Effects of LLDPE on Mechanical Properties, Degradation Performance, and Water Absorption of Thermoplastic Sago Starch Blends

Corresponding email: novesarjamarun@sci.unand.ac.id

Published at : 18 Jan 2023

Volume : IJtech

Vol 14, No 1 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i1.4926

Tanjung, D.A., Jamarun, N., Arief, S., Aziz, H., Isfa, B., Ritonga, A.H., Sisca, V., 2023. Effects of LLDPE on Mechanical Properties, Degradation Performance, and Water Absorption of Thermoplastic Sago Starch Blends. International Journal of Technology. Volume 14(1), pp. 173-184

| Denny Akbar Tanjung | Department of Agrotechnology, Faculty of Agriculture, Universitas Medan Area, Medan-20223, Indonesia |

| Novesar Jamarun | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Andalas, Padang-25163, Indonesia |

| Syukri Arief | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Andalas, Padang-25163, Indonesia |

| Hermansyah Aziz | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Andalas, Padang-25163, Indonesia |

| Boy Isfa | Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Andalas, Padang-25163, Indonesia |

| Ahmad Hafizullah Ritonga | Institut Kesehatan Medistra Lubuk Pakam, Deli Serdang-20512, Indonesia |

| Vivi Sisca | Department of Biology Education, STKIP YPM Bangko, Jambi 37313-Indonesia |

The purpose of this

study was to improve the mechanical and physical properties, degradation

performance, and water absorption of a thermoplastic mixture of sago starch

with the addition of Linear Low-Density Polyethylene (LLDPE). The method used

is the grafting method where polyethylene is grafted onto Maleic Anhydride

(LLDPE-g-MA). In this research, Thermoplastics Sago Starch (TPSS) was made with

a mixture of Sago Starch (65%) and Glycerol (35%), added with water as a

solution. Compatibilizer (PE-g-MA) was made by reacting LLDPE (88%) and Maleate

Anhydride (9%) with an additional initiator of Benzoyl Peroxide (3%). The

concentration of LLDPE varied from 10,15, 20, 25, and 30%. Substances were

mixed into an internal mixer Thermo Haake Polydrive with a speed of 100 mm/minute, for 15

minutes. The concentration of 30% LLDPE produced the highest tensile strength

and elongation at a break of 4.30 N/mm2 and 2.15%, respectively. Simultaneously, as LLDPE concentration

increased, Young's Modulus decreased. This was powered by the morphology of the

sampling surface, with the occurred reaction of adhesion interface or

dispersion of LLDPE toward the whole surface with the assistance of

compatibilizer as connecting substance between hydrophilic polymer and a hydrophobic

polymer, which could improve the properties of mechanical. The formation of ester groups from the

reaction of inter groups of hydroxyls derived from the starch with the groups

of anhydride derived from the mixture of compatibilizer was visibly seen at the

peak of 1693 cm-1. The degradation performance of the TPSS: LLDPE

mixture with a ratio of 70:30 showed good performance where the degradation

continued to increase up to 42% on the 30th day of degradation in freshwater,

18% in seawater, and 17% in soil burial. While the water absorption test showed

that the higher concentration of LLDPE, the lower speed of water absorption.

Bioplastics; Compatibilizer, Coupling agent, Grafting, Starch

In 2018, the production of global plastic was nearly 360 million tons (Barnaba et al., 2020). Meanwhile, the production of bioplastic reached just 2.01 million tons or 0.56 percent of global plastic production (European Bioplastics, 2017). The increasing market of bioplastics could reduce dependency on fossil-based source and transform to be a biobased society (Imre et al., 2019; Geueke et al., 2018 ). Nowadays, approximately 80% of the world's plastic production is not recycled (Blank et al., 2020) and the usage of plastics polluting is on the rise (Sidek et al., 2019). Bioplastic, which by definition is biodegradable and/or gained from a renewable source, is a sustainable alternative to conventional plastic and its production capacity is estimated to increase to 2.43 million tonnes in 2024(European Bioplastics, 2018).

