Characterization and potential production of glass-ceramics biomaterial from basalt rock of local Lampung Province

Corresponding email: irza.sukmana@eng.unila.ac.id

Published at : 07 Oct 2022

Volume : IJtech

Vol 13, No 4 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i4.4958

Sukmana, I., Hendronursito, Y., Savetlana, S., Isnugroho, K., Amin, M., Birawidha, D.C., 2022. Characterization and potential production of glass-ceramics biomaterial from basalt rock of local Lampung Province. International Journal of Technology. Volume 13(4), pp. 870-879

| Irza Sukmana | Mechanical Engineering Department, Engineering Faculty, Universitas Lampung, Jl. Prof. Soemantri Brojonegoro No.1, Bandar Lampung 35143, Indonesia |

| Yusup Hendronursito | 1. Mechanical Engineering Department, Engineering Faculty, Universitas Lampung, Jl. Prof. Soemantri Brojonegoro No.1, Bandar Lampung 35143, Indonesia 2. Mining Technology Research Center – National R |

| Shirley Savetlana | Mechanical Engineering Department, Engineering Faculty, Universitas Lampung, Jl. Prof. Soemantri Brojonegoro No.1, Bandar Lampung 35143, Indonesia |

| Kusno Isnugroho | Mining Technology Research Center – National Research and Innovation Agency, Jl. Ir. Sutami Km. 15 Tanjung Bintang, Lampung Selatan 35361, Indonesia |

| Muhammad Amin | Mining Technology Research Center – National Research and Innovation Agency, Jl. Ir. Sutami Km. 15 Tanjung Bintang, Lampung Selatan 35361, Indonesia |

| David Candra Birawidha | Mining Technology Research Center – National Research and Innovation Agency, Jl. Ir. Sutami Km. 15 Tanjung Bintang, Lampung Selatan 35361, Indonesia |

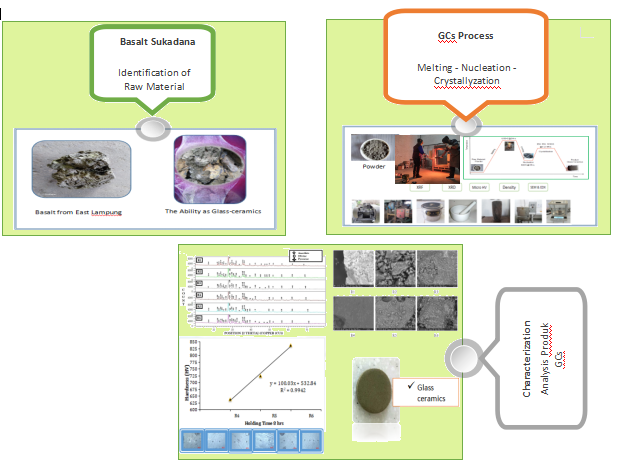

Glass-ceramics were fine-grained polycrystalline materials produced by

controlled crystallization in the glass phase to have outstanding

characteristics. The establishment of basalt from Sukadana - Lampung Province

into glass-ceramic begins with the process of reduced size and milled under 200 mesh using an ASTM sieve. The

initiated glass-ceramics formation was created by melting the basalt powder at

a temperature of 1,250oC for 2hrs to obtain the glass phase. Glass parent crystallization begins with the stage

of nucleation growth. The nucleation process occurs at a temperature 600oC for

1hr. The crystallization temperature at variations of 850, 950, or 1,050oC

for 3 and 8hrs. The mechanical hardness test result was 637.28 HV1N

of the sample with 1,050oC heating for 3hrs. The highest hardness

value is at 837.33 HV1N for a sample of 1,050oC heating

for 8hrs. The hardness value was decreased at samples for 3hrs heating, while

it increased for 8hrs of a heating process. All of the heating treatments

formed olivine and Anorthite phase but a pyroxene phase was initiated from 950oC

heating process for 3hrs. The use of glass ceramic as an engineering material

and biomaterials are promising. It is necessary to continue the development studies on the production process of

local basalt resources.

