Strength of Concrete through Ultrasonic Pulse Velocity and Uniaxial Compressive Strength

Corresponding email: edwinforero@usantotomas.edu.co

Published at : 20 Jan 2022

Volume : IJtech

Vol 13, No 1 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i1.4819

Zárate, D.M., Cárdenas, F.Forero, E.F., Peña, F.O., 2022. Strength of Concrete through Ultrasonic Pulse Velocity and Uniaxial Compressive Strength. International Journal of Technology. Volume 13(1), pp. 103-114

| Daniel Melo Zárate | Faculty of Civil Engineering, University Santo Tomás, 9th avenue No. 51-11, 110231, Bogotá, Colombia |

| Fernando Cárdenas | Faculty of Electric Engineering, University Santo Tomás, 9th avenue No. 51-11, 110231, Bogotá, Colombia |

| Edwin Francisco Forero | Faculty of Electric Engineering, University Santo Tomás, 9th avenue No. 51-11, 110231, Bogotá, Colombia |

| Ferney Oswaldo Peña | Faculty of Civil Engineering, University Santo Tomás, 9th avenue No. 51-11, 110231, Bogotá, Colombia |

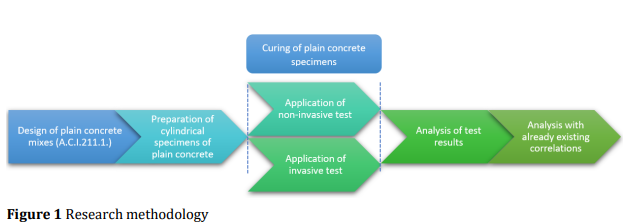

The noninvasive

technique of ultrasonic pulse rate (UPV) is increasingly used in the evaluation

of the quality of concrete, providing information about the integrity of

structures and preventing possible disasters. Therefore, for its direct

application, it is necessary to have a prior correlation between the

noninvasive UPV technique and the invasive uniaxial compression resistance

(UCS) assay. While correlations have been determined by various authors, each

has been given specific conditions and guidelines by the authors because there

is no standardized way to perform the correlations. Rather, there are only

experimental tests that have generated experimental correlations—both linear

and logarithmic—with different graphic shapes. Therefore, this research aims,

first, to validate the aforementioned relationship, which allows the

compressure resistance of concrete (f'c) to be determined for a given design of

concrete mixtures following the American Concrete Institute (ACI. 211.1.).

Second, it aims to determine the most accurate trend and the possibly correct

form of the correlation plot between the UPV and UCS. In the first instance, 15

plain concrete specimens were designed with an f’c of 28 MPa, whose dosage was

carried out following the method of ACI. 211.1. Then, UPV and UCS tests were

performed according to regulations in the first 28 days of curing the

specimens. Finally, a logarithmic correlation was obtained between the UPV

values and the values of the invasive tests for the UCS of concrete. A

graphical analysis with some existing correlations of other investigations was

then performed, and a similarity in the logarithmic tendency, with a

coefficient of determination greater than that of the linear trend, was

observed.

Concrete structures; Design concrete mixes; Uniaxial compressive strength (UCS); Ultrasonic pulse velocity (UPV); Ultrasound

Knowing the integrity of concrete structures is important when considering the avoidance or prevention of disasters that may cause loss of life, time, and economic resources. This, added to the exponential growth of the construction sector due to ease of production and the wide use of concrete (Han et al., 2016), has led to a need for structural analysis and monitoring of the mechanical properties of this material, especially the compressive strength of concrete (f'c) —its main property (Sánchez, 2001). This property can be determined using noninvasive and invasive tests, with the noninvasive ones used as complementary tests for concrete (ACI, 2013).

Among the invasive scanning techniques used to

determine the compressive strength of concrete, the most commonly used for the

quality evaluation of plain concrete specimens is the uniaxial compressive

strength test (Hincapié and Vidal, 2003).

This assay has limitations in diagnosing and monitoring the condition of

concrete at any age of the structure. Because cylinders are used for the test, the above are

made from a concrete mixture with which the structural elements are melted (ASTM, 2019; ICONTEC,

2020). However, although there is a method for extracting the nuclei,

which allows a fairly precise determination in real time of the resistance of

the element from which they have been extracted, it presents the disadvantage

of the necessary repair of the same element (Hincapié

and Vidal, 2003; Orozco et al., 2020).

