Construction and Characterization of the Diode and Triode Electron Sources for EBM 300 keV/20 mA

Corresponding email: darsono@brin.go.id

Published at : 25 Jan 2024

Volume : IJtech

Vol 15, No 1 (2024)

DOI : https://doi.org/10.14716/ijtech.v15i1.4406

Darsono, Taufik, Suprapto, Saefurrochman, Nuraini, E., Sutadi, 2024. Construction and Characterization of the Diode and Triode Electron Sources for EBM 300 keV/20 mA. International Journal of Technology. Volume 15(1), pp. 154-165

| Darsono | Research Center for Accelerator Technology, Research Organization of Nuclear Technique (ORTN)-National Research and Innovation Agency (BRIN), Puspitek Serpong 15310, Indonesia |

| Taufik | Research Center for Accelerator Technology, Research Organization of Nuclear Technique (ORTN)-National Research and Innovation Agency (BRIN), Puspitek Serpong 15310, Indonesia |

| Suprapto | Research Center for Accelerator Technology, Research Organization of Nuclear Technique (ORTN)-National Research and Innovation Agency (BRIN), Puspitek Serpong 15310, Indonesia |

| Saefurrochman | Research Center for Accelerator Technology, Research Organization of Nuclear Technique (ORTN)-National Research and Innovation Agency (BRIN), Puspitek Serpong 15310, Indonesia |

| Elin Nuraini | Research Center for Accelerator Technology, Research Organization of Nuclear Technique (ORTN)-National Research and Innovation Agency (BRIN), Puspitek Serpong 15310, Indonesia |

| Sutadi | Research Center for Accelerator Technology, Research Organization of Nuclear Technique (ORTN)-National Research and Innovation Agency (BRIN), Puspitek Serpong 15310, Indonesia |

The technical challenge in constructing the

electron source (ES) lies in the joining of metal and ceramic tubes.

Furthermore, there is a lack of available technical comparison data for the

output performance between the diode and triode ES under the same experimental

conditions. The research aim is to describe a simple technique for constructing

the diode and triode ES for an electron beam machine (EBM) of 300 keV/20 mA,

and to investigate their output characteristics. The method used is to make a

flange for mounting the Tungsten filament, Pierce electrodes, and heat shield.

Two or three electrodes of the NEC (National Electric Corporation) accelerator

tube are removed before the flange is united into the NEC tube, becoming the

ES. The ES‘s are investigated in terms of their electron beam profiles and beam

current output for the variation of the extraction electrode voltage as well as

the focusing electrode voltage. The experimental results show that for the

triode ES, the focusing electrode voltage greatly affects the shape of the

electron beam profile up to 3 kV. However, for the diode ES, the shape of the

electron beam profile is slightly affected by the extraction electrode voltage.

The beam current output increases rapidly with the increase of the extraction

electrode voltage up to 2.5 kV. Above this voltage, the beam current slowly increases, and it

tends to reach saturation. The diode ES

provides a higher electron beam current output than the triode ES output, but

the triode ES provides a better shape of the electron beam profile. The

constructed ES can provide the electron beam current of 40 mA at the filament

current of 18 A.

Beam profile; Beam current; Diode and triode; Electron source; Extraction anode; NEC tube

The

Electron Beam Machine (EBM) is a type of electron accelerator technology that

has been widely utilized in industry as a tool for electron beam processing of

an object for various purposes. Prominent applications of EBM are the cross-linking of wire and cables (Seung-Tae et al., 2022), surface curing of

materials

One of the main components of the

EBM is the electron source (ES), which generates the electron beam. The use of

ES is not only for EBM but also for X-ray radiotherapy

Research Centre for Accelerator

Technology has been constructing the EBM for irradiation processing of the

natural rubber latex with the specification of 300 keV/20 mA. It needs the ES,

which can provide the electron beam current output of at least 30 mA with a

better beam diameter profile. Taufik and Darsono have carried out the

simulation of the diode ES by using two

NEC (National Electric Corporation) accelerator tubes for EBM latex using 3D OPERA software

