Investigation on Saprolitic Laterite Ore Reduction Process using Palm Kernel Shell Charcoal: Kinetics and Phase Transformation

Corresponding email: bayupetrus@ugm.ac.id

Published at : 01 Jul 2022

Volume : IJtech

Vol 13, No 3 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i3.4701

Petrus, H.T.B.M., Putera, A.D.P., Warmada, I.W., Nurjaman, F., Astuti, W., Prasetya, A., 2022. Investigation on Saprolitic Laterite Ore Reduction Process using Palm Kernel Shell Charcoal: Kinetics and Phase Transformation. International Journal of Technology. Volume 13(3), pp. 565-574

| Himawan Tri Bayu Murti Petrus | 1. Department of Chemical Engineering (Sustainable Mineral Processing Research Group), Faculty of Engineering, Universitas Gadjah Mada, Jl. Grafika No. 2, Yogyakarta 55281, Indonesia 2. Unconventiona |

| Andreas Diga Pratama Putera | Department of Chemical Engineering (Sustainable Mineral Processing Research Group), Faculty of Engineering, Universitas Gadjah Mada, Jl. Grafika No. 2, Yogyakarta 55281, Indonesia |

| I Wayan Warmada | 1. Unconventional Geo-resources Research Center, Faculty of Engineering, Universitas Gadjah Mada, Jl. Grafika No. 2, Yogyakarta 55281, Indonesia 2. Department of Geological Engineering, Faculty of En |

| Fajar Nurjaman | Research Unit for Mineral Technology, Indonesian Institute of Sciences (LIPI), Jl. Ir. Sutami Km. 15, Tanjung Bintang, Lampung Selatan, Indonesia |

| Widi Astuti | Research Unit for Mineral Technology, Indonesian Institute of Sciences (LIPI), Jl. Ir. Sutami Km. 15, Tanjung Bintang, Lampung Selatan, Indonesia |

| Agus Prasetya | 1. Department of Chemical Engineering (Sustainable Mineral Processing Research Group), Faculty of Engineering, Universitas Gadjah Mada, Jl. Grafika No. 2, Yogyakarta 55281, Indonesia 2. Unconventiona |

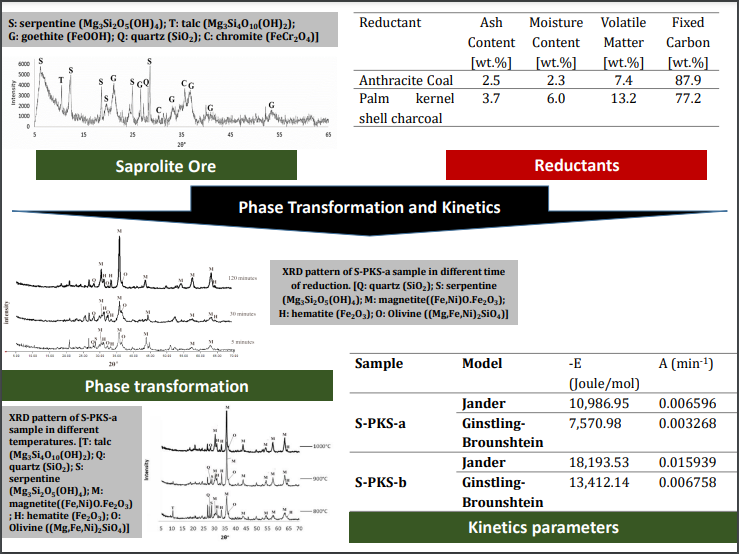

The performance and kinetic of saprolitic laterite reduction using palm

kernel shell charcoal and anthracite were studied. The anthracite coal

represents the conventional high-grade carbon content matter, and palm kernel

shell charcoal represents biomass-based reductant. The experiment was conducted

at a temperature ranging from 800oC and 1000oC. XRD analysis was applied to

observe phase transformation. For the kinetic study, two models, namely (1)

Jander and (2) Ginstling-Brounhstein diffusion model, were applied. The mineral

phase results indicated that both reductants yield Magnetite from Goethite in

the laterite. The best fit model is obtained by the Jander model with the

energy activation of 33.68 kJ/mol for anthracite reductant and

10.99 – 18.19 kJ/mol for palm kernel shell reductant, indicating that reduction

is easier to occur using palm kernel shell.

Kinetics; Phase transformation; Reduction; Roasting; Saprolite

Nickel could be a transition component

with properties of ferrous and nonferrous metals (Kim

et al., 2010). Nickel ore is affiliated with oxide (nickel laterite) or

sulfur (nickel sulfide). Almost 58% of nickel requests are provided by sulfide

metals, even though 78% of nickel is stored in laterite minerals (Dalvi et al., 2004). However, as the continuous

exploitation of sulphidic ores occurred in recent years, the sources became

scarce and underground mining was introduced. Consequently, the exploitation

cost was rising, especially the labour cost. On the contrary, the mining activity

of laterite deposits is considerably shallow (usually less than 50 meters) (Elias, 2002). So, much concern has been

concentrated on using low-grade nickel ore (especially those containing <2.0

wt.% nickel) (Lee et al., 2005), such as

laterites.

