A Technological Capability Assessment of Company in the Crude Palm Oil Industry in Indonesia

Published at : 28 Jul 2023

Volume : IJtech

Vol 14, No 5 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i5.4036

Siallagan, S., Ishak, A., 2023. A Technological Capability Assessment of Company in the Crude Palm Oil Industry in Indonesia. International Journal of Technology. Volume 14(5), pp. 1072-1080

| Sahala Siallagan | Mechanical Engineering Education Department, Faculty of Engineering, Universitas Negeri Medan, Medan 20221, Sumatera Utara, Indonesia |

| Aulia Ishak | Industrial Engineering Department, Faculty of Engineering, Universitas Sumatera Utara, Medan 20155, Sumatera Utara, Indonesia |

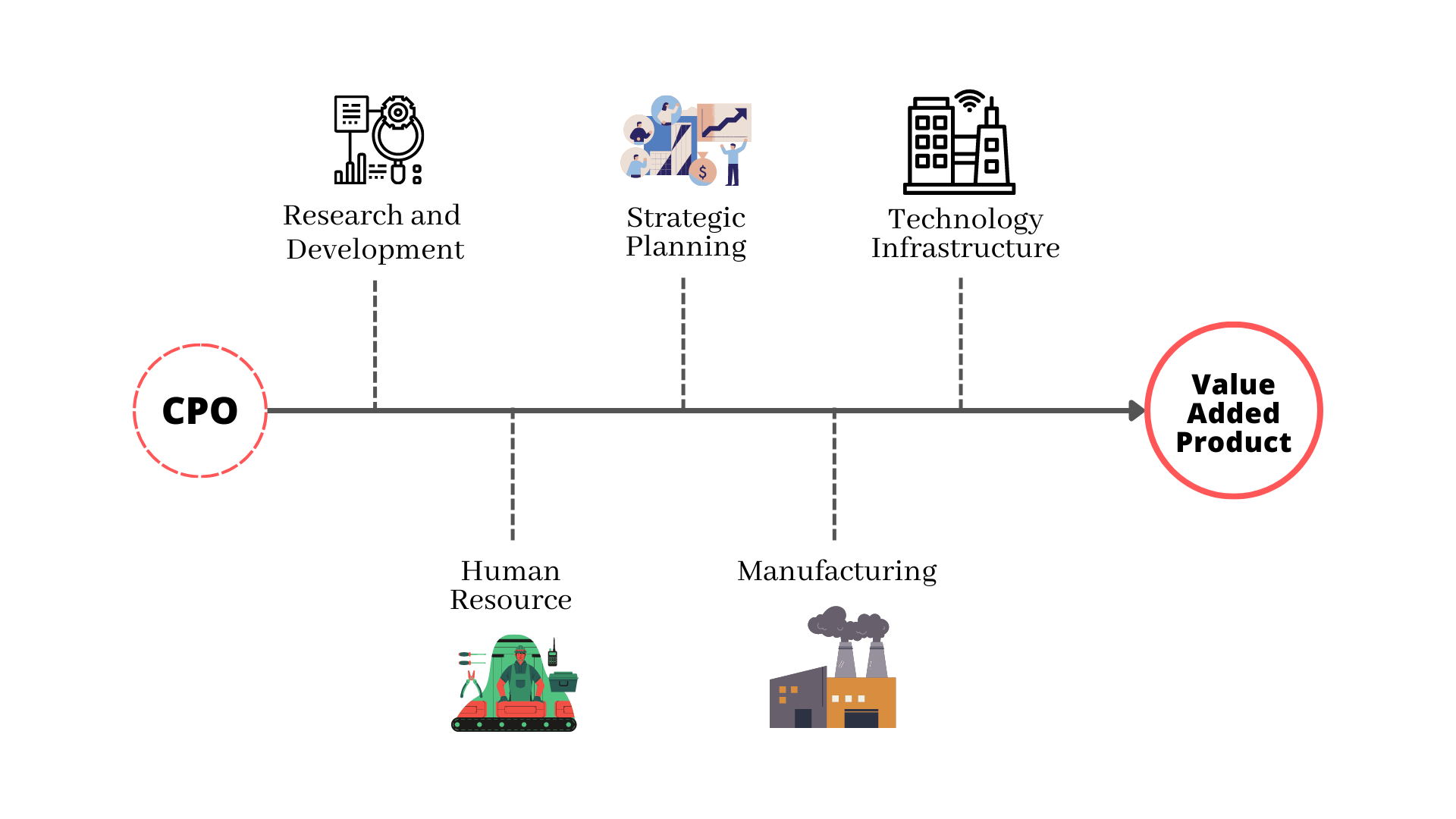

Indonesia is the world’s largest producer of Crude Palm Oil (CPO). Accordingly, it

is vital that Indonesian CPO industries diversify and add value to downstream

products. Technological capability is a key component for agricultural-based industries to

retain their global competitiveness and holds immense importance in

facilitating product-based diversification. In terms of technological

capabilities that are specific to agricultural-based industries, unique

indicators and parameters have been identified and include research and

development, human resources, strategic planning, technology infrastructure,

and manufacturing. Having knowledge of organizational technological

capabilities can contribute to expanding the range of available downstream

Crude Palm Oil (CPO) products. However, the income generated from CPO in

Indonesia is currently lower compared to that achieved by its competitors. The

current study was conducted on 11 CPO companies in Sumatera Utara Province,

Indonesia. The purpose of the study is to develop an assessment tool. The tool

is proposed to measure the capability of technology in crude palm oil-based

industries. The device developed is also to obtain empirical data in order to

determine the capability of technology in CPO companies. The descriptive

analysis approach is applied in this study.

Crude Palm Oil (CPO) industries; Downstream products; Technological capability

Introduction

