Dry Milling Machining: Optimization of Cutting Parameters Affecting Surface Roughness of Aluminum 6061 using the Taguchi Method

Corresponding email: sayuti_m@unimal.ac.id

Published at : 20 Jan 2022

Volume : IJtech

Vol 13, No 1 (2022)

DOI : https://doi.org/10.14716/ijtech.v13i1.4208

Sulaiman, S., Alajmi, .M.S., Wan Isahak, W.N., Yusuf, M., Sayuti, M., 2022. Dry Milling Machining: Optimization of Cutting Parameters Affecting Surface Roughness of Aluminum 6061 using the Taguchi Method. International Journal of Technology. Volume 13(1), pp. 58-68

| Shamsuddin Sulaiman | Faculty of Engineering, Department of Mechanical and Manufacturing Engineering, Universiti Putra Malaysia, 43400 Serdang, Selangor, Malaysia |

| Mohammad Sh Alajmi | Faculty of Engineering, Department of Mechanical and Manufacturing Engineering, Universiti Putra Malaysia, 43400 Serdang, Selangor, Malaysia |

| Wan Norizawati Wan Isahak | Faculty of Engineering, Department of Mechanical and Manufacturing Engineering, Universiti Putra Malaysia, 43400 Serdang, Selangor, Malaysia |

| Muhammad Yusuf | Department of Mechanical Engineering, Faculty of Engineering, Universitas Malikussaleh, 24351 Aceh Indonesia |

| Muhammad Sayuti | Department of Industrial Engineering, Faculty of Engineering, Universitas Malikussaleh, 24351 Aceh Indonesia |

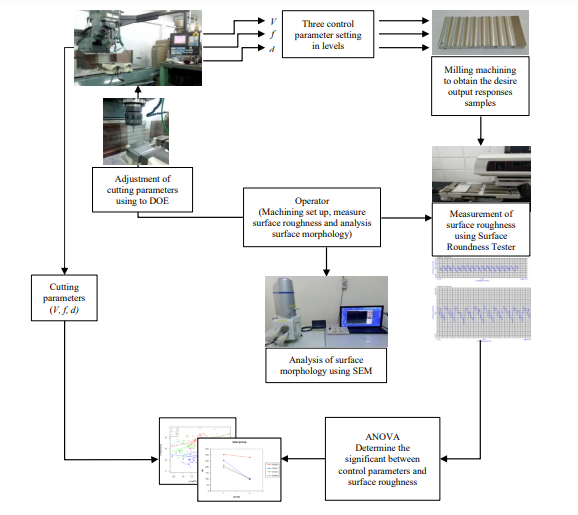

In this paper, the application of dry machining as

part of contributions for development of a sustainable environment in the

machining industry is explained. Achieving a good surface roughness product is

one the most important factors that must be considered in the metal machining

process. Surface quality control is a complicated process, and a reliable

technique is required during machining operation. Currently, an appropriate

cutting conditions in most of machining cases are determined by trial and

error, which leads to time increased, energy consumption, and manufacturing

costs. Most of the previous studies have investigated factors that affect

surface roughness, but different machining conditions require the control of

different factors. In this study, experiments were conducted to optimize

cutting parameters and determine the factors significant for the surface

roughness quality. Machining experiments were conducted on a vertical milling

machine using square non-coated two flutes HSS Co end mill with selected

cutting parameters on aluminum 6061. This

study focused on the surface roughness in one direction and combined with the Taguchi design method. Signal-to-noise (S/N) ratio

and analysis of variance (ANOVA) were employed to examine and reveal the

factors that are significant in affecting surface roughness quality. The

analysis result revealed that cutting speed exerts the highest effect on

surface roughness, followed by feed rate and depth of cut. Finally, the

combination of dry machining performance and an eco-friendly environment would

result in competitive sustainable growth of the machining industry.

ANOVA; Machining process; Signal-to-noise; Surface roughness; Taguchi method

In the

machining industry, a liquid coolant, also called a cutting fluid, is used to

remove the heat produced during machining. However, the use of cutting fluids

incurs considerable economic and ecological burden, which is continuously

increasing (Wickramasinghe et al., 2020).