2.1.

Material

Sago starch Parang brand is a production of Warna

Jaya Indonesia. Obtained from the traditional market of Serpong-Tangerang,

Indonesia. Moisture content was 14%. Low Linear Density of Polyethylene (LLDPE)

UF 1810S1 Pellet with density: 0.922 g/m3, Melt Index (1900C/2.16

kg): 1.0g/10 min, melting point 1220C, obtained from PT.

Chandra Asri Petrochemical Tbk (TPIA) Cilegon-Indonesia. Maleic anhydride for

sinthesis Merck KGaA, 64271 Darmstadt Germany, Benzoyl peroxide Merck for

sinthesis Merck KGaA, 64271 Darmstadt Germany and Glycerol

Analytical Reagent merck Univar Produksi Ajax Finechem. These can beobtained

from the Rudang shop Medan-Indonesia.

2.2. Preparation of TPSS

In order to prepare TPSS, sago starch and glycerol were reacted at a ratio of 65:35, and water was added at a concentration of up to 250% of the amount of sago starch. The mixture is heated to 100°C until it turns into gelatin. To reduce the water content in TPSS gelatin to 5%, it is oven-dried for 24 hours at 80°C (Majid et al,, 2009). Figure 1 depicts a flowchart of the process of TPSS preparation.

Figure 1 Flow diagram of the process of preparation of TPSS

2.3. Preparation of Compatibilizer

The blends were mixed with Haake Polydrive Thermo. LLDPE was first added into the mixing chamber, followed by Maleate Anhydride after 5 minutes of a mixture, then Benzoyl Peroxide (BPO) was added at last. The mixture was completed at 1500C and a speed of 100 rpm, with the mixture’s total time, being 15 minutes. The composition comparison of LLDPE: Maleate Anhydrous: Benzoyl Peroxide, the ratio was 88:9:3. The compound was removed, cooled, and cut into pellets. Figure 2 illustrates a Flow Diagram of the Compatibilizer (LLDPE-g-MA) Preparation Process.

Figure 2 Flow diagram of the process of preparation of

Compatibilizer (LLDPE-g-MA)

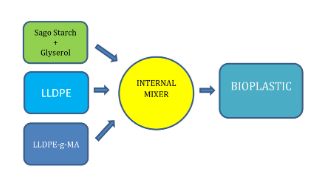

2.4. Preparation of TPSS/LLDPE/PE-g-MA

blends

The mixture preparation of TPSS / LLDPE/PE-g-MA was the final phase in this research, in which the whole phases that have been prepared above would be mixed here, such as TPSS, LLDPE, and compatibilizer. The compound was produced by mixing TPSS and LLDPE with the comparison of 90:10, 85:15, 80:20, 75:25, and 70:30. PE-g-MA was used with an amount of 10 wt. % based on the weight of TPSS (Majid et al., 2009). Figure 3 shows the process flow diagram of the TPSS/LLDPE/LLDPE-g-MA (compatibilizer) preparation.

Figure 3 Flow diagram of the process of preparation

of TPSS/LLDPE/LLDPE-g-MA (Compatibilizer)

2.5. Compression Molding

The

blend of TPSS / LLDPE was printed with hydraulic pressure compression at a

temperature of 1500C for 15 minutes. The pressure was increased to

its maximum every 5 minutes. All compression molded sheets by ASTM D638 Type

1.

2.6. Tensile Properties

A tensile test was carried out by examining the machine of

Universal Band Tensilon with the specimen of ASTM D638 Type 1. The

temperature in the chamber was 250C, humidity on 60% RHdn, 10mm

speed/minute. 3 Specimens were used to obtain the average value of Tensile Strength, Elongation

at Break, and Modulus Young.

