Silica-Chitosan Nanocomposite Coatings for Enhancing Hydrophilicity of Polyester Fabric

Corresponding email: nuruddin@tf.itb.ac.id

Published at : 28 Jun 2023

Volume : IJtech

Vol 14, No 4 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i4.4786

Mulyani, R.W.E., Nuruddin, A., Suprijanto, Sunendar Purwasasmita, B., 2023. Silica-Chitosan Nanocomposite Coatings for Enhancing Hydrophilicity of Polyester Fabric. International Journal of Technology. Volume 14(4), pp. 761-769

| Rr. Wiwiek Eka Mulyani | 1. Doctoral Program of Engineering Physics, Faculty of Industrial Technology, Institut Teknologi Bandung, Bandung 40132, Indonesia, 2. Textile Chemistry Department, Polytechnic of Textile Technology, |

| Ahmad Nuruddin | Advanced Functional Materials Research Group, Faculty of Industrial Technology, Institut Teknologi Bandung, Bandung 40132, Indonesia |

| Suprijanto | Instrumentation and Control Research Group, Faculty of Industrial Technology, Institut Teknologi Bandung, Bandung 40132, Indonesia |

| Bambang Sunendar Purwasasmita | Laboratory of Advanced Materials Processing, Faculty of Industrial Technology, Institut Teknologi Bandung, Bandung 40132, Indonesia |

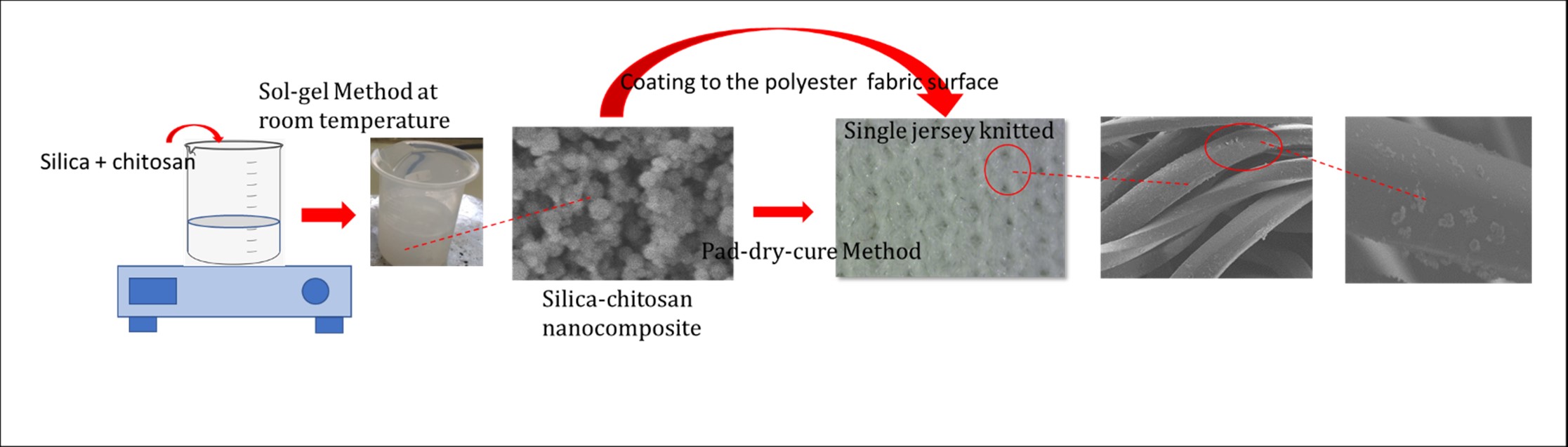

The hydrophilicity of polyester fabric surfaces has

been modified using silica-chitosan nanocomposites. The silica-chitosan

nanocomposite was synthesized by the sol-gel method from sodium silicate and

various chitosan concentrations of 0 – 1.5% at a pH of 3 – 5. A single jersey

knitted polyester fabric was coated by silica-chitosan nanocomposite using the

pad-dry-cure method. It was found that the chitosan concentration and the

solution pH controlled the formation of various size distributions of sphere

nanocomposites with an average size of 96.0-201nm. The coated polyester fabric

with sphere silica-chitosan exhibits a rough surface and produces a contact

angle approaching 0°, facilitating the polyester fabric's speed-up water

absorption and hydrophilic properties.

