An Integrated Approach for Supplier Evaluation and Selection using the Delphi Method and Analytic Hierarchy Process (AHP): A New Framework

Corresponding email: muataz.alhazza@aurak.ac.ae

Published at : 20 Jan 2022

Volume : IJtech

Vol 13, No 1 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i1.4700

Al Hazza, M.H., Abdelwahed, A., Ali, M.Y., Sidek, A.B.A., 2022. An Integrated Approach for Supplier Evaluation and Selection using the Delphi Method and Analytic Hierarchy Process (AHP): A New Framework. International Journal of Technology. Volume 13(1), pp. 16-25

| Muataz Hazza Al Hazza | Department of Mechanical and Industrial Engineering, School of Engineering, American University of Ras Al Khaimah, United Arab Emirates |

| Alaa Abdelwahed | Department of Manufacturing and Materials Engineering, Faculty of Engineering, International Islamic University Malaysia, Kuala Lumpur 50728, Malaysia |

| Mohammad Yeakub Ali | Mechanical Engineering Programme Area, Faculty of Engineering, Universiti Teknologi Brunei, Jalan Tungku Link, Gadong, BE1410, Brunei Darussalam |

| Atiah Bt. Abdullah Sidek | Department of Manufacturing and Materials Engineering, Faculty of Engineering, International Islamic University Malaysia, Kuala Lumpur 50728, Malaysia |

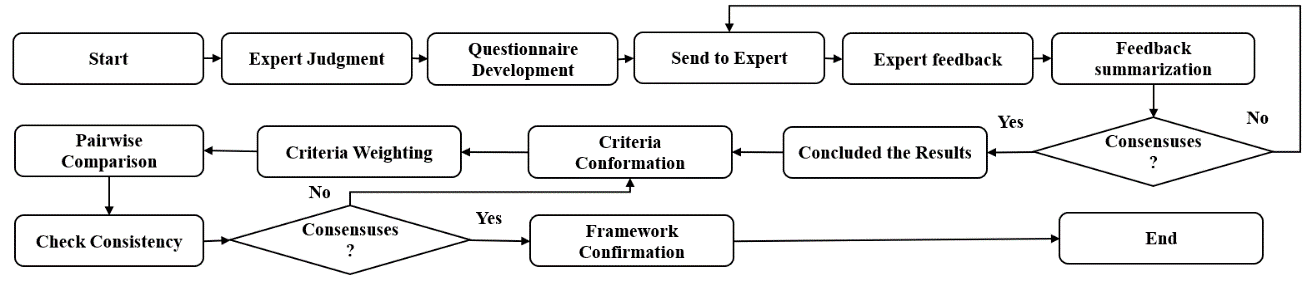

Supplier

selection is one of the most critical processes in supply chain management

(SCM). Most small and medium enterprises (SMEs) face difficulties choosing the

best supplier using conventional methods. A hybrid multi-criteria

decision-making (MCDM) approach is proposed in supplier selection. This

proposed framework integrates the Delphi technique as a data-gathering tool and

Analytic Hierarchy Process (AHP) as the MCDM methodology for data analysis;

both were used to select an effective supplier. This project applies the Delphi

technique, allows experts to select the main criteria, and compares the

trade-offs between the available alternatives depending on the main criteria.

The criteria selected were price, delivery time, online ranking, rejection rate,

and flexibility. Using the AHP approach, the criteria's weights were then

assigned. The highest was for the price (43.84%), followed by the rejection

rate (21.81%), online ranking (19.27%), delivery time (9.44%), and flexibility

(5.64%). Lastly, a new framework was suggested using the weighted criteria

collection for supplier selection.