2.7. Spectroscopy Fourier Transform

Infra-Red (FTIR)

Fourier transform infrared spectroscopy (FTIR; Perkin Elmer System

2000) was utilized to obtain qualitative information on the groups and chemical

characteristics of TPSS / LLDPE blends. For each spectrum, 45 scans with a

resolution of 4 cm-1 were recorded consecutively with Wd: 9:5 mm. The sample

was measured in the form of a 1-millimeter-thick layer produced through

hot-press molding.

2.8. Test of Morphology

The scanning test of Electron Microscopy (SEM) was carried out to

evaluate the morphology surface of the blended sampling of TPSS / LLDPE. The

sampling was dried up in the oven to reduce water content and avoid

electrostatic filling as well as worse resolution. By the time of sampling

surface inspection, it was installed on the piece of aluminum stubs and

sputter-coated with a thin layer of gold.

2.9. Test of Water Absorption

The sampling sheet was cut into a

dimension of 20mm x 20mm (Obasi et al., 2015) with a

thickness of 3mm. It was then washed with aquadest and dried up to 80% for 12

hours, cooled down in a desiccator, and weighed to gain initial weight. It was

then immersed into aquadest for ten days with a chamber temperature of 28-300C

and reweighed to gain weight afterward.

2.10. Test of Biodegradability

The compatible blend of TPSS / LLDPE with

a dimension of 20mm x 20mm with a thickness of 3 mm was examined with different

condition control (Spaccini et al., 2016; Maran et al., 2014). The

first sampling was stored in a container containing just fresh water. The

second one was immersed in seawater. The test for weight loss was done every

10, 20, and 30 days.

2.11. Test of Soil burial

The sampling was buried at a 10mm depth

from the surface of alluvial soil (Henry & Isaac, 2014) which was

placed in the holed box. Regularly wet it to keep its humidity. The weight loss

of the samples was monitored at regular intervals of 10, 20, and 30th days.

The test was carried out by washing the sample with aquadest, drying it up at

chamber temperature until its weight remained constant, and then weighing

it.

2.12. Analysis of Thermogravimetric

(TGA)

The

implemented analysis of Thermogravimetric was STA module with channel TGDTA

7300. The measurement was done at 7.73 mg with a heating rate of 100C/minute. The heating was

begun at 30C to 6500C. The rate of nitrogen gas was 50 mL/min.

3.1. Mechanical Properties

The

Tensile Strength (TS), Elongation at Break (EB), and Young’s Modulus (YM) from

the blend of TPSS/LLDPE Compatibilized, as shown in Figure 1, showing the

affecting result of additional LLDPE, at the combination of PE –g-MA as a

compatibilizer on the tensile strength and elongation at break, experienced

continuous increase with the increased concentration of LLDPE from 3.20 N/mm2

become 4.30 N/mm2 and 0.72% to 2.15% at the maximum

concentration at LLDPE 30% concentration (Matzinos

et al., 2001) as can be

seen in Table 1.

When the young modulus decreased from 447N/mm2 to 201N/mm2 due to the higher

concentration of LLDPE, the young modulus decreased as well. Figure 4-6 illustrates

the Tensile Strength (TS), Young's Modulus (YM), and elongation break charts of

TPSS/LLDPE compatibilizer blends.

Table 1 Mechanical Properties Test of TPSS/LLDPE-Compatibilizer

|

LLDPE Content (%) |

Tensile Strength (N/mm2) |

Elongation at Break (%) |

Young Modulus (N/mm2) |

Reference |

|

0 |

1.80 |

0.38 |

479 |

(Majid et

al., 2009) |

|

10 |

3.20 |

0.72 |

448 | |

|

15 |

3.39 |

1.25 |

271 | |

|

20 |

3.60 |

1.43 |

252 | |

|

25 |

3.82 |

1.60 |

239 | |

|

30 |

4.31 |

2.50 |

205 |

Figure 4 Tensile strength (TS) and Young’s Modulus (YM) test of TPSS/LLDPE compatibilizer blends

