Effect of Thermal Pretreatment of Pineapple Peel Waste in Biogas Production using Response Surface Methodology

Corresponding email: fahmiarifan@live.undip.ac.id

Published at : 01 Jul 2022

Volume : IJtech

Vol 13, No 3 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i3.4747

Arifan, F., Broto, R.T.D.W., Sumardiono, S., Sutaryo, Dewi, A.L., Yudanto, Y.A., Sapatra, E.F., 2022. Effect of Thermal Pretreatment of Pineapple Peel Waste in Biogas Production using Response Surface Methodology. International Journal of Technology. Volume 13(3), pp. 619-632

| Fahmi Arifan | Industrial Chemical Engineering, Vocational School, Diponegoro University, 50275, Semarang, Indonesia |

| Raden Teguh Dwiputro Wisnu Broto | Industrial Chemical Engineering, Vocational School, Diponegoro University, 50275, Semarang, Indonesia |

| Siswo Sumardiono | Department of Chemical Engineering, Faculty of Engineering, Diponegoro University, 50275, Semarang, Indonesia |

| Sutaryo | Faculty of Animal and Agricultural Sciences, Diponegoro University, 50275, Semarang, Indonesia |

| Aprilia Larasati Dewi | Industrial Chemical Engineering, Vocational School, Diponegoro University, 50275, Semarang, Indonesia |

| Yusuf Arya Yudanto | Industrial Chemical Engineering, Vocational School, Diponegoro University, 50275, Semarang, Indonesia |

| Enrico Fendy Sapatra | Industrial Chemical Engineering, Vocational School, Diponegoro University, 50275, Semarang, Indonesia |

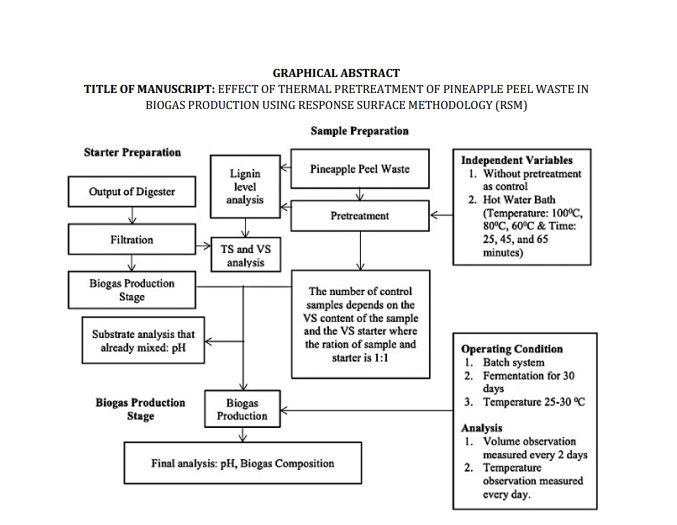

This study aims to

determine the effect of thermal pretreatment from pineapple peel waste on

biogas production using a batch anaerobic digestion process. The experimental

process was carried out on various variables, including observation time (30

days), operating temperature (25 – 35

Anaerobic digestion; Biogas; Pineapple peel waste; Thermal pretreatment

A Indonesia is one of the largest pineapple producers in the world, producing around 1,396,153 million tons per year (Widowati, 2019). A large amount of fruit peels biomass from the pineapples mostly ends up as wastes in most production areas. Eventually, the waste will build up and become a source of concern for the environment if it is not controlled. Making value-added products out of pineapple waste is one approach to deal with these wastes in an environmentally friendly manner (Hamzah et al., 2020; Lun et al., 2014; Maneeintr et al., 2018). Peel of pineapple waste can be utilized as the raw materials for producing biogas, however the amount of nitrogen is insufficient (Lun et al., 2014).

Animal waste

includes a large amount of nitrogen (N) and phosphorus (P), causing nutrient

imbalance and environmental degradation if not effectively managed (Chakravarty,

2016; Deressa et al., 2015; Hamzah et al.,

2020). Therefore, combining pineapple peel

waste and animal waste could produce biogas with high content of carbohydrates

and methane gas while also be the solution for the environmental issues. The

gas composition in biogas fuel has a generally higher percentage of CH4

than CO2, N2, O2, and H2S.