Basalt; Crystallization; Glass ceramics; Hardness; Phase

Glass-ceramics (G.C.s) were fine-grained

polycrystalline materials produced by controlled crystallization in the glass

phase (Rawlings et al., 2006). G.C.s are preferred

for wear-resistant and corrosion-resistant electronics and medicine materials (Yilmaz et al., 2006). G.C.s can be produced by materials such as TiO2-SiO2 (Kusrini et al., 2017), SnO2 and amorphous silica xerogel (S.X.) (Aripin et al., 2016) until waste-based materials (Rawlings et al., 2006).

G.C.s can be produced by

sintered basalt. Basalt glass ceramics (BGCs) are used

in many applications. For example, as a coating (Ate? et

al., 2017; Yilmaz

et al., 2006), bio-ceramics for an implant (SDVOSB, 2018), and for reinforcing material (Boshytska et al.,

2017; Kaplunenko et al., 2016). The BGCs have a homogeneous structure of finely dispersed

crystals (Yilmaz et al.,

1996). Basaltic tuff was sintered at a temperature of 1,100oC

showing a similar structure to G.C.s and has characteristic

8-9% closed porosity and zero water absorption. The crystalline phase consisted of pyroxene,

anorthite, spinel, and hematite. The BGCs with suitable properties such as a bending strength of 100 MPa and a elasticity modulus of

90 GPa (Karamanov et al., 2009). Compared with G.C.s from soda-lime-silica on the market, the BGCs are of great economic,

technological, and scientific importance (Lopes & Shelby,

2005). BGCs have an extensive and low production cost with excellent

mechanical, thermal, and chemical properties (Todic et al., 2011). The application of G.C.s in biomaterials

can be divided into two groups: bone implant and dental restoration. G.C.s are

a group of bioceramics potentially used for scaffolding (Habibie et al., 2019). Recent studies present the G.C.s in

bone regeneration and tissue engineering (Lima et al., 2020).

Basalt is

a volcanic igneous rock formed from the rapidly cooling of magma on the earth's

surface. In the field of advanced materials, basalt can be used in the form of cast basalt (Isnugroho et al., 2020), fiber (Ivanitskii & Gorbachev, 2011), and composites (Subagia et al., 2017). In Indonesia, basalt is traditionally only used as a

building material (Isnugroho et al., 2018). In less than the last five years, basalt in Indonesia has begun to be

used as an advanced material, including as a substitute material for cement

clinker (Amin et al., 2020), soil

fertilizer (Hendronursito et al.,

2019), PCC aggregate

materials (Rajiman et al., 2018), and filler for paving block material (Muttaqii et al., 2020).

This study aims to determine the potential use

of basalt rock from the Sukadana area in Lampung Province for G.C.s biomaterial application.

The chemical and mineral composition of Sukadana - East Lampung basalt allows the formation of glass-ceramics at relatively low temperatures. The anorthite phase present in all samples. Basalt melts have the ability to produce glass-ceramics. The crystalline phase significantly influences the hardness of glass-ceramics. East Lampung basalt has a high iron oxide content which affects of the glass-ceramics hardness. Glass-ceramics with high iron oxides have a bubble structure in the form of glass. Besides being seen in the topography through the SEM test, low mechanical properties are also characterized by the presence of a more dominant olivine (fayalite) phase. The longer holding time provides sufficient time for the crystallization process to occur with the dominant pyroxene phase. This causes the formed glass-ceramics to have a high hardness with a finer structure. Glass-ceramics made from Sukadana Basalt have good properties and can be developed as bioceramics that require high hardness.

This research was supported in some parts

by the BLU Universitas Lampung of “Penelitian Terapan” grant FY 2021 contract

no. 1583/UN26.21/PN/2021. The authors acknowledge the facilities, scientific

and technical support from Advanced Characterization Laboratories Lampung,

National Research and Innovation Agency through E- Layanan Sains, Badan Riset

dan Inovasi Nasional.

