The Formation Process of Hydroxyapatite Nanoparticles by Electrolysis and Their Physical Characteristics

Corresponding email: supriyono16@ub.ac.id

Published at : 04 Apr 2023

Volume : IJtech

Vol 14, No 2 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i2.4452

Supriyono, Kartikowati, C.W., Poerwadi, B., Wulandari, C., Hikma, L.L.F., Azzahra, A., Ghanyysyafira, K., Pinastika, H.L., 2023. The Formation Process of Hydroxyapatite Nanoparticles by Electrolysis and Their Physical Characteristics. International Journal of Technology. Volume 14(2), pp. 330-338

| Supriyono | Chemical Engineering Department, Faculty of Engineering, Universitas Brawijaya, Jl. MT. Haryono No. 167, Malang 65145, Indonesia |

| Christina Wahyu Kartikowati | Chemical Engineering Department, Faculty of Engineering, Universitas Brawijaya, Jl. MT. Haryono No. 167, Malang 65145, Indonesia |

| Bambang Poerwadi | Chemical Engineering Department, Faculty of Engineering, Universitas Brawijaya, Jl. MT. Haryono No. 167, Malang 65145, Indonesia |

| Chindy Wulandari | Chemical Engineering Department, Faculty of Engineering, Universitas Brawijaya, Jl. MT. Haryono No. 167, Malang 65145, Indonesia |

| Lyla Liilia Fitria Hikma | Chemical Engineering Department, Faculty of Engineering, Universitas Brawijaya, Jl. MT. Haryono No. 167, Malang 65145, Indonesia |

| Aulia Azzahra | Chemical Engineering Department, Faculty of Engineering, Universitas Brawijaya, Jl. MT. Haryono No. 167, Malang 65145, Indonesia |

| Kharisma Ghanyysyafira | Chemical Engineering Department, Faculty of Engineering, Universitas Brawijaya, Jl. MT. Haryono No. 167, Malang 65145, Indonesia |

| Hira Listya Pinastika | Chemical Engineering Department, Faculty of Engineering, Universitas Brawijaya, Jl. MT. Haryono No. 167, Malang 65145, Indonesia |

The

electrolysis method for synthesizing hydroxyapatite nanoparticles (NPs) has the

advantage of controlling the particle size by adjusting the potential and

current used. This study aims to study the electrolysis of hydroxyapatite NPs

formation and its characteristics. The solution contained Na2H2EDTA.2H2O,

KH2PO4, and CaCl2, with an EDTA/PO43-/Ca2+

concentration of 0.2/0.2/0.2 M. The electrolytic potential are 4, 5, and 6

volts for 6 hours. The carbon electrode spacing used is 2 cm. The precipitate

formed is filtered with a vacuum jet ejector. Retentate was washed with

demineralized water and dried in an oven at 105oC. The synthesis of pure

hydroxyapatite by electrolysis was successfully carried out at a potential of 5

volts. The OH- ion, which comes from the H2O reduction

process at the cathode, is essential in the formation of brushite, which then

forms hydroxyapatite. The hydroxyapatite, synthesized at a potential of 4

volts, had the smallest particle size (442.4 nm) with the largest particle

surface area (417.22 m2/gram).

Bioceramics; Electrolysis; Hydroxyapatite; Nanoparticles

Hydroxyapatite (HA) particles are a biomaterial having a chemical

formula of Ca10(PO4)6(OH)2. HA has

good biocompatibility and bioactivity properties. The structure of HA

approximates the structure possessed by bones and teeth (Pietrzykowska et al., 2021; Tomozawa and Hiromoto, 2011; Suchanek

and Yoshimura, 1998). HA can bind directly to tissue and stimulate tissue growth. Therefore,

HA has the potential to be applied in the biomedical field, especially for bone

and dental applications (Zhou and Lee, 2011).