The importance and novelty of

this research lie in the simplicity of the construction technique for the ES,

and notably, there has been no prior investigation comparing the technical data

of the output performance between diode and triode ES under the same

experimental conditions. These data are very important to choose the suitable

ES which will be used in the EBM of 300 keV/20 mA for irradiation processing of

the natural rubber latex. Therefore, the output performance of the diode and

triode ES is crucial to be investigated. This paper describes the construction

and characterization of the locally made ES by taking advantage of a general

accelerator tube of NEC. Two types of ES, namely the diode and the triode ES,

were constructed and investigated in this research. The two ES use the

electrode of Pierce type with the same specification, and they use the tungsten

filament of spiral shape with the same diameter. The purpose of this research

is to get the characteristic data of the ES output consisting of the electron

beam profile, and the beam intensity.

In the construction

of the ES, some important things that should be taken into account are the shape of the

filament, the electrode shape, the distance between electrodes, the hole of the

electrodes, and the materials used. The materials must meet the UHV (ultra-high

vacuum) standard, and mechanical work must use precise machinery. The ES

characterization uses the fluorescent detector to monitor a beam profile shape and uses the

Faraday Cup to measure the electron beam output.

2.1.

Construction of Electron Source

In this

work, the construction of the diode ES is based on the simulation result done by Taufik and Darsono (Taufik and Darsono, 2014). Meanwhile, the construction of the triode ES is based on the simulation

result conducted by Darsono et al.