AHP; Delphi; MCDM; Supplier selection; Supply chain

The multi-criteria decision-making (MCDM) approach is a decision aid framework that can evaluate multiple conflicting criteria (Shukor et al., 2018). It is a method of operational research in which various criteria are included in decision-making conditions to give optimal solutions (Anaokar et al., 2018). MCDM looks at the paradigm in which an individual decision-maker or a group of experts contemplate a choice of action in an uncertain environment. MCDM methods were highly efficient at solving selection problems (Chatterjee et al., 2014). One of the critical selection problems is supplier selection, which involves conflicting criteria such as price, quality, and delivery time. Therefore, the need for an efficient MCDM method is required. Many MCDM approaches have been proposed to deal with such problems. Velasquez and Hester (2013) analyzed the MCDM techniques and their applicability to different areas. They identified 11 MCDM methods that have been widely applied, highlighting the need for an efficient MCDM method. In the literature, many researchers have used MCDM methods in the supplier selection process, such as Multi-Attribute Utility Theory (Shaik and Abdul-Kader, 2011), Analytic Hierarchy Process (AHP) (Yadav and Sharma, 2016), fuzzy set theory (Chen et al., 2006), fuzzy AHP (Chan et al., 2008), case-based reasoning (Zhao and Yu, 2011), data envelopment analysis (DEA) (Garfamy, 2006), Simple Multi-Attribute Rating Technique (Ng, 2008), Goal Programming (Choudhary and Shankar, 2014), ELECTRE method (Fahmi et al., 2016), Simple Additive Weighing (Kaur and Kumar, 2013), and Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) (Zouggari and Benyoucef, 2012). Other researchers prefer to integrate two methods and techniques to yield more robust decisions: fuzzy AHP and TOPSIS (Jain et al., 2018); AHP and Delphi (Su and Zhan, 2020); AHP and Monte Carlo Method Approach (Kristy and Zagloel, 2020); goal programming and AHP (Khorramshahgol, 2012); AHP and VIKOR (Büyüközkan et al., 2019); Analytical Network Process (ANP) and VIKOR (Abdel-Baset et al., 2019); fuzzy TOPSIS and MCGP (Liao and Kao, 2011); ELECTRE and fuzzy clustering (Azadnia et al., 2011); AHP and ELECTRE II (Wan et al., 2017); utility function and ELECTRE (de Almeida, 2007); fuzzy AHP and fuzzy multi-objective linear programming (Shaw et al., 2012); ANP and DPA (Kuo and Lin, 2012); and ANP and linear programming (Ghodsypour and O'Brien, 1998).

One of the most used methods is AHP, which was developed in 1970s

by Thomas Saaty. Various researchers have implemented the AHP method in

supplier selection. For example, Chan and Chan

(2010) used AHP for their supplier selection to evaluate four suppliers

in different countries, considering five levels. Kahraman

et al. (2003) used fuzzy AHP for the supplier selection problem, using

data from one Turkish enterprise, considering the most important criteria

determined by a questionnaire. Ramanathan (2007) used

the hybrid of AHP-DEA-TCO as his methodology in supplier selection, integrating

the total cost of ownership (TCO), AHP, and DEA.

The Delphi method is a “structured group communication” developed by Dalkey and Helmer (1963). This technique was defined as the method used for data gathering from subjects within their domain of expertise. Its goal is to converge their opinions about the specific issue (Hsu and Sandford, 2007). Generally, the Delphi method collects data using a series of questionnaires delivered by the investigator through multiple iterations, looking for a consensus of opinions regarding the topic at hand. An agreement is considered when 80% of the participants vote in favor of the case.

After a comprehensive review of the existing literature in the field, it was identified that different researchers used different sets of criteria. In our research, the traditional criteria (price and delivery time), semi-traditional criteria (flexibility to change and the average number of rejected parts), and nontraditional factors (online ranking) were merged. The modern era and changes in people's attitudes toward to technological developments and globalization have rendered these factors critical in selecting the suppliers. Moreover, the integration between the qualitative approach afforded by the Delphi method and the quantitative approach afforded by the AHP method will corroborate the results and reduce the risk of selecting inappropriate suppliers.

A new framework was developed by integrating the Delphi method and the

AHP method. Five main criteria were identified: price, delivery time, rejection

number, flexibility, and online ranking. The questionnaire given to the experts

was designed in a specific way to develop the pairwise matrix. Saaty's Scale of

Relative Importance was used to prioritize the factors. Two runs were conducted

using the Delphi method for the experts to reach a consensus. The results show

the effectiveness of the integrated framework, and the factors were ranked by

percentage as follows: price

(43.84%), rejection rate (21.81%), online ranking (19.27%), delivery time

(9.44%), and flexibility (5.64%).

