & Engineering. Volume 9(6), pp. 2591–2599

Geng, S., Wei, J., Jonasson, S., Hedlund,

J., Oksman, K., 2020. Multifunctional carbon aerogels with hierarchical

anisotropic structure derived from lignin and cellulose nanofibers for CO2

capture and energy storage. ACS

Applied Materials and Interfaces, Volume 12(6), pp. 7432–41

Harahap, M., Hararak, B., Khan, I.,

Pandita, S., Gea, S., 2019. Wet-spinning of cellulose acetate reinforced with

acetylated nano-crystalline cellulose as carbon fibre precursors. IOP

Conference Series: Materials Science and Engineering, Volumee 553, pp. 1–8

Ház, A., Jablonsky, M., Surina, I., Kacik,

F., Bubenikova, T., Durkovic, J., 2019. Chemical composition and thermal

behavior of kraft lignins. Forests, Volume 10(6), pp. 1–12

Helmiyati, Anggraini,

Y., 2019. Nanocomposites comprising cellulose and nanomagnetite as

heterogeneous catalysts for the synthesis of biodiesel from oleic acid. International

Journal of Technology, Volume 10(4), pp. 808–17

Hoeng, F., Denneulin, A., Bras, J., 2016.

Use of nanocellulose in printed electronics: a review. Nanoscale, Volume

8(27), pp. 13131–54

Le, N.D., Trogen, M., Ma, Y., Varley, R.J.,

Hummel, M., Byrne, N., 2020. Cellulose-lignin composite fibers as precursors

for carbon fibers: part 2–the impact of precursor properties on carbon fibers. Carbohydrate

Polymers, Volume 250, pp. 116918

Lin, N., Dufresne, A., 2014. Nanocellulose

in biomedicine: current status and future prospect. European Polymer

Journal, Volume 59, pp. 302–25

Ma, A., Li. Z., Chang, J, 2015. Conversion

of lignin-nanofibers to CNFs. Nano, Volume 10(6), pp. 1–9

Misran, E., Wirdjosentono, B., Noor, N.M.,

Gea, S., Situmorang, S.A., Harahap, M., 2020. Preparation and characterisation

of electrospun composite nanofibre polyvinyl alcohol/nanofibrillated cellulose

isolated from oil palm empty fruit bunches. BioResources, Volume 15(4),

pp. 7906–17

Morais, J.P.S., Rosa, M.d.F., Filho,

M.M.S., Nascimento, L.D., Nascimento, D.M., Cassales, A.R., 2013. Extraction

and characterization of nanocellulose structures from raw cotton linter. Carbohydrate

Polymers, Volume 91(1), pp. 229–35

Oun, A.A., Rhim, J.W., 2016.

Characterization of nanocelluloses isolated from ushar (calotropis procera)

seed fiber: effect of isolation method. Materials Letters, Volume 168,

pp. 146–50

Pramono, A.E., Rebet, I., Zulfa, A., 2017.

Electrical and mechanical properties of phenolic resin and gigantochloa apus

carbon fibre composite. International Journal of Technology, Volume 5,

pp. 920–929

Rochardjo, H.S.B., Fatkhurrohman., Ahmad,

K., Yudhanto, F., 2021. Fabrication of nanofiltration membrane based on

polyvinyl alcohol nanofibers reinforced with cellulose nanocrystal using

electrospinning techniques. International Journal of Technology, Volume

12(2), pp. 329

Roman, J., Neri, W., Derré, A., Poulin, P.,

2019. Electrospun lignin-based twisted carbon nanofibers for potential

microelectrodes applications. Carbon, Volume 145, pp. 556–64

Wang, L., Ago, M., Borghei, M., Ishaq, A.,

Papageorgiou, A.C.P., Lundahl, M., Rojas, O.J., 2019. Conductive carbon

microfibers derived from wet-spun lignin/nanocellulose hydrogels. ACS

Sustainable Chemistry and Engineering, Volume 7(6), pp. 6013–22

Xia, Z., Li, J., Zhang, J., Zhang, X.,

Zheng, X., Zhang, J., 2020. Processing and valorization of cellulose, lignin

and lignocellulose using ionic liquids. Journal

of Bioresources and Bioproducts, Volume 5, pp. 79–98

Xie, J., Hse, C.H., Hoop, C.F.C., Hu, T.,

Qi, J., Shupe, T.F., 2016. Isolation and characterization of cellulose nanofibers

from bamboo using microwave liquefaction combined with chemical treatment and

ultrasonication. Carbohydrate Polymers, Volume 151, pp. 725–34

Zhang, M., Amod A.O., 2014. Carbon fibers

from dry-spinning of acetylated softwood kraft lignin. Carbon, Volume

69, pp. 626–29

Zhao, X., Huang, Z., Zhang, Y., Yang, M.,

Chen, D., Huang, K., Hu, H., Huang, A., Qin, X., Feng, Z., 2017. Efficient solid-phase

synthesis of acetylated lignin and a comparison of the properties of different

modified lignins. Journal of Applied

Polymer Science, Volume 134(1), pp. 1–13