Chitosan; Hydrophilic; Nanocomposite; Polyester; Sodium silicate

Synthetic

fibers such as polyester are the most popular and common fiber used in

activewear and sportswear. It is cheap, easy to manufacture, and has excellent

washing and wearing properties (Shishoo,

2005). Polyester

fibers also have a good wicking rate and better dimensional stability (Ramakrishnan

and Jagannathan, 2018). However,

the fiber is generally hydrophobic and has a much lower water absorption

capacity. Polyester deficiencies are usually overcome by improving the wicking

ability through chemical treatment, which is achieved by applying a hydrophilic

coating to each polyester filament. The resulting hydrophilic surface allows

moisture to migrate along the outer surface of the filament.

Researchers have tried to modify the polyester surface's hydrophilicity, for example, by blending polyester with cellulosic (Zaman et al., 2013; Troynikov and Wardiningsih, 2011) and hydrolysis of the polyester surface using enzymes and surfactants (Gao et al., 2017). Wu et al. (2014) modified the polyester surface using cutinase treatment. Natarajan and Moses (2012) used polyvinyl alcohol to modify the polyester hydrophilicity. Recently Chen, Haase, and Mahltig (2019) modified a polyester fabric surface using a silica-chitosan composite, which succeeded in enhancing the hydrophilicity of the polyester fabric surface by measuring the sink-in time. They use tetraethoxysilane (TEOS) as primary precursors for preparing a spherical shape of silica nanoparticles. However, considering the material cost, alkoxide may not be commercially viable in the textile industry.

Sodium silicate has been

considered as an alternative inexpensive silica precursor to substitute

expensive alkoxide compounds (Hwang,

Lee, and Chun, 2021). Researchers have

prepared diverse nanostructured silica from sodium silicate (Owoeye,

Abegunde,

and Oji, 2021; Chiang et al., 2017, 2011; Jesionowski and

Krysztafkiewicz, 2002). However, they synthesized sodium silicate

precursor in an alkaline medium to produce non-agglomerated silica

nanoparticles. In contrast, the synthesis of silica from sodium silicate in

acid conditions tends to result in agglomeration (Zulfiqar,

Subhani, and Husain, 2016).

Chitosan is a unique

cationic polysaccharide that can easily be modified with chemicals, radiation,

and enzymes (Barleany et al.,

2020; Usman et al., 2018). It is a

biodegradable biopolymer used in an environmentally friendly synthesis process (Lim et al.,

2021; Usman et al., 2018;

Kusrini et al., 2015). As a

biopolymer, chitosan is a useful polymer for synthesizing metal oxide and

encapsulating small particles (Lim et al.,

2021; Matusiak, Grzadka, and

Bastrzyk, 2018). Recent

interest in chitosan has increased due to its structure's presence of main

amino groups that acts as crosslinker (Chen, Haase, and Mahltig, 2019; Haerudin et al.,

2010).

This study is aimed to synthesize

silica-based chitosan nanocomposites using the sol-gel method from sodium

silicate and chitosan. The relationship between pH and chitosan concentration

in forming silica-chitosan composites was investigated. The effects of

silica-chitosan nanocomposite coating on the polyester fabric surface were

demonstrated.

2.1.