Therefore, researchers have attempted to utilize machining components without

using cutting fluids, which is referred to dry machining.

In the

last few years, the monitoring of surface roughness has been developed, and a

few different measuring systems are also available to measure surface roughness

(Saif and Tiwari,

2021). To obtain the desired

surface quality of parts by end-milling machining, few cutting parameters

should be selected and controlled appropriately during machining, including

cutting speed, feed rate, and depth of cut. Poor selection of machining

parameters leads to the rapid wear and breakage of cutting tools.

A

few number of processes that can be utilized to produce raw materials of any

desired shape from its initial stage to its final stage are available. Among

various machining processes, end milling is one of the most widely employed

material removal processes in industries (Nisar et

al., 2021). Cutting operations by

end mills can be as simple as face milling on the top of a flat surface using a

rigid cutter or the milling of extremely complex parts (Hoang et

al., 2019). Aluminum is mainly used

in industries to produce various parts, especially for the assembly of machine

parts (Daghfas et

al., 2017).

Typically, surface roughness is utilized as an

extremely good performance predictor of mechanical components of machined

materials as irregular surface properties may lead to cracks or corrosion (Dinesh et

al., 2014). Sometimes,

although surface roughness is undesirable for certain manufacturing products, it

is quite difficult to control and may incur higher machining costs (Singh et

al., 2020).

Elmunafi (2015)

has reported that cutting speed is the most significant cutting parameter, followed

by feed rate and depth of cut (Elmunafi et

al., 2015;

Tapadar et

al., 2017). On the other

hand, Liu (2016) has reported

that feed rate is the most significant factor that affects surface roughness,

followed by depth of cut and cutting velocity, for minimizing energy

consumption (Liu et al.,

2016). Shah and Bhavsar (2020) have

investigated four machining parameters, namely cutting speed, feed rate, depth

of cut, and nose radius, respectively, to examine the maximum tool life and

minimum power consumption (Shah and

Bhavsar, 2020). Their study results revealed that cutting speed

is the most significant parameter to achieve the maximum tool life with minimum

power consumption, followed by depth of cut, feed rate, and nose radius.

In studies on surface roughness, various

methodologies and practices have been employed and applied for the prediction

of quality surface roughness, such as artificial intelligence or soft computing

techniques, the Taguchi method, response surface methodology (RSM), machining

theory, classical experimental design, and artificial neural network (Qehaja et

al., 2015;

Kilickap et

al., 2017). Recently, the

design of experiments (DOE) method has been widely used in various industries

for several years to improve the product and manufacturing process (Razavykia

et al., 2015). Vishnu Vardhan (2017) has applied the Taguchi method to investigate the

effects of feed rate, cutting speed, nose radius, depth of cut, and cutting

environment of AISI P20 tool steel machining on power consumption. The results

revealed that cutting speed is the most significant factor, followed by feed

rate and depth of cut (Vishnu

Vardhan et al., 2017). Meanwhile, Qasim (2015) has employed the

Taguchi design and analysis of variance (ANOVA) to investigate the effect of

cutting parameters on surface finish and power consumption during the

high-speed machining of AISI 1045 steel with a coated carbide tool (Qasim et

al., 2015). The result

revealed that cutting speed is the most significant factor, followed by depth

of cut, to reduce power consumption. Therefore, generally, it is complicated to

determine the relationship between cutting parameter as a machining control

parameter and response characteristics due to various factors that affect

surface finish (Singh et al., 2020).

In conclusion,

dry machining was demonstrated to contribute to an eco-friendly environment in

the machining industry. In this study, an experimental study for the prediction

and optimization of cutting parameter is discussed, where a minimum surface

roughness of aluminum 6061 using an HSS-Co Helical Shank Insert is subjected to

a dry milling cutting condition. The Taguchi method combined with the design of

experiment is applied for the response characteristic optimization. The

relationship between control parameters (e.g., cutting speed, feed rate, and

depth of cut) and surface roughness on the basis of different levels by the DOE

method is determined. Analysis in terms of the significant effect clearly

revealed that the three control parameters exhibit an important correlation

between each other. In terms of the three control parameters, surface roughness

quality mainly depends on cutting speed, followed by feed rate and depth of

cut. A high cutting speed affords high surface roughness quality. However, surface roughness quality decreases

with a low feed rate and depth of cut.