Industries in developing countries must secure their trade for survival. Globalization has not only allowed a reduction in the number of barriers to participation in international commerce, it has also enabled the proliferation of competitors. The global economy has meant that industries have had to modify their system of goods production in order to attain market hegemony. The Food and Agricultural Policy Research Institute has predicted that global Crude Palm Oil (CPO) consumption will increase by 30%, with total anticipated production of 60 million tonnes by 2020 (Robbani, Fahmi, and Suprayitno, 2015). An estimate of CPO global production of 315 million tonnes by 2030 was reported in the study by (Rifai et al., 2014). It was anticipated that Indonesia would produce 30 million tonnes ofm CPO by 2020, of which 23 million tonnes would be assigned to the export market, but the production of 31 million tonnes of CPO was achieved in Indonesia in 2013 (Hoffmann et al., 2015).

Technology is important to the economic development of countries. Technological

developments and managerial capabilities are needed by countries to establish

technological efficiency and stimulate economic growth (Chien,

Wang, and Lin, 2011).

Technology is vital to remaining competitive since the rapid advancement of

technology accelerates global transformation. Technological evolution has meant

that traditional organizational management strategies are no longer

appropriate. Advanced technology is required to optimize productivity, ensure

appropriate quality, reduce costs, and facilitate flexibility. Perpetual

investment in technological developments, as a means of establish energetic

capability, has been identified as a key approach to successfully competing in

the global market in the twenty-first century. Perpetual investment in

technological developments, aimed at establishing an energetic capability, has

been identified as a key approach for achieving success in the global market

during the twenty-first century (Chien, Wang, and

Lin, 2011). There are three basic factors to sustain

development, they are: management, design, and technology. They are very

necessary and play roles for competitive advantage. The quality of products is

solely relied on high patterns and technology (Suwartha et al., 2018).

The technology-related capability of a

country is assessed according to the implementation of new technology,

technology infrastructure, and human development (Archibugi

and Coco, 2004).