In terms of nickel laterite, Indonesia has an abundant deposit of

it. About 12% of nickel

There are two kinds of laterite, namely limonite and saprolite. Limonite is

low-nickel content laterite (around 0.8-1.5% Ni-mass), and saprolite is a rich-nickel content

(more than 1.5-3%

Ni-mass) (Whittington

& Muir, 2000). Both

hydrometallurgical and pyrometallurgical processes can be used to extract

nickel from the laterites. However, due to its high nickel content, saprolite

ore is better

processed by pyrometallurgy

(Li et al., 2011; Minister of Energy and Mineral Resources Republic

of Indonesia, 2013). There are usually

three unit operations in the pyrometallurgical process: roasting, smelting, and

converting. The reduction process consumes carbon-based reductant, usually coke,

and produces a tremendous amount of carbon dioxide. This process is highly

energy-consuming (Guo et al.,

2009) and not

environmentally friendly.

Replacing the coke with

bio-reductant has been an interesting issue concerning carbon dioxide emission

to be studied.

Palm kernel shell charcoal is the

potential to be utilized as a reductant in the saprolite roasting process. The

saprolite sample mixed with palm kernel shell charcoal can yield the identical

mineral phase to the sample that used anthracite coal after the roasting

process, namely Magnetite, Olivine, and Hematite. The product minerals are

transformed from Goethite, confirming the reduction in all samples. In

addition, higher temperature and prolonged reduction process increase the

conversion of Goethite into magnetite. In terms of kinetics results, the Jander

model fits better for both reductants than the Ginstling-Brounshtein model,

with lower energy activation for the biomass-based reductant of 10.99 – 18.19

kJ/mol compared to that of anthracite reductant of about 33.68 kJ/mol. The

positive results of biomass-based charcoal utilization hopefully encourage the

development of a sustainable pyro-based nickel laterite processing process.

We highly appreciate the Ministry of

Research, Technology and Higher Education of Indonesia for the financial

support in the scheme of PUPT (Penelitian Unggulan Perguruan Tinggi) 2364/UN1.P.III/DIT-LIT/LT/2017

and BPDP Kelapa Sawit Research Grant for Students. On behalf of all authors,

the corresponding author states that there is no conflict of interest.

Chen, G..,

Hwang, W., Liu, S., Shiau, J.,

2015. The Effect oF Bio-Coal on the on the Carbothermic Reduction of Laterite

'Ores', Materials Transactions, Volume 56(4), pp. 550–555

Citrawati, F., Dwiwandono, R., Firmansyah, L. 2020. The Effect

of Ni on the Formation of Bainite in Fe-Ni Lateritic Steels Through Semi-Continuous

Cooling Method. International Journal of Technology, Volume 11(1), pp.

60–70

Dalvi, A.D., Bacon, W.G., Osborne, R.C., 2004. The Past and

the Future of Nickel Laterites World's Land Based Nickel Resources and Primary

Nickel Production Nickel Production. kt / 'yr', PDAC 2004 International

Convention, pp. 1–27

Elias, M., 2002. Nickel Laterite Deposits–Geological

Overview, Resources and Exploitation. Centre

for Ore Deposit Research, University of Tasmania, Special Publication, pp.

205-220

Fu, J.X., Zhang, C.,

Hwang, W., Liu, Y., Lin, Y., 2012. Exploration of Biomass Char for CO2

Reduction in RHF Process For Steel Production. International Journal of

Greenhouse Gas Control, Volume 8, pp. 143–149

Guo, X., Li, D., Park, K., Tian, Q., Wu, Z., 2009. Leaching Behavior

of Metals from a Limonitic Nickel Laterite using a Sulfation-Roasting-Leaching

Process. Hydrometallurgy, Volume 99(3–4), pp. 144–150

Kartohardjono, S., Pamitran, A.S., Putra, N., 2019. Biomass:

from Waste to Valuable Materials. International Journal of Technology,

Volume 10(8), pp. 1465–1468

Khawam, A., Flanagan, D.R., 2006. Solid-State Kinetic Models:

Basics and Mathematical Fundamentals. Journal of Physical Chemistry B, Volume

110(35), pp. 17315–17328

Kim, J., Dodbiba, G., Tanno, H., Okaya, K., Matsuo, S.,

Fujita, T., 2010. Calcination of Low-Grade Laterite for Concentration of Ni by

Magnetic Separation. Minerals Engineering, Volume 23(4), pp. 282–288

Lee, H.Y., Kim, S.G., Oh, J.K., 2005. Electrochemical Leaching

of Nickel from Low-Grade Laterites. Hydrometallurgy, Volume 77(3–4), pp.

