Development of Artificial Neural Networks Model to Determine Labor Rest Period Based on Environmental Ergonomics

Published at : 28 Jul 2023

Volume : IJtech

Vol 14, No 5 (2023)

DOI : https://doi.org/10.14716/ijtech.v14i5.3854

Amalia, R., Ushada, M., Pamungkas, A.P., 2023. Development of Artificial Neural Networks Model to Determine Labor Rest Period Based on Environmental Ergonomics. International Journal of Technology. Volume 14(5), pp. 1019-1028

| Rosa Amalia | Department of Agro-industrial Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada, Jl. Flora No.1 Bulaksumur, 55281, Indonesia |

| Mirwan Ushada | Department of Agro-industrial Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada, Jl. Flora No.1 Bulaksumur, 55281, Indonesia |

| Agung Putra Pamungkas | Department of Agro-industrial Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada, Jl. Flora No.1 Bulaksumur, 55281, Indonesia |

Food

SMEs (Small and Medium Enterprises) were examples of labor-intensive industry,

which involved laborers in pursuing production activities. Food SMEs require

complex processes in production activities. Support to increase work

productivity and reduce ergonomic risks of the activities was needed. The study

was conducted at Tofu SMEs. The determination of the rest period could be developed

to give some recovery times to laborers. WBGT (Wet Bulb Globe Temperature) was

estimated to determine the rest period. The rest period was determined by the

workstation environment and workload labor. ANN (Artificial Neural Networks)

model was carried out due to a nonlinear relationship. ANN was used to process

the information from the data set and predict the amount of rest period and

WBGT. ANN was trained using backpropagation. The backpropagation algorithm used

the error value to change the weight with forward and backward propagation. The

result showed that dry bulb temperature, heart rate, wet bulb temperature, and

gender significantly impacted the rest period and WBGT. A total of 180 data

sets from tofu SMEs were divided into training data (80%) and validation data

(20%). The optimal ANN structure was determined by four input, four hidden, and

two output neurons. The activation function was sigmoid for both layers. SSE

(Sum of Squared Errors) was used to obtain the best structure. The value of R2

was equal to above 0.900, which indicated that ANN could model the labor rest

period based on environmental ergonomics.

Artificial neural networks; Labor; Rest period; Wet bulb globe temperature

SMEs had a vital role

in developing the Indonesian economy. SMEs carry out most business

organizations in Indonesia, with a total of 56.54 million units (Bank Indonesia and LPPI, 2015). SMEs also

employed a considerable amount, more than 90% of labor (Bank

Indonesia and LPPI, 2015). One of the characteristics of SMEs is

labor-intensive. Food SMEs require complex processes to produce value-added

products. Food product requires particular handling techniques due to their

perishable characteristic. Ushada et al.

(2017) mentioned some SMEs product delivery activities, such as boiling,

steaming, frying, baking, and assembly. The activities were closely influenced

by the workstation environment in SMEs.

Good management

practices and Sustainable Manufacturing practices (Hami

et al., 2018) could increase eco-efficiency and labor

productivity. The conditions were explored by Ushada

et al. (2017), as shown in Table 1. Production activities with

high temperatures could cause various effects on the body (Ushada et al., 2017). Physical work

combined with high temperature, radiation, and lousy air ventilation impacted

losses in productivity (Yi and Chan, 2013).

The body could experience muscle fatigue, decreased concentration, and heat

stress. The temperature between SMEs (Table 1) was above 30°C. Thus, laborers

could not perform activities effectively at 29.1°C due to heat discomfort (Ushada et al., 2017). Working under

thermal stress conditions had associated risks and consequences (Miller and Bates, 2007). Therefore, laborers

needed sufficient rest periods under these circumstances.

Table 1

Environment temperature in SMEs (Ushada et al.,

2017)

SMEs' work system was

influenced by various factors and mainly by workplace environmental ergonomics (Ushada and Okayama, 2018). Determining the rest

period could be adapted to reduce ergonomic risk at work (Tiacci, 2018). The determination of the rest period

was pursued to provide recovery time to laborers. Recovery time gave laborers

time to rest their bodies and restore the energy that comes out while working.