HA belongs to the bioceramic

type. In the medical world, ceramic materials are divided into two groups,

namely bioinert ceramics and bioactive ceramics. Bioinert ceramics have no

effect and interact with body tissues (Panda, Biswas, and Paul,

2021). Meanwhile, bioactive ceramics can

bind to living bone tissue, such as HA and calcium phosphate. HA can be used in

a variety of biomedical applications, including matrices for drug release

control (Kamitakahara, Imai, and Ioku, 2013), scaffolds for new bone formation (Rezwan et al., 2006), and

fillers and coatings for repairing osseous damage (Zhou

and Lee, 2011; Banerjee,

Various methods have been

developed to synthesize HA NPs, including precipitation, hydrothermal,

mechano-chemical, flame spray, and electrolysis (Co?rdova-Udaeta

et al., 2021; Lin et al., 2017; Martins et al., 2008; Fathi

and Hanifi, 2007; Chang and Tanaka, 2002). Djosic et al. (2009) have succeeded in synthesizing monetite nanoparticles electrochemically

and transforming them into hydroxyapatite by immersion in NaOH solution.

However, no research has been conducted on the conditions affecting the

electrochemical process to produce hydroxyapatite directly (one step) (Djosic et al., 2009).

Electrolysis is a method that offers an easy and straightforward process (Corona-Gomez, Chen, and Yang, 2016). The particle diameter can be controlled by adjusting

the voltage or current during electrolysis (Djosic

et al., 2009). These results were

obtained from tests with relatively high solution pH and current density.

Theoretically, the higher the pH and current density will accelerate the

particle formation reaction and encourage particle agglomeration (Kim, Kim, and Hirasawa, 2002). If the

pH and current density are relatively high, the pH and current density no

longer affect the particle size but are more influenced by the number of

reactants available and the synthesis time. At relatively low current

densities, these two parameters may have an effect (Montero

et al., 2006). Therefore, this

research focuses on studying the operating conditions, namely the potential for

synthesizing hydroxyapatite NPs.

2.1. Materials and

Instrumentations

The raw materials used in this study

include Na2H2EDTA.2H2O (Merck), KH2PO4

(Merck), CaCl2.7H2O (Merck), and commercial

hydroxyapatite (Merck). While the instrumentation used includes a DC power

supply (GPD X303S, GW Instek), Particle Size Analyzer (Cilas 1190), Surface

Area Analyzer (Quantachrome NOVA 1200), and Powder X-ray Diffraction

(PANalytical X’Pert3 Powder).

2.2. Synthesis

of Hydroxyapatite NPs Powder

3.1. Synthesis

of Hydroxyapatite NPs

Figure 2 shows the synthesized white

powder's X-ray diffraction pattern (XRD). The synthesized white powder shows a

tendency to form hydroxyapatite NPs which is consistent with the peak position

at an angle of 2with JCPDS 03-0747, hexagonal, a = b = 9.4302, c = 6.88911 Å,

space group P63/m. Referring to the reaction, the formation of hydroxyapatite

NPs occurs reversibly; the synthesis of hydroxyapatite NPs requires an optimal

reaction equilibrium (Nur et al., 2014). If

the electrolysis voltage during the hydroxyapatite NPs formation process is set

to the correct value, then the reaction tends to lead to the formation of

hydroxyapatite NPs.

The white powder synthesized from bulk solution at potential 4 Volt has a mixture composition of brushite and hydroxyapatite NPs. The lack of energy used resulted in converting the brushite to hydroxyapatite NPs. The white powder synthesized from bulk solution at a potential of 5 Volts has a pure hydroxyapatite NPs composition. Meanwhile, the white powder which was synthesized from bulk solution at a potential of 6 volts had a dominant composition of hydroxyapatite NPs with a small amount of brushite. This is because the reaction to form hydroxyapatite from brushite is a back-and-forth reaction (Tripathi & Basu, 2012). If the hydroxyapatite NPs still contain brushite, it will reduce their bioactivity when applied medically (Dorozhkin, 2010). The hydroxyapatite formed also has a tendency with the amorphous phase.