Strategic planning, Research and Development (R&D), human resources, and technology infrastructure

influence the technological capabilities of firms in developing countries (Madanmohan, Kumar, and Kumar, 2004). In previous research, the technological capability of Korea’s Random

Access Memory (DRAM) and Thin Film Transistor–Liquid Crystal Display (TFT–LCD)

industries were assessed in terms of R&D, human resources,

and technology infrastructure (Park, Choung,

and Min, 2008). Technology capability is also used to

examine the telecommunication industry in China (Wu

et al., 2014). Manufacturing industries have been evaluated based

on their technology capabilities (Zahra and Nielsen, 2002), and a similar assessment has been

conducted for firms operating in the tourism sector (Figueiredo, Gomes, and Farias, 2010). The

technological capabilities of Finnish multi-industries have been assessed in

terms of the availability of human resources, technology infrastructure, and

manufacturing capacity (Kylaheiko et al., 2011). R&D

and strategic planning have been assessed in research to determine the

technological capabilities of manufacturing industries (Lang, Lin, and Vy, 2012). South

Korea’s semiconductor industry develops new products through technological

advances, such as R&D and technology infrastructure (Tzokas et al., 2015).

Technological capability plays an important role in

accelerating product diversification. The development of the technological

capabilities of an organization is crucial to modernization and increasing its

levels of competitiveness and productivity. At the company level, technological

capabilities simplify innovation and advance productivity.

A survey was used in

the present study to determine the technological capabilities of CPO-based

industries in Sumatera Utara Province, Indonesia. The purpose of the study is

to develop an assessment tool. The tool is proposed to measure the capability

of technology in crude palm oil-based industries. The developed tool is to

quantify and determine the classification of the capability of technology. It

will evoke an awareness to develop plans on how to make the improvements. This

then allows the company to increase some aspects of the capabilities of

technology. The company may improve itself both theoretically and practically.

The technological capabilities of 11 companies in the CPO-based industry (i.e.,

one multinational company and 10 locally owned corporations) were evaluated in

the current research. This Province is very potential for oil palm with 5.07

tonnes/year, which contributes 28.04% to Indonesia National production (Badan Kebijakan Fiskal, 2012).

Indonesia is the

world’s largest producer of CPO. However, the income derived from CPOs in

Indonesia is less than that of its competitors, primarily because of the low

value-added to derivative products.

There is a need to diversify the downstream product range and create

value-added products. Indonesia’s main competitor has more than 100 types of

downstream CPO products. The diversification of assorted downstream products

and the creation of value-added products are needed. To be able to diversify

its product range, the Indonesian CPO industry must first determine its

technological capabilities.

Literature Review

2.1. Technological Capabilities

Technology is an emergence of human creativity and a generator mechanism

for economic growth. According to (Berawi, 2015),

technology is the way how to create, which supported by science from design to

transformation and from prediction to production, model creation, continuous

improvement, enhancement new distinctions are to increase the grade of

technology for competitive advantage. Technology is not for industrial used

only but also useful for business case. Likewise, (Berawi,

2018) proposed that technology may be used as a helpful tool for

generating new designs of innovative business processes. He furthermore said

that technology has been applied to organize society, products, and projects in

over the world. The invention of new technology is crucial to encourage

innovation in various developments of outcomes (Berawi,

2019). Technology cultivation may improve the circumstances economically

that can rectify the life quality of human beings (Berawi,

2021).

Investment in technological

capabilities is considered crucial because the latter is a viable response to

dynamic market demands. Technological capability is a function of the ability

to access, adapt, and manage technologies. (Schoenecker

and Swanson, 2002) used various criteria to assess technological capabilities, such as

R&D, expenditure, statistics for patented products and services, and data

for newly introduced products. They considered the advantages and disadvantages

of each and their validity in the chemicals, electronics, and pharmaceuticals

industries. (Zahra and Nielsen, 2002) proposed that technological capability could be determined using four

characteristics: (1) the frequency with which new products are introduced, (2)

the speed at which new products are introduced compared to competitors, (3) the

ability to create highly innovative novel products, and (4) the knowledge

created by the organization (i.e., reflected in patents).