263–268

Li, B., Wang, H., Wei, Y., 2011. The Reduction of Nickel from

Low-Grade Nickel Laterite Ore using a Solid-State Deoxidisation Method. Minerals

Engineering, Volume 24(14), pp. 1556–1562

Li, Y.J., Sun, Y., Han,

Y., Gao, Y., 2013. Coal-Based Reduction Mechanism of Low-Grade Laterite Ore. Transactions

of Nonferrous Metals Society of China, Volume 23(11), pp. 3428–3433

Minister of

Energy and Mineral Resources Republic Of Indonesia, 2013. Regulation Of The Minister Of Energy And

Mineral Resources Republic Of Indonesia No 20. Indonesia. Available online

at http://Jdih.Esdm.Go.Id/Peraturan/Permen ESDM 20 2013. pdf.

Mondal, K., Lorethova, H., Hippo, E., Wiltowski, T., Lalvani,

S.B., 2004. Reduction of Iron Oxide in Carbon Monoxide Atmosphere-Reaction Controlled

Kinetics. Fuel Processing Technology, Volume 86(1), pp. 33–47

Oediyani, S., Willyandhika, K., Suharto. 2016. The Effect of

Reduction Time and Size Distribution of Mixed Iron Ore with Coconut Shell

Charcoal on the Percentage Of Metallization by using a Rotary Kiln. International

Journal of Technology, Volume 7(3), pp. 366–373

Petrus, H.T.B.M., Rhamdani,

A.R., Putera, A.D.P., Warmada, I.W., Yuliansyad, A.T., Perdana, I., 2016.

Kinetics Study of Carbon Raiser on the Reduction of Nickel Laterite from Pomalaa,

Southeast Sulawesi. In: IOP Conference Series: Materials Science and

Engineering, Volume 162, Second International Conference on Chemical

Engineering (ICCE) UNPAR 26–27 October 2016, Bandung, Indonesia

Petrus, H.T.B.M., Putera,

A.D.P., Rhamadani, A., Warmada, I.W., Yuliansyad, A.T., Perdana, I., 2017.

Lamtoro Charcoal (L. Leucocephala) as Bioreductor in Nickel Laterite Reduction:

Performance and Kinetics Study. In: 2nd International Symposium on Frontier of

Applied Physics (ISFAP 2016) 3–5 October 2016, Jakarta, Indonesia

Petrus, H.T.B.M., Putera,

A.D.P., Sugiarto, E., Perdana, I., Warmada, I.W., Nurjaman, F., Astuti,

W., Mursito, A.T., 2019. Kinetics on Roasting Reduction oLimonitic Laterite Ore

using Coconut-Charcoal and Anthracite Reductants. Minerals Engineering, Volume

132(2), pp. 126–133

Putera, A.D.P., Sugiarto, E., Sutijan, Warmada, I.W., Petrus,

H.T.B.M., 2017. Coconut Shell Charcoal as a Bioreductor in Roasting Process of

Nickel Laterite from Pomalaa, Southeast Sulawesi: Performance and Kinetics

Study. Materials Science Forum, Volume 901, pp. 182–189

Rasyid, M.H. Al., Rhamdani, A.R., Putera, A.D.P., Putrus,

H.T.B.M., 2016. Study on Biomass Performance in Reduction of Nickel Laterite

from Pomalaa, Sulawesi Tenggara. In: AIP Conference Proceedings 1755, p. 050007

Rhamdhani, M.A., Hayes, P.C., Jak, E., 2009. Nickel Laterite

Part 1-Microstructure and Phase Characterisations During Reduction Roasting and

Leaching. Transactions of the Institutions of Mining and Metallurgy, Section

C: Mineral Processing and Extractive Metallurgy, 118(3), pp. 129–145

Ribeiro, P.P.M.,

Neumann, R., Santos, I.D.D., Rezende, M.C., Radino-Rouse, P., Dutra, A.J.B.,

2019. Nickel Carriers in Laterite Ores and Their Influence on the Mechanism of

Nickel Extraction by Sulfation-Roasting-Leaching Process. Minerals

Engineering, 131, pp. 90–97

U.S. Geological

Survey, 2014. Mineral Commodity Summaries 2014: U.S. Report, Geological Survey,

USA

Whittington, B.I. Muir, D., 2000. Pressure Acid Leaching of

Nickel Laterites: A Review. Mineral Processing and Extractive Metallurgy

Review, Volume 21(6), pp. 527–599

Yunus, N.A., Ani, M.H., Salleh, H.M., Rashid, R.Z.A.,

Akiyama, T., Purwanto, H., Othman, N.E.F.,

2014. Effect of Reduction Roasting by using Biochar Derived from Empty Fruit

Bunch on the Magnetic Properties of Malaysian Iron Ore. International

Journal of Minerals, Metallurgy and Materials, Volume 21(4), pp. 326–330