Every activity in production had specific characteristics; therefore, rest

period models, times, and frequencies were diverse and challenging to

standardize (Negreiros et al., 2019).

A Murell formula has been

developed to determine the rest periods model (Iridiastadi

and Yassierli, 2017). The Murell formula used work time and metabolic

rate to determine rest time. Also, in a previous study, Yi and Chan (2013) optimized the rest time schedule for

construction laborers in hot and humid working conditions. Ushada et al. (2017) developed an ANN model

to determine food-based SMEs' set initial temperature values. Batubara and Dharmastiti (2017) stated that

ergonomics intervention was used to improve work systems to reduce workload. Ushada et al. (2017) indicated the

nonlinear relationship between worker ergonomics status and workplace

environment. ANN (Artificial Neural Networks), as one of the Artificial

Intelligence approaches could frame nonlinear structures based on the human

brain system and were known as an estimator and could detect nonlinear

relationships between variables (Vinoth et al.,

2016). Previous studies did not demonstrate a link between the WBGT and

the rest period. Thus, an advanced rest period model using ANN was developed in

this study, considering the environmental ergonomics, labor circumstances, and

production times factor.

The study was conducted at

SME tofu in five districts in the Special Region of Yogyakarta. Based on the

preliminary research, the Special Region of Yogyakarta has a tofu SMEs center

in each district as the representative. The research objectives were (1) to

analyze the environmental workstation, labor workload, and rest period; and (2)

to develop an ANN model for determining labor rest periods. Based on the

objectives, the model could be expanded as an appropriate technology for

sustainable, ergonomic application in food SMEs. Thus, the research would

benefit the stakeholders in food SMEs, especially the owners, managers, and

laborers.