According to (Alvarez

& Lidén, 2009), cow dung and the mixture of

agricultural waste yielded CH4 fertilizer in 47% and 47 – 55%,

respectively. Thermal pretreatment is one of the processes to increase biogas

production. It is used to help the compound contained in plants be easily

broken so that microorganisms can easily convert polymers in cellulose and

hemicellulose into biogas (Budiyono

et al., 2017; Darwin et al., 2016). A method that can be used to produce

biogas is the anaerobic fermentation method using a biogas reactor

(biodigester). Biogas is a gas mixture consisting mainly of methane and carbon

dioxide. Biogas is produced anaerobically through the following three stages:

hydrolysis, acidogenesis, and methanogenesis (Biarnes,

2016; Prasetyo et al., 2017). Various kinds of organic wastes such

as animal manure, municipal solid waste, agricultural residues, and industrial

waste can be used as a substrate in biogas production. Other substrates are

kitchen, garden, cow dung, and domestic waste. Different biomass sources

(waste) will produce different quantity of biogas, e.g., two liters tapioca

waste water could produce 2458 mL of biogas (Budiyono

et al., 2018a; Nwokolo et al., 2020; Sumardiono et al., 2015). The biogas production system has several advantages, such as:

reducing the effect of greenhouse gases, reducing unpleasant odor pollution, as

fertilizer also producing power and heat, creates a healthier environment by

converting waste to biofuel, also compost sludge and liquid fertilizer can be

made from biogas (Koopmans

& Consultation, 1999; Pertiwiningrum et al., 2017).

The pineapple peel is the outer part

of the pineapple fruit (Ananas comosus),

it’s also the biomass source that is usually thrown away (Sianipar,

2006). Characterization of pineapple peel

waste with C and N content according to (Fu

et al., 2016), namely C in the amount of 41.02% and

N in the amount of 0.79%. The composition between the C and N content in the

pineapple peel waste was reported to affect the biogas CH4

production (Arifan

et al., 2018; Laopaiboon et al., 2010). The pre-treatment and hydrolysis processes are essential processes

that affect the yield of biogas.

Large organic molecules cannot be directly absorbed and used by microorganisms

as a substrate source and yield methane (Schnurer

& Jarvis, 2010; Verma, 2002). The pretreatment process is carried out to condition

lignocellulosic materials both in terms of structure and size. The

pre-treatment process directly affects biogas production by breaking down the

lignin content (Ghatak

& Mahanta, 2017; Sumardiono et al., 2017). Research conducted by (Basaria

& Priadi, 2016) and (Arifan

et al., 2021a) shows that the pretreatment process

can improve the performance of anaerobic digestion (AD) by increasing the contact between

the substrate and microorganisms resulted in the higher amount of methane

yields produced of 0.229 L CH4/g VS. According to (Casabar

et al., 2019), the purpose of pretreatment is to open the

lignocellulose structure and to make the cellulose more accessible to enzymes

that break down saccharide polymers into sugar monomers. Pre-treatment provides easier access

to the enzymes to increase glucose and xylose yield. According to (Harmsen

et al., 2010) the pretreatment process in which

hemicellulose hydrolysis may occur, includes physical pretreatment (heated, crushed, milled, sheared), chemical pretreatment (hydrolysis of

weak acids, strong acids, alkalis), a combination of physical and chemical pretreatments (steam explosion, CO2

explosion, ammonia fiber explosion (AFEX)), and biological pretreatment

(enzymes and microorganisms).

An

advantage of thermal pretreatment is its cost-effectiveness, as it dissolves

the biomass waste's high lignin concentration without the use of sodium hydroxide,

which is typically required for other pretreatment methods. The research objective is to determine pineapple peel waste thermal

effect on biogas production using a batch anaerobic digestion process. As

a result, this research will be used to the problem of finding solutions for

renewable energy.