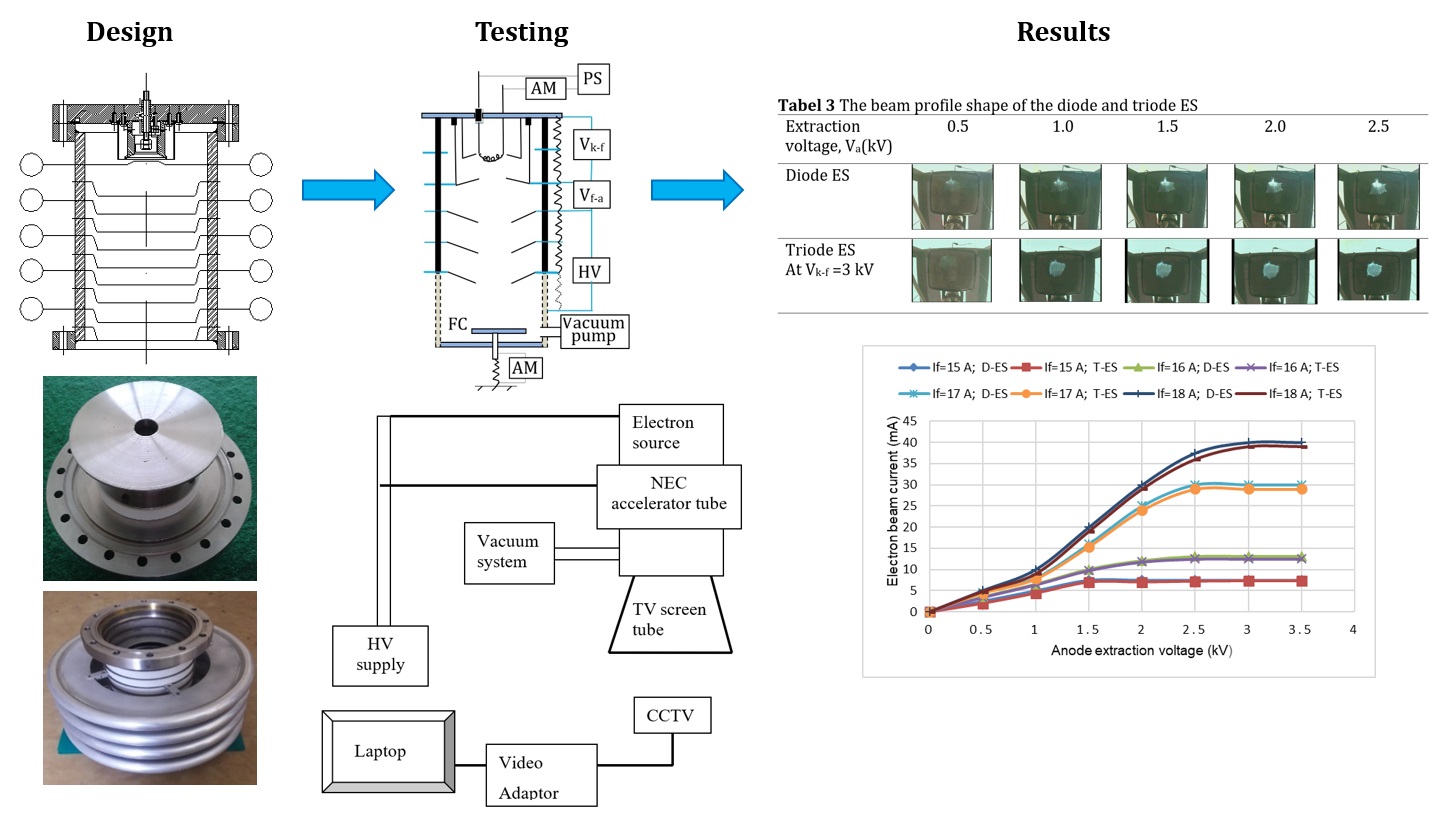

Figure 1 The schematic structure

of the designed ES: (a) Diode ES; (b) Triode ES

Caption Figure 1(a): No. 1 is a flange, No. 2 is a

screw, No. 3 is UHV power feedthrough, No. 4 is a heat shield in the diode ES

and it is the focusing electrode in the triode ES, No. 5 is the cathode

electrode of Pierce type, No. 6 is a feedthrough for filament holder, No. 7 is

a tungsten filament

Figure 1(b):

No. 1 is a flange, No. 2 is a screw, No. 3 is UHV power feedthrough, No. 4 is a

heat shield in the diode ES and it is the focusing electrode in the triode ES,

No. 5 is the cathode electrode of Pierce type, No. 6 is a feedthrough for

filament holder, No. 7 is a tungsten filament, No. 8 is Alumina ring

The construction was started by making a flange of DN-160 CF that matched the NEC tube for mounting the Tungsten filament, the electrodes of Pierce type, and the heat shield. For the filament's power supply input, a UHV (Ultra-High Vacuum) power feedthrough was employed to provide insulation between the anode and cathode of the tungsten filament. For the triode ES, the focusing anode electrode was inserted between the cathode electrode and the extraction anode electrode. The focusing anode should be designed so that it is in contact with the first metal ring of the NEC tube in the incident direction of the electron beam. Moreover, the focusing anode was insulated with the flange of the NEC tube using the Alumina ring. All components of the ES were made in our mechanical workshop. After completing the construction of the ES components, they were assembled into the flange of DN-160 CF. Then, this flange was mounted on the NEC accelerator tube to become an ES.

Table 1 Parameter design of the ES

|

No |

Paramater |

Diode ES |

Triode ES | |

|

|

|

Spesification | ||

|

1 |

Filament |

Tungsten

Materials, wire diameter of 0.5 mm, spiral

shape of 12 mm diameter |

Tungsten

Materials, wire diameter of 0.5 mm spiral

shape of 12 mm diameter | |

|

2 |

Cathode

electrode |

Pierce

type with an opening diameter of 25 mm |

Pierce

type with an opening diameter of 25 mm | |

|

3 |

Focusing

anode |

None |

Modified

heat shield of diode ES. The electrode of

Pierce type with a hole diameter of 20 mm.