A variety of noninvasive tests can be found in the

literature, including ultrasonic pulse velocity (UPV), ultrasonic echo, impact

echo, sonic echo, and cross hole sonic logging (ACI,

2013). The UPV method is characterized by its application to evaluate

the quality of concrete (Ramadhansyah et al., 2011;

ACI, 2013; ASTM, 2016). The noninvasive scanning technique of UPV

measurement consists of determining the velocity of an ultrasonic wave that

travels through the concrete, estimating the compressive strength of the

concrete using correlations (ASTM, 2016; Orozco et

al., 2020) without altering the physical or chemical properties of the

concrete (Suárez, 2004; Benítez-Herreros, 2011;

Salles et al., 2017; Pedreros et al., 2020).

These types of waves are acoustic pressure waves with frequencies higher than

those of the auditory spectrum of the human ear (Edwin,

2005; Martinez et al., 2007). The UPV

technique involves the following two fundamental parts: the generation of

ultrasonic waves and the corresponding reception of those waves (Rodriguez et al., 2009; Sharma

et al., 2017; Hidayat et al., 2018).

In this sense, previous studies have determined

correlations between the noninvasive measurement of UPV and the magnitude of

the uniaxial compressive strength (UCS) in plain concrete specimens (Trtnik and Gams, 2015; Sabba? and Uyan?k, 2017).

Some have used specific conditions, including Wolfs

et al. (2018), with 3D printed concrete for early ages; Hong et al. (2020), with three different concrete

mixture designs and nine parameters for 123 plain concrete specimens; Orozco et al. (2020), with a design of concrete

mixtures for aggregates and cements from high temperatures, such as the

Caribbean region of Colombia; Pedreros et al.

(2020), with three conventional mixture designs for six plain concrete

specimens; and Troncoso (2012), with concretes

made of arid limestone in Ecuador.

However, the studies present variability in the correlation trend as they depend on individual authors, which generates confusion regarding what the most accurate trend and correct form of the graph for this correlation should be. Moreover, ICONTEC (1997) NTC 4325, as a standard method for the application of UPV in Colombia, and ASTM (2016) C597-16 worldwide do not recommend a particular form for the trend and the graph for the correlation between the UPV and UCS.

This article aims, first, to validate the aforementioned relationship that allows the f’c to be determined using the measurement of UPV based on the correlation of UPV and UCS for a given design of concrete mixtures of A.C.I. 211.1. Second, it aims to determine the most correct trend and the possibly correct form of the graph for the correlation between UPV and UCS, increasing the reliability in the application of the noninvasive UPV test and allowing the f'c to be found directly in buildings’ structural elements.

The results shown in Figures 7b

and 8 indicate that during the 28 days of the concrete curing, the UPV and the

compressive strength of the concrete increase as the days pass. Therefore, this

study proposes a correlation with a logarithmic trend that can be used to

approximate the relationship between the UPV and the compressive strength of

concrete, which would be useful to implement in devices used to measure the UPV

in concrete.

For future research, it is recommended that a correlation be performed

involving the application of the noninvasive and invasive tests in the first 24

hours (red section of Figure 9b) and in the interval after 28 days of curing of

the concrete specimens (green section of Figure 9b), with the objective of

obtaining a more complete picture in those intervals of the graph.

Considering the comparison of Figures 9 and 10, it is suggested that the appropriate form of the correlation graph between the noninvasive UPV test and the invasive UCS test is a logarithmic trend. However, future researchers should consider comparing the correlations in the missing intervals shown in the green and red sections of Figure 9b.

The results obtained in this research demonstrate that the noninvasive UPV test can be established as a reliable way in the in situ estimation of the quality of concrete, thus allowing the f'c of concrete to be determined directly in the structural elements of buildings and avoiding the application of invasive tests that alter the physical or chemical properties of concrete.