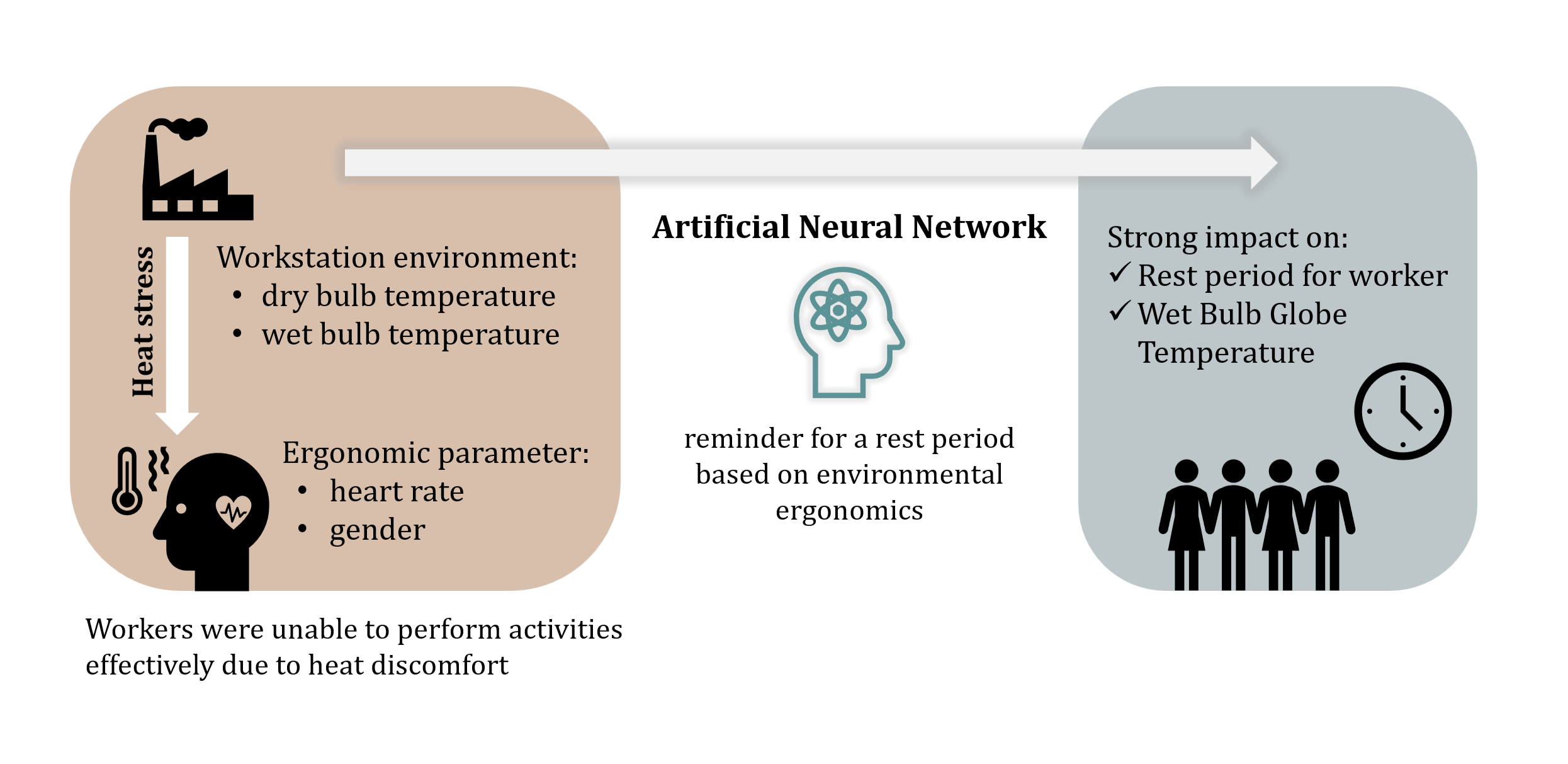

Figure 1 Conceptual

modelling of the ergonomic parameters of the labor and workstation environment

The

previous research by Li et al. (2016) showed that 14:00 to 15:00 was the high-risk

time for laborers, while 07:00 to 08:00 was the non-hazardous time for

laborers. Based on Li et al. (2016), the data were collected three times: initial,

intermediate, and final labor shift.

2.2. Rest Period and WBGT

Metabolic

rate (y) was determined by heart rate labor (x) in tofu SMEs. The metabolic

rate was calculated using a formula from Astuti in Ushada and Okayama (2018), as

shown in Equation 1.

Rest

period (R) was determined by labor work time (w), metabolic rate (b), and the

threshold value of labor work time (s). The rest period was calculated using a

Murell formula in Iridiastadi and Yassierli (2017), as shown in Equation 2.

WBGT was

determined by effective temperature (ET) and wet bulb temperature. ET was

obtained from Effective Temperature Chart, and wet bulb temperature from

Psychrometric Chart. WBGT was calculated using Equation 3 (OSHA, 2012).

Table 2

indicates the categories of metabolic rate and threshold for WBGT value based

on the Indonesian government (Minister of Health Indonesia, 2016). Table 2 is a standard

by the Minister of

Health Indonesia (2016) compared with the actual condition in tofu SMEs.

Table 2

Work cycle and rest period in an hour

2.3. Development

of ANN Model

Based on

Figure 1, the inputs of ANN were ergonomic parameters of labor and workstation

environment. The predicted outputs were the rest period and WBGT. Data sets

were divided into training data (n=144) and testing data (n=36). SSE (Sum of

Squared Errors) was used as an error value to determine the optimal combination

on the ANN model. SSE was minimized between the system output and the neural

network model output (Janczak, 2005). The R2 correlation was used to express

the reliability of the ANN model. ANN was used to predict continuous variables,

and a valuable measure of goodness of fit for each output was the coefficient

of multiple determination (R2) (Lingireddy and Brion, 2005).

ANN was

trained based on the backpropagation algorithm. Backpropagation had a layered

feed-forward neural network structure in which the nonlinear neurons were

arranged in consecutive layers; afterward, the information passed from the

input layer to the output layer through hidden layers (Vinoth et al., 2016). Ushada et al. (2017) found a

nonlinear relationship between environmental ergonomics in Food SMEs. Thus, ANN

could be a powerful computing approach for complex computations (Cavalieri, Maccarrone,

and Pinto, 2004).