Alumina ring between the flange and focusing anode | |

|

4 |

Extraction

anode |

As the

electrode shape of the NEC accelerator tube |

As the

electrode shape of the NEC accelerator tube | |

|

5 |

Distance filament

to focusing anode |

None |

10 mm | |

|

6 |

Distance

filament to extraction anode |

38 mm |

38 mm | |

|

7 |

Distance

between the electrode of the NEC accelerator tube |

19 mm |

19 mm | |

|

8 |

ES Flange |

DN-160 CF |

DN-160 CF | |

|

9 |

Heat

shield |

Cylinder

shape |

Cylinder

shape | |

The construction was started by making a flange of DN-160

CF that matched the NEC tube for mounting the Tungsten filament, the electrodes of Pierce type, and the heat shield. For the

filament's power supply input, a UHV (Ultra-High Vacuum) power feedthrough was

employed to provide insulation between the anode and cathode of the tungsten

filament. For the triode ES, the focusing anode electrode was inserted between

the cathode electrode and the extraction anode

electrode. The focusing anode should be designed so that it is in contact with the first

metal ring of the NEC tube in the incident

direction of the electron beam. Moreover, the focusing anode was insulated with the flange of the

NEC tube using the Alumina ring. All components of the ES were made in our mechanical workshop. After completing the construction of the ES components, they were

assembled into the flange of DN-160 CF. Then, this flange was mounted on the NEC

accelerator tube to become an ES.

2.2. Characterization

The

constructed ES was characterized in terms of the electron beam profiles and beam current

output. The schematic for the measurement of the beam profile is shown in Figure 2. The beam profile

measurements used the method as described by Darsono et al.

Figure 2 A schematic of the beam profile measurement

of the ES

Figure 3

shows the experimental setup to measure the electron beam current output of the

diode and triode ES. The beam current was measured using a water-cooled Faraday Cup. The

power supply (PS) of the filament was locally made with the specification of 20

V-DC/25 A. Two regulated high voltages were used for the focusing anode voltage

of 10 kV-DC and for the extraction anode voltage of 30 kV-DC. In the case of

the diode ES, there are 8 electrodes used in the NEC tube, meanwhile, in the

case of the triode ES, there are 7 electrodes used. Both measurements were

carried out at the same experimental condition.

Figure 3 A schematic of the measurement of the beam current output of the ES: (a)

Diode ES; (b) Triode ES

3.1. Construction

of Electron Sources

Figures 4a and 4b show the construction results of the

flange for the diode ES and the triode ES, where Figure 4c

shows the NEC accelerator tube used. The white color observed

on the top of the flange, as depicted in Figure 4b, represents an Alumina ring.

This ring has been specifically designed to withstand the high voltage of 20

kV. On top of

the Alumina ring is the focusing anode electrode. The cathode electrode of the

triode ES is placed inside the tube of the focusing anode. The cathode

electrode of the Pierce type can be seen in Figure 4a, located on the inner

side of the heat shield.

Figure 4 The model of the diode and triode ES and its

NEC accelerator tube: (a) The flange of diode ES; (b) The flange of triode ES;

(c) The NEC accelerator tube

3.2. Characterisation

of Electron Sources

Table 2 is the measurement result of the electron beam profile using the phosphorescent TV

screen. The photograph image of the shape of the electron beam profile was

taken in the same experimental condition for both the diode and the triode ES. The experimental vacuum condition was 3 × 10-6

Torr, and the filament current was 14 A. At this filament current value and

fixed extraction voltage, the

electron beam current in the phosphorescent TV screen ranged from 28 µA to 50 µA depending on the magnitude value

of the focusing.

From Table 2, it can be said that the shape and the brightness intensity

of the electron beam profile are

influenced by the focusing and extraction anode voltages. At a

constant extraction anode voltage, it is observed that increasing the focusing

anode voltage results in improved beam profiles, indicating a more favorable

shape. This case is due to the potential

difference between the focusing anode and the heated filament,

which forces more electrons to emit from near the filament

surface. While at

fixed focusing anode voltage, the greater the extraction anode voltage is, the brighter the intensity of the electron

beam profile would be.

Tabel 2 The beam profile shape of the triode ES output

The

theoretical explanation of this experimental result is the following. When the filament is heated then the electron cloud

will form in front of the cathode. The applied voltage on the focusing anode will attract the electron

cloud from near the surface of the hot

filament. Moreover, the electron cloud can also change the

configuration of the electric field so that the electron emission from the

filament surface is limited. The magnitude of this electric field depends on

the focusing anode voltage due to the distance of the focusing anode electrode to the cathode electrode is kept constant. In order

for the electron beam to be removed or extracted from the ES chamber, a strong

electric field is required in the direction from the focusing anode to the cathode

(filament). In the

triode ES, the

configuration of three electrodes

functions as the Einzel lens. For a constant extraction anode voltage, therefore, the shape of the electron beam

profile is determined by the focusing anode voltage.