Figure 5 Elongation at Break test of TPSS/LLDPE compatibilizer blends

Figure 6 Young Modulus test of TPSS/LLDPE compatibilizer blends

3.2. FTIR

Figure 7 The Spectra of TPSS, PE-g-MA, and TPSS/LLDPE

Compatibilized blends

3.3. Test of Morphology

Morphology

affects the mechanical properties of a product and polymer dispersion evenly,

indicating that interface and adhesion have increased. On the other hand, the

occurrence of agglomeration in the polymer, shows that there was a worse

interface reaction, in which agent dispersion, formed the copolymer with its

kind. Differences in polarity were one of the causative factors. As in this

TPSS/LLDPE blend, TPSS was the main component of the major blend on the

polarized matrix. While LDDPE was the minor component of the dispersed phase,

which was expected to be the non-polarizing reinforcing agent. Figure 8 shows

how the difference in polarity led to an uneven distribution, which shows that

the LLDPE is grouped or aggregated. (Rodriguez-Gonzalez et al., 2003; Yoo et al., 2001). To

unite the natural polymer of hydrophilic with the synthesis polymer, which is

hydrophobic, the coupling agent needs an ordinary connector, known as a

compatibilizer. In the case of LLDPE, this minor polymer was evenly distributed

throughout the blend, providing evidence of interface activity in a

heterogeneous polymer blend. This is supported by the fact that bioplastic's

mechanical properties increase when compatibilizers are added. Figure 9 shows

an SEM image of a compatible blend of TPSS/LLDPE at a 20% LLDPE concentration,

scaled to 1:150.

Figure 9 SEM Image of TPSS/LLDPE Compatibilized blends, (20% concentration of LLDPE) with scale 1: 150

3.4.

Water Absorption Test

The

balance of TPSS water absorption was increased to 120% as can be

seen in Figure 10. This resulted from the hydrophilic nature of the starch due to the

many hydroxyl groups available to react with the water (Vinhas et al., 2007). The

compatibilizer blend of TPSS and LLDPE demonstrates that the balance of water

absorption decreased as LLDPE concentration increased. This was probably due to

the decrease in the number of hydroxyl groups from starch as the concentration of

TPSS decreased, which could have reacted with a water molecule (Obasi et al., 2015; Majid et al., 2009; Gáspár et al., 2005).

Figure 10 Equilibrium of water uptake test for TPSS/LLDPE Compatibilized blends

3.5. Biodegradability Test

In this degradation test, the three

conditions were shown in figure 11-13, namely, freshwater immersion,

seawater immersion, and being buried in the ground. In general, it could be

said that the sample size weight of compatible blend-based bioplastics made

from TPSS and LLDPE was going down as the quantity of concentrated LLDPE and

time went up. For example, the sampling weight of freshwater decreased from 46

to 42% at concentrated LLDPE 10 to 30% of concentrated LLDPE until the 30th

Day. Meanwhile, the decrease of seawater sampling weight from 56 to 18% at a

concentrated LLDPE of 10- 30%, as well as the decreased percentage of soil

buried sampling achieved 50% at a concentrated LLDPE of 30%, with the

decomposition of 17% at the 30th Days. The

more concentration of LLDPE contained in bioplastic, the smaller percentage of

degradation rate (Abdullah et al., 2013). Table

2 contains specific data.