The

training process was pursued to evaluate weights and biases in ANN (Argatov and Chai, 2019). The training process required a data set of

experimentally measured input-output (Argatov and Chai, 2019). The

training process was carried out in several stages as follows.

3. Training with variations in the value of the learning rate

3.1.

Respondents and Sample Location

This study obtained sixty

(60) respondents from laborers with three times different sampling times. A

total sample of one hundred and eighty (180) data sets was obtained. The data

samples were obtained from each district in the Special Region of Yogyakarta,

such as Yogyakarta, Bantul, Kulon Progo, Gunungkidul, and Sleman. Table 3

indicates the demographic information of the respondents. The

average age of the laborers in Tofu SMEs was 42.78 ± 13.64 years old, and the

majority ranged from 31 to 40 years old and 41 to 50 years old. The majority

gender of the laborers were men (n = 39), and the rest were women (n =

21). Based on the correlation test, age, and weight parameters had a value

below 0.200, which indicated a low degree of correlation

between the rest period and WBGT.

3.2.

Workload and Workstation Environment

Various tofu-making

processes were generally carried out in several SMEs. The processes were

soaking, milling, boiling, filtering, processing, solidifying, cutting, and

frying. These processes were pursued in a batch continuously. The activities in

the tofu production process can be categorized into potentials that cause

physical workload (Widyanti et al., 2017).

Thus, the activities affected the labor heart rate. Figure 2a shows a graph of

labor heart rate, indicating an increase in labor heart rate from the initial

to the final shift of the laborer.

Metabolic rate was counted

from labor heart rate. The result indicated three (3) categories such as light,

moderate, and heavy (Table 4). Figure 2b indicates an increase in metabolic

rate from the initial to final labor shift.

Figure 2 Labor condition: (a) Heart

rate; and (b) Metabolic rate

Table 4 Metabolic categories of labor

The workstation

environment was where the laborers did some activities to process the tofu. The

environment was observed during working time. The result showed dry bulb

temperature increased during work time (Figure 3a).

The average WBGT value in

tofu SME workstations was 26.39 °C. The value was still at the threshold for

WBGT in the industry (Minister of Health Indonesia,

2016). Although it met the threshold, the value had a level of

discomfort. WBGT value was included in the extremely hot environment category (Chowdhury, Hamada, and

Ahmed, 2017). Based on Chowdhury, Hamada,

and Ahmed (2017), it had the

risk of discomfort, but there was no health risk. Work inconvenience at SMEs

arose from 25.82 to 26.86 °C due to the extremely hot environment at the tofu

SMEs workstation (Figure 3b). Tofu SMEs use heat sources in most of the

process, which could impact increasing the temperature at the workstation.

Figure 3 Workstation environment: (a) Dry bulb temperature; and (b) WBGT

Table

5 indicates one hundred and sixty-three (163) laborers with a positive WBGT

gap. The positive value of the WBGT gap meant that WBGT in laborers did not

exceed the threshold value. Laborers were still comfortable with the WBGT

values and did well in their activities. On another side, the negative WBGT gap

value was found in ten (10) laborers. If the WBGT gap was negative, the WBGT

value exceeded the specified threshold. If the WBGT value exceeds the standard

value, it could indicate high heat stress on laborers (Bolghanabadi,

Ganjali, and Ghalehaskar 2019). Thus, during working hours, the activities increased, and performance

did rise after the activities began.