This study used thermal pretreatment

using a hot water bath with pineapple peel waste as the raw material. The

results indicate that pretreatment of pineapple peel waste with hot water bath

significantly affects the CH4 content in biogas. In contrast to the

analysis of lignocellulose in lignin, hemicellulose, and cellulose in variable

A (without pretreatment), which revealed a high lignin concentration, the

lignin content decreased in variables B1 – B10 with pretreatment. This result

indicates that the pretreatment process affects lignin yields, affecting the

amount of cellulose and hemicellulose digested by microorganisms. The CH4 gas

content in hot water pretreated bath (B1 – B10) resulted in a higher % CH4 than

those without pretreatment (A). The optimum results of % CH4 reached

were 67.27%, which was achieved in pretreated hot water bath of pineapple peel

waste at a temperature of 100° in 25 minutes. Future works may consider

comparing the process and method of thermal pretreatment with other

pretreatments such as mechanical and chemical pretreatment. The results can

determine which pretreatment method is the best pretreatment to increase the

yield of production and obtain the purest CH4 content without

impurities in the produced biogas.

The authors would like to thank the Industrial Chemical

Engineering of Vocational School UNDIP, and Department of Animal Science UNDIP

for providing the laboratory for conducting this research. This work was

supported by the PNBP Universitas Diponegoro [185-59/UN7.6.1/PP/2021].

Acharjee,

T.C., Coronella, C.J., Vasquez, V.R., 2011. Effect of Thermal Pretreatment on

Equilibrium Moisture Content of Lignocellulosic Biomass. Bioresource

Technology, Volume 102(7),

pp. 4849–4854

Alvarez,

R., Lidén, G., 2009. Low Temperature Anaerobic Digestion of Mixtures of Llama,

Cow and Sheep Manure for Improved Methane Production. Biomass and Bioenergy,

Volume 33(3), pp. 527–533

Arifan,

F., Abdullah, A., Sumardiono, S., 2021a. Effect of Organic Waste Addition into

Animal Manure on Biogas Production Using Anaerobic Digestion Method. International

Journal of Renewable Energy Development, Volume 10(3), pp. 623–633

Arifan,

F., Abdullah, A., Sumardiono, S., 2021b. Effectiveness Analysis of Anaerobic

Digestion Method in Making Biogas from Animal Manure and Tofu Liquid Waste. Jurnal

Ilmu Dan Teknologi Hasil Ternak (JITEK), Volume 16(2), pp. 84–94

Arifan,

F., Muhammad, F., Winarni, S., Devara, H.R., Hanum, L., 2018. Optimization of

Methane Gas Formation Rate with The Addition of EM4 Starter-made from Tofu

Liquid Waste and Husk Rice Waste Using Biogas Reactor-Fixed Dome in Langensari

West Ungaran. In The 2nd International Conference on Energy, Environmental

and Information System (ICENIS 2017), Volume 31, p. 02016

Basaria,

P., Priadi, C.R., 2016. Influence of Organic Fraction of Municipal Solid Waste

Particle Size on Biogas Production. International Journal of Technology,

Volume 7(8), pp. 1431–1437.

Biarnes,

M., 2016. Biomass to Biogas: Anareobic Digestion. Resource Center in

Manufacturer of Portable Emissions & Combustion Analyzers and Indoor Air

Quality Monitors. Available online at https://www.e-inst.com/training/biomass-to-biogas/

Bougrier,

C., Delgenès, J.P., Carrère, H., 2008. Effects of Thermal Treatments on Five

Different Waste Activated Sludge Samples Solubilisation, Physical Properties and

Anaerobic Digestion. Chemical Engineering Journal, Volume 139(2), pp. 236–244

Budiyono, Wicaksono, A., Rahmawan, A., Matin, H.H.A., Wardani, L.G.K.,

Kusworo, D.T., Sumardiono, S., 2017. The Effect of Pretreatment using Sodium

Hydroxide and Acetic Acid to Biogas Production from Rice Straw Waste. MATEC

Web of Conferences,

Volume 101, p. 02011

Budiyono, Primaloka, A.D., Ardhannari, L., Matin, H.H.A., Sumardiono,

S., 2018a. Study of Biogas Production from Cassava Industrial Waste by

Anaerobic Process. MATEC Web of Conferences,

Volume 156, p. 03052

Budiyono, Manthia, F., Amalin, N., Hawali Abdul Matin, H., Sumardiono, S.,

2018b. Production of Biogas from

Organic Fruit Waste in Anaerobic Digester using Ruminant as the Inoculum. MATEC Web of Conferences, Volume