Table 2 Performance of degradation in 3 conditions

|

Condition |

Time (day) |

LLDPE Concentrations |

Reference | |||||

|

0% |

10% |

15% |

20% |

25% |

30% | |||

|

Fresh

Water |

10 |

17 |

46 |

43 |

40 |

38 |

36 |

(Ashok et

al., 2018) |

|

20 |

33 |

58 |

53 |

49 |

44 |

40 | ||

|

30 |

56 |

64 |

57 |

53 |

48 |

42 | ||

|

Sea Water |

10 |

15 |

47 |

43 |

38 |

11 |

9 | |

|

20 |

31 |

52 |

48 |

45 |

17 |

14 | ||

|

30 |

52 |

56 |

52 |

49 |

21 |

18 | ||

|

Soil

Burial |

10 |

14 |

34 |

32 |

23 |

15 |

13 | |

|

20 |

29 |

47 |

43 |

37 |

19 |

15 | ||

|

30 |

49 |

50 |

47 |

46 |

23 |

17 | ||

Figure 11 Degradation

test of TPSS/LLDPE Compatibilized

blends in

freshwater

Figure 12 Degradation test of TPSS/LLDPE

Compatibilized blends in Seawater

Figure 13

Degradation test of TPSS/LLDPE

Compatibilized blends in Soil Burial

3.6. Analysis of

Thermogravimetric (TGA)

The Thermogravimetric Analysis

technique was used to determine the thermal decomposition and stability of the

mixed TPSS/LLDPE compatibilizer film. Thermal decomposition occurs in four

stages. The initial stage of degradation occurs at a temperature of 201.10C

with a mass loss of 17.1%. At this stage, there is evaporation or dehydration

of water into H2 and O2 gases at a temperature of 1000C

with a mass loss of 6.36%. According to the findings (González Seligra et al., 2016),

plasticizer compounds (glycerol) evaporate between the first and second stages

at temperatures between 125 and 290°C. This thermal decomposition will continue

along with the increase in temperature into compounds to other compounds. The

initial thermal decomposition of plasticized starch occurs at around 3000C,

during the second stage. At this stage, hydrogen groups are removed, and the

starch carbon chain is decomposed and depolymerized (Nascimento et al., 2012).

Furthermore, in the third stage, polyethylene begins to degrade at a

temperature of 400°C, producing gas and hydrocarbon oil (Abdullah et al., 2013). The curve of TGA shows that degradation of TPSS

/LLDPE compatibilized blends does not show a significant reduction in each

phase. This indicates that the amount of mass loss in each temperature increase

at each stage is almost the same (stable). The results of the TGA curve are

presented in Figure 14.

Figure 14 The TGA Spectrum of TPSS/LLDPE Compatibilized blends

The

addition of LLDPE as a strength agent followed by a compatibilizer between the

blend of TPSS and LLDPE could inadvertently rectify the weaknesses of

bioplastics, such as their low mechanical properties and high water absorption.

The increase in concentrated LLDPE or the decrease in concentrated TPSS could

reduce the water absorption percentage. Meanwhile, the degradation rate of

blended TPSS/LLDPE decreased because the hydroxyl groups of TPSS getting less

reacted with water molecules or were degraded by water. In this case, dispersed

particles of LLDPE in the compatible blend are significantly better than those

in the incompatible one. Future studies will focus on TPPS/LLDPE/Compatibilizer

blends.

Thank

you to LPDP for funding this research (2020).

Abdorreza, M.N., Cheng, L.H., Karim, A.A., 2011. Effects of Plasticizers on Thermal Properties

and Heat Sealability of Sago Starch Films. Food Hydrocolloids, Volume 25(1), pp. 56–60

Abdullah, M.A.A., Mamat, M., Awang,

M., Kusrini, E., Mubin, F.A.N., Sudin, N.H., 2013. Effect of trihexyltetradecylphosphonium on

thermal degradation properties of low linear density

polyethylene/montmorillonite nanocomposites. International Journal of

Technology, Volume 4(2), pp. 129–135

Amni, C., Ismet, A.S., Akbar, S., 2020. Mechanical properties of

bioplastics janeng starch (dioscorea hispida) film with glycerol and zinc oxide

as reinforcement. Rasayan Journal of Chemistry, Volume 13(1), pp. 275–281

Ashok, A., Abhijith, R., Rejeesh, C.R., 2018. Material characterization of starch-derived

biodegradable plastics and their mechanical property estimation. Materials Today: Proceedings, Volume 5(1), pp. 2163–2170