Table 5 Gap of

WBGT

3.3. Rest

Period

The rest period was a scheduled break

during a working day, and the laborers stopped their activities to rest, eat,

and any other needs (ILO, 2019). The rest

period was determined by metabolic rate labor during work time. Table 6

indicates the rest period of labor categorized by workload. Work breaks had a

range from -44.3 to 11.3 minutes for an hour. The negative number said that

laborers did not need an additional rest period because the workload was not

too heavy. It could be interpreted that the labor had an extra rest period of 0

minutes to calculate negative numbers. In light and moderate workloads, the

average additional rest period was obtained by a negative number, so laborers

in tofu SMEs did not need extra work breaks. Labors in the heavy workload

category had an average break time of 11.33 minutes. The results show the need

for additional breaks of one hour for each work with heavy categories carried

out in production activities. The work preferences related to the rest period

length were not equal for every labor (Di-Pasquale et

al., 2017). Research by Dababneh, Swanson,

and Shell (2001) showed

that frequent rest periods with short time would not decrease productivity.

Table 6 Rest

period based on workload categories

The rest period depended on the situation

in tofu SMEs. Production activities would affect the labor rest period.

Activities increased during working hours, and performance increased 2 hours

after starting work (Fahed, Ozkaymak, and Ahmed 2018). These conditions were similar to the

workstation at tofu SMEs. Labors took a rest during the working day to take

toilet breaks, prayer breaks or breaks to address other personal needs (ILO, 2019).

3.4. ANN

Model

Data normalization was performed by the

min-max normalization method. The method changed the data into a smaller range.

The data changed to a 0 to 1 range. T-test, F-test, and correlation tests were

performed. The result showed that dry bulb temperature (i1), heart

rate (i2), gender (i3), and wet bulb temperature (i4)

had a significant impact on the rest period (o1) and WBGT (o2).

These parameters had a high correlation value toward dependent variables so

that they could be used as an ANN input.

The result of the training process was an

optimum structure for WBGT and the rest period, as shown in Figure 4. To

improve the performance, ANN changed the weights between neurons in each layer

to modify the structure of the training data (Darvishi

et al., 2017). Training data with the lowest error value was at 4-4-2.

The activation function for the between layers was sigmoid. The optimum

learning rate was 0.01. That combination got SSE training 0.113 and SSE testing

0.037. The SSE indicated a low error.

Figure 4 ANN structure for

the rest period

The value of R2 between the

calculation and prediction of resting time was 0.989 (Figure 5a), while the

value of R2 between the calculation and prediction of WBGT was equal

to 0.968 (Figure 5b). An R2 value of 1.0 represented a perfect

prediction (Lingireddy and Brion, 2005). The

results indicated that the calculation of the rest period in explaining the

variance of the predicted rest period value was 98.9%. The value showed that

the prediction of the rest period could be explained well by calculating the

rest period. The WBGT value calculation explains that the WBGT prediction value

variance was 96.8%. The predicted WBGT value could be explained well by the

WBGT value calculation. An appropriate rest period could reduce the risk caused

by workload (Chen and Xie, 2014). Thus, the

ANN model of rest period was developed using dry bulb temperature, heart rate,

wet bulb temperature, and gender as the input with a rest period and WBGT as

the output.

Figure 5 R2 Value for (a) Rest period; (b) WBGT

Murell

formula (Equation 2) stated that the rest period was impacted by the labor work

time and metabolic rate (Iridiastadi and Yassierli,

2017). Tofu SMEs utilize heat sources for most of the process, which

affects the workstation's temperature. The results in this study indicated that

the dry bulb temperature, heart rate, wet bulb temperature, and gender

significantly impacted the rest period and WBGT, not only the work time and

metabolic rate. Laborers needed more time to rest in a hot work environment

since they were uncomfortable (Ushada et al.,

2017; Yi and Chan, 2013).

The novelty of the research was the relationship

between labor, workload, environmental ergonomics, rest periods, and WBGT. The

dry bulb temperature (i1), heart rate (i2), gender (i3),

and wet bulb temperature (i4) demonstrated a strong impact on the

rest periods (o1) and WBGT (o2) in the performance of

production tasks. The ANN model of WBGT and rest periods were the best

combination to solve the SME's issues. The rest periods could reduce the

discomfort, whereas the WBGT displayed a temperature-based measure of work

discomfort as the environment's temperature significantly impacted the rest

periods.

3.5.