The S/N ratio

analysis revealed that the cutting speed is the most significant factor

affecting surface roughness, followed by feed rate (moderately significant) and

depth of cut (least significant factor), of a machined surface. The optimal

combination of the control parameters in minimizing surface roughness is

A3B1C1, indicating a cutting speed of 300 m/min (level 3), a feed rate of 150

mm/rev (level 1), and a depth of cut of 0.5 mm (level 1). Similarly, ANOVA

results also revealed the same result as that of S/N ratio analysis.

SEM analysis

is employed to observe the morphology of the machined surface on the workpiece

material. SEM images revealed that surface roughness is uneven when machining

is conducted under a lower cutting speed and the surface is covered by a thin

film, and it is less uneven when machining is conducted under a higher cutting

speed, which affords a better surface roughness quality. Besides, a low feed

rate and depth of cut contribute to a better surface finish quality compared

with a higher feed rate and depth of cut, leading to disruption in the metal

removal process.

Finally,

positive outcomes of the dry machining process should be implemented in the

machining industry worldwide, especially in Euro-Mediterranean countries. The

combination of dry machining performance and an eco-friendly environment would

lead to competitive sustainable growth in the machining industry.

The authors would like to thank the staff at the Department of

Mechanical and Manufacturing Engineering, Faculty of Engineering, Universiti

Putra Malaysia UPM Serdang, Selangor Malaysia and Faculty of Engineering

Universitas Malikussaleh for their supports and laboratory facility. This study

was financially supported by the Fundamental Research Grant Scheme (FRGS) with

contract number FRGS/1/2015/TK03/UPM/01/1 from Ministry of Education (MOHE),

Malaysia.

Ahmed, G.M.S., Quadri, S.S.H., Mohiuddin,

M.S., 2015. Optimization of Feed and Radial Force in Turning Process by using

Taguchi Design Approach. Materials Today: Proceedings, Volume 2(4–5), pp. 3277–3285

Daghfas, O., Znaidi, A., Ben Mohamed, A., Nasri, R., 2017.

Experimental Study on Mechanical Properties of Aluminum Alloys under Uniaxial

Tensile Tests. International Journal of Technology, Volume 8(4), pp. 662–672

Dinesh, K., Vishal, P., Singh, J., Gour, M.K., 2014. Taguchi

Method and ANOVA: An Approach for Selection of Process Parameters of EDM of

EN-353 Steel. International Journal of Emerging Technology and Advanced

Engineering, Volume 4(6), pp. 313–321

Elmunafi, M.H.S., Mohd Yusof, N., Kurniawan, D., 2015. Effect of

Cutting Speed and Feed in Turning Hardened Stainless Steel using Coated Carbide

Cutting Tool under Minimum Quantity Lubrication using Castor Oil. Advances

in Mechanical Engineering, Volume 7(8), pp. 1–7

Hoang, D.T., Nguyen, N.-T., Tran, Q.D., Nguyen, T.V., 2019.

Cutting Forces and Surface Roughness in Face-Milling of SKD61 Hard Steel. Strojniški

Vestnik - Journal of Mechanical Engineering, Volume 65(6), pp. 375–385

Khentout, A., Kezzar, M., Khochemane, L., 2019. Taguchi

Optimization and Experimental Investigation of the Penetration Rate of Compact

Polycrystalline Diamond Drilling Bits in Calcareous Rocks. International

Journal of Technology, Volume 10(2), pp. 226–235

Kilickap, E., Yardimeden, A., Çelik, Y.H., 2017. Mathematical

Modelling and Optimization of Cutting Force, Tool Wear and Surface Roughness by

using Artificial Neural Network and Response Surface Methodology in Milling of

Ti-6242S. Applied Sciences, Volume 7(10), pp. 1–12

Liu, N., Wang, S.B., Zhang, Y.F., Lu, W.F., 2016. A Novel Approach

to Predicting Surface Roughness based on Specific Cutting Energy Consumption

When Slot Milling Al-7075. International Journal of Mechanical Sciences,

Volume 118, pp. 13–20

Maiyar, L.M., Ramanujam, R., Venkatesan, K., Jerald, J., 2013.