Barnaba, G., Carita, S., Costantino, S., Gallo, M.D., Giordano, R.,

2020. L’ Impiego degli imballaggi in plastica nel settore alimentare (The

use of plastic packaging in the food sector). Youth Network for Government September, pp. 1–13

Bikiaris, D., Panayiotou, C., 1998. LDPE/starch blends compatibilized with PE?g?MA copolymers. Journal of Applied Polymer Science, Volume 70(8), pp. 1503–1521

Blank, L.M, Narancic, T., Mampel, J., Tiso, T., O'Connor, K., 2020. Biotechnological upcycling of plastic waste and

other non-conventional feedstocks in a circular economy. Current Opinion in

Biotechnology, Volume 62, pp. 212–219

European Bioplastics. 2017.Report -

Bioplastic Marked Data 2017. Bioplastics market data 2017, global production capacities of bioplastics

2017-2022: 1–7. https://docs.europeanbioplastics.org/publications/market_data/2017/Report_Bioplastics_Market_Data_2017.pdf.

European Bioplastics. 2018. Bioplastics Market Data 2018. Berlin.

https://www.european-bioplastics.org/new-market-data-the-positive-trend-for-the-bioplastics-industry-remains-stable/.

Gáspár, M., Benko, Z., Dogossy, G., Reczey, K., Czigany, T., 2005. Reducing water absorption in

compostable starch-based plastics. Polymer Degradation and Stability, Volume 90(3), pp. 563–569

Geueke, B., Groh, K., Muncke, J., 2018. Food packaging in the circular economy:

overview of chemical safety aspects for commonly used materials. Journal of Cleaner Production, Volume 193, pp. 491–505

Hasan, M., Zulfadli, M., Rahmayani, R.F.I.,

Fajri, G., Fansuri, H., 2019. Thermomechanical and morphology of

biodegradable film made of taro starch and chitosan plasticized by castor oil. Rasayan Journal of Chemistry, Volume 12(3), pp. 1390–1398

Henry, C., Isaac, O., 2014. Cassava starch-mixed polypropylene

biodegradable polymer: preparation, characterization, and effects of

biodegradation products on growth of plants. International Journal of

Science and Research, Volume 3(7), pp. 802–807

Imre, B., Pukánszky, B., 2013. Compatibilization in bio-based and

biodegradable polymer blends. European Polymer Journal, Volume 49(6), pp. 1215–1233

Imre, B., García, L., Puglia, D., Vilaplana, F., 2019. Reactive

compatibilization of plant polysaccharides and biobased polymers: review on

current strategies, expectations, and reality. Carbohydrate Polymers, Volume 209, pp. 20–37

Judawisastra, H., Sitohang. R.D.R., Taufiq, D.I., Mardiyati, 2018.

The Fabrication of Yam Bean (Pachyrizous Erosus) Starch-Based Bioplastics. International Journal of Technology, Volume

9(2), pp. 345–352.

Kaewtatip, K., Tanrattanakul, V., 2012. Structure and properties of pregelatinized

cassava starch/kaolin composites. Materials and Design, Volume 37, pp. 423–428

Majid, R.A., Ismail, H., Taib, R.M., 2009. Effects of PE-g-MA on tensile properties,

morphology, and water absorption of LDPE/thermoplastic sago starch blends. Polymer - Plastics Technology and Engineering, Volume 48(9), pp. 919–924

Maran, J.P., Sivakumara, V., Thirugnanasambandhama, K., Sridhar, R.,

2014. Degradation behavior of biocomposites based on cassava starch

buried under indoor soil conditions. Carbohydrate Polymers, Volume 101(1), pp. 20–28

Matzinos, P., Bikiaris, D., Kokkou, S., Panayiotou, S., 2001. Processing and

characterization of LDPE/starch products. Journal of Applied Polymer Science, Volume 79, pp. 2548–2557