156, p. 03053

Brownell,

H.H., Saddler, J.N., 1987. Steam Pretreatment of Lignocellulosic Material for

Enhanced Enzymatic Hydrolysis. Biotechnology and Bioengineering, Volume

29(2), pp. 228–235

Casabar,

J.T., Unpaprom, Y., Ramaraj, R., 2019. Fermentation of Pineapple Fruit Peel

Wastes for Bioethanol Production. Biomass Conversion and Biorefinery, Volume

9(4), pp. 761–765

Chakravarty,

G., 2016. Evaluation of Fruit Wastes as Substrates for the Production of

Biogas. Scholars Research Library Annals of Biological Research, Volume

7(3), pp. 25–28

Darwin,

D., Yusmanizar, Y., Ilham, M., Fazil, A., Purwanto, S., Sarbaini, S., Dhiauddin,

F., 2016. Application of Thermal Pre-Treatment of Corn (Zea mays) Waste as Co

Substrate in Anaerobic Digestion Process for Biogas Production. AgriTECH,

Volume 36(1), pp. 79–88

Deressa,

L., Libsu, S., Chavan, R.B., Manaye, D., Dabassa, A., 2015. Production of

Biogas From Fruit and Vegetable Wastes Mixed with Different Wastes. Environment

and Ecology Research, Volume 3(3),

pp. 65–71

Fu,

B., Ge, C., Yue, L., Luo, J., Feng, D., Deng, H., Yu, H., 2016.

Characterization of Biochar Derived from Pineapple Peel Waste and Its

Application for Sorption of Oxytetracycline from Aqueous Solution. BioResources,

Volume 11(4), pp. 9017–9035

Ghatak,

M., Mahanta, P., 2017. Kinetic Model Development for Biogas Production from

Lignocellulosic Biomass. International Journal of Technology, Volume 8(4), pp. 673–680

González,

L.M.L., Reyes, I.P., Dewulf, J., Budde, J., Heiermann, M., Vervaeren, H., 2014.

Effect of Liquid Hot Water Pre-Treatment on Sugarcane Press Mud Methane Yield.

Bioresource Technology, Volume 169,

pp. 284–290

Hamzah,

A.F.A., Hamzah, M.H., Mazlan, F.N.A., Man, H.C., Jamali, N.S., Siajam, S.I.,

2020. Anaerobic Co-digestion of Pineapple Wastes with Cow Dung: Effect of

Different Total Solid Content on Bio-methane Yield. Advances in

Agricultural and Food Research Journal, Volume 1(1), pp. 1–12

Harmsen,

P.F.H., Huijgen, W., Bermudez, L., Bakker, R., 2010. Literature Review of Physical

and Chemical Pretreatment Processes for Lignocellulosic Biomass. Report

number: ECN-E—10-013. Energy Research Centre of The Netherlands, Petten, The

Netherlands

Koopmans,

A., Consultation, E., 1999. Trends in Energy Use. Natural Gas, Volume 9(1), pp. 2–173

Laopaiboon,

P., Thani, A., Leelavatcharamas, V., Laopaiboon, L., 2010. Acid hydrolysis of

Sugarcane Bagasse For Lactic Acid Production. Bioresource Technology, Volume

101(3), pp. 1036–1043

Lei,

H., Cybulska, I., Julson, J., 2013. Hydrothermal Pretreatment of

Lignocellulosic Biomass and Kinetics. Journal of Sustainable Bioenergy

Systems, Volume 3(04), p.

250

Lun,

O.K., Wai, T.B., Ling, L.S., 2014. Pineapple Cannery Waste as a Potential Substrate

for Microbial Biotranformation to Produce Vanillic Acid and Vanillin. International

Food Research Journal, Volume 21(3),

p. 953

Maneeintr,

K., Leewisuttikul, T., Kerdsuk, S., Charinpanitkul, T., 2018. Hydrothermal and

Enzymatic Treatments of Pineapple Waste for Energy Production. Energy

Procedia, Volume 152, pp.