Furthermore, from Table 2, it can be seen that for extraction anode voltage higher than 0.5

keV, increasing the

focusing anode voltage higher than 3 kV it is no longer affects the

shape of the electron

beam profile. However, it affects the brightness intensity of the electron beam

shape. It is presumed that when the focusing anode voltage exceeds 3 kV,

the electron cloud is unable to alter the configuration of the electric field,

resulting in a consistent beam shape. In this condition, all electron clouds in the ES chamber are directed

to the acceleration tube by focusing anode voltage; therefore, the brightness

intensity increases. It can be summed that the focusing anode

voltage functions to control the beam profile. This experimental result is in

accordance with the experimental results which are reported by Deore et al.

The comparison of the shape of the beam profiles between the

triode and diode ES as function of the extraction anode voltage is shown in Table 3. In this comparison,

the triode ES is operated on the focusing anode voltage of 3 kV. It can be

seen that the shape of the beam profile of the triode ES is better than that of

the diode ES. From Table 3 also indicates that with an increase in extraction anode

voltage, there is a corresponding enhancement in the brightness intensity of

the electron beam profile. In simpler terms, higher extraction anode voltages

result in a greater extraction of electron beam charges.

The investigation results of the electron beam current output for both diode and triode ES as a function of the

extraction electrode voltages for various filament currents (If) are

shown in Figure 5. As a note in Figure 5 D-ES represents the diode ES, and T-ES

represents the triode ES. In these experiments, the data of the electron beam

current output were taken in the same values of the filament current ranging from 15 A up to 18 A and also in the same vacuum

condition. The magnitude

value of the initial vacuum condition at off filament current was 3 × 10-6

Torr, then this vacuum decreased with increasing the magnitude value of

the filament

current.

Tabel 3 The beam profile shape of the

diode and triode ES

The

investigation results of the electron beam current output for both diode and triode ES as a function of the

extraction electrode voltages for various filament currents (If) are

shown in Figure 5. As a note in Figure 5 D-ES represents the diode ES, and T-ES

represents the triode ES. In these experiments, the data of the electron beam

current output were taken in the same values of the filament current ranging from 15 A up to 18 A and also in the same vacuum

condition. The magnitude

value of the initial vacuum condition at off filament current was 3 × 10-6

Torr, then this vacuum decreased with increasing the magnitude value of

the filament

current.

From Figure 5, when the extraction anode voltages are increased,

then the electron beam current outputs of both ES’s also increase to a certain extent, and after

that, it tends to be saturated

at the extraction

anode voltage higher than 2.5 kV.

These experimental results are in agreement with similar previous studies, which show the same curve pattern of the

beam current output of the ES as a function of the extraction anode

voltage

El-Saftawy et al. have investigated the extraction beam characteristics and beam diagnosis for a

Pierce-type of diode electron gun with a spherical anode to acquire an electron beam

suitable for different applications

Figure 5 The effect of the anode

extraction voltage on the output of the

ES

Moreover, from Figure 5, it can

be seen that at a fixed extraction anode voltage, the variation of the filament

currents changes the magnitude value of the saturation electron beam current.

In other word, at constant electrode anode voltage, the saturation electron

beam current increases when the filament current increases. As

predicted, in this case, the current density of the saturated electron

emission, derived from the energized filament within the ES chamber, aligns

with the Richardson-Dushman equation. His equation states that the magnitude of the electron

cloud emitted from the filament is proportional to the square of the filament

temperature, whereas the filament temperature is proportional to the increasing

filament current. Our experimental results are also in agreement with

similar previous investigations carried out by Deore et al.