This research was supported

by the SIMSE and University Santo Tomás, to whom we are deeply grateful.

| Filename | Description |

|---|---|

| R2-CVE-4819-20210904233653.png | Figura 1 |

| R2-CVE-4819-20210904234319.png | Figure 2a |

| R2-CVE-4819-20210904234344.png | Figure 2b |

| R2-CVE-4819-20210904234704.png | Figure 3a |

| R2-CVE-4819-20210904234742.png | Figure 3b |

| R2-CVE-4819-20210904234809.png | Figure 4 |

| R2-CVE-4819-20210904234830.png | Figure 5a |

| R2-CVE-4819-20210904234850.png | Figure 5b |

| R2-CVE-4819-20210904234913.png | Figure 6a |

| R2-CVE-4819-20210904234936.png | Figure 6b |

| R2-CVE-4819-20210904234953.png | Figure 7a |

| R2-CVE-4819-20210904235016.png | Figura 7b |

| R2-CVE-4819-20210904235034.png | Figura 8 |

| R2-CVE-4819-20210904235058.png | Figure 9a |

| R2-CVE-4819-20210904235132.png | Figure 9b |

| R2-CVE-4819-20210904235154.png | Figure 10 |

Asociación

Colombiana de Ingeniería Sísmica (AIS), 2010. Reglamento Colombiano

de Construcción Sismo Resistente (NSR-10, Titulo C) (Colombian Regulation for

Earthquake Resistant Construction (NSR-10, Title C)). Colombian

Association of Seismic Engineering, 20th Avenue # 84-14 Oficina 502,

Bogotá, D. C., Colombia

American Concrete Institute (ACI), 2013. Report on Nondestructive Test Methods for Evaluation

of Concrete in Structures (ACI 228.2R-13). American Concrete Institute, Farmington Hills, MI, USA

ASTM,

2005. Standard Test Method for

Compressive Strength of Cylindrical Concrete Specimens (ASTM C39/C39M-15). American Society for Testing and Materials, West

Conshohocken, PA, USA

ASTM,

2007. Standard Practice for Preparation

and Curing of Concrete Specimens for Laboratory Testing (ASTM C192/C192M-07).

American Society for Testing and Materials, West Conshohocken, PA, USA

ASTM,

2013. Standard Test Method for Total

Evaporable Moisture Content of Aggregate by Drying (ASTM C566-13). American

Society for Testing and Materials, West Conshohocken, PA, USA

ASTM,

2014. Standard Test Method for Sieve

Analysis of Fine and Coarse Aggregates (ASTM C136/C136M-14). American

Society for Testing and Materials, West Conshohocken, PA, USA

ASTM,

2015a. Standard Test Method for Relative

Density (Specific Gravity) and Absorption of Coarse Aggregate (ASTM C127-15).

American Society for Testing and Materials, West Conshohocken, PA, USA

ASTM,

2015b. Standard Test Method for Relative

Density (Specific Gravity) and Absorption of Coarse Aggregate (ASTM C128-15).

American Society for Testing and Materials, West Conshohocken, PA, USA

ASTM,

2015c. Standard Test Method for Slumping

of Hydraulic Cement Concrete (ASTM C143/C143M-15). American Society for

Testing and Materials, West Conshohocken, PA, USA

ASTM,

2016. Standard Test Method for Pulse

Velocity Through Concrete (ASTM C597-16). American Society for Testing and

Materials, West Conshohocken, PA, USA

ASTM,

2017. Standard Test Method for

Determining Bulk Density ("Unit Weight") and Air Voids of Aggregate

(ASTM C29/C29M-17a). American Society for Testing and Materials, West

Conshohocken, PA, USA

ASTM,

2019. Standard Practice for Preparation

and Curing of Concrete Test Specimens in the Field (ASTM C31/C31M-19).

American Society for Testing and Materials, West Conshohocken, PA, USA

Benítez-Herreros, J.A., 2011. Estudio de la evolución de la velocidad de

ultrasonidos en probetas de hormigón con distintos grados de humedad (Study of the Evolution of the Ultrasound

Velocity in Concrete Specimens with Different Degrees of Humidity). Master’s Thesis, Graduate Program, Polytechnic

University of Madrid, Madrid, Spain

BSI,

2004. Testing Concrete. Determination of Ultrasonic

Pulse Velocity (BS 12504-4). British Standards Institution, United Kingdom, London

Damanik, N.H.C., Susanto, D., Suganda, E., 2020. The Compressive Strength of Unfired Clay Brick

with Sugarcane Bagasse Fiber (SBF) and Bio-Enzyme Reinforcements. International Journal of Technology,