Material

Knitted polyester fabric having a single

jersey knitted design, mass per unit area 150.6 g/m2, thickness 0.57

mm, yarn count 9.61 tex, 51 courses per inch, 43.67 wales per inch was used as

a substrate for coating. The fabric samples were knitted on a single Fukuhara

machine from 100% polyester filament yarn. Ethanol (99.9%) and acetic acid

(98%) were obtained from Merck. Sodium silicate, chitosan, and distilled water

were obtained from a local market. All chemical reagents were used without

further purification.

2.2.

Preparation of precipitated silica-chitosan

Precipitated silica-chitosan was

prepared by mixing sodium silicate with ethanol and distilled water under

continuous magnetic stirring. The solution was then divided into three equal

parts. Acetic acid was titrated to each solution to adjust the pH value to 3,

4, and 5. Chitosan solution with concentrations of 0%, 0.5%, 1%, and 1.5% was

added to the different pH of sodium silicate solutions. Finally, white

precipitated silica-chitosan was collected by centrifugation and filtering and

then dried in an electric oven at 50oC for 2 h.

2.3.

Coating silica-chitosan on polyester fabric

Five pieces of polyester fabrics were

coated with silica-chitosan nanocomposite using a pad-dry-cure method. The

polyester fabric was padded for double-nip and double-dip in a 100 mL bath with

a wet pick-up ratio of 70%. The silica-chitosan-treated polyester fabric was

then dried at 100oC for 1 min and cured at 150oC for 2

min.

2.4. Characterization of silica-chitosan

nanocomposite

The silica-chitosan nanocomposite and

coated fabric surface morphology were observed using a Hitachi TM SU-3500

Scanning electron microscope (SEM). The functional groups of nanocomposites

were analyzed using a Shimadzu Prestige 21 Fourier-transform infrared (FTIR)

Spectrophotometer. The microstructure of the samples was measured using a

Bruker X-ray diffractometer (XRD) at 40 kV with a radiation source

2.5.

Characterization of the coated fabric surface

The polyester fabric surface was

evaluated, including water contact angle and absorption. The wettability or

absorbency of polyester fabrics was examined before and after treatment using

the AATCC test method 79 (AATCC, 2018). In brief, a drop of water is dropped from a fixed height onto the

surface of a test specimen. The time required for the specular reflection of

the water drop to disappear is measured and recorded as sink-in time. The water

contact angle on polyester fabric before and after treatment was measured using

a Kyowa KYOWA interFAce Measurement and Analysis System. The volume of the

water droplet was set at

3.1. The morphology of silica-chitosan

nanocomposites

SEM examined the surface

morphology of the silica and silica-chitosan products; representative images

are shown in Figure 1. At pH 3, the silica product synthesized without chitosan

(pH 3 Ch 0) depicted a loose spherical particle of various sizes from 50 nm to

200 nm. With increasing chitosan concentration (pH 3 Ch 0.5 – 1.5), the surface

morphology did not change, but the silica-chitosan product decreased the size

(96.0 nm – 120.3 nm) and was narrowly distributed. The surface morphology of

the silica-chitosan product prepared at pH 4 and 5 have the same trend as the

surface morphology of the silica-chitosan product prepared at pH 3.

Figure 1 SEM images of silica and silica-chitosan particles

synthesized at different pH and chitosan concentrations

To reveal the particle size distribution

of the silica and silica-chitosan, the particle images in Figure 1 were

analyzed using ImageJ software. Figure 2 shows the particle size distribution

of the silica and silica-chitosan products prepared at pH 3 – 5. It can be seen

from Figure 2 that the silica and silica product prepared at low pH tends to

have a narrow particle size distribution. This is because the pH value strongly

influences the hydrolysis and condensation reactions in the sol-gel process.