A more detailed examination of

Figure 5 reveals that the saturation electron beam current of the triode ES is

approximately 10% lower than that of the diode ES. These differences might be

due to the hole diameter of the

focusing anode electrode of the triode ES being smaller than that of the diode

ES, as depicted in Table 1. The highest electron beam current output, which can be achieved in

our experiment, is 40 mA. The magnitude of the resulting electron beam current

meets the specification of the ES of the EBM for irradiation processing of natural rubber latex.

Mostly, the focusing and

extraction anodes are one part of the ES and are separated from the accelerator

tube. However, manufacturing the ES, including the focusing and extraction

anodes inside, requires an advanced technology called the vacuum brazing

technique for joining the metal anode and a ceramic as an insulation material

that can hold several kV anode voltage differences. The metal and ceramic

joints also have to be able to withstand high vacuum. Therefore, the cost of

manufacturing that kind of ES becomes expensive. Meanwhile, in our design, one

or two acceleration electrodes of the electrostatic accelerator tube that have

been separated by ceramic insulation are modified to focusing and extraction

anodes. Therefore, no vacuum brazing process is required, and the cost of

manufacturing ES becomes much cheaper. Nevertheless, our ES can be used to

reduce the cost of the EBM for the electrostatic acceleration type only, which

is widely used in industrial applications and in

life and materials sciences

Moreover, the electron source

that has been successfully constructed uses a new and simple production

technique of the ES, namely by making a special flange as a main mechanical

component of ES shown in Figure 1. For the diode ES, this flange is loaded with

a power feedthrough that functions as a tungsten filament holder, a pierce

cathode electrode and a heat shield. For the triode ES, the flange is loaded

with a power feedthrough that functions as a tungsten filament holder, the

pierce cathode electrode and the modified heat shield function as focusing

controlled electrodes, plus an alumina ring to insulate the voltage on the

pierce cathode electrode and the focusing controlled electrode. Meanwhile, the

extractor electrode voltage utilizes an electrode on the accelerator tube.

The advantage of this ES’s

production technique is that the dimensions of the special flange of the ES can

be adjusted accordingly to that of the accelerator tube to be used in the

electron beam machine. The ES’s production can be done anywhere with a cheap

production cost as long as there is a machinery workshop. The market price of

the electron source is around 26,300 USD

Two types of ES have been

successfully constructed and characterized. The diode ES provides a slightly

higher output of the electron beam current compared with the triode ES output,

but the triode ES provides a better shape of the electron beam profile. The shape of the electron beam profile is predominantly determined by the focusing

anode voltage. The focusing electrode voltage from 0

kV up to 3 kV affects the shape of the electron beam profile. The greater the filament current is, the greater the electron

beam current output of the two ES would be. The magnitude of the electron beam current

output is greatly determined by the extraction electrode voltage and the

filament current, where the largest yield is 40 mA. For the two types of ES investigated, the experimental

results show that the beam current output increases rapidly with the increase of the extraction electrode voltage up to 2.5 kV,

but above this voltage, it tends to be saturated. The constructed ES meets the specifications required for EBM

latex. The production technique of the ES is very simple with low-cost

production, and the ES is easy to maintain.

The authors extend their

gratitude to the Head of the Research Center for Accelerator Technology for

providing IDR 200M of the 2020-2021 R&D budget essential for

conducting this research. Special thanks also go to our technicians, Mr.

Suhartono, Mr. Sukidi, and Mr. Sumaryadi, for their invaluable assistance in

completing this study.

| Filename | Description |

|---|---|

| R1-EECE-4406-20230727095116.jpg | Revision Figure 3.a |

| R1-EECE-4406-20230727095145.jpg | Revision Figure 3.b |

Abuzairi,

T., Sumantri, N.I., Putri, N.A., Andarini, M.V., Lampung, E.J., Sitinjak, D., 2022. Development of the Sterilization

Box for Medical Equipment with an Ozone Gas Leak Sensor Feature. International

Journal of Technology, Volume 13(8), pp. 1672–1680

Alabdullah,

A.I.M., 2022. Simulation Study for the Characterization of Anode Shape Effect on the Electron Beam Emittance of Thermionic