Ergonomic Benefit and Practical Implication to SMEs

The model would benefit the stakeholders

in food SMEs, especially the owners, managers, and laborers. The owners and

managers could use it as a reminder for rest periods based on the condition of

environmental ergonomics. The worker could use the rest period properly and

feel comfortable while working.

The study results indicated that the

workload in tofu SMEs had three categories: light, moderate, and heavy. The

average threshold value of WBGT in tofu SMEs was 26.39 °C which was below the

threshold. Thus, laborers still felt comfort in carrying out their activities.

Additional rest periods for laborers in tofu SMEs are known to have a range

from 0 to 11.3 minutes for every hour of work. The result showed that dry bulb

temperature, heart rate, wet bulb temperature, and gender significantly

impacted the rest period and WBGT. The best ANN model was a 4-4-2 network

structure with four neurons in a hidden layer. The activation function used

between the layers both were sigmoid. The best learning rate used was 0.01. The

structure resulted in the value of SSE training at 0.113 and SSE testing at

0.037. The value of R2 between the calculation and prediction of

resting time was 0.989, while the value of R2 between the

calculation and prediction of WBGT was equal to 0.968. Thus, the model fits the

performance and can be applied to calculate the rest period and WBGT using

programming software. Therefore, the model could be used as a reminder for a

rest period based on the condition of environmental ergonomics.

This research was supported by the Ministry of Research, Technology and Higher Education of the Republic of Indonesia by 2019 Universitas Gadjah Mada Grants of "Penelitian Terapan Unggulan Perguruan Tinggi" No: 2770/UN1.DITLIT/DIT-LIT/LT/2019 and National Competitive Grants of "Penelitian Dasar" No: 2788/UN1.DITLIT/DIT-LIT/LT/2019.00.

Argatov, I.I., Chai, Y.S., 2019. An Artificial

Neural Network Supported Regression Model for Wear Rate. Tribology

International, Volume 138, pp. 211–214

Bank Indonesia and LPPI, 2015. Profil

Bisnis Usaha Mikro, Kecil dan Menengah (Business Profile of Small and Medium

Enterprises). Indonesia

Batubara, H., Dharmastiti, R. 2017. Redesign of

Liquid Aluminum Pouring Tool Based on Participatory Ergonomics to Improve

Productivity, Workload, and Musculoskeletal Disorders. International Journal

of Technology, Volume 8(2), pp. 352–361

Bolghanabadi, S., Ganjali, A., Ghalehaskar, S.,

2019. Investigation of Thermal Exposure in Traditional Neyshabur Bakeries Using

Heat Strain and Physiological Indices. MethodsX, Volume 6, pp. 355–359

Cavalieri, S., Maccarrone, P., Pinto, R., 2004.

Parametric Vs. Neural Network Models for The Estimation of Production Costs: A

Case Study in The Automotive Industry. International Journal of Production

Economics, Volume 91, pp. 165–177

Chen, C., Xie, Y., 2014. The Impacts of Multiple

Rest-Break Periods on Commercial Truck Driver's Crash Risk. Journal of

safety research journal, Volume 48, pp. 87–93

Chowdhury, S., Hamada, Y., Ahmed, K.S., 2017.

Prediction and Comparison of Monthly Indoor Heat Stress (WBGT and PHS) for RMG

Production Spaces in Dhaka, Bangladesh. Sustainable Cities and Society,

Volume 29, pp. 41–57

Dababneh, A.J., Swanson, N., Shell, R.L., 2001.