Figure 2 The X-ray

diffraction pattern of the synthesized white powder by electrolysis

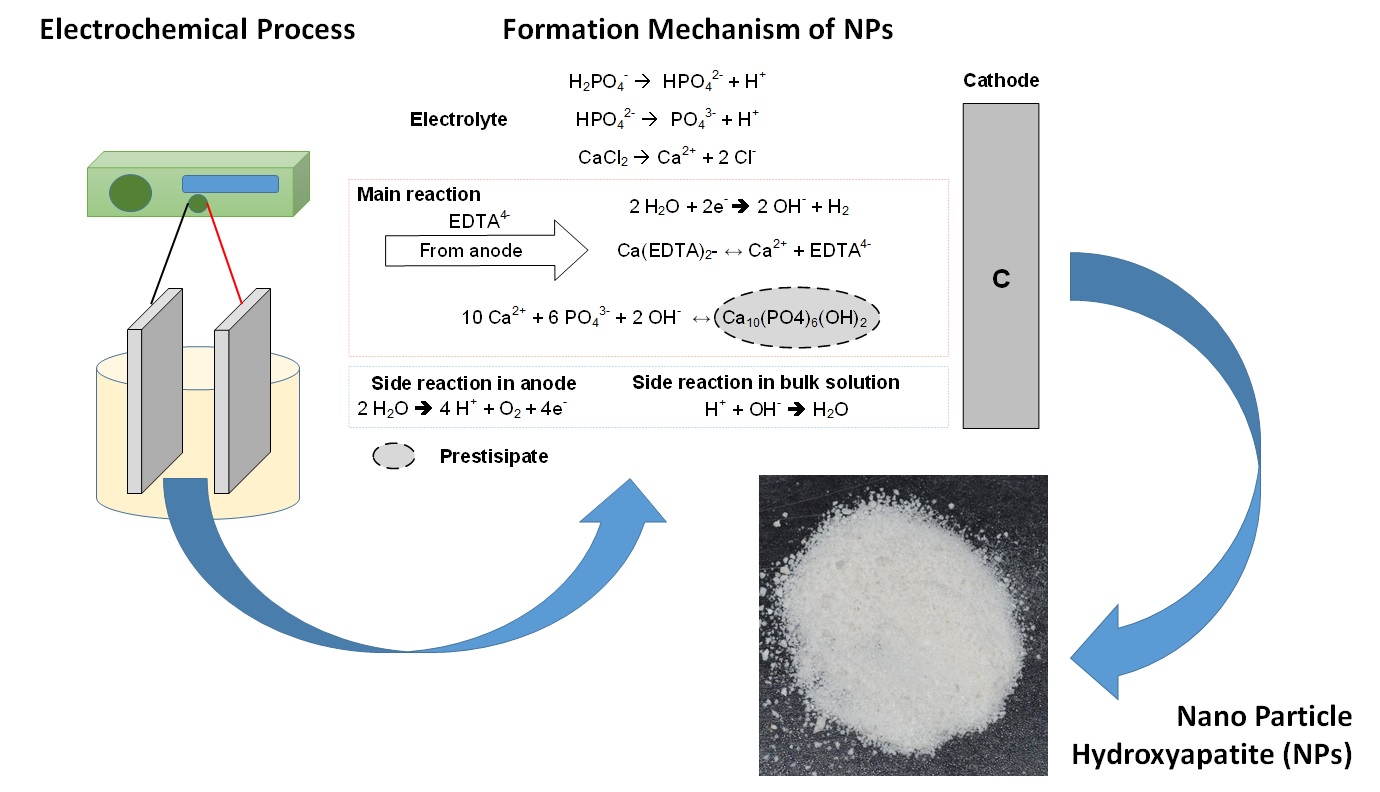

3.2. Reaction

Mechanism for the Formation of Hydroxyapatite NPs

Figure 3

Schematic diagram of the reaction to the electrolytic formation of

hydroxyapatite

Figure 4 Photo of color

change with time of electrolysis of hydroxyapatite NPs by electrolysis

3.3. Distribution

of Hydroxyapatite Nanoparticles Diameter

Figure 5

Size distribution of as-synthesized HA NPs by electrolysis and commercial HA

Figure 6

Schematic diagram of the behavior of hydrogen gas formed on the particle size

of hydroxyapatite

H2 gas in the bulk solution causes an

outward pushing force through the cracks of the hydroxyapatite NPs, causing the

electrolytic synthesized particles to have a smaller size. The white powder

synthesized by electrolysis at a potential of 6 Volt has a more heterogeneous

particle distribution than the particles synthesized at 4 and 5 Volts.