Volume 11(7), pp. 1422–1429

Edwin,

F., 2005. Diseño de un prototipo para la medición de espesores usando

ultrasonido (Design of a Prototype for

Thickness Measurement using Ultrasound). Master’s Thesis, Master of Engineering: Electrical and Electronics,

Industrial University of Santander, Bucaramanga, Colombia

Galván-Ceballos, M., Restrepo, I.A., 2016. Correlación de

la resistencia a compresión uniaxial con la humedad y porosidad eficaz en rocas

(Correlation of Uniaxial Compressive

Strength with Moisture and Effective Porosity in Rocks). Dyna, Volume 83(198), pp. 9–15

Gea, S.M., Batanero, C., Guzmán, R., 2014. El sentido de

la correlación y regresión (The Sense of

Correlation and Regression). Números,

Volume 87, pp. 25–35

Han, A., Gan, B.S., Pratama, M.M.A., 2016. Effects of Graded Concrete on Compressive

Strengths. International Journal of

Technology, Volume 7(5), pp. 732–740

Hidayat,

D., Setianto, Syafei, N.S., Wibawa, B.M., 2018. MOSFET-based High Voltage Short

Pulse Generator for Ultrasonic Transducer Excitation. In: AIP Conference Proceedings, Volume 1927 (030018), pp. 1–7

Hincapié,

A., Vidal, V., 2003. Resistencia al hormigón: Núcleos vs. Cilindros (Strength to Concrete: Cores

vs Cylinders). EAFIT University Magazine, Volume 39(131), pp. 87–95

Hong,

S., Yoon, S., Kim, J., Lee, C., Kim, S., Lee, Y., 2020. Evaluation of Condition

of Concrete Structures using Ultrasonic Pulse Velocity Method. Applied Sciences, Volume 10(2), 706, pp. 1–19

ICONTEC, 1994. Ingeniería civil y arquitectura. Elaboración y curado de

especímenes de concreto para ensayos de laboratorio (Civil Engineering and Architecture.

Preparation and Curing of Concrete Specimens

for Laboratory Tests) (NTC 1377). Instituto Colombiano de Normas Técnicas y Certificación, Bogotá D. C., Colombia

ICONTEC, 1995. Ingeniería

civil y arquitectura. Refrentado de especímenes cilíndricos de concreto (Civil Engineering

and Architecture. Facing of Concrete Cylindrical Specimens) (NTC 504). Instituto Colombiano de Normas

Técnicas y Certificación, Bogotá D. C., Colombia

ICONTEC, 1997. Ingeniería

civil y arquitectura. Método de ensayo

para la determinación de la velocidad del pulso ultrasónico a través del

concreto (Civil Engineering and Architecture. Recommendations

for Measurement of Velocity of Ultrasonic Pulses in Concrete) (NTC 4325). Instituto Colombiano de Normas Técnicas y Certificación,

Bogotá D. C., Colombia

ICONTEC, 2010. Ensayo de

resistencia a la compresión de especímenes cilíndricos de concreto (Compressive

Strength Test of Cylindrical Concrete Specimens) (NTC 673). Instituto

Colombiano de Normas Técnicas y Certificación, Bogotá D. C., Colombia

ICONTEC, 2018. Concretos.

Método de ensayo para determinar el asentamiento del concreto (Concrete. Test Method

for Determining the Settlement of Concrete) (NTC 396). Instituto Colombiano de

Normas Técnicas y Certificación, Bogotá D. C., Colombia

ICONTEC, 2020. Concretos.

Elaboración y curado de especímenes de concreto en el sitio de trabajo

(Concrete. Making and Curing of Concrete Test Specimens

in the Field) (NTC 550). Instituto Colombiano de

Normas Técnicas y Certificación, Bogotá D. C., Colombia

Martinez, R.J.A., Vitola Oyaga, J., Sandoval Cantor,

S.D.P., 2007. Fundamentos teórico-prácticos del ultrasonido (Theoretical-Practical

Foundations of Ultrasound). Tecnura,

Volume 10(20), pp. 4–18

Melo, D., Cárdenas, F., Casagua, J., Mora, V., Pedreros,

L., Ramírez, N., Forero, E., Liscano, M., 2020. Ultrasonic Pulse Velocity Measurement in Simple Concrete

Specimens, pp. 1–7, https://doi:

10.13140/RG.2.2.12737.71521

Orozco, W.M., Ospino, J.O., Montero, A.R., 2020.