Under acidic conditions, the hydrolysis reaction rate is faster than the

condensation reaction rate to produce a small particle size (Barker et.al.,

2022; Budnyak et al., 2015). Therefore, the average particle size of the silica

(119.5 nm) and silica-chitosan (96 - 120.3 nm) compared at pH 3 is smaller than

the silica (182 nm and 165.5 nm) and silica-chitosan (126.6 – 144.2 nm and

177.6 – 201.4 nm) prepared at pH 4 and 5, respectively. It is also clearly

noticed in Figure 2 that the average size of silica prepared without chitosan

is larger than that prepared by adding chitosan. Increasing the concentration

of chitosan tends to enhance the size of silica-chitosan. The higher the concentration

of chitosan involved in the reaction, the larger the size of the

silica-chitosan formed. In an acidic environment, the chitosan acts as a

crosslinker that connects the formed silica particles (Pierog, Gierszewska-Druzynska, and Ostrowska-Czubenko, 2009). The amine group of chitosan (NH2) is

protonated to be positively charged to form -NH3+ ion,

while silica is negatively charged. The interactions between the negatively

charged silicon oxide surface and the positively charged polymer chains formed

silica-chitosan nanocomposite (Chen,

Haase,

and Mahltig, 2019; Budnyak et al., 2015).

Figure 2 Particle size distribution of silica and

silica-chitosan prepared at (a) pH 3, (b) pH 4, and (c) pH 5

3.2. FTIR of silica-chitosan nanocomposites

Figure 3 shows the FTIR spectra of the

silica and silica-chitosan nanocomposite with chitosan concentration and pH

variations. The FTIR spectra pose similar peak vibrations for all samples,

indicating that changing pH and adding chitosan does not alter the silica

backbone. A large vibration area peak at 3424 cm-1 corresponds to

O-H and N-H stretching. A small peak at 1638 cm-1 relates to the

possible interaction between the hydroxyl group of silica and the amine group

of chitosan (Imani et

al., 2022). Sharp

peaks at 1092 cm-1 and 789 cm-1 are attributed to

asymmetric and symmetric stretching vibration Si-O-Si. The peak at 941 cm-1

indicates a functional group of Si-OH stretching vibration (Ryu

and Lee, 2018; Shariatinia and Jalali, 2018), and the

peak at 457 cm-1 indicates the existence of O-Si-O symmetric

deformation vibration (Mahmoud

et al., 2012).

Figure 3 FTIR spectra of

silica and silica-chitosan

The

silica and silica-chitosan product synthesized at pH 3 have relatively the same

peak intensities, while the samples synthesized at pH 4 and 5 have changed the

peak intensities. Therefore, peak intensities of OH vibration change slightly

in the sample. Chitosan is easily soluble in acidic solutions with a pH of less

than 6. At pH 2-3, silica has a zero charge point where the concentration of

the positively charged group is the same as the negative charge. Therefore, it

is possible that at pH 3, even though different concentrations of chitosan are

added, the intensity in the FTIR spectra is not changed. In acid conditions,

the silica surface is generally negatively charged (Matusiak,

Grzadka, and Bastrzyk, 2018). At pH 4

and 5, silica surfaces tend to be more negatively charged than at pH 3.

On the other hand, the polymer chain of

chitosan has a positively charged -NH3+ group. The

interaction between the negatively charged SiO2 surface and the

positively charged chitosan became possible due to the increasing negative

charge on the silica surface at pH 4 and 5 and the increasing positive charge

from adding chitosan. As a result, the intensity of the OH and Si-O-Si, Si-OH,

and O-Si-O groups in the FTIR spectrum changes.

3.3.

Morphology of the silica-chitosan coated polyester fabric

The polyester fabrics were coated with

silica-chitosan nanocomposite using a pad-dry-cure method. The surface

morphology of the untreated and treated polyester fabric is shown in Figure 4.

The optimal condition was determined to

be pH 3 with 0.5 % chitosan (pH 3 Ch 0.5) based on an analysis of the

morphology of the silica chitosan nanocomposite, particle distribution, and

functional groups. It shows the presence of a layer on the surface of the

fabric coated with silica-chitosan. The presence of a layer on the surface of

the polyester affects the surface roughness, so it influences its wetting

ability.