Abdel-Baset, M., Chang,

V., Gamal, A., Smarandache, F., 2019. An Integrated Neutrosophic ANP and VIKOR Method

for Achieving Sustainable Supplier Selection: A Case Study in Importing Field. Computers

in Industry, Volume 106, pp. 94–110

Anaokar, G.S., Khambete,

A.K., Christian, R.A., 2018. Evaluation of a Performance Index for Municipal

Wastewater Treatment Plants using MCDM – TOPSIS. International Journal of

Technology, Volume 9(4), pp. 715–726

Azadnia, A.H., Ghadimi,

P., Saman, M.Z.M., Wong, K.Y., Sharif, S., 2011. Supplier Selection: A Hybrid

Approach Using ELECTRE and Fuzzy Clustering.

In: International Conference on Informatics Engineering and Information

Science, Volume 252, Springer, Berlin, Heidelberg, pp. 663–676

Büyüközkan, G., Göçer, F.,

Karabulut, Y., 2019. A New Group Decision Making Approach with IF AHP and IF

VIKOR for Selecting Hazardous Waste Carriers. Measurement, Volume 134,

pp. 66–82

Chan, F.T., Chan, H.K.,

2010. An AHP Model for Selection of Suppliers in the Fast-Changing Fashion

Market. The International Journal of Advanced Manufacturing Technology,

Volume 51(9-12), pp. 1195–1207

Chan, F.T., Kumar, N.,

Tiwari, M.K., Lau, H.C., Choy, K., 2008. Global Supplier Selection: A Fuzzy-AHP

Approach. International Journal of Production Research, Volume 46(14),

pp. 3825–3857

Chatterjee, P., Mondal,

S., Chakraborty, S., 2014. A Comprehensive Solution to Automated Inspection

Device Selection Problems using ELECTRE Methods. International Journal of

Technology, Volume 5(2), pp. 193–208

Chen, C.T., Lin, C.T., Huang,

S.F., 2006. A Fuzzy Approach for Supplier Evaluation and Selection in Supply

Chain Management. International Journal of Production Economics, Volume

102(2), pp. 289–301

Choudhary, D., Shankar, R.,

2014. A Goal Programming Model for Joint Decision Making of Inventory Lot-Size,

Supplier Selection and Carrier Selection. Computers & Industrial

Engineering, Volume 71, pp. 1–9

Dalkey, N., Helmer, O.,

1963. An Experimental Application of the Delphi Method to the Use of Experts. Management

Science, Volume 9(3), pp. 458–467

De Almeida, A.T., 2007.

Multicriteria Decision Model for Outsourcing Contracts Selection based on

Utility Function and ELECTRE Method. Computers & Operations Research,

Volume 34(12), pp. 3569–3574

Fahmi, A., Kahraman, C.,

Bilen, Ü., 2016. ELECTRE I Method using Hesitant Linguistic Term Sets: An Application

to Supplier Selection. International Journal of Computational Intelligence

Systems, Volume 9(1), pp. 153–167

Ghodsypour, S.H., O'Brien,

C., 1998. A Decision Support System for Supplier Selection using an Integrated

Analytic Hierarchy Process and Linear Programming. International Journal of

Production Economics, Volume 56, pp. 199–212

Garfamy, R.M., 2006. A

Data Envelopment Analysis Approach based on Total Cost of Ownership for

Supplier Selection. Journal of Enterprise Information Management, Volume

19(6), pp. 662–678

Hsu, C.C., Sandford, B.A.,

2007. The Delphi Technique: Making Sense of Consensus. Practical Assessment,

Research & Evaluation, Volume 12(10), pp. 1–8

Jain, V., Sangaiah, A.K.,

Sakhuja, S., Thoduka, N., Aggarwal, R., 2018. Supplier Selection using Fuzzy AHP

and TOPSIS: A Case Study in the Indian Automotive Industry. Neural Computing

and Applications, Volume 29(7), pp. 555–564

Kahraman, C., Cebeci, U.,

Ulukan, Z., 2003. Multi-Criteria Supplier Selection using Fuzzy AHP. Logistics

Information Management, Volume 16(6), pp. 382–394

Kaur, P., Kumar, S., 2013.