Electron Gun. Optik, Volume 268, p. 169761

Andreev,

M., Kovalsky, S., Kornilov, S., Motorin, M., Rempe, N., 2017. A Device for

Measuring Electron Beam Characteristics . AIP Advances, Volume 7(1), p. 015033

Darsono,

D., Suhartono, S., Suprapto, S., Nuraini, E., 2015. Pengukuran Bentuk Profil Berkas Elektron Dari Sumber

Elektron Tipe Pierce Menggunakan Sensor Tabung TV Bekas (Measurement of Electron

Beams Profile of Pierce Type Electron Source Using Sensor of Used TV Tube). In: Prosiding Pertemuan Dan

Presentasi Ilmiah Teknologi Akselerator Dan Aplikasinya Volume 17, pp. 85–91

Darsono,

D., Suprapto, S., Taufik, T., 2017. Sumber Elektron Tiga Elektroda Menggunakan Tabung Pemercepat

NEC untuk MBE-Lateks 300kV/20 mA (The Electron Source with Three Electrodes Using Nec Accelerator Tube for Ebm -Latex Of 300

Kv/20 Ma). Jurnal Iptek Nuklir Ganendra, Volume 20(2), pp. 91–102

Deore,

A.V., Patil, B.J., Bhoraskar, V., Dhole, S.D., 2012. Design, Development and Characterization of Tetrode Type Electron Gun System for Generation of Low Energy Electrons. Indian

Journal of Pure and Applied Physics, Volume

50(7), pp. 482–485

Eckert,

P., Achenbach, P., Drexler, P., Herrmann, P., Klag, P., Lauth, W., Pochodzalla,

J., 2022. Octagonal-Shaped

Scintillation Counter as Position Detector for Low-Intensity Electron Beams. Nuclear Instruments and

Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors

and Associated Equipment, Volume 1041, p. 167357

El-Saftawy,

A.A., Elfalaky, A., Ragheb, M.S., Zakhary, S.G.H., 2012. Investigation Of Beam Performance Parameters in A Pierce-Type

Electron Gun. Science and Technology, Volume

2(6), pp. 191–197

Febriasari,

A., Suhartini, M., Yunus, A.L., Rahmawati, R., Sudirman, S., Hotimah, B.,

Hermana, R.F., Kartohadjono, S., Fahira, A., Permatasari, I.P., 2021. Gamma Irradiation

of Cellulose Acetate-Polyethylene Glycol 400 Composite Membrane and Its Performance Test for

Gas Separation. International Journal of Technology, Volume 12(6), pp. 1198–1206

Fichtner,

J., Kowalik, Y., Kowalik, T., Fahlteich, J., Mayer, B., 2021. Electron Beam Cured

Acrylates as Potential Planarization Layers. Materials Chemistry and Physics,

Volume 274,

p. 125161

Gotzmann,

G., Portillo, J., Wronski, S., Kohl, Y., Gorjup, E., Herbert Schuck, Rögner,

F.H., Müller, M., Chaberny, I.F., Schönfelder, J., Wetzel, C., 2018. Low Energy Electron

Beam Treatment as Alternative for on-Site Sterilization of Highly

Functionalized Medical Products – A Feasibility Study. Radiation Physics and

Chemistry, Volume 150, pp. 9–19

Islam,

G.ul, Rehman, A., Iqbal, M., Zhou, Z., 2016. Simulation And Test of a Thermioic Hairpin Source DC Electron Beam Gun. Optik, Volume 127(4), pp. 1905–1908

JongChul,

L., HuiSu, K., Ghergherehchi, M., SeungWook, S., YongSeok, L., YeongHeum, Y.,

ByeongNo, L., JongSeo, C., 2014. Design and Analysis of an Electron Beam in an Electron Gun

for X-Ray Radiotherapy. In: Proceedings of the 5th International Particle

Accelerator Conference, pp. 688–691

Kimball

Physics, 2023. Model#:EGA-1012/ EGPS-1012. Https://Www.Kimballphysics.Com/Product/Ega-1012-Egps-1012-2/