Meanwhile, the distribution of commercial hydroxyapatite particles tends to

have a large distribution range. This is due to particle agglomeration, which

causes a larger range of particle size distribution.

3.4. The Surface Area of the Synthesized Particles

The surface area of the HA NPs showed that the

hydroxyapatite particles synthesized at the 4 Volt potential had a smaller

surface area than those synthesized at the 5 Volt and 6 Volt potentials, which

had almost the same surface area. The particles synthesized with low potential

have better porosity than those synthesized at high potential. This is because

the pores structure of HA NPs

synthesized at the high potential has a tendency to collapse, so that the pore

area tends to be small (Hong et al., 2013). Whereas commercial

hydroxyapatite particles have a smaller surface area than synthetic

hydroxyapatite at a potential of 4 Volts and greater than synthetic

hydroxyapatite at 5 Volts and 6 Volts.

Table 1 The surface area of the

synthesized particles by electrolysis and commercial hydroxyapatite

|

Electrolysis

Potential (Volt) |

Surface

area (m2/gram) |

|

4 |

417.22 |

|

5 |

304.247 |

|

6 |

303.419 |

|

HA

commercial |

355.779 |

Synthesis of pure hydroxyapatite

(100% hydroxyapatite) by electrolysis was successfully carried out at a

potential of 5 volts. The OH- ion, which comes from the H2O

reduction process at the cathode, plays a critical role in the formation of brushite

forming hydroxyapatite. The hydroxyapatite, synthesized at a potential of 4

volts, had the smallest particle size (442.4 nm) with the largest particle

surface area (417.22 m2/gram). Further research needs to examine the

effect of the synthesis time of HA NPs, which is longer than 6 hours with a

voltage of 4 Volts to determine the most effective time variable in the

synthesis of hydroxyapatite.

This work was supported by HPP (HIBAH PENELITI

PEMULA) 2020 through grant Number 436.74/UN10.C10/PN/2020.

Banerjee, A., Bandyopadhyay, A., Bose, S., 2007. Hydroxyapaptite nanopowders: synthesis,

densification and cell materials interaction. Materials Science and

Engineering: C, Volume 27(4), pp. 729–735

Chang, M.C., Tanaka, J., 2002. FT-IR study for

hydroxyapatite/collagen nanocomposite cross-linked by glutaraldehyde. Biomaterials,

Volume 23(24), pp. 4811–4818

Co?rdova-Udaeta, M.,

Kim, Y., Yasukawa, K., Kato, Y., Fujita, T., Dodbiba, G., 2021. Study on the synthesis of hydroxyapatite

under highly alkaline conditions. Industrial & Engineering

Chemistry Research, Volume 60(11), pp. 4385–4396

Corona-Gomez, J., Chen, X., Yang Q., 2016. Effect of

nanoparticle incorporation and surface coating on mechanical properties of bone

scaffold: a brief review. Journal of Functional Biomaterials, Volume

7(3), p. 18

Djosic, M.S.,

Miskovic-Stankovic, V.B., Kacarevic-Popovic, Z.M., Jokic, B.M., Bibic, N.,

Mitric, M., Milonjic, S.K., 2009. Electrochemical

synthesis of nanosized monetite powder and its electrophoretic deposition on

titanium. Colloids and Surfaces A: Physicochemical and Engineering

Aspects, Volume 341(1), pp. 110–117

Dorozhkin, S.V.,

2010. Bioceramics of calcium

orthophosphates. Biomaterials, Volume 31(7), pp. 1465–1485

Fathi, M.H., Hanifi, A., 2007.