Three key components of

technological capability have been identified; these are the creation of new

technologies, technology infrastructure, and human skill development (Archibugi and Coco, 2004). These components are vital for the

development of technological capabilities According to (Madanmohan, Kumar, and Kumar, 2004), the transfer of international technologies is considered the preferred

method for acquiring technological capability. The process of technology

transfer is characterized by several stages, including discovery, evaluation,

acquisition, adaptation, and implementation. The ability of companies to

utilize imported technology depends on their technical and organizational

capabilities. In order to disseminate new technology effectively, the recipients must

develop the in-house capacity to perform R&D and carry out training

programs, as well as implement planning and control. Two main external

resources, the government, and the national technology infrastructure, were

identified as having the capacity to impact technological development (Madanmohan, Kumar, and Kumar, 2004).

Technology capability is a

driving force for innovation in a company. It is defined as the ability to

utilize technological knowledge to duplicate and diffuse existing technologies,

make new ones, and develop new processes and products in response to economic

fluctuations (Park, Choung, and Min, 2008). Technological capabilities constitute the ability to execute all

pertinent technical-related activities in a company, encompassing, but not

limited to, the ability to make new products and implement novel processes to

maximize the use of equipment. It has been proposed that technological

capability is compatible with the growth of innovation because it implies that

a wealth of knowledge is available to create and manage technical change.

The technology comprises

substantial knowledge that has been mastered by people and organizations (Figueiredo,

Gomes, and Farias, 2010). According to them that technological capabilities can be defined as an

abundance of knowledge-based resources in four areas, namely, (1)

techno-physical (i.e., capabilities manifested in the equipment, software, and

databases), (2) organizational and managerial systems (i.e., capabilities

developed by the organization through a set of routines that drive

organizational activities, (3) people (i.e., capabilities reflected in formal

education and tacit knowledge, such as experience, skills, and adroitness), and

(4) products and services (i.e., capabilities that are evident in the

organization’s products and services, the latter of which have been designed,

developed, manufactured, supplied, and commercialized by the company).

Zhou and Wu (Zhou and Wu, 2010) suggested that technological capabilities

are evident in a company’s ability to foster a new product and expedite the

speed with which the product is developed. Technological capabilities are

thought to denote the accumulated technological knowledge that a firm develops

by introducing new products or services, making improvements to existing

products, establishing technological expertise, and investing in machinery and

manufacturing systems (Kylaheiko et al.,

2011).

Organizations with sound

technological capabilities are characterized by high performance because they

are able to implement state-of-the-art technologies. It enables them to produce

innovative product emerging to competitive benefit. The organizations are also

more innovative and may reach higher distinction by innovating products in

responding to the fluctuated market atmosphere (Tzokas

et al., 2015). A company seeking

to enhance its technological capabilities needs to invest in R&D to help it

develop innovative products (Tzokas et al.,

2015). In one study, technological capabilities are also a significant

indicator to describe the success of Korea in catching technology (Park,

Choung, and Min, 2008). Similarly, (Khayyat and Lee, 2015) investigated

the role of technological capabilities as a recent tool with which to measure

standards of innovation in developing nations. Unsal and Cetindamar

specifically employed this measure to assess the level of technology

establishment within the information technology, defense, and banking

industries in Turkey (Unsal and Cetindamar, 2015) China has succeeded in cultivating its technological capability by

importing technology from abroad through foreign direct investment, joint

ventures, and foreign-owned businesses. The potential for adaptive new thought

is greater if a company invests in technological capabilities. Technological

capabilities encompass numerous indicators and parameters. There are some

indicators of technological capability in various sectors, such as the

semiconductor, automotive, electronic, and manufacturing industries, are

detailed in Table 1.