The presence of silica-chitosan particle

aggregates on the polyester fabric surface suggests that silica-chitosan

nanocomposites adhere to the polyester fabric surface, most likely by van der

Waals interactions. The polyester chain has a hydroxyl group at the end,

enabling it to bond to the hydroxyl group of the silica-chitosan.

Figure 4 SEM images of (a) untreated polyester fabric surface and treated

polyester fabric surface at pH 3 with (b) no chitosan, with chitosan of (c)

0.5%, (d) 1.0%, and (e) 1.5%

Figure

5 shows a prediction of the reaction between silica and silica chitosan

nanocomposite in the polyester layer. As

predicted in the reaction, the hydroxyl group on silica (Si-OH) will bond to

the polyester hydroxyl group at the end of the polymer chain (a). Figure b

illustrates the hydroxyl group of chitosan bonds to the hydroxyl group of

silica (Si-OH), and the hydroxyl group of silica bonds to the hydroxyl group of

polyester after forming the silica chitosan nanocomposite. These findings

indicate that the addition of hydroxyl groups to the surface of polyester can

enhance its hydrophilic characteristics.

Figure 5 Schematic representation of the proposed reaction of polyester fabric

surface with (a) silica nanocomposite, (b) silica-chitosan nanocomposite

3.4.

Measurement of static and dynamic contact angles

Figure 6 shows images of water droplets

on polyester fabric surfaces before and after treatment with silica-chitosan

sol. The static contact angle was measured 3 seconds after a water droplet of was placed on the fabric surface. Figure 6(a) shows the static contact angle

of water droplets on untreated fabric is 122o. While dropping water

droplets on treated fabric with silica-chitosan 0 – 1.5% resulted in zero

degrees contact angle, which suggests that coating fabric with silica or

silica-chitosan produced a hydrophilic polyester surface. Furthermore, the

hydrophilicity of treated polyester with silica and silica-chitosan was tested

by measuring the time elapse for a water droplet to disappear or be completely

absorbed by the fabric.

Figure 6 Water droplets on the polyester fabric surface, (a) static, and (b)

dynamic contact angle

Figure

6(b) shows time elapses for a water droplet to disappear from the untreated and

treated fabric surface. For the untreated fabric, the water droplet formed a

ball-like water droplet with a contact angle of 1220. The ball-like

water droplet remained unchanged for 60 seconds, and then the water droplet

suddenly disappeared. On the other hand, the treated fabric absorbed the water

droplet as the droplet immediately touched the fabric surface. It requires 9

seconds for the water droplet to absorb completely into the fabric, while the

silica-chitosan-treated fabric requires 2-4 seconds. It suggests that coating

fabric with silica-chitosan enhances surface energy and hydrophilicity.

Chitosan and sodium silicate were used to create a silica-chitosan

nanocomposite. This research investigated the morphology, particle

distribution, functional groups, and prospective applications of

silica-chitosan nanocomposites in modified polyesters. The pH condition and the chitosan concentration affected particle growth.

The optimal conditions for making nanocomposites during the synthesis process

were pH 3 and chitosan 0.5%. The application of a silica-chitosan

nanocomposite coating to polyester fabrics has been proven to enhance the

hydrophilic properties of polyester. Surface modification with silica-chitosan

nanocomposites provides an opportunity in the process of functional textile

modification but also presents a challenge for future research on the

application of bio nanocomposites in the textile industry.

The author would

like to thank Mr. Rifki Septawendar and Mrs. Wiah Wardiningsih for their

contributions that have helped us during the research and discussion. This

research was funded by the Ministry of Industry of the Republic of Indonesia as

part of a program for doctoral fellowships (Beasiswa S3

Mandiri BPSDMI,2018).