Lu,

J., Wei, D., Wang, R., Sui, X., Yin, J., 2017. Surface Polishing and

Modification of 3Cr2Mo Mold Steel by Electron Beam Irradiation. Vacuum, Volume 143, pp. 283–287

Lee, S.B., Kang, S.G., Jung, J., Sung, S., Yo, S.J., Han, H.M., 2022. Lattice Shear and Non-Random

Rotation of Au Nanoparticles Under Electron Beam Irradiation. Acta

Materialia, Volume 241, p. 118387

Matejcek,

C., Winter, J., Aulenbacher, K., Dimroth, A., Natour, G., Bartzsch, S., 2023. A Novel Electron

Source for a Compact X-Ray Tube for Microbeam Radiotherapy with Very High Dose Rates. Physica Medica, Volume 106, p. 102532

Matsievskiy,

S.V.,Savin, E.A., 2014. Three Electrode Electron Gun with the Decreased Anode Voltage

Geometry Optimization. In: Proceedings of RuPAC2014 of Modern Trends in Accelerators, pp. 45–47

Nuraini,

E., Darsono, D., Andriyanti, W., Saefurrochman, S., Sutadi, S., Adabiah, S.R., 2021. The Effect of

Stirring Speed Variations on the Mechanical Properties of Latex

Post-Irradiation Using the Arjuna 1.0 Electron Beam. AIP Conference

Proceedings, Volume 2381(1), p. 020050

Oks,

E.M., Tyunkov, A.V., Yushkov, Y.G., Zolotukhin, D.B., 2017. Ceramic Coating

Deposition by Electron Beam Evaporation. Surface and Coatings Technology,

Volume 325,

pp. 1–6

Pillai,

S.D., Pillai, E.T., 2021. Agriculture: Electron Beam Irradiation Technology

Applications in the Food Industry. Encyclopedia of Nuclear Energy, pp. 313–329

Reowdecha,

M., Dittanet, P., Sae-oui, P., Loykulnant, S., Prapainainar, P., 2021. Film and Latex Forms

of Silica-Reinforced Natural Rubber Composite Vulcanized Using Electron Beam

Irradiation. Heliyon, Volume 7(6), p. e07176

Saefurrochman,

S., Darsono, D., Adabiah, S.R., Nuraini, E., Sutadi, S.,Ardiyati, T., 2021. A Novel Design of

17.5 kV HV Feedthrough for Arjuna 2.0. Jurnal Iptek Nuklir Ganendra, Volume 24(1), pp. 21–28

Seung-Tae,

J., Seong-Hwan, P., Won-Gu, K., Yu-Ri, K., Jin-Kyu, K., Young-Chang, N.,

Jong-Seok, P., Jae-Hak, C., Chang M., K., 2022. Effect of Backscattering on Irradiation of Electrical Wire and Cables by Electron Beam.

Radiation Physics and Chemistry, Volume

193, p. 109979

Taufik,

T., Darsono, D., 2014. Simulasi Sumber Elektron Jenis Dioda MBE Lateks PSTA Menggunakan

Program Opera-3D (Simulation of Diode

Electron Source of Psta Latex Ebm Using Opera-3d Software). In: Prosiding PPI Penelitian Dasar Ilmu Pengetahuan Dan Teknologi

Nuklir, Batan, Yogyakarta

Toonen,

W.F., Rajabi, A., van den Berg, R.G.W., Stragier, X.F.D., Mutsaers, P.HA.,

Smorenburg, P. W., Luiten, O.J., 2021. Development of a Low-Emittance High-Current Continuous

Electron Source. Nuclear Instruments and Methods in Physics Research Section

A: Accelerators, Spectrometers, Detectors and Associated Equipment, Volume 1013, p. 165678

Widiyati,

C., Poernomo, H., 2018. Design of a Prototype Photoreactor UV-Leds for Radiation

Vulcanization of Natural Rubber Latex. International Journal of Technology,

Volume 9(1), pp. 130–141

Xiaomeng,

L., Quanlin, D., Pengfei, W. He, C., 2021. Review of Electron Beam Welding Technology in Space Environment.

Optik, Volume 225, p. 165720