Table 1 Indicators of technological capability in various industries and sectors

3.1. Indicators of Technological Capability in

the Crude Palm Oil Industry

Suggested

indicators of technological capability identified in the literature, were

selected in the current study to conform to the palm oil-based industries. The

chosen indicators mostly related to generating innovation aspect and mass

production. Table 2 depicts chosen indicators of technological capability in

the CPO industry. The proposed indicators were compiled to be a check sheet and

utilized as a measurement tool (Table 3) to collect data about technological

capability as indicated in indicators from 11 palm oil industries in Sumatera

Utara Province, Indonesia. The palm oil-based industries are only 11 companies

in this area, all of them were used as research objects. A survey was completed

by company representatives (i.e. members of top or middle management/production

managers). The purpose of the study was clarified by the researcher, who aimed

to measure the capability of technology in order to ensure the acquisition of

accurate and factual information. The participants were assured that the data would

be used for research purposes only.

Descriptive analysis approach is applied in this study. Descriptive

statistics is to calculate and describe the actual characteristics of collected

data in a logical, meaningful, and efficient way.

Table 2 Proposed

Indicators of Technological Capability in the Palm Oil Industry

4.1 Results

Table 3 shows selected indicators were collated in

a survey that was administered to the participants to obtain empirical data on

the technological capabilities of companies in the palm oil industry. A check

sheet was utilized in this study. The check sheet is a structured, prepared

form for collecting and analyzing data. The

indicators of technological capability value from 10 to 40. The empirical data obtained were formulated to

describe the CPO-based industries.

Table 3 Indicators

Selected for Application in the Current Study to Determine Technological Capabilities in the Palm Oil Industry in

Indonesia

The empirical data

obtained by means of the tool were then formulated to describe companies in the

palm oil-based industries related to technological capability. A total score of

151 to 200 is considered a high category, while a score of 101 to 150 is considered

a medium category, and a score of 50 to 100 is considered a low category. The

table above describes the level of technological capability of the palm

oil-based industries.

A

score of 20 to 40 was considered high, while 10 to 19 was a low classification;

it indicated that 7 companies (64%) were in the low category, and four

companies (36%) were in the high category for R&D. Seven and 36% of companies received high and low scores,

respectively, for their technological capability in human resources. Five

companies (45 %) achieved a poor score, and 6 (54%) companies attained a high

score for strategic planning. A low score and a high score were realized by 6

companies (54%) and 5 companies (45%), respectively, for technology

infrastructure. Six companies (54%) did not score highly for technological

capabilities in manufacturing, compared to 5 companies (45%) that did. Based on

the overall ranking of technological capability, 5 companies (45%) scored

highly, and 6 companies (55%) were in the bottom category of technological

capability. Scoring below 150 was deemed to be poor, which demonstrates the

technological capabilities.

4.2. Discussion

Most companies in this study

made an insignificant investment in Research and Development (R & D). R & D includes activities that companies

undertake to innovate and introduce new products. It is often the first stage

in the development process. Technological capability of the palm oil-based

industries is supported by a high of human capital. The human resources are

employees to assist in the process of attaining main objectives of the palm oil

industries. Strategic planning is a little more than half in high category to

espouse the capability of technology in this region. Strategic planning is a process of defining,

directing, and making decisions on allocating the resources to pursue the

strategy. It may also extend to control mechanisms for guiding the

implementation of the strategy to maximize the products of the palm oil-based

industry. Technology infrastructure is one of the most important things to

support the operation in any industry. However, it is more than half of the

palm oil industry in the low category of it. Technological capability is

supported by less than half of the high category in manufacturing in this

study. Actually, manufacturing is a notable thing that functions to transform

goods, including crude palm oil into a raw material to be valuable products.