1260–1265

Matsushita,

S., Tani, T., Kato, Y., Tsunoda, Y., 2004. Effect of Low-Temperature Bovine

Ovary Storage on the Maturation Rate and Developmental Potential of Follicular

Oocytes After in Vitro Fertilization, Parthenogenetic Activation, or Somatic

Cell Nucleus Transfer. Animal Reproduction Science, Volume 84(3–4), pp. 293–301

Metcalf,

Eddy., 2003. Wastewater Engineering: Treatment and Reuse. Fourth

edition, revised by George Tchobanoglous, Franklin L. Burton, H. David

Stensel. Boston. McGraw-Hill

Nwokolo,

N., Mukumba, P., Obileke, K., Enebe, M., 2020. Waste to Energy: A Focus On the

Impact of Substrate Type in Biogas Production. Processes, Volume 8(10), p. 1224

Olatunji,

K.O., Ahmed, N.A., Ogunkunle, O., 2021. Optimization of Biogas Yield from

Lignocellulosic Materials with Different Pretreatment Methods: A Review. Biotechnology

for Biofuels, Volume 14(1),

pp. 1–34

Penghe,

Z., Yuling, L., Chuanchuan, D., Pengliang, W., 2020. Study on Dissolution

Characteristics of Excess Sludge by Low-Temperature Thermal Hydrolysis and

Acid Production by Fermentation. ACS Omega, Volume 5(40), pp. 26101–26109

Pertiwiningrum,

A., Budyanto, E.C., Hidayat, M., Rochijan, Soeherman, Y., Habibi, M.F., 2017.

Making Organic Fertilizer using Sludge from Biogas Production as Carrier Agent

of Trichoderma Harzianum. Journal of Biological Sciences, Volume 17(1), pp. 21–27

Prasetyo, T., Sumardiono, S., Aji, H.A., Pratama,

A.Y., 2017. Effect of C/N Ratio and pH on Biogas Production from Industrial

Cassava Starch Wastewater Through Anaerobic Process. Advance Science

Letter, Volume 23, pp.

5810–5814

Rafique,

R., Poulsen, T.G., Nizami, A.-S., Murphy, J.D., Kiely, G., 2010. Effect of Thermal,

Chemical and Thermo-Chemical Pre-Treatments to Enhance Methane Production. Energy,

Volume 35(12), pp. 4556–4561

Ramos,

L.P., 2003. The Chemistry Involved in the Steam Treatment of Lignocellulosic

Materials. Química Nova, Volume 26(6),

pp. 863–871

Schnurer,

A., Jarvis, A., 2010. Microbiological

Handbook for Biogas Plants. Swedish

Waste Management U2009:03 and Swedish Gas Centre Report 207

Schwede,

S., Rehman, Z.-U., Gerber, M., Theiss, C., Span, R., 2013. Effects of Thermal

Pretreatment on Anaerobic Digestion of Nannochloropsis Salina Biomass. Bioresource

Technology, Volume 143,

pp. 505–511

Sianipar,

J., 2006. Evaluation of Three Types of Agricultural Waste as Goat Feed. National Seminar on Animal Husbandry and

Veterinary Technology, Indonesia

Sutaryo,

2017. Animal Husbandry Waste Handling

Practicum Book. Faculty of Agricultural and Animal Science, Universitas

Diponegoro, Indonesia

United States Environmental Protection Agency., 2015. Anaerobic Digestion and

its Applications. Available online at

https://www.epa.gov/sites/default/files/2016-07/documents/ad_and_applications-final_0.pdf

Verma,

S., 2002. Anaerobic Digestion of Biodegradable Organics in Municipal Solid

Wastes. Doctor’s Thesis, Graduate Program, Columbia University, USA

Wang,

G., Schmidt, J.E., 2010. Biogas Production from Energy Crops and

Agriculturalresidues: A Review. Information

Service Department, Risø National Laboratory for Sustainable Energy, Technical

University of Denmark, Denmark

Widowati,

H., 2019. Indonesia is the 9th Largest

Pineapple Producer in the World. Available online at

https://databoks.katadata.co.id/datapublish/2019/06/05/indonesia-produsen-nanas-terbesar-ke-9-di-dunia

Yulianto,

M.E., Amalia, R., Wahyuningsih, W., Sutrisno, S., Yudanto, Y.A., 2020.

Bioadsorption of Modified Empty Fruit Bunch Palm Oil for Reducing its 3-MCPD

Compounds using Response Surface Methodology. E3S Web of Conferences, Voluem

202, p. 12019

Yulianto,

M.E., Paramita, V., Hartati, I., Amalia, R., 2018. Response Surface

Methodology of Pressurized Liquid Water Extraction of Curcumin from Curcuma

Domestica Val. Rasayan Journal of Chemistry, Volume 11(4), pp. 1564–1571