Nascimento, T.A., Calado, V., Carvalho, C.W.P., 2012. Development and characterization of a flexible

film based on starch and passion fruit mesocarp flour with nanoparticles. Food

Research International, Volume 49(1), pp. 588–595

Obasi, H.C., Egeolu, F.C., Oparaji, O.D., 2015. Comparative analysis of the tensile and

biodegradable performances of some selected modified starch filled

polypropylene blends. American

Journal of Chemistry and Materials Science, Volume 2(2), pp. 6–13

Pedroso, A.G., Rosa, D.S., 2005. Effects of the compatibilizer PE-G-GMA on the

mechanical, thermal and morphological properties of virgin and reprocessed

LDPE/corn starch blends. Polymers for Advanced Technologies, Volume 16(4), pp. 310–317

Rodriguez-Gonzalez, F.J., Ramsay, B.A., Favis, B.D., 2003. High-performance LDPE/thermoplastic starch

blends: a sustainable alternative to pure polyethylene. Polymer, Volume 44(5), pp. 1517–1526

Sari, T.I., Saputra, A.H., Bismo, S.,

Maspanger, D.R., 2020. deproteinized natural rubber

grafted with polyacrylonitrile (PAN)/polystyrene (PS) and degradation of its

mechanical properties by dimethyl ether. International Journal of Technology, Volume 11(1), pp. 15–25

Seligra,

P.G., Jaramillo, C.M., Famá, L., Goyanes, S., 2016. Data of Thermal Degradation and Dynamic

Mechanical Properties of Starch-Glycerol Based Films with Citric Acid as

Crosslinking Agent. Data in Brief, Volume 7, 1331–34

Sidek, I.S., Draman. S.F.S., Abdullah, S.R.S., Anuar, N., 2019. i tech mag current development on bioplastics and

its future prospects: an introductory review. INWASCON

Technology Magazine, Volume 1, pp. 3–8

Silviana, S., Subagio, A., 2019. Biocomposite characterization of bagasse starch

derived from cassava reinforced by acetylated bamboo cellulose and plasticized by

epoxidized waste cooking oil. Rasayan Journal of Chemistry, Volume12(3), pp. 1470–1477

Spaccini, S.R.,

Todisco D., Drosos, M., Nebbioso, A., Piccolo,A., 2016. Decomposition of bio-degradable

plastic polymer in a real on-farm composting process. Chemical and

Biological Technologies in Agriculture, Volume 3(1), pp. 1–13

Suharty, N.S., Mathialagan, M., Ismail, H., Wirjosentono, B., Firdaus, M., Wardani, G.K., 2014. Tensile properties and biodegradability of rice

husk powder-filled recycled polypropylene composites: effect of crude palm oil

and trimethylolpropane diacrylate. Journal

of Physical Science, Volume 25(2), pp. 55–71.

Vinhas, G.M., Lima S.M.D., Santos, L.A., Lima, M.A.G.D.A., Almeida

Y.M.B.D., 2007. Evaluation of the types of starch for preparation of

ldpe/starch blends. Brazilian Archives of Biology and Technology, Volume 50(3), pp. 361–370

Wang, Y.J., Liu, W., Sun, Z., 2004. Effects of glycerol and PE-g-MA on morphology,

thermal and tensile properties of LDPE and rice starch blends. Journal of Applied Polymer Science, Volume 92(1), pp. 344–350

Yoo, S.I., Lee, T.Y., Yoon, J.S., Lee, I.M., Kim, M.N., Lee, H.S., 2001. Interfacial adhesion reaction of polyethylene and

starch blends using maleated polyethylene reactive compatibilizer. Journal of Applied Polymer Science, Volume 83(4), pp. 767–776

Zaman, H.U., Beg, M.D.H., 2021. Study on binary low-density polyethylene (LDPE)/thermoplastic

sago starch (TPS) blend composites. Progress

in Applied science and Technology, Volume 11(1), pp. 53–65