It is slightly more than half of the CPO industry

in this region was in the low category and never considered modernizing their

technological capabilities. The results of the survey demonstrate that most

companies in the CPO industry rely on existing

technology rather than creating

novel innovations. In this region, the majority of CPO (Crude Palm Oil)

industries focus solely on survival and often neglect the importance of

modernizing and upgrading their infrastructure. In addition, the development of

technological capabilities in Malaysia, which includes those in the CPO

industry, is primarily undertaken by multinational companies. Investment in

technological capabilities is applied to areas such as joint ventures,

subsidiary-parent relationships, machine imports, technology cooperation

agreements, and the acquisition of foreign companies (Hansen

and Lema, 2019). In the past-changing technology era, the company should

update itself to avoid lagging behind the others (Tatiana

and Mikhail, 2020). This study will be the impression that the

capability of technology is pivotal to escalating the value-added products for

competitive advantage in worldwide competition.

In the current study,

it was important to determine the technological capabilities of companies in

the CPO industry because improvements cannot be made if the former cannot be

quantified. Measurement is a milestone for improvement. Historically, over the

past decade, technological capabilities have been recognized as vital for

positioning organizations to compete effectively against other companies within

the industry. Performing a technological assessment helps managerial staff to

make necessary improvements. Conversely, most CPO industries in this region are

arguably assumed to survival basis only because they do not consider

modernizing their technological capabilities since slightly more than half

are in the low category of capability. Currently, the technology capabilities

of the majority of CPO industries in Indonesia are not equivalent to, or

capable of surpassing, those of similar industries in Malaysia. The Indonesian

CPO industry continues to lag behind other countries (i.e. industrial front

runners) due to numerous multinational companies in Malaysia. Accordingly, they

are able to help Malaysia advance its technological capabilities. It enables to

study the assessment tool for other agro-based industries for future research

because the tool can be applied to those industries. The research data in this

study is limited to a region, future research will be more valuable if it

covers a whole region in a country.

The authors are grateful to Assoc. Prof.

Dr. Amir Yazid Ali, Universiti Sains Malaysia for his supervision

of this study. (no grant)

Archibugi, D., Coco, A., 2004. A New Indicator of Technological Capabilities for Developed and Developing Countries (ArCo). World Development, Volume 32(4), pp. 629–654

Badan Kebijakan Fiskal (Fiscal

Policy Agency), 2012. Study Report of value added of Agricultural

Products, Kementerian Keuangan Republik Indonesia (Ministry of

Finance of the Republic of Indonesia)

Berawi, M.A., 2015. Technology

Breakthrough: A Need for Continuous Improvement. International Journal of

Technology, Volume 6(3), pp. 302–305

Berawi, M.A., 2018. Improving

Business Processes through Advanced Technology Development. International

Journal of Technology, Volume 9(4), pp. 641–644

Berawi, M.A., 2019. Managing Nature 5.0 in

Industrial Revolution 4.0 and Society 5.0 Era. International Journal of

Technology, Volume 10(2), pp. 222–225

Berawi, M.A., 2021. Philosophy of Technology

Design: Creating Innovation and Added Value. International Journal of

Technology, Volume 12(3), pp. 444–447

Chien, S.C., Wang, T.Y., Lin, S.L., 2011.

Building the Measurement Framework of Technology Efficiency with Technology

Development and Management Capability-Evidence from the ASEAN

Countries. Expert Systems with Applications, Volume 38(6), pp. 6856–6865

Figueiredo, P.N., Gomes, S., Farias, R.,

2010. Innovative Technological Capability in Firms of the Tourism Sector: A

Study of the Hotels in the City of Rio de Janeiro during the 1990–2008 Period. Revista