Diagnóstico de estructuras de hormigón utilizando ultrasonido (Concrete Structures Diagnostic using Ultrasound).

Colombian

Magazine of Advanced Technologies, Volume

1(35), pp. 38–43

Pedreros, L., Cárdenas, F., Ramírez, N., Forero, E.,

2020. NDT Non-Destructive Test for Quality

Evaluation of Concrete Specimens by Ultrasonic Pulse Velocity Measurement. In: IOP Conference Series: Materials

Science and Engineering, Volume 844(012041), pp. 1–9

Peña-Rey,

F.O., Becerra, J.E.B., Pirabán, A.C.C., Farfán, F.J.R., 2020. Influence of Crushed

Stone Aggregates from the Rodeb Distribution Center in the Mechanical

Properties of the Concretes Employed for the Construction of the Tocancipá Free

Trade Zone. Ing. Solidar, Volume

16(2), pp. 1–23

Ramadhansyah,

P.J., Bakar, B.H.A., Azmi, M.J.M., Ibrahim, M.H.W., 2011. Engineering Properties of

Normal Concrete Grade 40 Containing Rice Husk Ash at Different Grinding Times. International Journal of Technology,

Volume 2(1), pp. 10–19

Robles, S.L., Cárdenas, N.B., 2016. Comparison of the Resistance of Normal Concrete to

Compression, through the Curing Process by the Method of Direct Hydration or

Immersion vs Exudation by Coating in Vinipel. Degree work. Faculty of Engineering, Civil Engineering Program,

Catholic University of Colombia. Bogotá, Colombia

Rodriguez, J., Vitola, J., Sandoval, S., Forero, E.,

2009. Diseño y construcción de un sistema para examen no destructivo de fallas

y defectos en metales utilizando señales ultrasónicas (Design and Construction

of a System for Non-Destructive Examination of Flaws and Defects in Metals using

Ultrasonic Signals). EIA Magazine, Volume 6(12), pp. 9–21

Salles, L.S., Balbo, J.T., Khazanovich, L., 2017. Non-Destructive Ultrasonic Tomography for

Concrete Pavement Evaluation: Signal Processing and Image Analysis of Crucial

Parameters. The IBRACON Structures and

Materials Journal, Volume 10(6), pp. 1182–1191

Sánchez, de-G.D., 2001. Tecnología del concreto y del mortero (Concrete

and Mortar Technology) (5th ed.). Bogotá D.C. - Colombia: Bhandar Editores Ltda

Sabba?, N., Uyan?k, O., 2017. Prediction of Reinforced Concrete

Strength by Ultrasonic Velocities. Journal of Applied Geophysics, Volume 141, pp. 13–23

Sharma, K., Singh, S., Dubey, P.K., 2017. Design of Low Cost Broadband Ultrasonic

Pulser–Receiver. Mapan, Volume 32(2), pp. 95–100

Suárez, A.R., 2004. Ensayo no destructivo de hormigones por

ultrasonidos (Non-destructive Testing of Concrete by Ultrasound). Conference: Course on Non-Destructive Testing by Ultrasound, University of the Republic, Montevideo,

Uruguay. https://doi:

10.13140/2.1.3752.4484

Troncoso, N.L.G., 2012. Correlaciones entre ensayos

destructivos y no destructivos para hormigones fabricados con árido calizo en

Ecuador (Correlations between Destructive and Non-Destructive Tests for

Concretes Made with Limestone Aggregate in Ecuador). Cemento Hormigón, Volume 954, pp. 44–46

Trtnik, G., Gams, M., 2015. Ultrasonic Assessment of Initial

Compressive Strength Gain of Cement based Materials. Cement and Concrete

Research. Volume 67, pp. 148–155

Wolfs,

R.J.M., Bos, F.P., Salet, T.A.M., 2018. Correlation between Destructive

Compression Tests and Non-Destructive Ultrasonic Measurements on Early Age 3D Printed

Concrete. Construction and Building

Materials, Volume 181, pp. 447–454

Yadav,

N., Deo, S.V., Ramtekkar, G.D., 2018. Workable and Robust Concrete using High

Volume Construction and Demolition Waste in Sub Tropical Climate. International Journal of Technology,

Volume 9(3), pp. 537–548