AATCC, 2018. AATCC Test Methode 79, Test Method for Absorbency of Textiles

Barker, C.R., Lewns, F.K.,

Poologasundarampillai, G. and Ward, A.D., 2022, In Situ Sol-Gel Synthesis of Unique Silica Structures Using Airborne

Assembly: Implications for In-Air Reactive Manufacturing, ACS Applied Nano

Materials, Volume 5(8), pp. 11699–11706

Barleany, D.R., Ananta, C.V.,

Maulina, F., Rochmat, A., Alwan, H., Erizal, E., 2020. Controlled Release of

Metformin Hydrogen Chloride from Stimuli-Responsive Hydrogel Based on Poly(N-Isopropylacrylamide)/Chitosan/Polyvinyl

Alcohol Composite. International Journal of Technology, Volume 11(3), pp. 511–521

Budnyak, T.M., Pylypchuk, I. V., Tertykh, V.A., Yanovska, E.S., Kolodynska,

D., 2015. Synthesis and Adsorption

Properties of Chitosan-Silica Nanocomposite Prepared by Sol-Gel Method. Nanoscale

Research Letters, Volume 10(1), pp. 1–10

Chen, G., Haase, H., Mahltig, B., 2019. Chitosan-Modified Silica Sol

Applications for The Treatment of Textile Fabrics: A View on Hydrophilic,

Antistatic and Antimicrobial Properties. Journal of Sol-Gel Science and

Technology, Volume 91(3), pp. 461–470

Chiang, W.Y., Usman, A., Sugiyama, T., Hofkens, J., Masuhara, H., 2017. Femtosecond Laser Trapping Dynamics of

Nanoparticles: A Single Transient Assembly Formation Leading to Their

Directional Ejection. Journal of Physical Chemistry C, Volume 122(25),

pp 13233–13242

Chiang, Y.D., Lian, H.Y., Leo, S.Y., Wang, S.G., Yamauchi, Y., Wu,

K.C.W., 2011. Controlling Particle Size and Structural Properties of

Mesoporous Silica Nanoparticles Using The Taguchi Method. Journal of

Physical Chemistry C, Volume 115(27), pp. 13158–13165

Gao, A., Shen, H., Zhang, H., Feng, G., Xie, K., 2017. Hydrophilic Modification of Polyester

Fabric by Synergetic Effect of Biological Enzymolysis and Non-Ionic Surfactant,

and Applications in Cleaner Production. Journal of Cleaner Production,

Volume 164, pp. 277–287

Haerudin, H., Pramono, A.W., Kusuma, D.S., Jenie, A., Voelcker,

N.H., Gibson, C., 2010. Preparation and Characterization of Chitosan/Montmorillonite

(MMT) Nanocomposite Systems. International Journal of Technology, Volume

1(1), pp. 65–73

Hwang, J., Lee, J.H., Chun, J., 2021. Facile Approach for The Synthesis of

Spherical Mesoporous Silica Nanoparticles from Sodium Silicate. Materials

Letters, Volume 283, p. 128765

Imani, N.A.C., Kusumastuti, Y., Petrus, H.T.B.M., Timotius, D.,

Putri, N.R.E., Kobayashi, M., 2022. Preparation, Characterization, and

Release Study of Nanosilica/Chitosan Composite Films. International Journal

of Technology, Volume 13(2), pp. 444–453

Jesionowski, T., Krysztafkiewicz, A., 2002. Preparation of The

Hydrophilic/Hydrophobic Silica Particles. Colloids and Surfaces A:

Physicochemical and Engineering Aspects, Volume 207(1-3), pp. 49–58

Kusrini, E., Shiong, N.S., Harahap, Y., Yulizar, Y., Arbianti, R., Pudjiastuti,

A.R., 2015. Effects of Monocarboxylic Acids and Potassium Persulfate on

Preparation of Chitosan Nanoparticles. International Journal of Technology,

Volume 6(1), pp. 11–21

Lim, M.J., Shahri, N.N.M., Taha, H., Mahadi, A.H., Kusrini, E.,

Lim, J.W., Usman, A., 2021. Biocompatible Chitin-Encapsulated Cds Quantum Dots: Fabrication

and Antibacterial Screening. Carbohydrate Polymers, Volume 260, p. 117806

Mahmoud, M.M., Folz, D.C., Suchicital, C.T., Clark, D.E., 2012. Crystallization of Lithium Disilicate