Abdel-Hameed, S.A., Bakr, I.M., 2007. Effect of Alumina on Ceramic

Properties of Cordierite Glass–Ceramic from Basalt Rock. Journal of the European Ceramic Society, Volume 27(2-3), pp. 1893–1897

Afriani, F., Tiandho, Y., 2020. Development of

Hydroxyapatite-Based Bioceramic Hardness Model Based on Variations in Synthesis

Conditions. Journal of Innovation and Technology,

Volume 1(1), pp. 33–38

Agathopoulos, S., Tulyaganov, D.U., Marques, P.A.A.P., Ferro, M.C.,

Fernandes, M.H.V., Correia, R.N., 2003. The Fluorapatite–Anorthite

System in Biomedicine. Biomaterials,

Volume 24(7), pp. 1317–1331

Amin, M., Birawidha, D.C., Muttaqii, M.A., Isnugroho, K.,

Hendronursito, Y., 2020. The Effect of Combustion Temperature on The

Characteristic of Clinker. In:

Proceedings of the 3rd International Seminar on Metallurgy and

Materials 2019, Serpong 23-24 October, Indonesia

Aripin, H.,

Mitsudo, S., Sudiana, I.N., Priatna, E., Kikuchi, H., Sabchevski, S., 2016.

Densification Behavior of SnO2-glass Composites Developed from the

Incorporation of Silica Xerogeland SnO2. International Journal of

Technology, volume 7(3), pp. 401–407

Ate?, A., Önen, U., Ercenk, E., Y?lmaz, ?., 2017. Crystallization Behaviors

and Seal Application of Basalt Based Glass-ceramics. In: Proceedings of the 6th International Advances in

Applied Physics and Materials Science Congress and Exhibition, Istanbul 1-3

June, Turkey

Boshytska, N.V, Fedorenko, Y.O., Perekos, A.O., Kaplunenko, N.V., 2017.

Stability Of the Phase Composition of Hydroxyapatite Powder Systems Reinforced with

Basalt Scale, When Interacting with Biological Environments. Powder Metallurgy and Metal Ceramics,

Volume 55, pp. 574–579

De Lima, L. F., Perottoni, C. A., Zorzi, J. E., & Cruz, R. C. D., 2021. Effect of iron on the microstructure of basalt glass-ceramics obtained by the petrurgic method. International Journal of Applied Ceramic Technology, 18(6), 1950–1959. https://doi.org/10.1111/ijac.13865

Ergul, S., Akyildiz, M., Karamanov, A., 2007. Ceramic

Material from Basaltic Tuffs. Industrial

Ceramics, Volume 27(2), pp. 1–6

Geologinesia, 2016. Mineral Olivin: Pengertian,

Genesa, Deskripsi dan Kegunaannya, Available Online at: https://www.geologinesia.com/2016/09/mineral-olivin-pengertian-genesa.html,

Accessed on February 2, 2020

Habibie, S., Tristiyanti, Y., Gustiono, D.,

Harahap, M.E., Chalid, S.Y., Effendi, D., 2019. Production and

Characterization of Scaffold made of Hydroxyapatite and Pectin of Green Cincau

Leaf (Premna Oblongifolia Merr). Journal

of

Engineering and Scientific Research, Volume 1,

pp. 12–17

Hendronursito, Y., Barus, J., Amin, M., Al Muttaqii, M.,

Rajagukguk, T.O., Isnugroho, K., Birawidha, D.C., 2019. The Local Mineral

Potential from East Lampung-Indonesia: The Use of Basalt Rock as a Stone Meal

for Cassava Plant. Journal of Degraded

and Mining Lands Management, Volume 7(1), pp. 1977–1985

Isnugroho, K., Birawidha, D. C.,

Hendronursito, Y., Amin, M., Muttaqii, M. Al, Efriyo Hadi, R. A., & Fazma,

M. F., 2020. Preliminary Study of Melting Basalt Rock As A Raw of Advanced

Material. In: IOP Conference Series: Materials Science and Engineering,

807(1). https://doi.org/10.1088/1757-899X/807/1/012001

Isnugroho, K., Hendronursito, Y., Candra, B.D.,

2018. Characterization

and Utilization Potential of Basalt Rock from East- Lampung District. In: Proceeding of Mineral Processing and

Technology International Conference, Jakarta 23-24 October, Indonesia

Ivanitskii,

S.G., Gorbachev, G.F., 2011. Continuous Basalt Fibers: Production Aspects and

Simulation of Forming Processes. I. State of the Art in Continuous Basalt Fiber

Technologies. Powder Metallurgy and Metal Ceramics, Volume 50(3), pp.

125–129

Kaplunenko, N.V, Ulyanchych, N.V, Klipov, V.D., Gorban, V.F., 2016.