de Administracao Publica, Volume 44(5), pp. 1139–1170

Hansen, U.E., Lema, R., 2019. The

Co-evolution of Learning Mechanisms and Technological Capabilities: Lessons

from Energy Technologies in Emerging Economies. Technological Forecasting

and Social Change, Volume 140, pp. 241–257

Hoffmann, M.P., Donough, C., Oberthür, T.,

Vera, A.C., Wijk, M.T.V., Lim, C.H., Asmono, D., Samosir, Y., Lubis, A.P.,

Moses, D.S., Whitbread, A.M., 2015. Benchmarking yield for sustainable

intensification of oil palm production in Indonesia using PALMSIM. The

Planter, Volume 91(1067), pp. 81-96

Khayyat, N.T., Lee, J.D., 2015. A Measure

of Technological Capabilities for Developing Countries. Technological

Forecasting and Social Change, Volume 92, pp. 210–223

Kylaheiko, K., Jantunen, A., Puumalainen,

K., Saarenketo, S., Tuppura, A., 2011. Innovation and Internationalization as

Growth Strategies: The Role of Technological Capabilities and Appropriability. International

Business Review, Volume 20(5), pp. 508–520

Madanmohan, T.R., Kumar, U., Kumar, V., 2004.

Import-led Technological Capability: A Comparative Analysis of Indian and

Indonesian Manufacturing Firms. Technovation, Volume 24(12), pp. 979–993

Park, T.Y., Choung, J.Y., Min, H.G., 2008.

The Cross-industry Spillover of Technological Capability: Korea’s DRAM and

TFT–LCD Industries. World Development, Volume 36(12), pp. 2855–2873

Rifai, N., Syaukat, Y., Siregar, H., Sa'id, E.G.,

2014. The Development and Prospect of Indonesian Palm Oil Industry and its

Derivative Products. International Organization of Scientific Research (IOSR) Journal of

Economics and Finance, Volume 4(5), pp. 27-39

Robbani, S.F., Fahmi, I., Suprayitno, G.,

2015. Sistem Implementasi Rencana Aksi Kebijakan Pengembangan Industri Hilir

Kelapa Sawit di Indonesia (Implementation

System of Action Plan for Palm Oil Downstream Development Policy in Indonesia), Journal

of Management and Agribusiness, Volume 12(2), p. 137

Schoenecker, T., Swanson, L., 2002.

Indicators of Firm Technological Capability: Validity and Performance

Implications. Institute of Electrical and Electronics Engineers (IEEE) Transactions on

Engineering Management, Volume 49(1), pp. 36–44

Suwartha, N., Berawi, M.A., Surjandari,

I., Zagloel, T.Y.M., Setiawan, E.A., Atmodiwiryo, P., Yatmo, Y.A., 2018. Creating a

sustainable future through the integration of management, design, and

technology. International Journal of Technology, Volume 9(8), pp. 1518–1522

Tatiana, B., Mikhail, K., 2020. Problems

of Competitive Strategy Choice According to Industry and Regional Factors. International

Journal of Technology, Volume 11(8), pp. 1478-1488

Lang, T.M., Lin, S.H., Vy,

T.N.T., 2012. Mediate effect of technology innovation capabilities investment

capability and firm performance in Vietnam. Procedia-social and

Behavioral Science, Volume 40, pp. 817–829

Tzokas, N., Kim, Y.A.,

Akbar, H., Al-Dajani, H., 2015. Absorptive Capacity and Performance: The Role

of Customer Relationship and Technological Capabilities in High-tech SMEs. Industrial

Marketing Management, Volume 47, pp. 134–142

Unsal, E., Cetindamar, D.,

2015. Technology Management Capability: Definition and its Measurement. European

International Journal of Science and Technology, Volume 4(2), pp. 181–196

Wu, W., Li, T., Yu, B., Wang,

J., 2014. Technological Capability and Technology Management: Which Dominates

the Development of China’s Telecommunications Industry? Chinese Management

Studies, Volume 8(2), pp. 180–200

Zahra, S.A., Nielsen, A.P.,

2002. Sources of Capabilities, Integration and Technology Commercialization. Strategic

Management Journal, Volume 23(5), pp. 377–398

Zhou, K.Z., Wu, F., 2010.

Technological Capability, Strategic Flexibility, and Product Innovation. Strategic

Management Journal, Volume 31(5), pp. 547–561