An Intuitionistic Fuzzy Simple Additive Weighting (IFSAW) Method for Selection of

Vendor. IOSR Journal of Business and Management, Volume 15(2), pp. 78–81

Khorramshahgol, R., 2012.

An Integrated Strategic Approach to Supplier Evaluation and Selection. International

Journal of Information Technology & Decision Making, Volume 11(01), pp.

55–76

Kristy, C.N., Zagloel,

T.Y., 2020. An Integrated Analytical Hierarchy Process and Monte Carlo Method

Approach for Supplier Selection in Construction's Supply Chain. In: 3rd

Asia Pacific Conference on Research in Industrial and Systems Engineering 2020,

pp. 300–304

Kuo, R.J., Lin, Y.J.,

2012. Supplier Selection using Analytic Network Process and Data Envelopment

Analysis. International Journal of Production Research, Volume 50(11),

pp. 2852–2863

Liao, C.N., Kao, H.P.,

2011. An Integrated Fuzzy TOPSIS and MCGP Approach to Supplier Selection in

Supply Chain Management. Expert Systems with Applications, Volume 38(9),

pp. 10803–10811

Ng, W.L., 2008. An Efficient

and Simple Model for Multiple Criteria Supplier Selection Problem. European

Journal of Operational Research, Volume 186(3), pp. 1059–1067

Ramanathan, R., 2007.

Supplier Selection Problem: Integrating DEA with the Approaches of Total Cost of

Ownership and AHP. Supply Chain Management: An International Journal,

Volume 12(4), pp. 258–261

Saaty, T.L., 2016. The

Analytic Hierarchy and Analytic Network Processes for the Measurement of

Intangible Criteria and for Decision-Making. Multiple Criteria Decision

Analysis. International Series in Operations Research & Management

Science, Volume 233, pp. 363–419. Springer, New York, NY

Saaty, T.L., 2008.

Decision Making with the Analytic Hierarchy Process. International

Journal of Services Sciences, Volume 1(1), pp. 83–98

Saaty, T.L., 1980.

Multicriteria Decision Making: The Analytic Hierarchy Process.

McGraw-Hill, New York (2nd impr. 1990, RSW Publishing, Pittsburgh)

Shaik, M., Abdul-Kader, W.,

2011. Green Supplier Selection Generic Framework: A Multi-Attribute Utility

Theory Approach. International Journal of Sustainable Engineering,

Volume 4(1), pp. 37–56

Shaw, K., Shankar, R.,

Yadav, S.S., Thakur, L.S., 2012. Supplier Selection using Fuzzy AHP and Fuzzy

Multi-Objective Linear Programming for Developing Low Carbon Supply Chain. Proceeding,

Volume 39(9), pp. 8182–8192

Shukor, J.A., Omar, M.F.,

Kasim, M.M., Jamaludin, M.H., Naim, M.A., 2018. Assessment of Composting

Technologies for Organic Waste Management. International Journal of

Technology, Volume 9(8), pp. 1579–1587

Su, T., Zhan, F., 2020.

Supplier Selection and Evaluation System of Delphi Method and Analytic Hierarchy

Process. In: IOP Conference Series: Materials Science and Engineering, Volume 768, pp. 1–6

Velasquez, M., Hester, P.T., 2013. An Analysis of

Multi-Criteria Decision-Making Methods. International Journal of

Operations Research, Volume 10(2), pp. 56–66

Wan, S.P., Xu, G.L., Dong,

J.Y., 2017. Supplier Selection using ANP and ELECTRE II in Interval 2-Tuple

Linguistic Environment. Information Sciences, Volume 385, pp. 19–38

Yadav, V., Sharma, M.K.,

2016. Multi-Criteria Supplier Selection Model using the Analytic Hierarchy

Process Approach. Journal of Modelling in Management, Volume 11(1), pp.

326–354

Zhao, K., Yu, X., 2011. A Case-Based

Reasoning Approach on Supplier Selection in Petroleum Enterprises. Expert

Systems with Applications, Volume 38(6), pp. 6839–6847

Zouggari,

A., Benyoucef, L., 2012. Simulation Based Fuzzy TOPSIS Approach for Group

Multi-Criteria Supplier Selection Problem. Engineering Applications of

Artificial Intelligence, Volume 25(3), pp. 507–519