Evaluation and chracterization of nanostructure hydroxyapatie powder

prepared by simple sol–gel method. Materials Letters, Volume 61(18), pp. 3978–3983

Hong, X.T., Wu, X.H.,

Mo, M.Y., Luo, Z. P., HUI, K., Chen, H.Y., Zhang, Q.Y., 2013. Synthesis and electrochemical capacitive

performances of novel hierarchically micro-meso-structured porous carbons

fabricated using Microporous rod-like hydroxyapatites as a template. Acta

Physico-Chimica Sinica, Volume 29(2), pp. 298–304

Kamitakahara, M.R., Imai, Ioku, K., 2013. Preparation and evaluation of spherical ca-deficient hydroxyapatite

granules with controlled surface microstructure as drug carriers. Materials

Science and Engineering: C, Volume 33(4), pp. 2446–2450

Kim, W.S., Kim, W.S., Hirasawa, I., 2002. Changes

in crystalline properties of nanosized

hydroxyapatite powders prepared by low-temperature reactive crystallization.

Journal of chemical engineering of Japan, Volume 35(11), pp. 1203–1210

Lin, D.J., Hung F.Y., Lee H.P., Yeh M.L., 2017. Development of a novel degradation-controlled magnesium-based

regeneration membrane for future guided bone regeneration (GBR) therapy.

Metals, Volume 7(11), p. 481

Martins, M., Santos, C.,

Almeida, M., Costa M., 2008. Hydroxyapatite micro and nanoparticles: nucleation

and growth mechanism in the presence of citrate species. Journal of Colloid and Interface

Science, Volume 318(2), pp. 210–216

Montero, M.L., Saenz,

A., Rodriguez, J., Arenas, J., Castano, V.M., 2006. Electro-chemical synthesis of nanoized hydroxyapatite. Journal of materials science, Volume 41(7), pp. 2141–2144

Nasiri-Tabrizi, B.,

Honarmandi, P., Ebrahimi-Kahrizsangi, R., Honarmandi, P., 2009. Synthesis of nanosize single-crystal

hydroxyapatite via mechanochemical method. Materials Letters,

Volume 63(5), pp. 543–546

Nur, A., Setyawan,

H., Widjaja, A., Lenggoro, I. W., 2014. Electrochemical

processes for the formation of hydroxyapatite powders. Bulletin of Chemical

Reaction Engineering & Catalysis, Volume 9(3), pp. 168–175

Panda, S., Biswas, C.K., Paul, S., 2021. A comprehensive review on the preparation and application of calcium

hydroxyapatite: a special focus on atomic doping methods for bone tissue engineering.

Ceramics International, Volume 47(20), pp. 28122–28144

Pietrzykowska, E.,

Romelczyk-Baishya, B., Chodara, A., Koltsov, I., Smogór, H., Mizeracki, J.,

?ojkowski, W., 2021. Microstructure

and mechanical properties of inverse nanocomposite made from polylactide and

hydroxyapatite nanoparticles. Materials, Volume 15(1), p. 184

Rezwan, K., Chen,

Q.Z., Blaker, J.J., Boccacini, A.R., 2006. Biodegradable and bioactive porous polymer/inorganic composite

scaffolds for bone tissue engineering. Bomaterias. Volume 27(18),

pp. 3413–3431

Suchanek, W.,

Yoshimura, M., 1998. Processing and

properties of hydroxyapatite-based biomaterials for use as hard tissue

replacement implants. Journal of Materials Research, Volume

13(1), pp. 94–117

Tomozawa, M., Hiromoto, S., 2011.

Microstructure of hydroxyapatite- and

octacalcium phosphate-coatings formed on magnesium by a hydrothermal treatment

at various pH values. Acta Materialia, Volume 59(1), pp. 355–363

Tripathi, G., Basu, B., 2012. A

porous hydroxyapatite scaffold for bone tissue engineering: Physico-mechanical

and biological evaluations. Ceramics

International, Volume 38(1), pp. 341-349

Xin, R., Ren,

F., Leng, Y., 2010. Synthesis and

characterization of nano-crystalline calcium phosphates with EDTA assisted

hydrothermal method. Materials & Design, Volume 31(4), pp.

1691–1694

Zhou, H., Lee, J., 2011. Nanoscale hydroxyapatite particles for bone

tissue engineering. Acta Biomaterialia, Volume 7(7), pp. 2769–2781