Impact of Added Rest Breaks on The Productivity and Well Being of Workers. Ergonomics,

Volume 44(2), pp. 164–174

Darvishi, E., Khotanlou, H., Khoubi, J., Giahi,

O., Mahdavi, N., 2017. Prediction Effects of Personal, Psychosocial, and

Occupational Risk Factors on Low Back Pain Severity Using Artificial Neural

Networks Approach in Industrial Workers. Journal of Manipulative and

Physiological Therapeutics, Volume 40(7), pp. 486–493

Di-Pasquale, V., Fruggiero, F., Iannone, R.,

Miranda, S., 2017. A Model for Break Scheduling Assessment in Manufacturing

Systems. Computers and Industrial Engineering, Volume 111, pp. 563–580

Fahed, A.K., Ozkaymak, M.,

Ahmed, S., 2018. Impacts of Heat Exposure on Workers' Health and

Performance at Steel Plant in Turkey. Engineering Science and Technology, an

International Journal, Volume 21, pp. 745–752

Hami, N., Yamin, F.M., Shafie, S.M., Muhamad,

M.R., Ebrahim, Z., 2018. Sustainable Manufacturing Practices Among SMEs in

Malaysia. International Journal of Technology, Volume 9(8), pp.

1658-1667

International Labour Organization (ILO), 2019. Rest Periods: Definitions and

Dimensions. International Labour Organization

Iridiastadi, H., Yassierli, 2017. Ergonomi: Suatu Pengantar

(Ergonomic: An Introduction). Bandung: PT Remaja Rosdakarya

Janczak, A., 2005. Identification of Nonlinear

Systems Using Neural Networks and Polynomial Models. New York: Springer

Berlin Heidelberg New York

Li, X., Chow, K.H., Zhu, Y., Lin, Y., 2016.

Evaluating The Impacts of High-Temperature Outdoor Working Environments on

Construction Labor Productivity in China: A Case Study of Rebar Workers. Building

and Environment, Volume 95, pp. 42–52

Lingireddy, S., Brion, G.M., 2005. Artficial

Neural Networks in Water Supply Engineering. Restton: American Society of

Civil Engineers

Miller, V.S., Bates, G.P., 2007. The Thermal Work

Limit is a Simple Reliable Heat Index for The Protection of Workers in

Thermally Stressful Environments. Annals of occupational hygiene, Volume

51(6), pp. 553–561

Minister of Health Indonesia, 2016.

Permenkes RI no.70 tentang Standar dan Persyaratan Kesehatan Lingkungan Kerja

Industri (Regulation of Minister of Health of Republic of Indonesia No. 70

About Standards and Requirements for Industrial Environmental Health).

Indonesia

Negreiros, A.W.F.T.R.W. de, Silva, P.R. da,

Arezes, P.M.F.M., Dangelino, R., Padula, R.S., 2019. Manufacturing Assembly

Serial and Cells Layouts Impact on Rest Breaks and Workers' Health. International

Journal of Industrial Ergonomics, Volume 70, pp. 22–27

OSHA, 2012. Heat Stress, Plant Stress

Physiology. Occupational Safety and Health Administration

Tiacci, L., 2018. The Problem of Assigning Rest

Times to Reduce Physical Ergonomic Risk At Assembly Lines. IFAC-PapersOnLine,

Volume 51(11), pp. 692–697

Ushada, M., Okayama, T., 2018. Development of

Green-Affective Work System for Food SMEs. KnE Life Science, Volume

2017, pp. 89–95

Ushada, M., Okayama, T., Khuriyati, N.,

Suyantohadi, A., 2017. Affective Temperature Control in Food Smes Using

Artificial Neural Network. Applied Artificial Intelligence, Volume 31,

pp. 555–567

Vinoth, B., Rajarathian, A., Baumgartner, A., Bargavi,

S.K.M., 2016. Nonlinear Regression and Artificial Neural Network Based Model

for Forecasting Paddy (Oryzasativa) Production in Tamil Nadu. IOSR

Journal of Mobile Computing and Application (IOSR-JMCA), Volume 3(3), 1–6

Widyanti, A., Sofiani, N.F., Soetisna, H.R.,

Muslim, K. 2017. Eye Blink Rate as a Measure of Mental Workload in a Driving

Task: Convergent or Divergent with Other Measures. International Journal of

Technology, Volume 8(2), pp. 283–291

Yi,

W., Chan, A.P.C., 2013. Optimizing Work-Rest Schedule for Construction Rebar

Workers in Hot and Humid Environment. Building and Environment, Volume

61, pp. 104–113