Optimization of Machining Parameters for end Milling of Inconel 718 Super Alloy

using Taguchi based Grey Relational Analysis. Procedia Engineering,

Volume 64, pp. 1276–1282

Nisar, L., Banday, B., Amatullah, M., Farooq, M., Thoker, A.N.,

Maqbool, A., Wahid, M.A., 2021. An Investigation on Effect of Process

Parameters on Surface Roughness and Dimensional Inaccuracy using Grey-Based

Taguchi Method. Materials Today: Proceedings, Volume 46(Part 15), pp.

6564–6569

Qasim, A., Nisar, S., Shah, A., Khalid, M.S., Sheikh, M.A., 2015.

Optimization of Process Parameters for Machining of AISI-1045 Steel using

Taguchi Design and ANOVA. Simulation Modelling Practice and Theory,

Volume 59, pp. 36–51

Qehaja, N., Jakupi, K., Bunjaku, A., Bruçi, M., Osmani, H., 2015.

Effect of Machining Parameters and Machining Time on Surface Roughness in Dry

Turning Process. Procedia Engineering, Volume 100, pp. 135–140

Rathod, N.J., Chopra, M.K., Vidhate, U.S., Gurule, N.B., Saindane,

U.V., 2021. Investigation on the Turning Process Parameters for Tool Life and

Production Time using Taguchi Analysis. Materials Today: Proceedings,

Volume 47(Part 17), pp. 5830–5835

Razavykia, A., Yusof, N.M., Yavari, M.R., 2015. Determining the

Effects of Machining Parameters and Modifier on Surface Roughness in Dry

Turning of Al-20%Mg2Si-PMMC using Design of Experiments (DOE). Procedia

Manufacturing, Volume 2, pp. 280–285

Saif, M., Tiwari, S., 2021. Investigation Towards Surface

Roughness & Material Removal Rate in Wire-EDM of Aluminum Alloy 6061 and

5083 using Taguchi Method. Materials Today: Proceedings, Volume 47(Part

4), pp. 1040–1047

Shah, D.,

Bhavsar, S., 2020. Effect of Tool Nose Radius and Machining Parameters on

Cutting Force, Cutting Temperature and Surface Roughness – An Experimental

Study of Ti-6Al-4V (ELI). Materials Today: Proceedings, Volume 22(Part

4), pp. 1977–1986

Singh, K.,

Singh, A.K., Chattopadhyay, K.D., 2020. Application of Taguchi Method to

Optimize the Surface Roughness During Face Milling of Rolled Steel (AISI 1040).

In: Proceeding of International Conference in Mechanical and Energy

Technology, pp. 239–249

Tapadar, J.,

Thakur, R., Chetia, P., Tamang, S.K., Samanta, S., 2017. Modeling of WEDM

Parameters while Machining Mg-SiC Metal Matrix Composite. International

Journal of Technology, Volume 8(5), pp. 878–886

Vishnu

Vardhan, M., Sankaraiah, G., Yohan, M., Jeevan Rao, H., 2017. Optimization of

Parameters in CNC Milling of P20 steel using Response Surface Methodology and Taguchi

Method. Materials Today: Proceedings, Volume 4(8), pp. 9163–9169

Wickramasinghe,

K., Sasahara, H., Rahim, E.A., Perera, G.I.P., 2020. Green Metalworking Fluids

for Sustainable Machining Applications: A Review. Journal of Cleaner

Production, Volume 257, https://doi.org/10.1016/j.jclepro.2020.120552