Glass Using Microwave Processing. Journal of the American Ceramic Society,

Volume 95(2), pp. 579–585

Matusiak, J., Grzadka, E., Bastrzyk, A., 2018. Stability, Adsorption and Electrokinetic

Properties of The Chitosan/Silica System. Colloids and Surfaces A: Physicochemical

and Engineering Aspects, Volume 554, pp. 245–252

Natarajan, S., Moses, J.J., 2012. Surface Modification of Polyester Fabric

Using Polyvinyl Alcohol in Alkaline Medium. Indian Journal of Fibre and

Textile Research, Volume 37(3), pp. 287–291

Owoeye, S.S., Abegunde, S.M., Oji, B., 2021. Effects of Process Variable on Synthesis and

Characterization of Amorphous Silica Nanoparticles Using Sodium Silicate

Solutions as Precursor by Sol–Gel Method. Nano-Structures & Nano-Objects,

Volume 25, p. 100625

Pierog, M., Gierszewska-Druzynska, M., Ostrowska-Czubenko, J., 2009. Effect of Ionic Crosslinking Agents on Swelling

Behaviour of Chitosan Hydrogel Membranes. Progress on Chemistry and

Application of Chitin and Its

Derivatives, Volume 75(82), p. 3

Ramakrishnan, V., Jagannathan, S., 2018. Design of Polyester-Elastane-Cotton

Plated Knitted Components for Hot and Dry Environment. International Journal

of Clothing Science and Technology, Volume 30(5), pp. 657–667

Ryu, Y.B., Lee, M.S., 2018. Infrared spectra and Thermal Properties of

Sodium Silicate Solutions: Molecular Binding Structure and Thermal Properties of

Sodium Silicate Aqueous Solution. Journal of Korean Institute of Metals and

Materials, Volume 56(1), pp. 72–78

Shariatinia, Z., Jalali, A.M., 2018. Chitosan-Based Hydrogels: Preparation,

Properties and Applications. International Journal of Biological

Macromolecules, Volume 115, pp. 194–220

Shishoo, R., 2005. Introduction. In: Textiles in Sport,

Shishoo, R., (ed.), CRC Press, Boca Raton, Boston, New York, Washington, DC,

USA, pp. 1-8

Troynikov, O., Wardiningsih, W., 2011. Moisture Management Properties of Wool/

Polyester and Wool/Bamboo Knitted Fabrics for The Sportswear Base Layer. Textile

Research Journal, Volume 81(6), pp. 621–631

Usman, A., Kusrini, E., Widiantoro, A.B., Hardiya, E., Abdullah,

N.A., Yulizar, Y., 2018. Fabrication of Chitosan Nanoparticles Containing Samarium Ion

Potentially Applicable for Fluorescence Detection and Energy Transfer. Chemical

Engineering, Volume 9(6), pp. 1112–1120

Wu, J., Cai, G., Liu, J., Ge, H., Wang, J., 2014. Eco-Friendly Surface Modification on

Polyester Fabrics by Esterase Treatment. Applied Surface Science, Volume

295, pp. 150–157

Zaman, M., Liu, H., Xiao, H., Chibante, F., Ni, Y., 2013. Hydrophilic Modification of Polyester Fabric by Applying Nanocrystalline Cellulose Containing Surface Finish. Carbohydrate Polymers, Volume 91(2), pp. 560–567

Zulfiqar, U., Subhani, T., Wilayat Husain, S., 2016. Synthesis of Silica Nanoparticles from Sodium Silicate under Alkaline Conditions. Journal of Sol-Gel Science and Technology, Volume 77(3), pp. 753–758