Refractory And Ceramic Materials Basalt Scale-Reinforced Hydroxyapatite. Powder Metallurgy and Metal Ceramics,

Volume 55, pp. 306–311

Karamanov, A., Arrizza, L., Ergul, S., 2009. Sintered

Material from Alkaline Basaltic Tuffs. Journal

of The Europe Ceramic Society, Volume 29(4), pp. 595–601

Kusrini, E., Kartohardjono, S., Sofyan, N., Yuwono,

A.H., 2017. Innovation of Renewable Energy, CO2 Capture and Storage Materials

for Better Applications. International Journal of Technology, volume

8(8), pp. 1371–1375

Lima, L.F., Mantas, P.Q., Segadães, A.M., Cruz, R.C., 2020.

Processing and Characterization of Sinter-Crystallized Basalt Glass-Ceramics. Journal of Non-Crystalline Solids, Volume

538, pp. 1–7

Lo, C.L., Duh, J.G., Chiou, B.S., Lee, W.H., 2002. Low?Temperature

Sintering and Microwave Dielectric Properties of Anorthite?Based

Glass?Ceramics. Journal of the American

Ceramic Society, Volume 85(9), pp.

2230–2235

Lopes, M., Shelby, J.E., 2005. Introduction to Glass Science and

Technology. Royal Society of Chemistry., Cambridge, UK

Matovic, B., Boskovic, S., Logar, M., 2003. Preparation

of Basalt-Based Glass Ceramics. Journal

of The Serbian Chemical Society, Volume 68, pp. 505–510

Muttaqii, M.A., Amin, M., Handoko, A.S., Birawidha, D.C.,

Isnugroho, K., Hendronursito, Y., Rahayu, N., Syafriadi., 2020. The Characterization and Physical Properties of Paving Block

Products Over Basalt Minerals. In: Proceedings of the 3rd

International Seminar on Metallurgy and Materials 2019, Serpong 23-24 October,

Indonesia

Pavlovi?, M., Doj?inovi?, M., Proki?-Cvetkovi?, R., Andri?, L., 2019. The

Mechanisms of Cavitation Erosion of Raw and Sintered Basalt. Science of Sintering, Volume 51(4),

pp. 409–419

Rajiman, Alisjahbana, S.W., Riyanto, H., Hasyim, C., Setiawan,

M.I., Harmanto, D., Wajdi, M.B.N., 2018. Substitution local resources basalt

stone scoria Lampung, Indonesia, as a third raw material aggregate to increase

the quality of portland composite cement (PCC). International Journal of Engineering &

Technology, Volume 7(2),

pp. 484–490

Rawlings, R.D., Wu, J.P., Boccaccini, A.R., 2006.

Glass-Ceramics: Their Production From Wastes — A Review. Journal of

Materials Science, Volume 41, pp. 733–761

SDVOSB., 2018. Trap Rock/Basalt Powder & Fiber.

Reade Int. Corp, Available Online at: https://www.reade.com/products/trap-rock-basalt-powder-fiber, Accessed

on November 3, 2020

Subagia,

I.D.G.A., Sugita, I.K.G., Wirawan, I.K.G., Dwidiani, N.M., Yuwono, A.H., 2017.

Thermal Conductivity of Carbon/Basal Fiber Reinforced Epoxy Hybrid Composites.

International Journal of Technology, volume 8(8), pp. 1498–1506

Todic, A., Nedeljkovic, B., Cikara, D., Ristovic, I., 2011.

Particulate Basalt–Polymer Composites Characteristics Investigation. Materials & Design, Volume 32(3),

pp. 1677–1683

Villas-Boas, M. O. C., Serbena, F. C.,

Soares, V. O., Mathias, I., & Zanotto, E. D., 2020. Residual stress effect

on the fracture toughness of lithium disilicate glass-ceramics. Journal of

the American Ceramic Society, 103(1), 465–479.

https://doi.org/10.1111/jace.16664

Yilmaz, S., Bayrak, G., Sen, S. Sen, U., 2006. Structural Characterization of Basalt-Based Glass–Ceramic Coatings. Materials and Design, Volume 27, pp. 1092–1096

Yilmaz, S., Özkan, O.T., Günay, V., 1996. Crystallization Kinetics of Basalt Glass. Ceramics International, Volume 22(6), pp. 477–481